Patents

Literature

39results about How to "Can be used in a wide range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

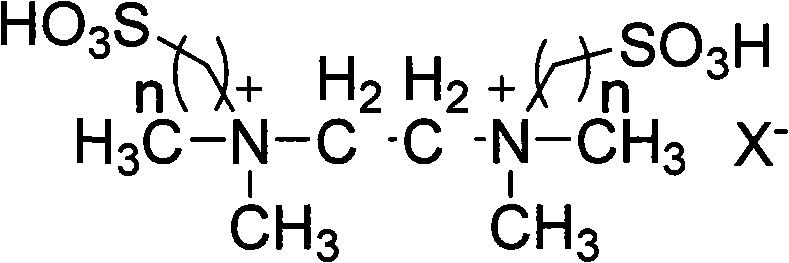

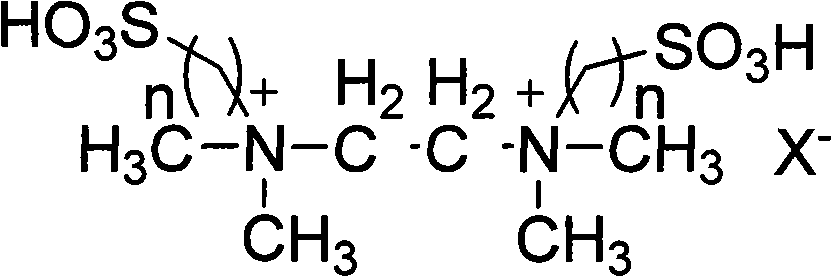

N,N,N,N-tetramethylethylenediamine sulphonate ionic liquid and preparation method thereof

InactiveCN101648894AHigh acid valueHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsSulfonic acid preparationChemical synthesisOrganic reaction

The invention provides N,N,N,N-tetramethylethylenediamine sulphonate ionic liquid and a preparation method thereof, belonging to the technical field of organic chemical synthesis. The preparation method of the ionic liquid comprises the following steps: using N,N,N,N-tetramethylethylenediamine and sultone to react at room temperature in the presence of acetone and absolute ethanol to obtain N,N,N,N-tetramethylethylenediamine sulphonate inner salt, and then using N,N,N,N-tetramethylethylenediamine sulphonate inner salt to react with inorganic acid or organic acid to obtain disulfonic acid groupacidic ionic liquid with N,N,N,N-tetramethylethylenediamine cationic group. The prepared ionic liquid can be used as the catalyst or solvent of organic reactions, in particular to the catalytic reaction of inorganic acid or organic acid; compared with the existing monosulfonic group acidic ionic liquid used as catalyst, the N,N,N,N-tetramethylethylenediamine sulphonate ionic liquid has higher catalytic activity, less dosage, less loss in cycle use, higher product yield and more environmentally friendly.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

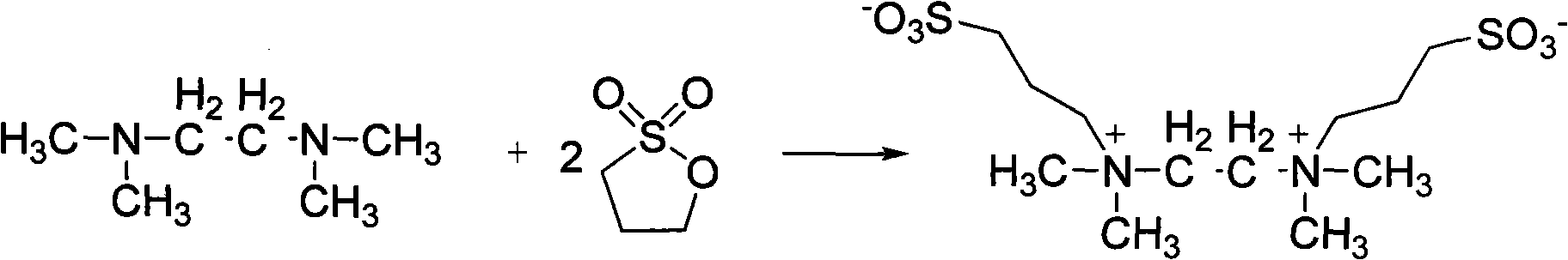

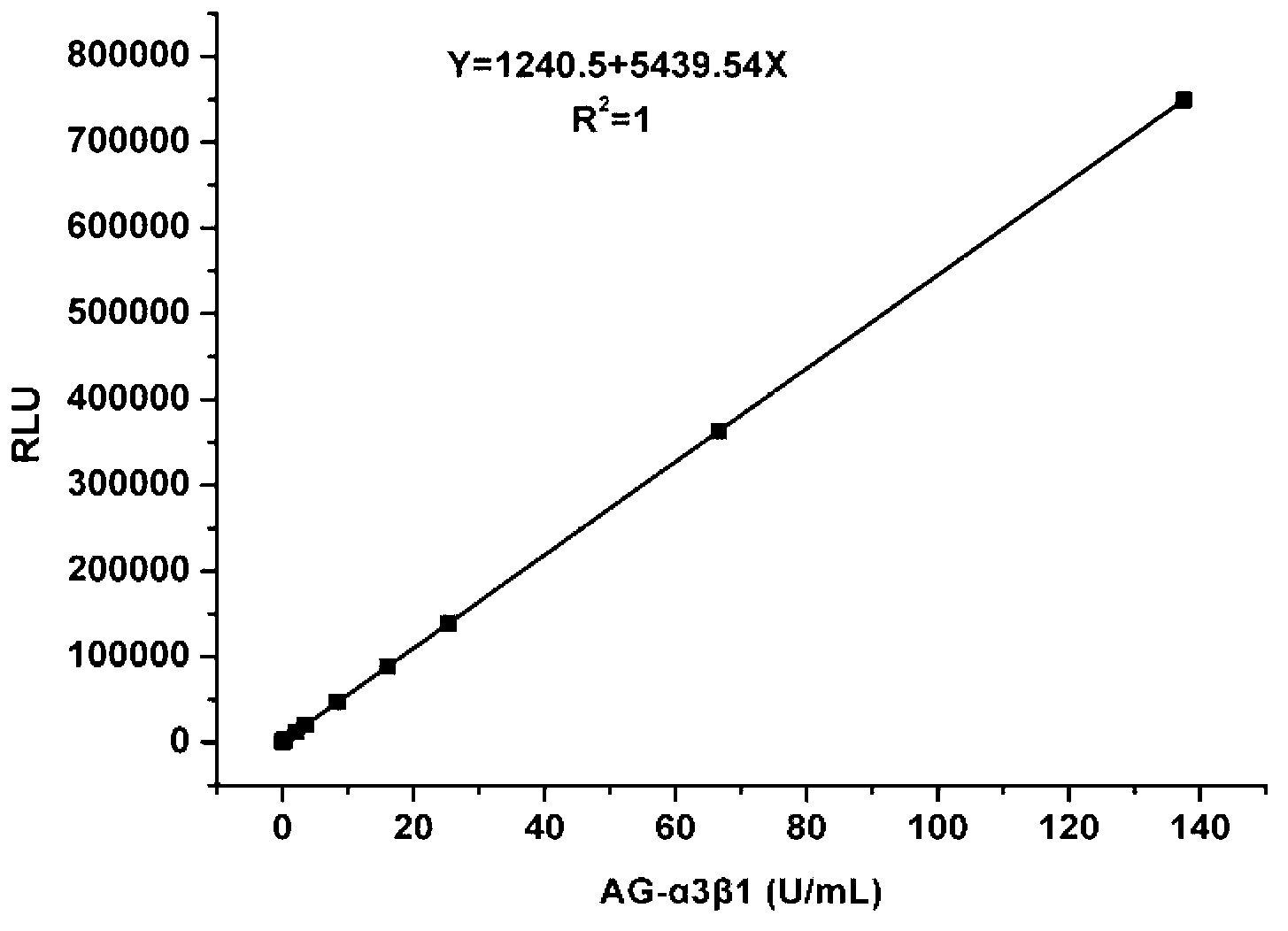

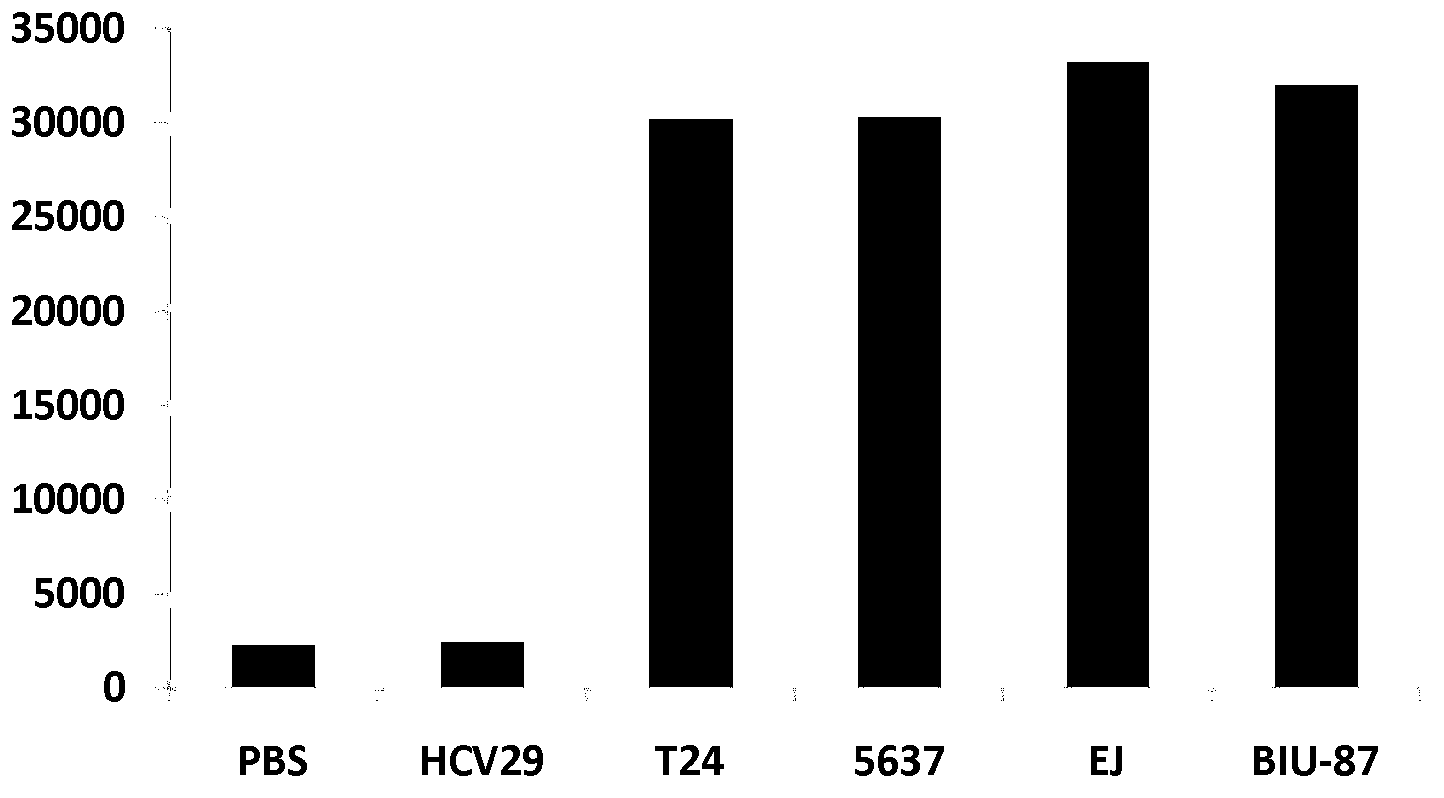

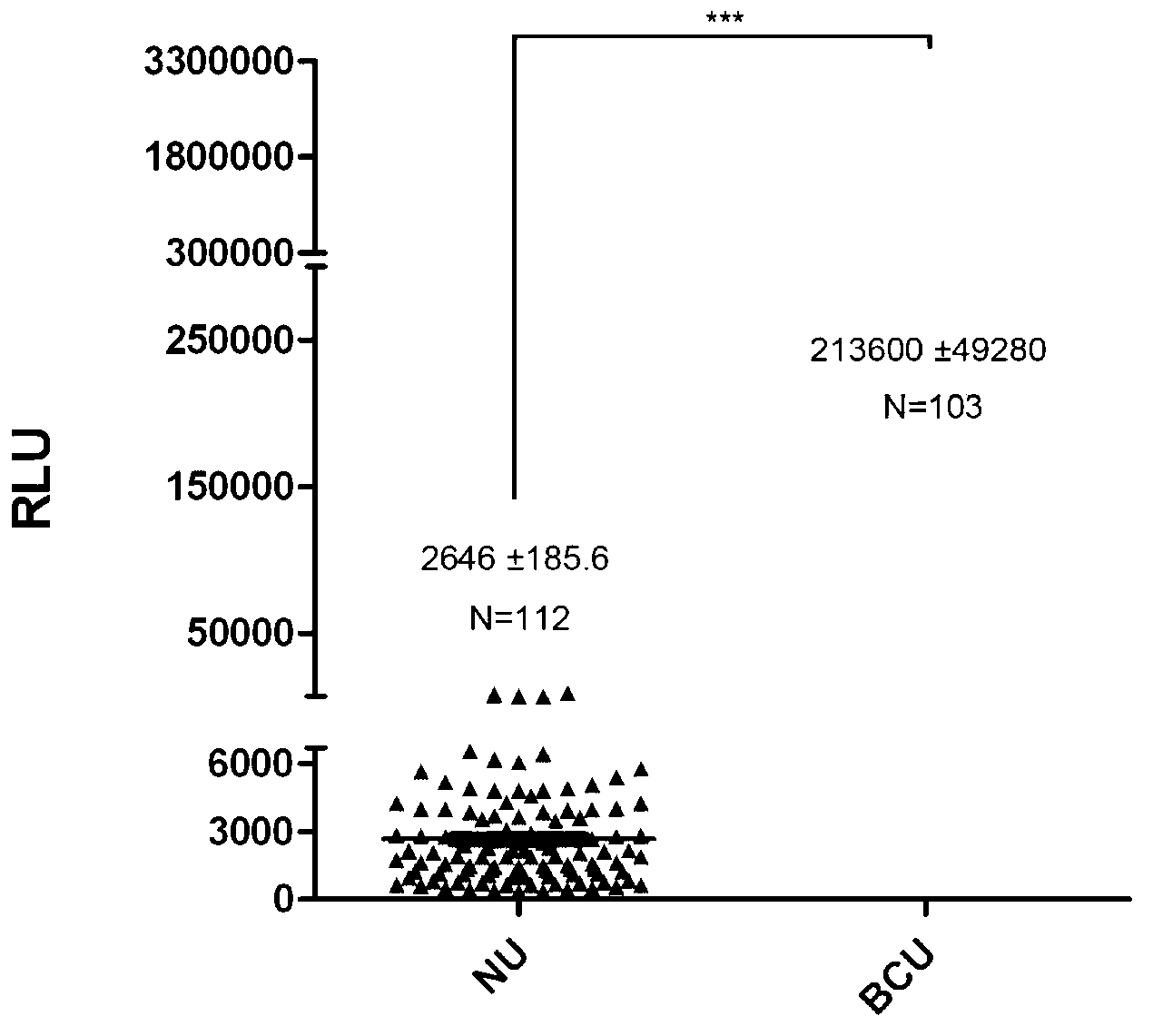

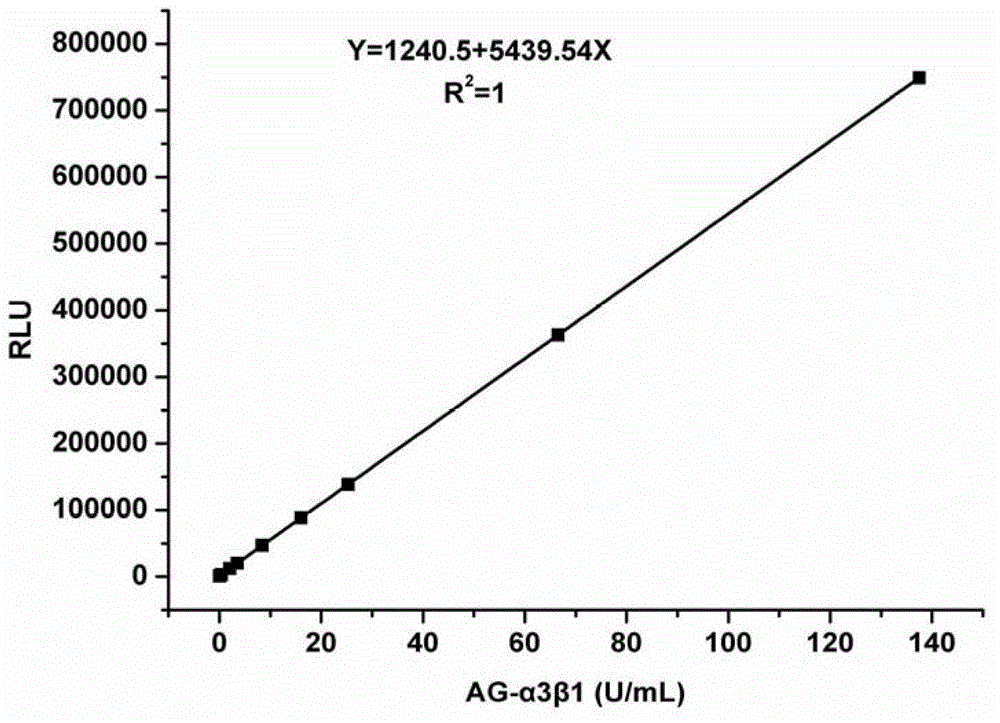

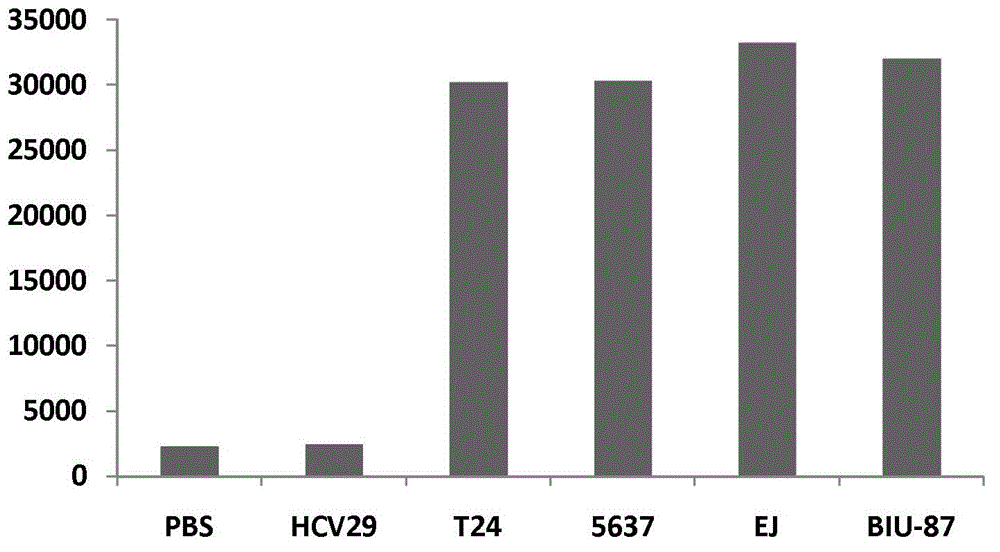

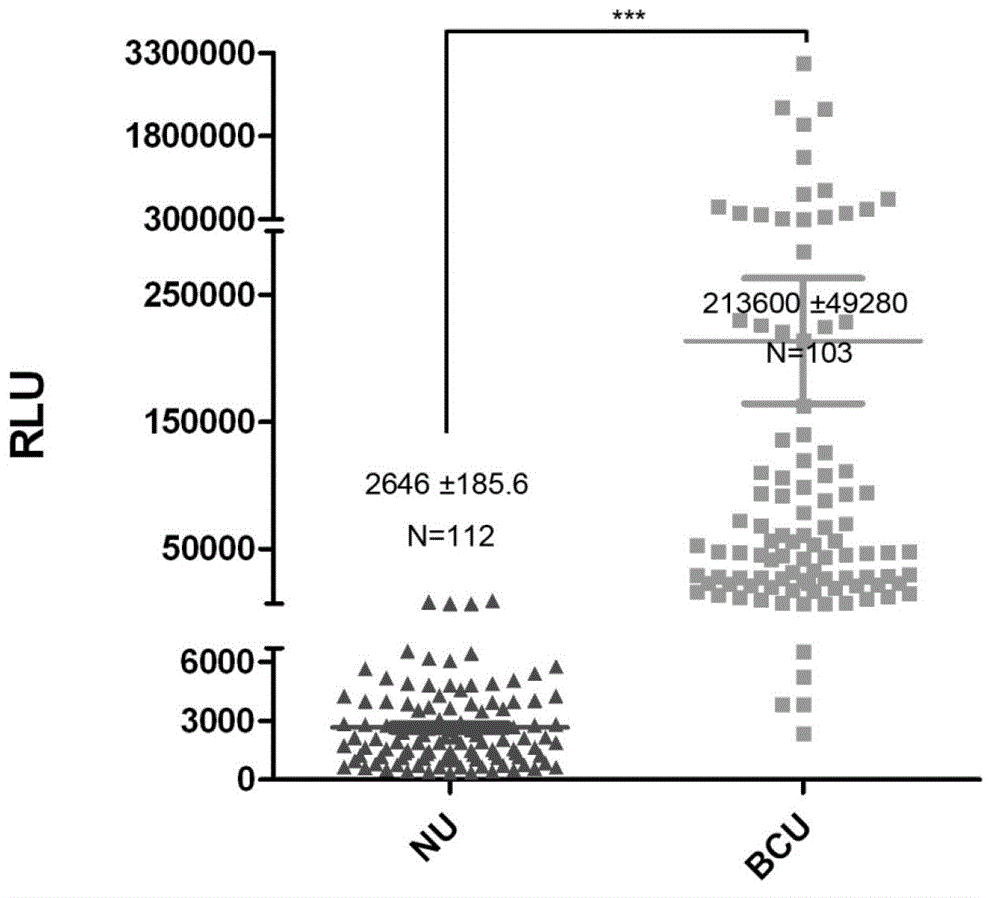

Kit for early diagnosis of bladder cancer and preparation method of kit

ActiveCN103018461AHigh sensitivitySensitive assayChemiluminescene/bioluminescenceBacteriuriaDiagnosis early

The invention discloses a kit for early diagnosis of bladder cancer and a method for preparing the kit, and relates to the field of biomedical immune analysis. The detecting kit, which is fast, sensitive, highly specific in the early diagnosis of the bladder cancer is created by detecting a tumor marker of the bladder cancer tumor marker, namely, abnormally glycosylated integrin AG-alpha3beta, in human urine by means of microplate chemiluminescence immunoassay. The kit provided by the invention has the advantages of simplicity, convenience, quickness, sensitivity, high specificity, stability and the like, can be applied to early screening of the bladder cancer in a routine examination and to tracking observation and prognostic evaluation of the bladder cancer, and can satisfy the need that the existing in-vitro diagnosis of the bladder cancer is lack in specific diagnosis method.

Owner:INSITUTE OF BIOPHYSICS CHINESE ACADEMY OF SCIENCES

Manufacturing method of tanned shrunk grain top layer leather

ActiveCN104762422AUnique shapeCan be used in a wide rangeTanning treatmentPre-tanning chemical treatmentTanninEngineering

The invention provides a manufacturing method of tanned shrunk grain top layer leather. In the method, crust leather is successively subjected to following processes: degreasing, re-tanning, neutralization, filling, dyeing, fat-liquoring, stacking, vibration-softening, leather grinding, painting-decoration and roll-burnishing. In the re-tanning process, by means of addition of sodium carbonate, the pH value of liquid in a drum machine is regulated to be 8-10 and meanwhile the temperature of the liquid is adjusted to be 33-35 DEG C, and then the crust leather is added with a shrunk grain agent to generate patterns on the crust leather, and finally when the processes are finished, the liquid in the drum machine is drained completely. In the invention, the shrunk grain agent is added at special pH value and temperature for generate bull-shoulder pattern on the crust leather, so that the tanned shrunk grain top layer leather is unique in appearance and is wider in available range when compared with a tanned leather prepared through a conventional technology. Meanwhile, by means of addition of a tannin extract in a special manner and at a special proportion during the filling process, the bull-shoulder pattern on the crust leather can be shaped to form a pattern shrinking effect.

Owner:FENGAN LEATHER

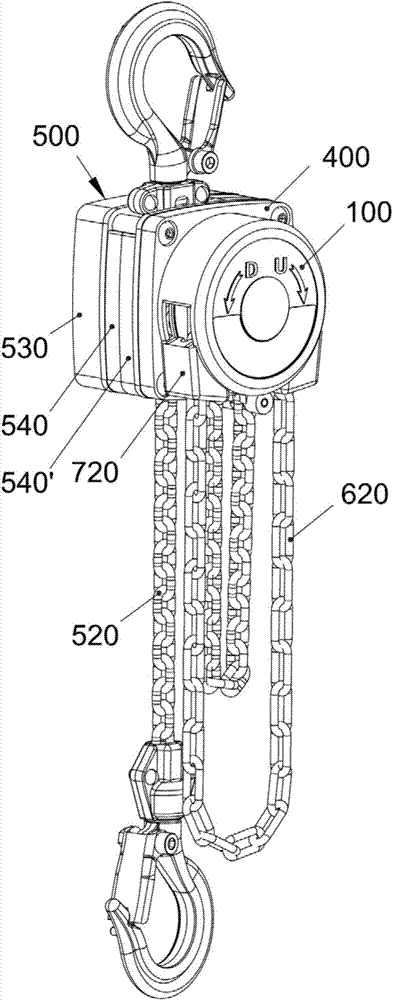

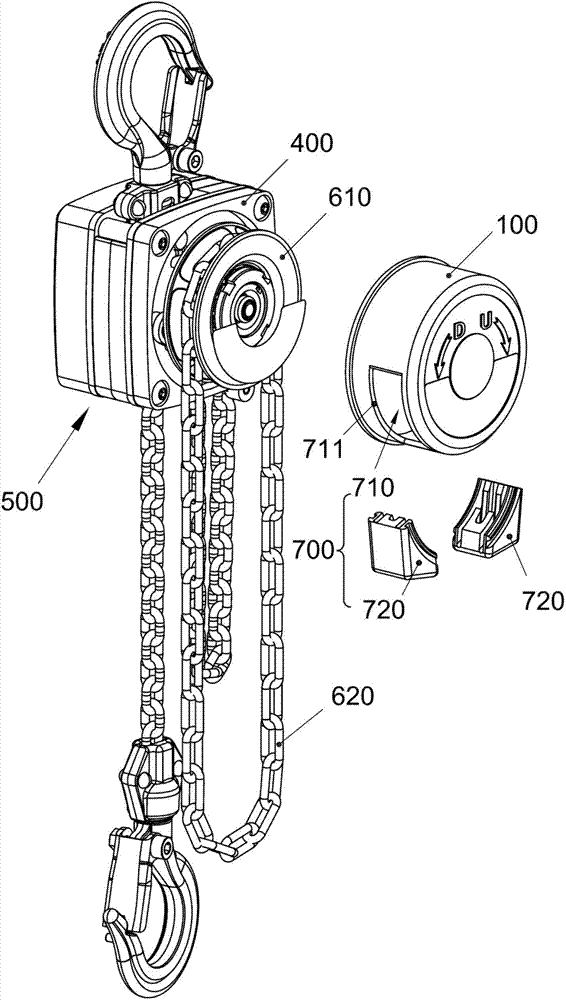

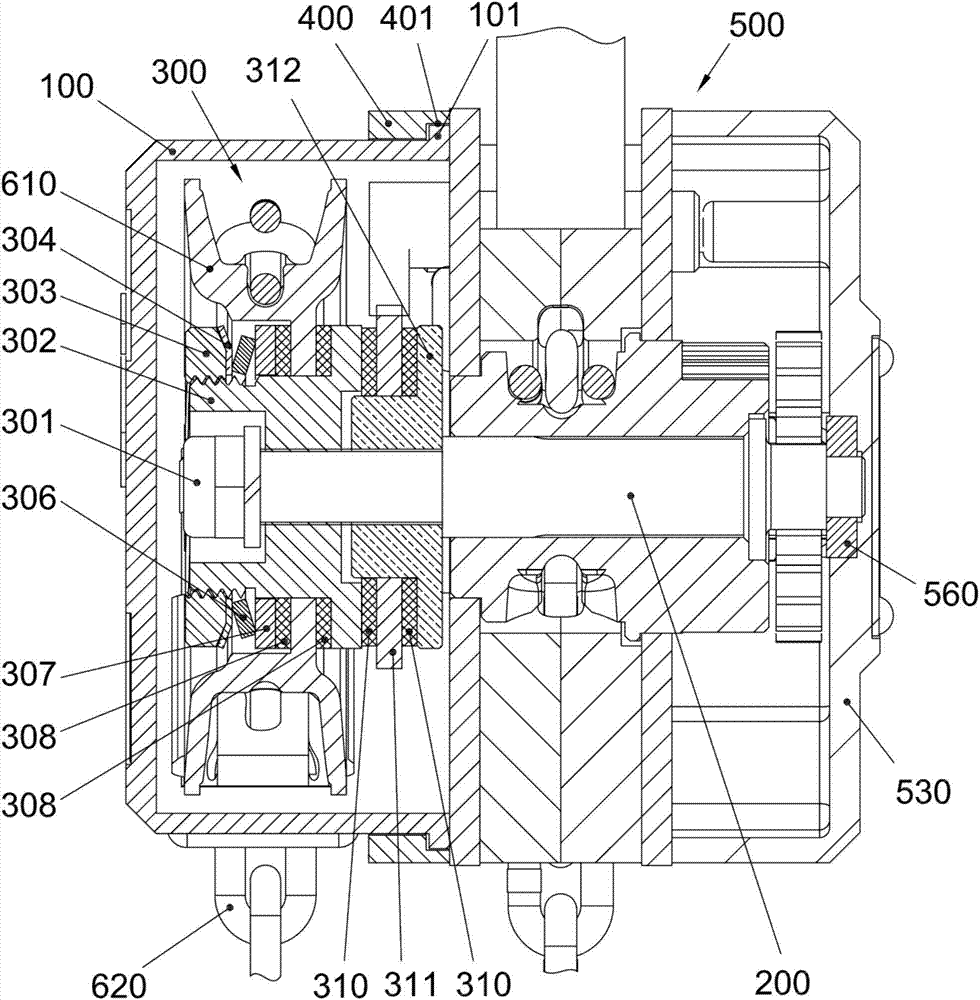

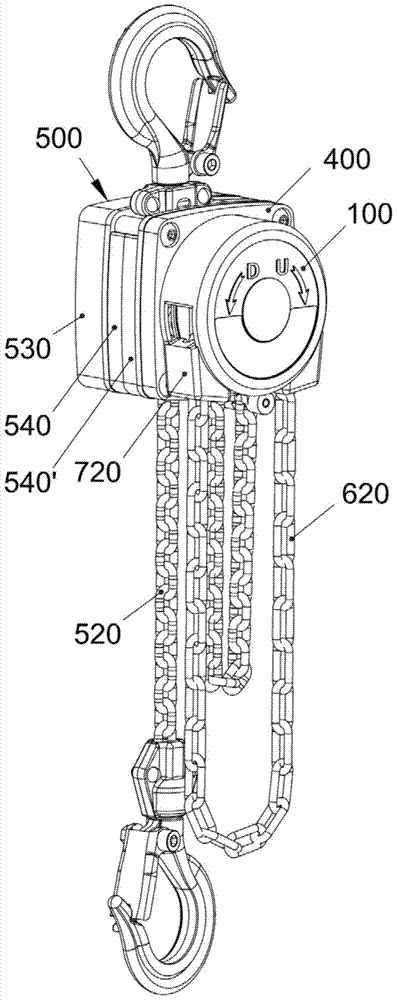

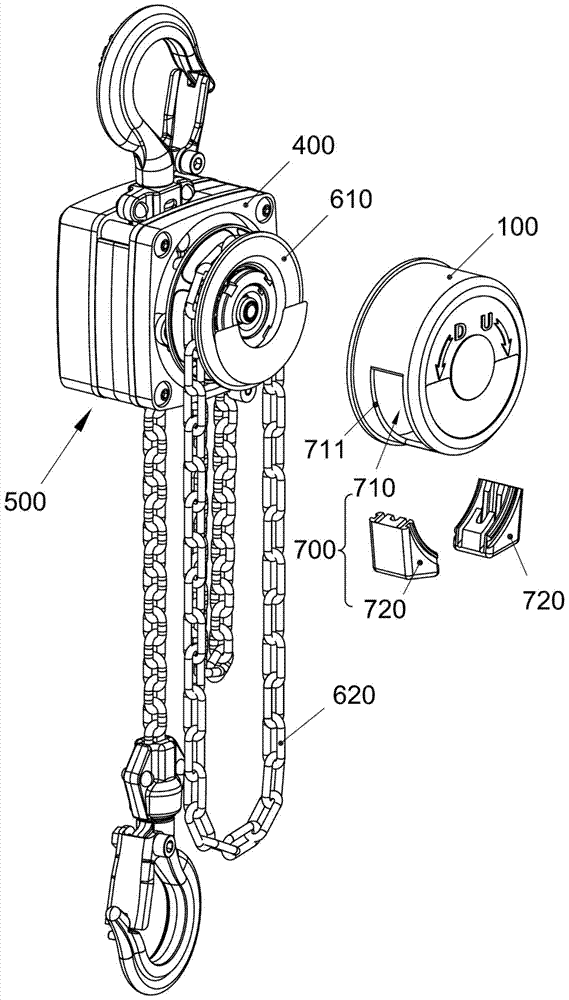

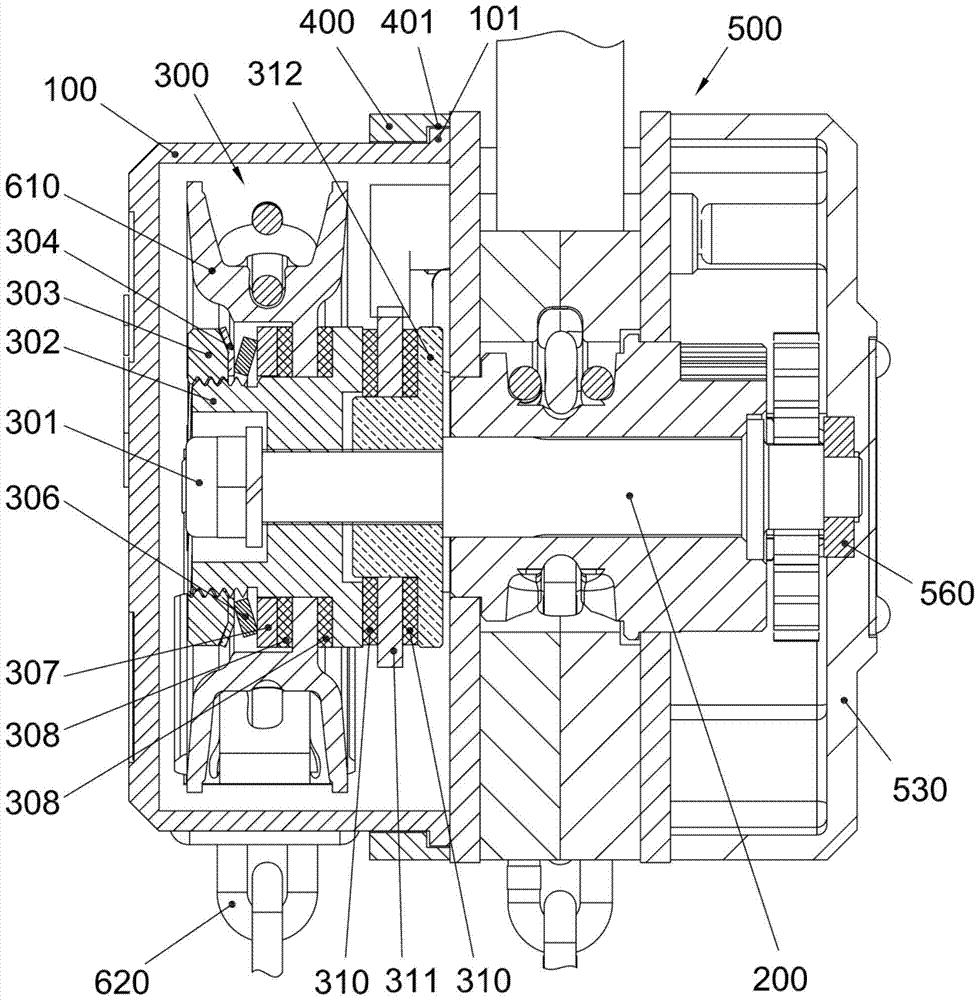

Chain block

Owner:CHONGQING VITAL ELEVATORING EQUIP

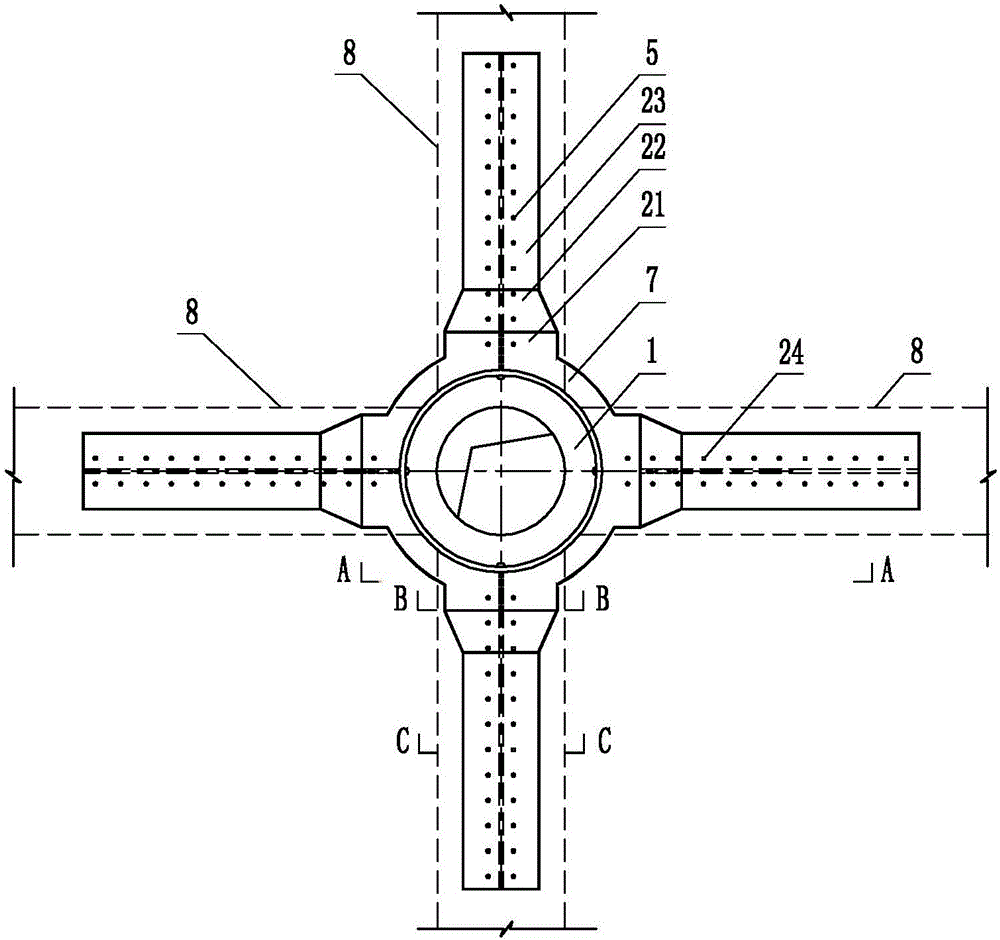

Steel pipe concrete column variable section broken-line-shaped steel bracket and connecting construction method thereof

InactiveCN106436924AGuarantee the construction qualityImprove securityBuilding constructionsRebarSteel tube

A steel pipe concrete column variable section broken-line-shaped steel bracket comprises an upper flange plate, a lower flange plate and a web perpendicularly connected between the upper flange plate and the lower flange plate. The upper flange plate and the lower flange plate are the same in structure and each comprises N flange plate bodies and N-1 transition sections. Every two adjacent flange plate bodies are connected through one corresponding transition section, and thus a broken-line-shaped multilayer structure is formed. The elevation of the flange plate bodies is sequentially decreased section layer by section layer, the width is decreased layer by layer, the height difference between every two adjacent flange plate bodies is 2d, and d is the steel bar diameter. A construction method of the variable section broken-line-shaped steel bracket comprises the following steps of S1, variable section broken-line-shaped steel bracket deep design, S2, steel bracket segmented manufacturing in a processing factory, S3, steel pipe column and steel bracket field installation welding, S4, simulation test, steel bar welding and binding, and S5, concrete pouring and maintenance. According to the construction method for connecting a steel pipe concrete column with a concrete beam by using the variable section broken-line-shaped steel bracket, operation is easy and convenient, the construction process quality is controllable, and the structure safety can be improved.

Owner:广西建工第五建筑工程集团有限公司

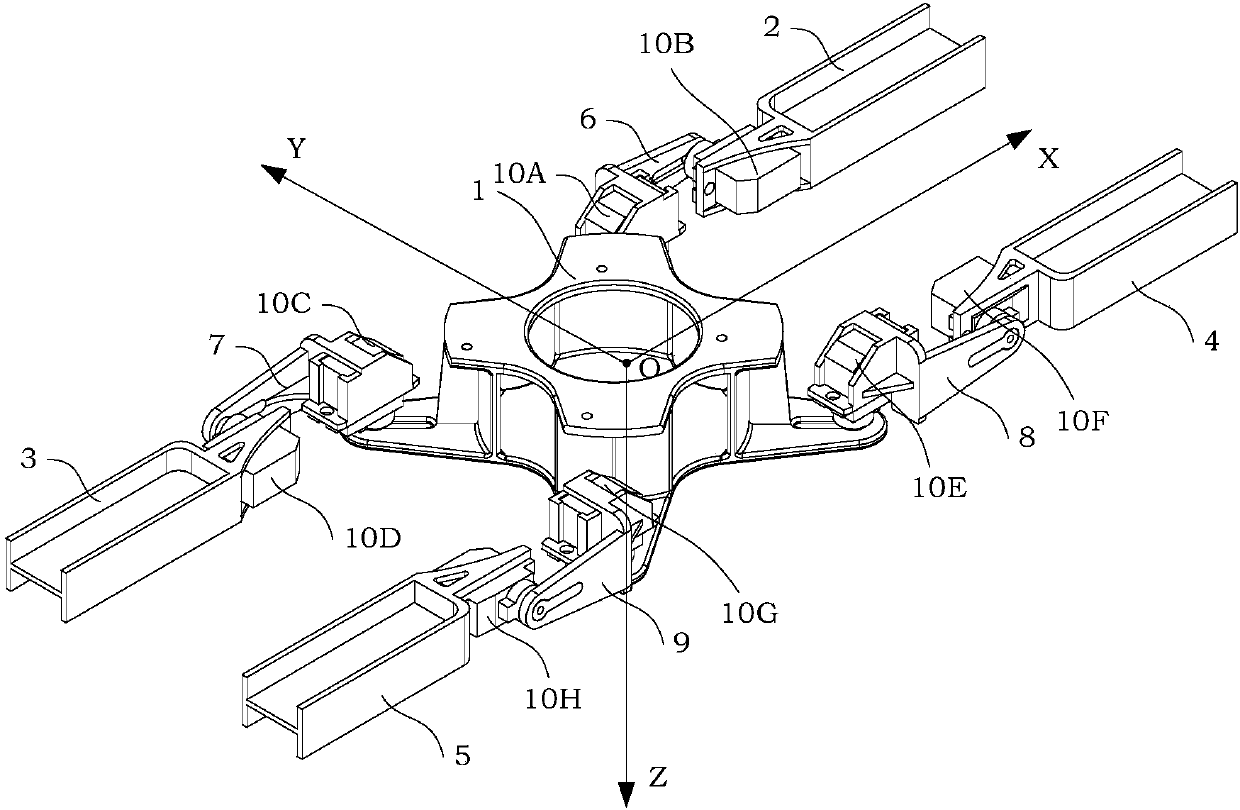

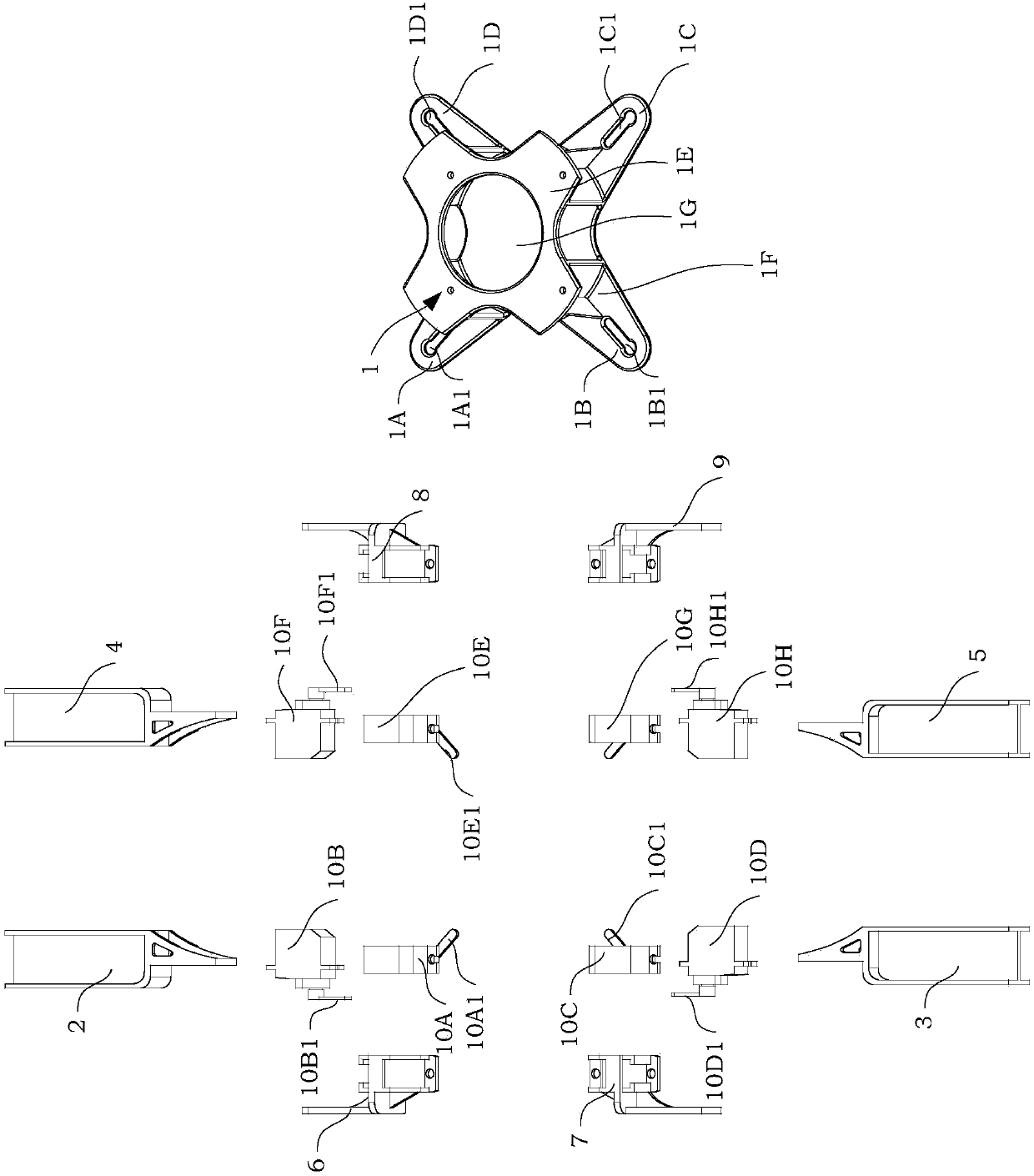

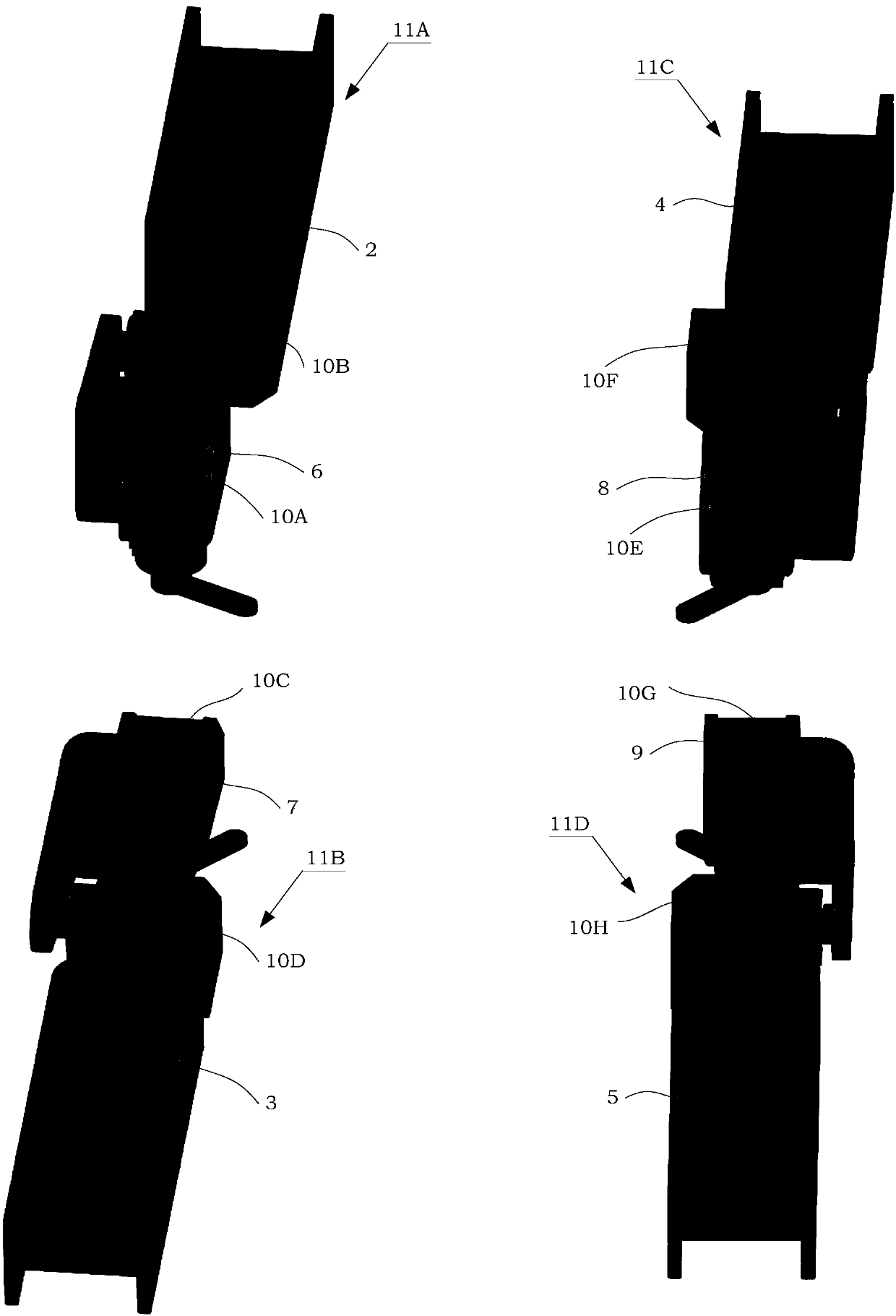

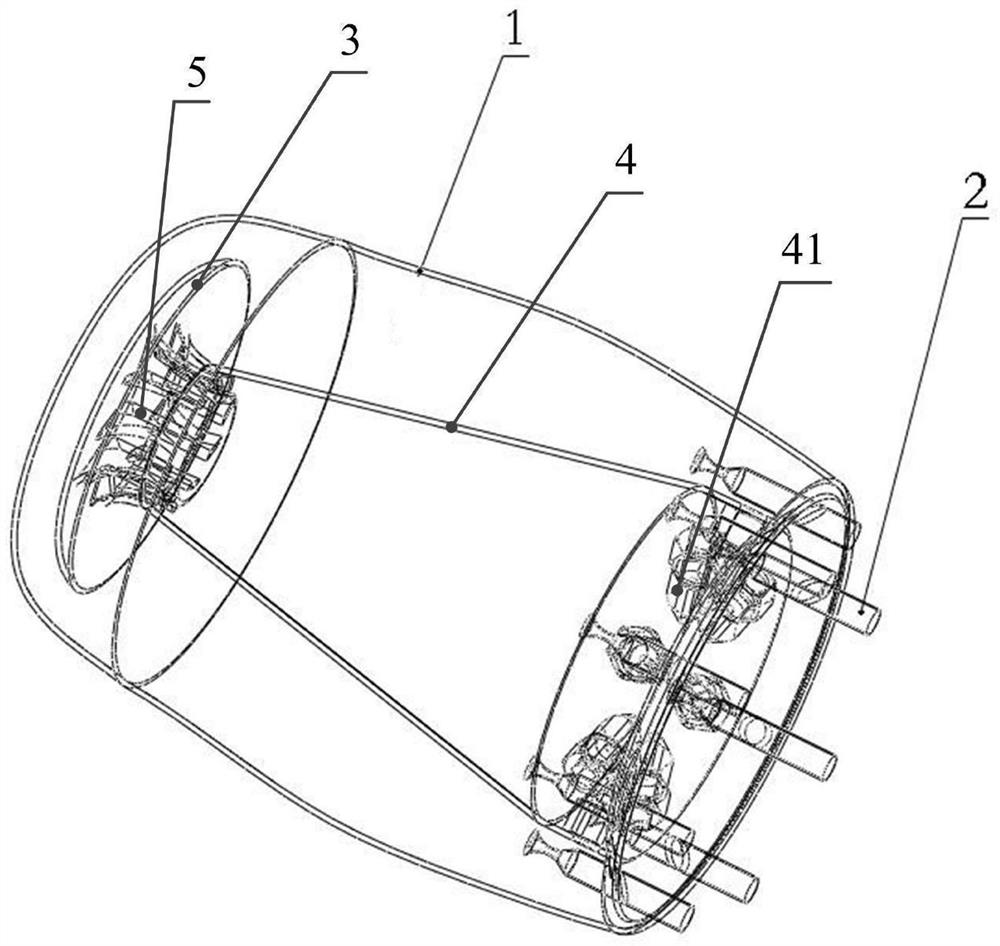

Quadruped robot self-adjusted from any posture in air to landing posture

InactiveCN108214519ASimple and lightweight designEasy to controlProgramme-controlled manipulatorJointsConical pendulumTwo degrees of freedom

The invention discloses a quadruped robot self-adjusted from any posture in the air to a landing posture. The robot comprises a steering engine control unit, steering engines and a quadruped robot body, wherein the quadruped robot body comprises a trunk body and leg units capable of carrying out spatial two-degree-of-freedom motion; through conical pendulum motion in different directions of the leg units, any posture in the air can be adjusted into the landing posture to enable the robot body to reach the ground; the four leg units of the quadruped robot body are provided with the steering engines respectively, and the steering engines are controlled by steering engine commands output by the steering engine control unit; and the steering engine control unit carries out control on the steering engines by adopting an adjusting sequence from an X axis to a Y axis and to a Z axis. According to the quadruped robot self-adjusted from any posture in the air to the landing posture, when the quadruped robot is adopted to bear a satellite structure body, posture adjustment of smooth and stable landing of the satellite structure body can be achieved without external force action.

Owner:BEIHANG UNIV

Kit for early diagnosis of bladder cancer and preparation method of kit

ActiveCN103018461BHigh sensitivitySensitive assayChemiluminescene/bioluminescenceBladder cancerBacteriuria

The invention discloses a kit for early diagnosis of bladder cancer and a method for preparing the kit, and relates to the field of biomedical immune analysis. The detecting kit, which is fast, sensitive, highly specific in the early diagnosis of the bladder cancer is created by detecting a tumor marker of the bladder cancer tumor marker, namely, abnormally glycosylated integrin AG-alpha3beta, in human urine by means of microplate chemiluminescence immunoassay. The kit provided by the invention has the advantages of simplicity, convenience, quickness, sensitivity, high specificity, stability and the like, can be applied to early screening of the bladder cancer in a routine examination and to tracking observation and prognostic evaluation of the bladder cancer, and can satisfy the need that the existing in-vitro diagnosis of the bladder cancer is lack in specific diagnosis method.

Owner:INSITUTE OF BIOPHYSICS CHINESE ACADEMY OF SCIENCES

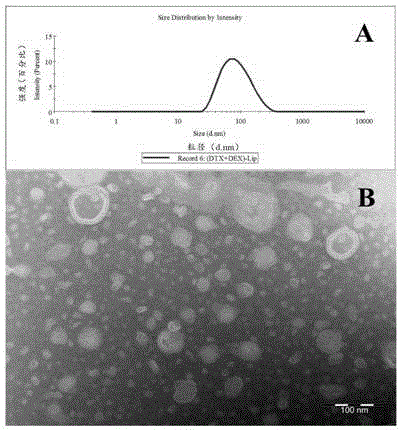

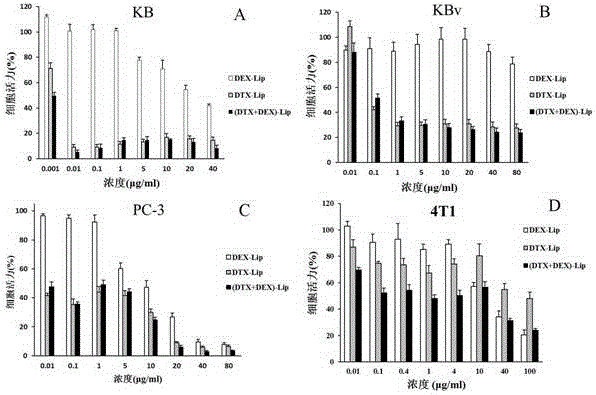

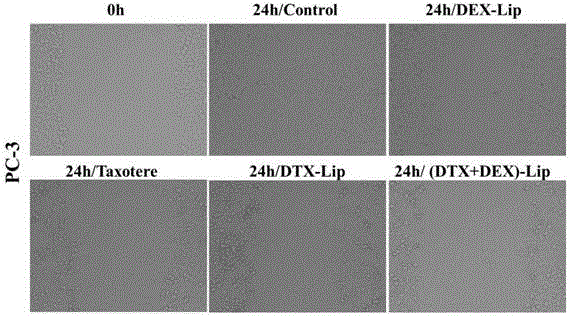

Anticancer composition as well as preparation and application thereof

InactiveCN106177959AGrowth inhibitionIncrease in tumor sizeOrganic active ingredientsPharmaceutical non-active ingredientsDexamethasoneSide effect

The invention discloses an anticancer composition as well as a preparation and application thereof and belongs to the field of preparation and application of anticancer drugs. The invention firstly discloses the anticancer composition. The anticancer composition is prepared from dexamethasone with effective dose in treatment and an anticancer drug. Compared with a mode of independently using the anticancer drug, a mode of jointly using the dexamethasone and the anticancer drug, disclosed by the invention, has a better tumor inhibiting effect. The invention further discloses an anticancer preparation. The anticancer preparation is prepared from the anticancer composition with the effective dose in treatment and pharmaceutically-acceptable accessories. Founded by the invention, when the anticancer preparation is prepared into a nano preparation for application, the dexamethasone can be released into a tumor microenvironment by using a targeting action and a slow release effect, related components of the tumor microenvironment is improved, the accumulation of the anticancer drug at a tumor part is further improved, the growth and the transfer of tumors are significantly inhibited, tumor cells are killed and an anticancer effect is enhanced; the inhibition rate of the tumors in a body reaches 97 percent, toxic or side effects of the anticancer drug can be relieved, and the treatment cost and the risk of the cancer are reduced.

Owner:PEKING UNIV

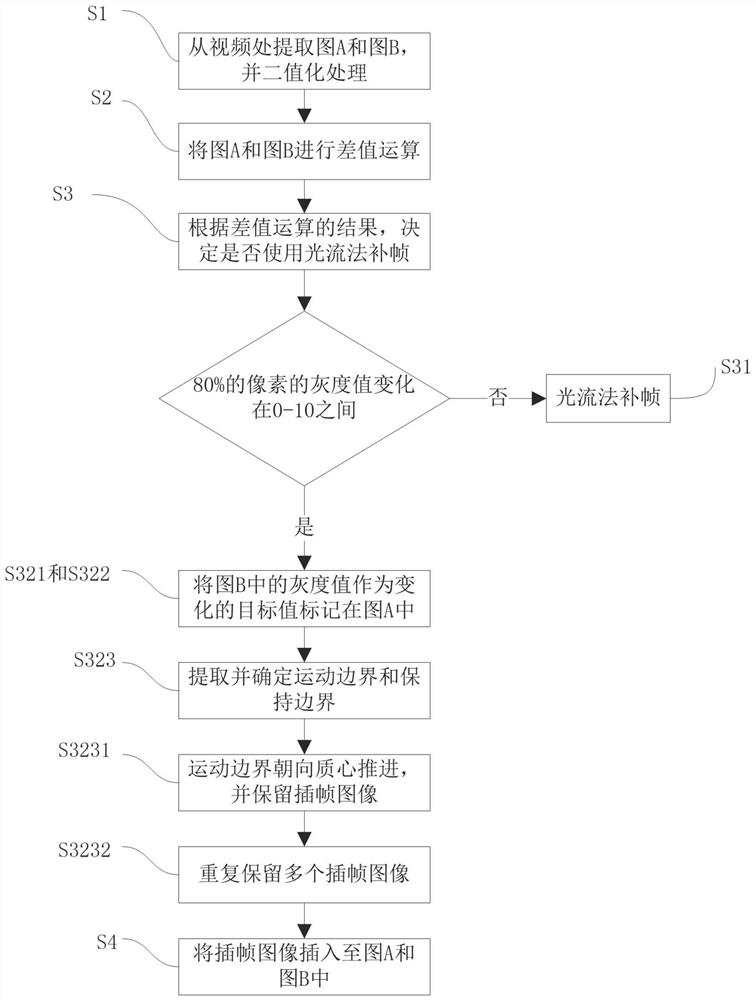

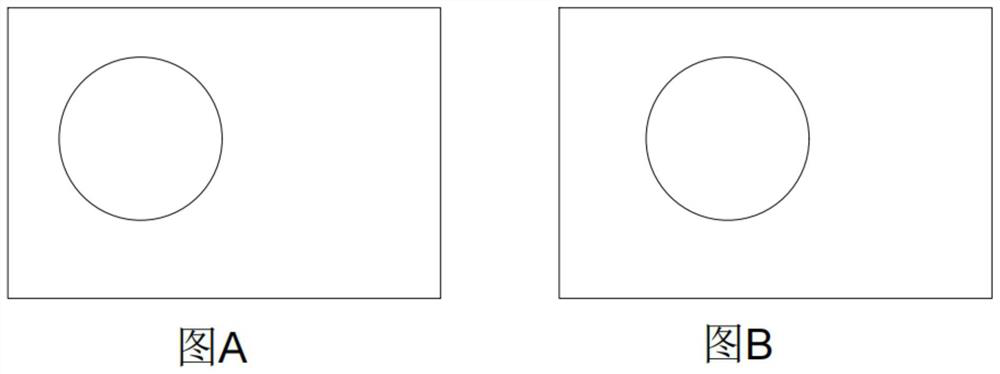

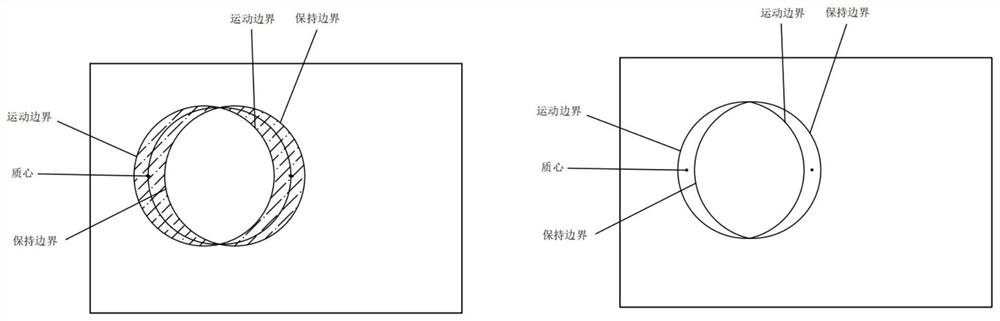

Video frame insertion processing method

ActiveCN113225589ASmall amount of calculationCan be used in a wide rangeSelective content distributionImaging processingComputer graphics (images)

The invention relates to the technical field of image processing, in particular to a video frame insertion processing method, which comprises the following steps of: performing simple similarity comparison on two frames of images of an original video to judge whether a large-scale pixel change exists between the two frames of images so as to determine whether a background is changed, and if the large-scale pixel change does not exist in the images, supplementing frames by using the existing optical flow method; if the two frames of images exist, pushing the boundaries of the original images to the changed boundaries by extracting the boundaries before and after the change, and extracting a plurality of frame insertion images from the boundaries, so that frame supplementation is performed between the two frames of images. Optical flow information does not need to be collected, and meanwhile, a moving object in the images does not need to be recognized, so that the calculation amount is relatively small, and the application range is wide.

Owner:北京凯视达信息技术有限公司

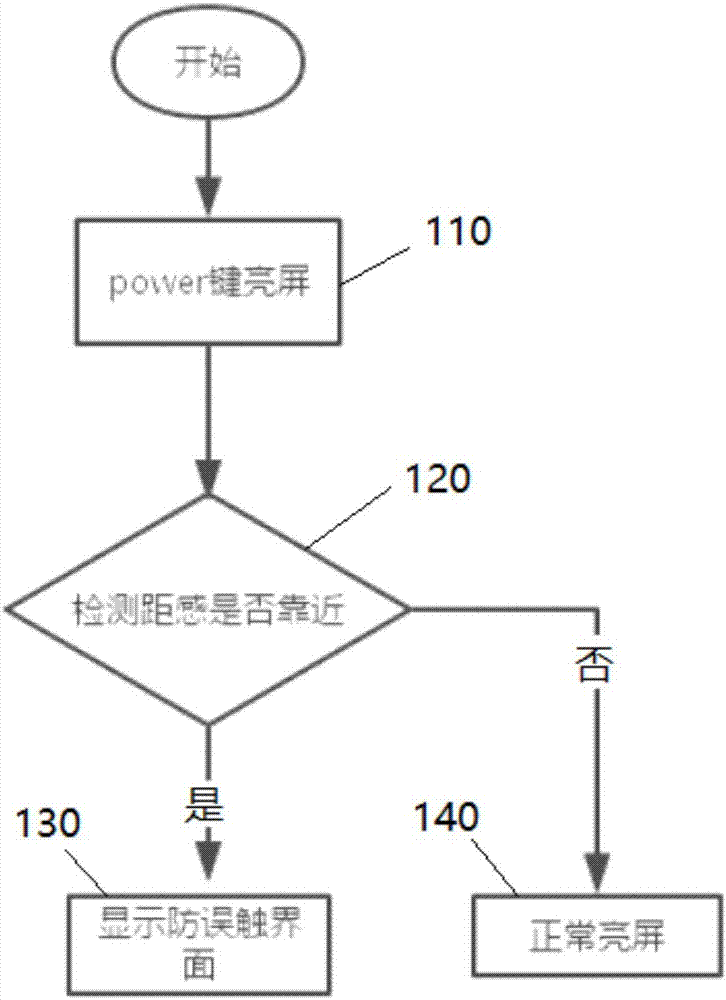

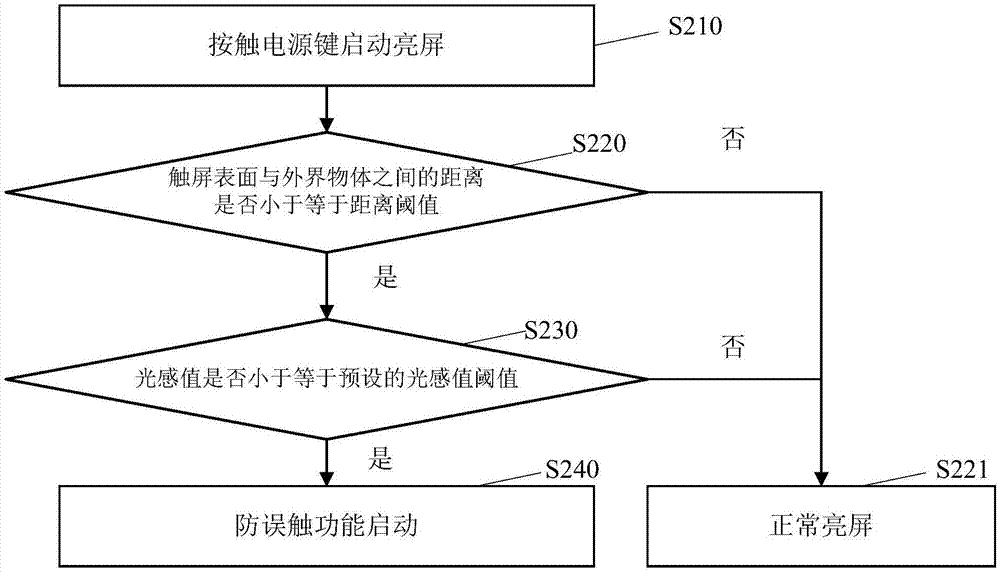

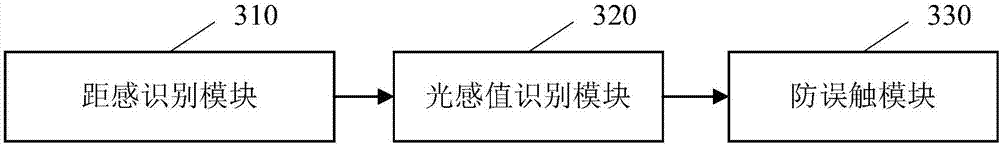

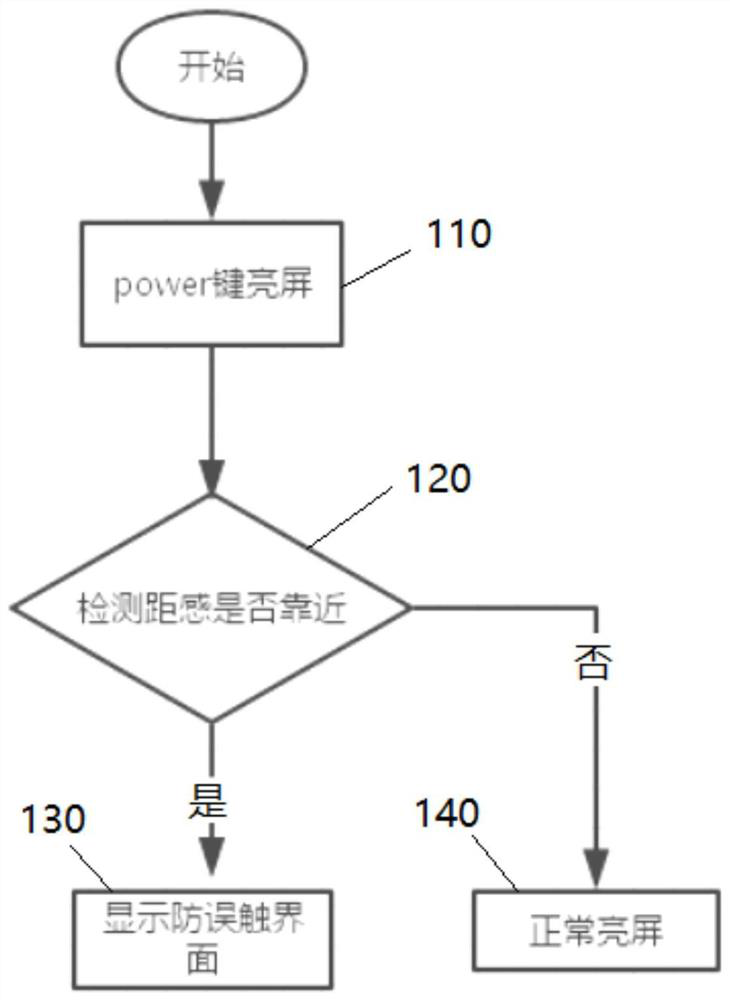

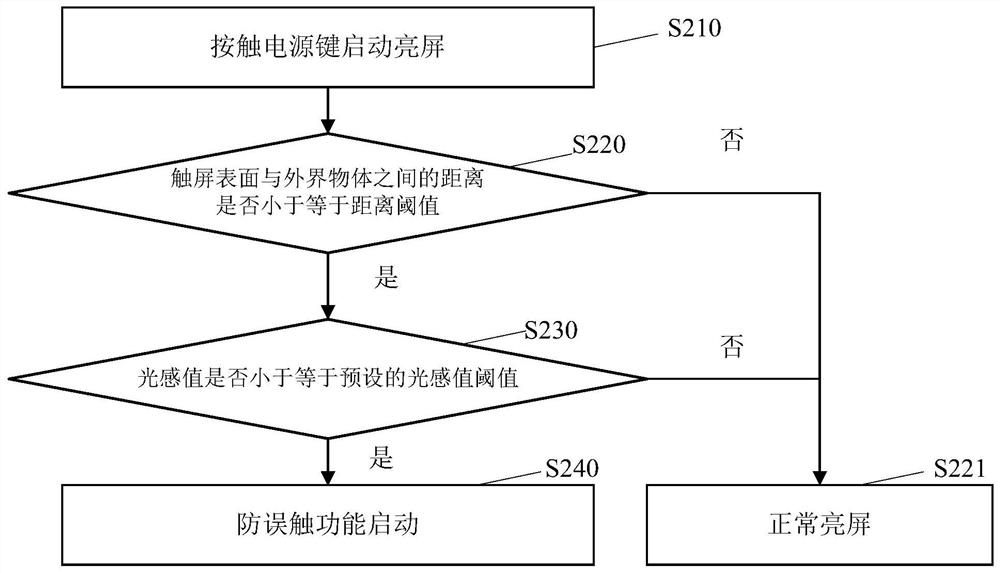

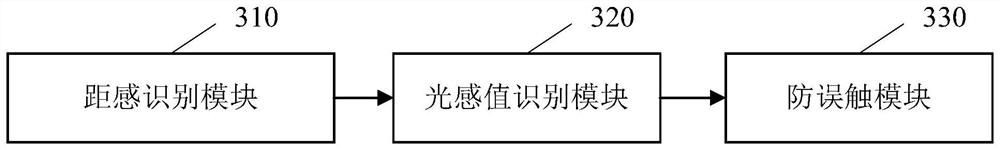

Touch screen device and mistaken touch preventing identification system and method thereof

ActiveCN107329613AImprove experienceSolve the problem of easy false alarm and anti false touchInput/output processes for data processingFalse alarmComputer science

The invention discloses a mistaken touch preventing identification method. The identification method comprises the steps that when it is detected through screen touching that the distances between one or more zones on the surface and an outside object are smaller than or equal to preset distance threshold values, light sensation values of the zones are detected through screen touching and judged; when it is detected through screen touching that the light sensation values of the zones are smaller than or equal to preset light sensation threshold values, mistaken touch preventing operation is triggered through screen touching. Judgment on touch screen surface light sensation values is added in the mistaken touch preventing identification process, triggering of the mistaken touch preventing operation of a touch screen device is determined when it is detected through screen touching that the light sensation values of the zones are smaller than or equal to the preset light sensation threshold values, the problem that it is erroneously identified through distance sensing detection of a touch screen that the outside object is close to a mobile phone under the situation that the touch screen surface is interfered by oil stains or a distance sensing structure portion deforms slightly, and accordingly false alarm or mistaken touching easily occurred in a bright state of the touch screen is caused is solved, the probability of false alarm or mistaken touching is reduced by judging the light sensation values, and user experience is improved.

Owner:SHANGHAI TRANSSION CO LTD

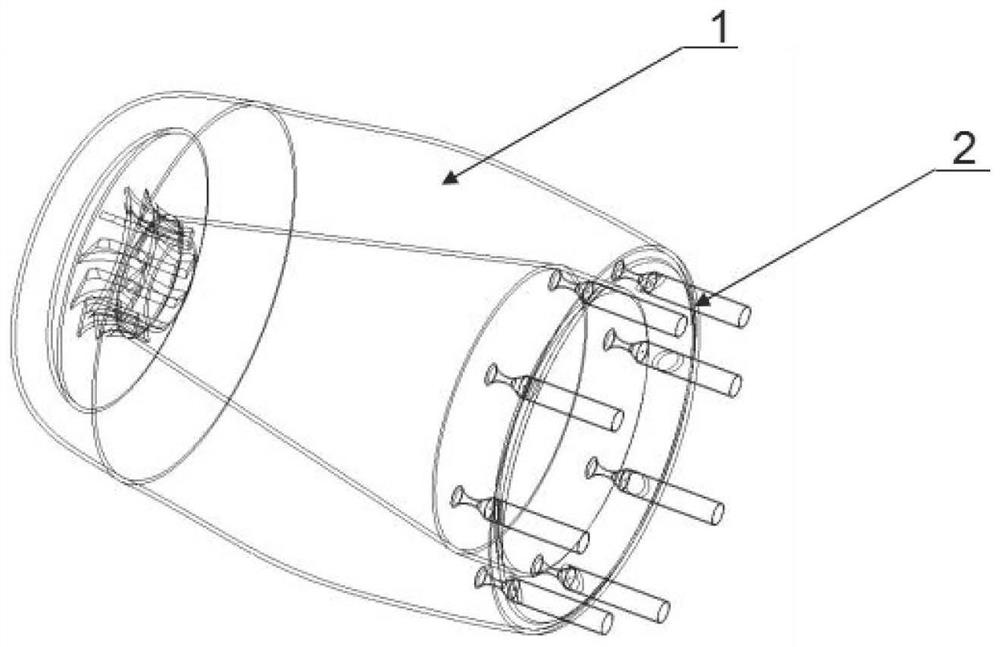

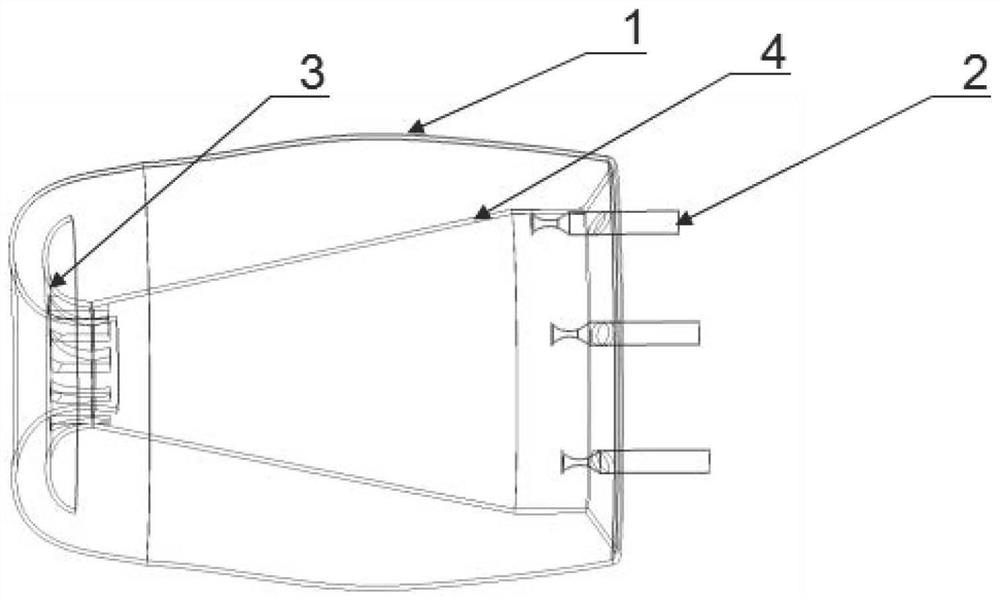

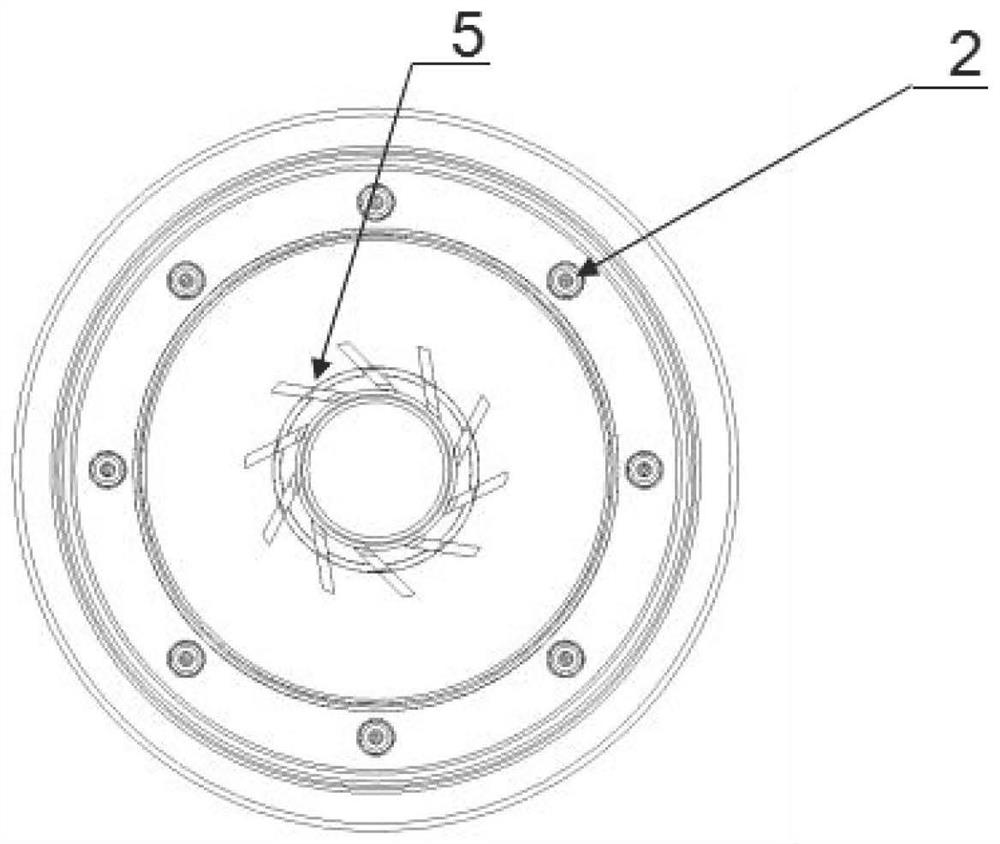

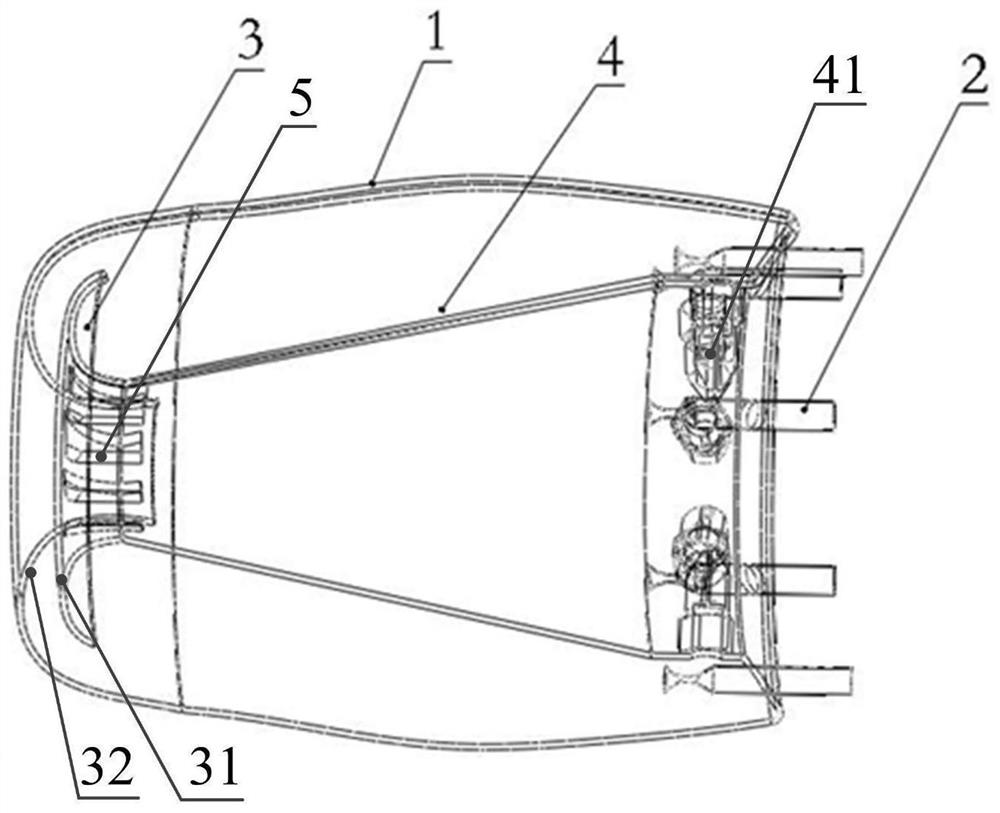

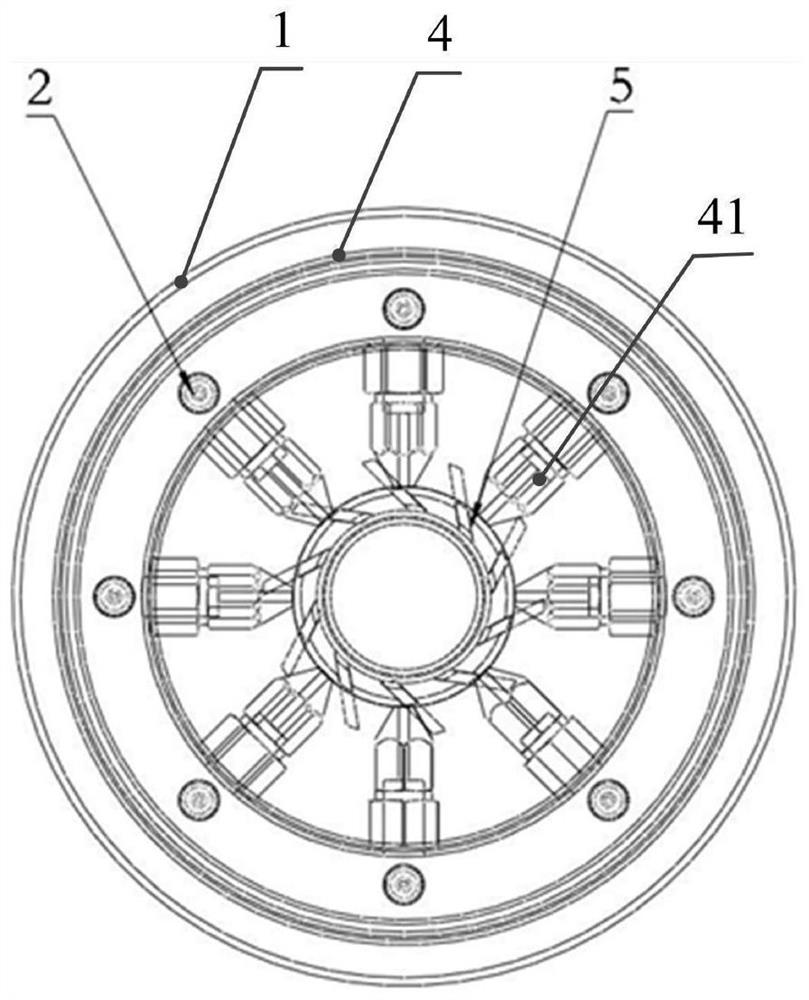

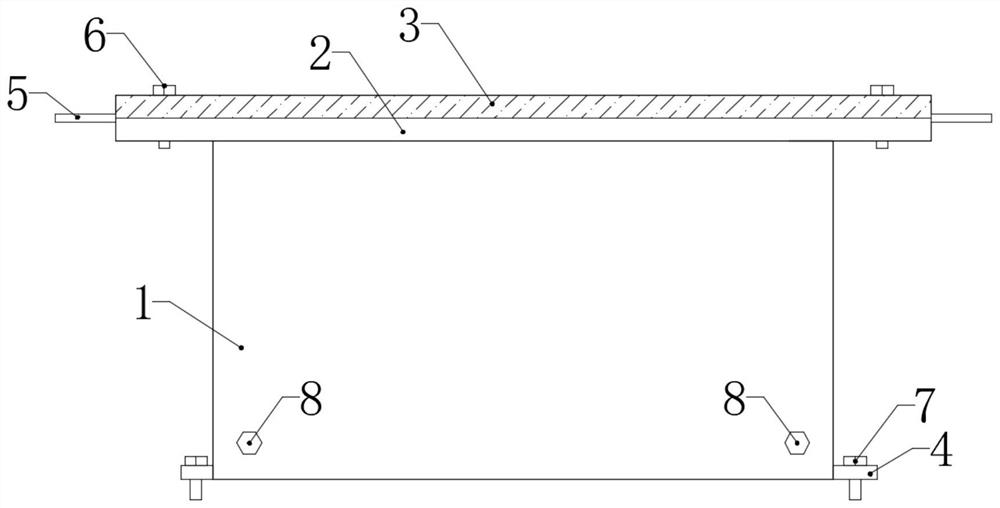

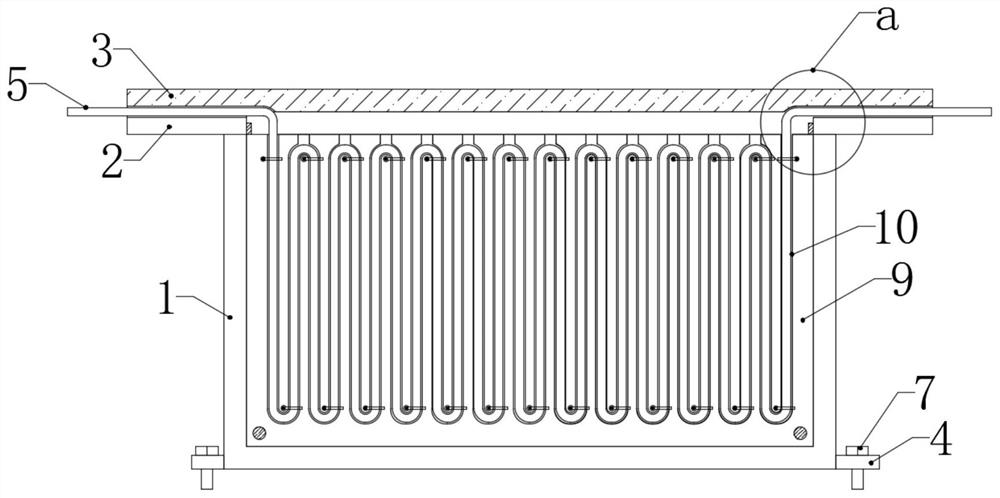

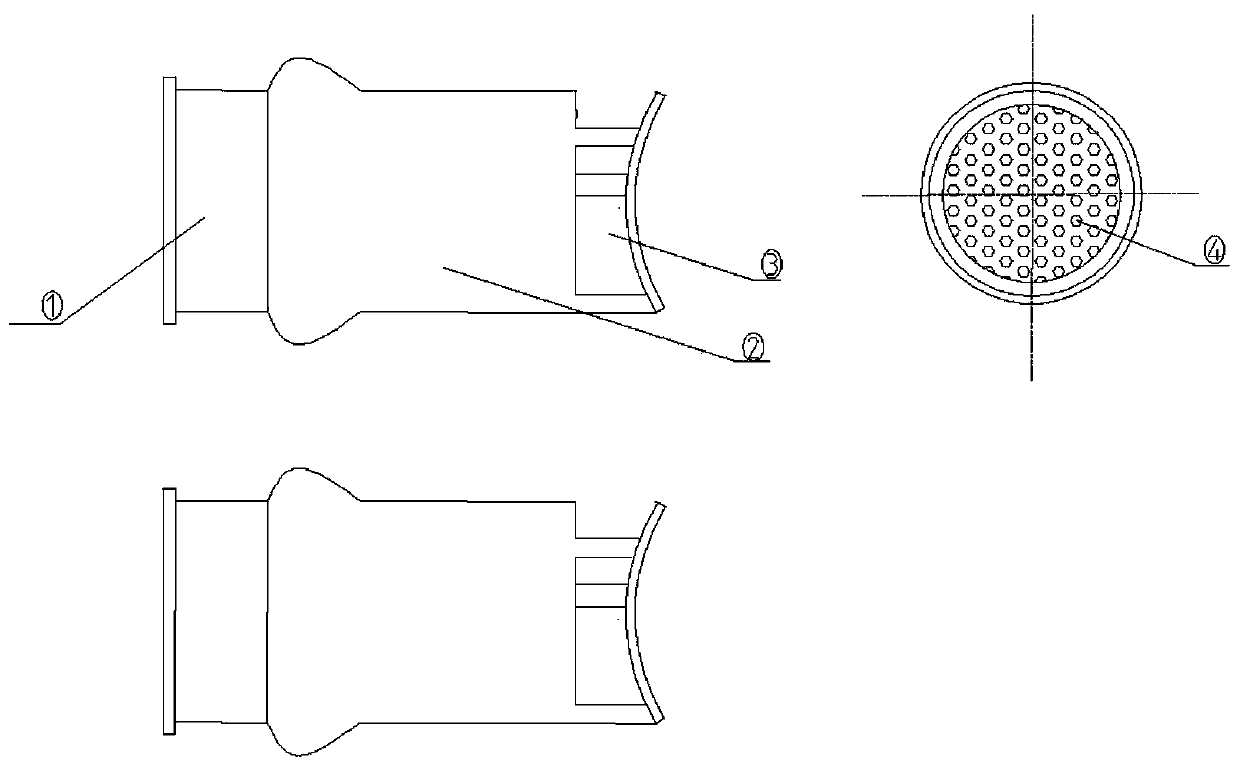

Supersonic spiral bladeless dust collection device suitable for coal mine transfer point

PendingCN114810185AWide range of useEquipment usage is limitedDust removalFire preventionPhysicsCoal

The invention discloses a supersonic speed spiral bladeless dust collection device suitable for a coal mine transfer point. The supersonic speed spiral bladeless dust collection device comprises a shell, a Laval supersonic speed airflow generation device, an airflow reversal acceleration device and a spiral airflow generation device. The shell is of a hollow cylindrical structure, and eight internal thread holes used for installing the laval tube supersonic speed airflow generating devices are formed in the front end of the shell. And the cylindrical section of the rear end of the shell is provided with a circle used for being connected with the air flow reversal acceleration device. A center cavity channel is formed in the center of the Laval supersonic speed airflow generating device, the center cavity channel is divided into a straight pipe cavity channel section and a Laval pipe cavity channel section, and the side wall of an expansion section of the Laval pipe cavity channel section is in a concave curve shape. The two layers of shells of the air flow reversal acceleration device are both horn-shaped, the shells are gradually shrunk from the upper edge to the bottom end, and an air outlet is formed when the shells are shrunk to the minimum position. The spiral airflow generating device is a double-layer ring, and an air splitter is mounted in an interlayer of the ring.

Owner:LIAONING TECHNICAL UNIVERSITY

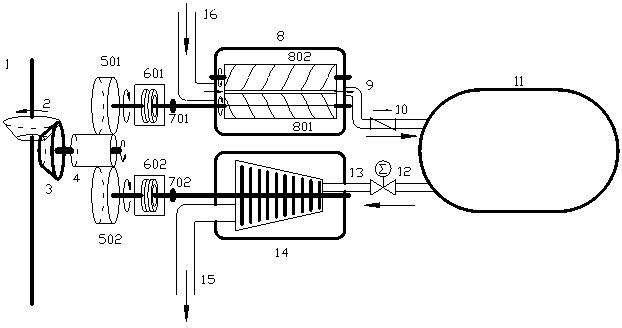

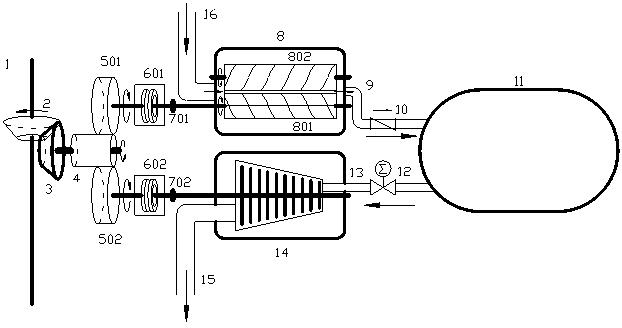

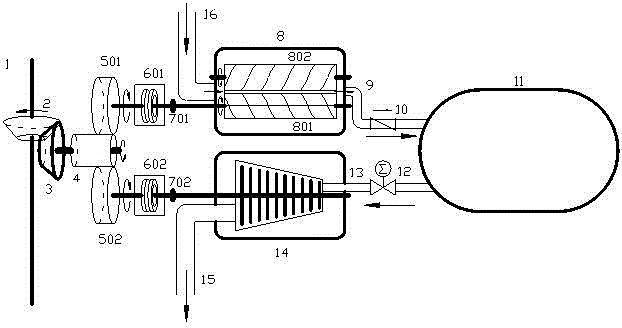

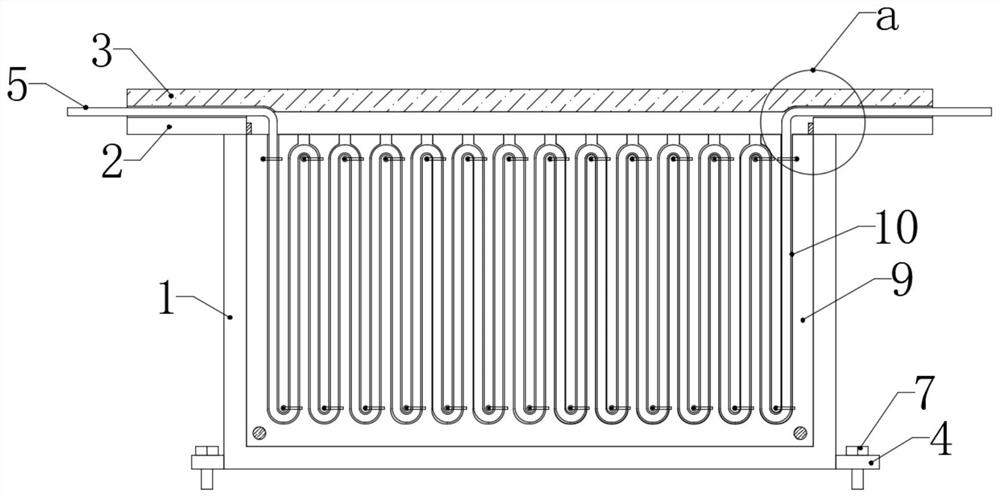

Power regeneration type braking and boosting integrated device used for locomotive

InactiveCN102085855AImprove recycling efficiencySafe and smooth brakingBraking action transmissionEnergy recoveryAir compressor

The invention discloses a power regeneration type braking and boosting integrated device used for a locomotive. The kinetic energy of the locomotive is recycled by virtue of a gear set, and the recycled kinetic energy of the locomotive is converted into air potential energy to be stored by virtue of a double screw air compressor. When the compressed air reaches a certain pressure, a generated counter acting force inhibits the action of the double screw air compressor, and finally the locomotive brakes. When the locomotive starts, the compressed air is released and expands to do work and then drive a high pressure air engine, thus the locomotive is driven. The dead weight of the device in the invention can be controlled in a lighter range, and the braking is safe and stable when a frictiontype braking is combined; and the energy recycling efficiency is high, the application range is wide, and the device can be applied to multiple locomotives and other traffic tools.

Owner:SHANGHAI LANXIN ENERGY SAVING TECH

Method for producing azodiisobutyronitrile from hydrobromic acid and hydrogen peroxide under action of catalyst

PendingCN112851548AImprove controllabilityCan be used in a wide rangeOrganic compound preparationCarboxylic acid nitrile purification/separationPtru catalystEngineering

The invention belongs to the technical field of chemical engineering, and particularly relates to a method for producing azodiisobutyronitrile from hydrobromic acid and hydrogen peroxide under the action of a catalyst. The method comprises the following steps: adding a hydrobromic acid solution, diisobutyronitrile hydrazine and a catalyst into a reaction kettle to form two phases; stirring the material, reacting the hydrogen peroxide with hydrobromic acid to generate bromine, reacting the bromine with diisobutyronitrile hydrazine under the action of a catalyst to generate azodiisobutyronitrile and hydrobromic acid, reacting the hydrobromic acid with the hydrogen peroxide dropwise added thereafter to generate bromine, continously reacting the bromine with diisobutyronitrile hydrazine to generate azodiisobutyronitrile and hydrobromic acid, and when no diisobutyronitrile hydrazine exists in the solution, and ending the reaction to finally form a mixed phase containing azodiisobutyronitrile and a hydrobromic acid solution. The mother liquor obtained after the hydrobromic acid reaction can be recycled, all components contained in the mother liquor cannot be separated out or discharged, no redundant substances are generated, recycling of materials is achieved, the cost is saved, the economical efficiency is excellent, the reaction time is shortened by half, and energy consumption is greatly saved.

Owner:孙晓伟

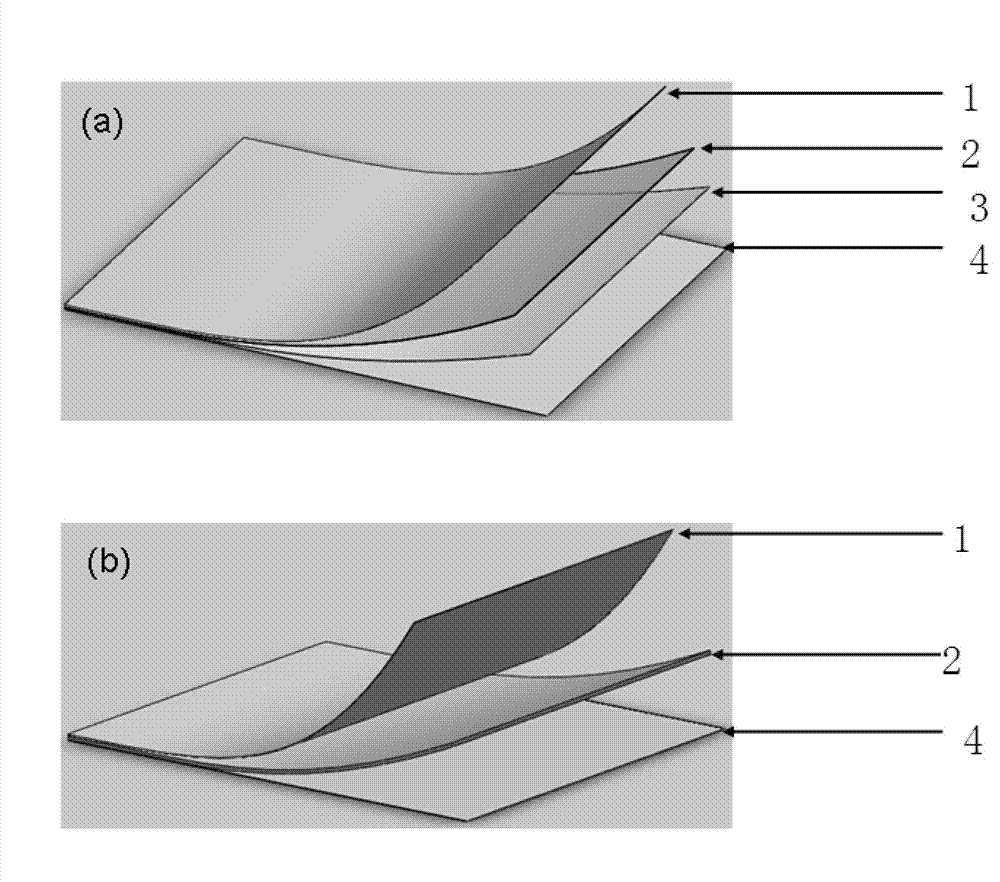

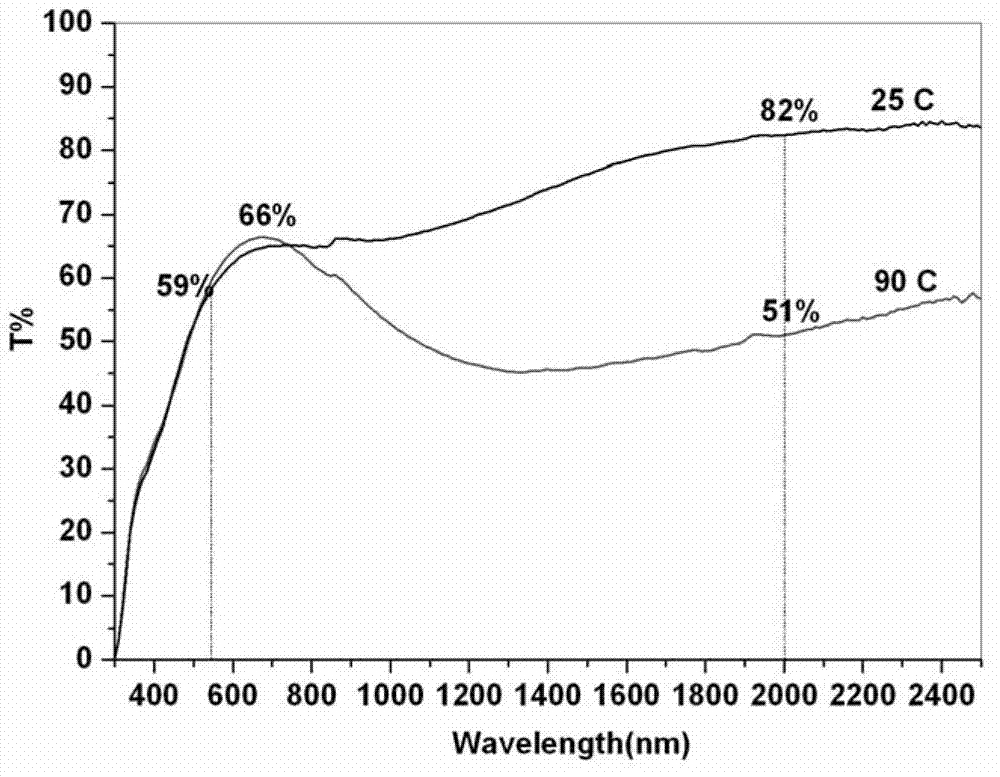

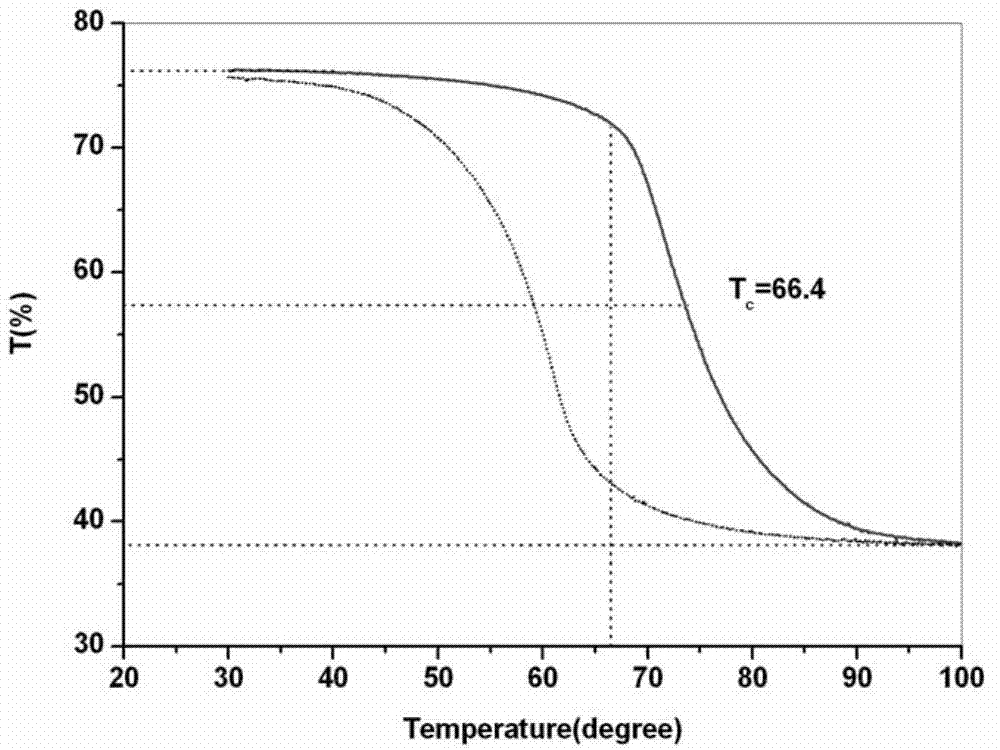

Preparation method of intelligent temperature control glue and film

ActiveCN103031077ASimple preparation processPracticalNon-macromolecular adhesive additivesFilm/foil adhesivesTemperature controlVanadium dioxide

The invention relates to a preparation method of intelligent temperature control glue and film, comprising the following steps of: (a) dispersing R-phase or M-phase vanadium dioxide (VO2) particles with phase change function into a dispersing agent; (b) dispersing the vanadium dioxide particles dispersed in the solvent into self-bonding glue, and forming a glue with intelligent temperature control performance based on the intelligent temperature control property of the vanadium dioxide nano particles; and (c) spreading the glue with intelligent temperature control performance on a flexible base material, forming a coating based on the self-bonding property of the glue, wherein the coating can be combined with a releasing film layer without a mounting glue so as to form the intelligent temperature control film. In comparison with the conventional film, the film provided by the invention not only has the intelligent temperature control effect, but also is simplified in technology, thus, cost is lowered, and the film can be widely used in various aspects, such as energy saving for buildings, heat insulation for car windows, and surface protection.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

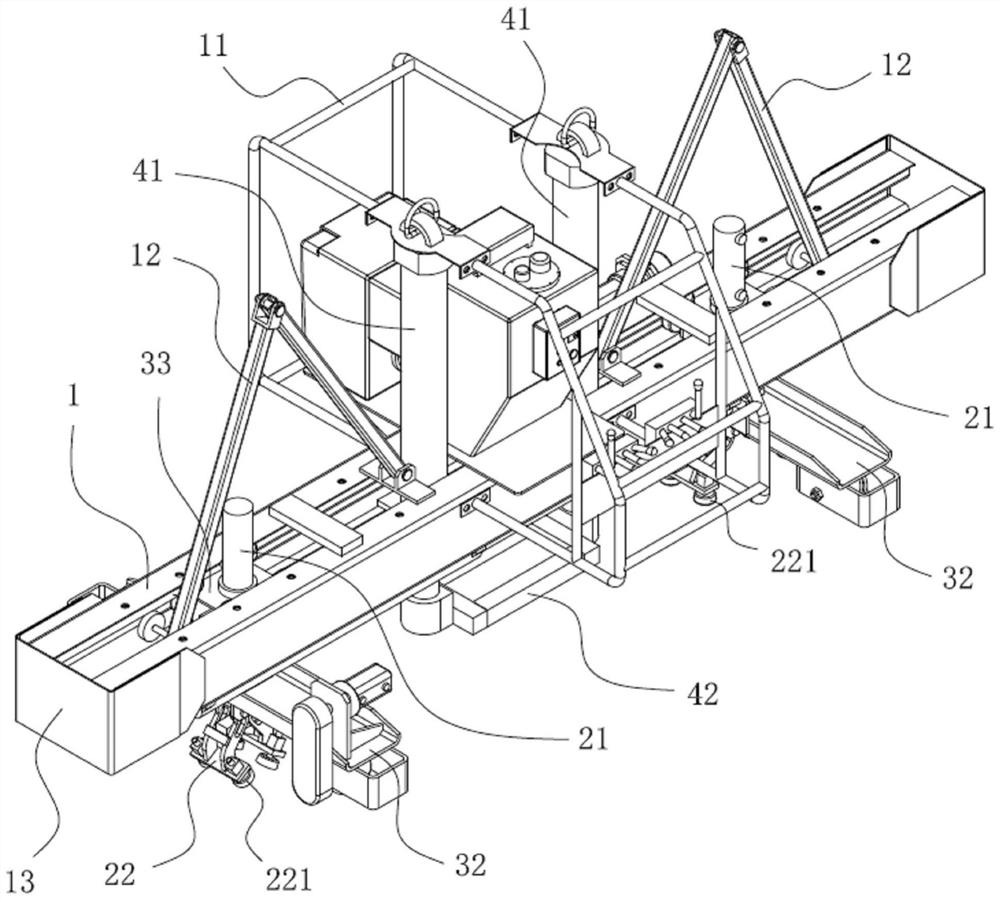

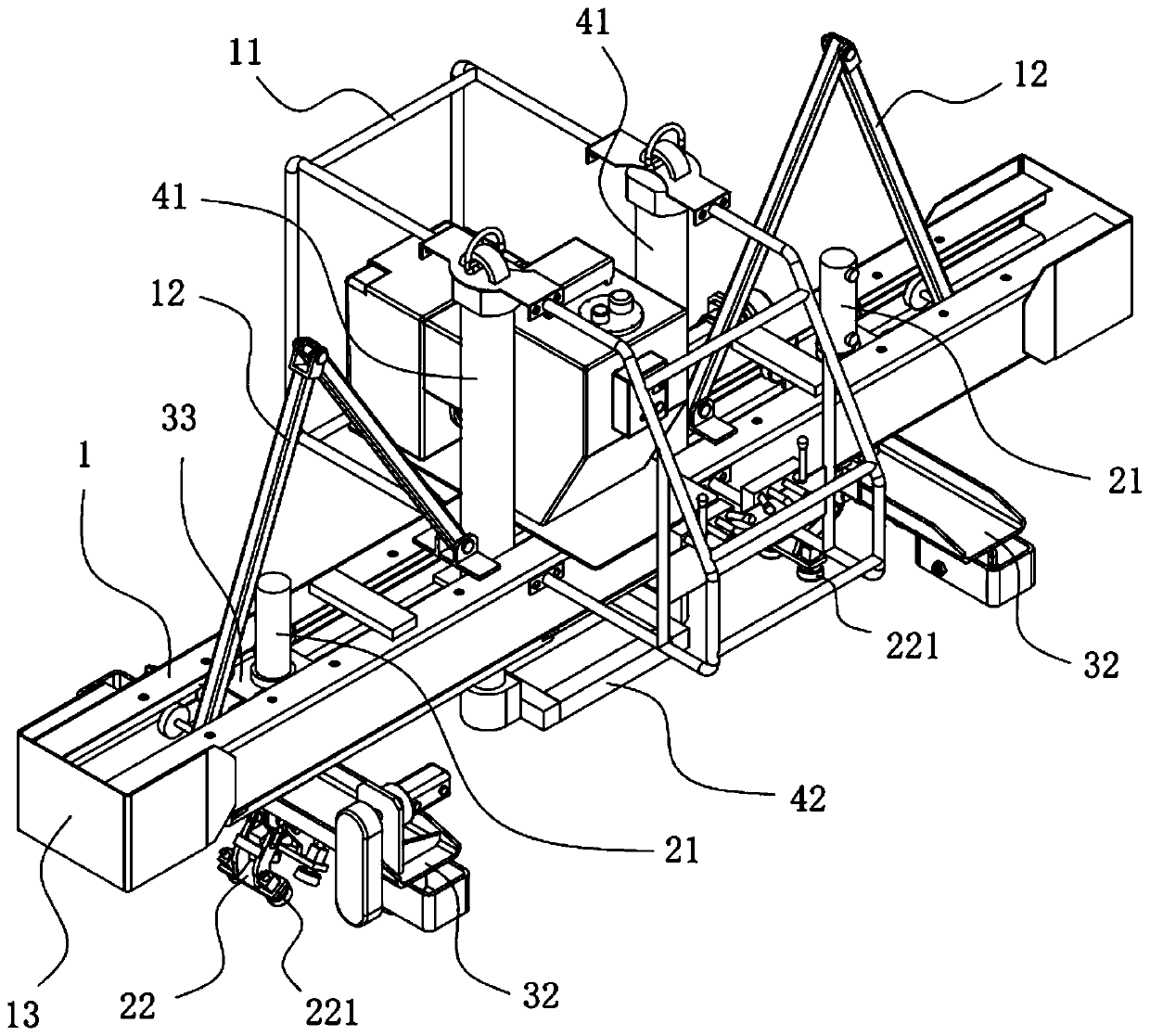

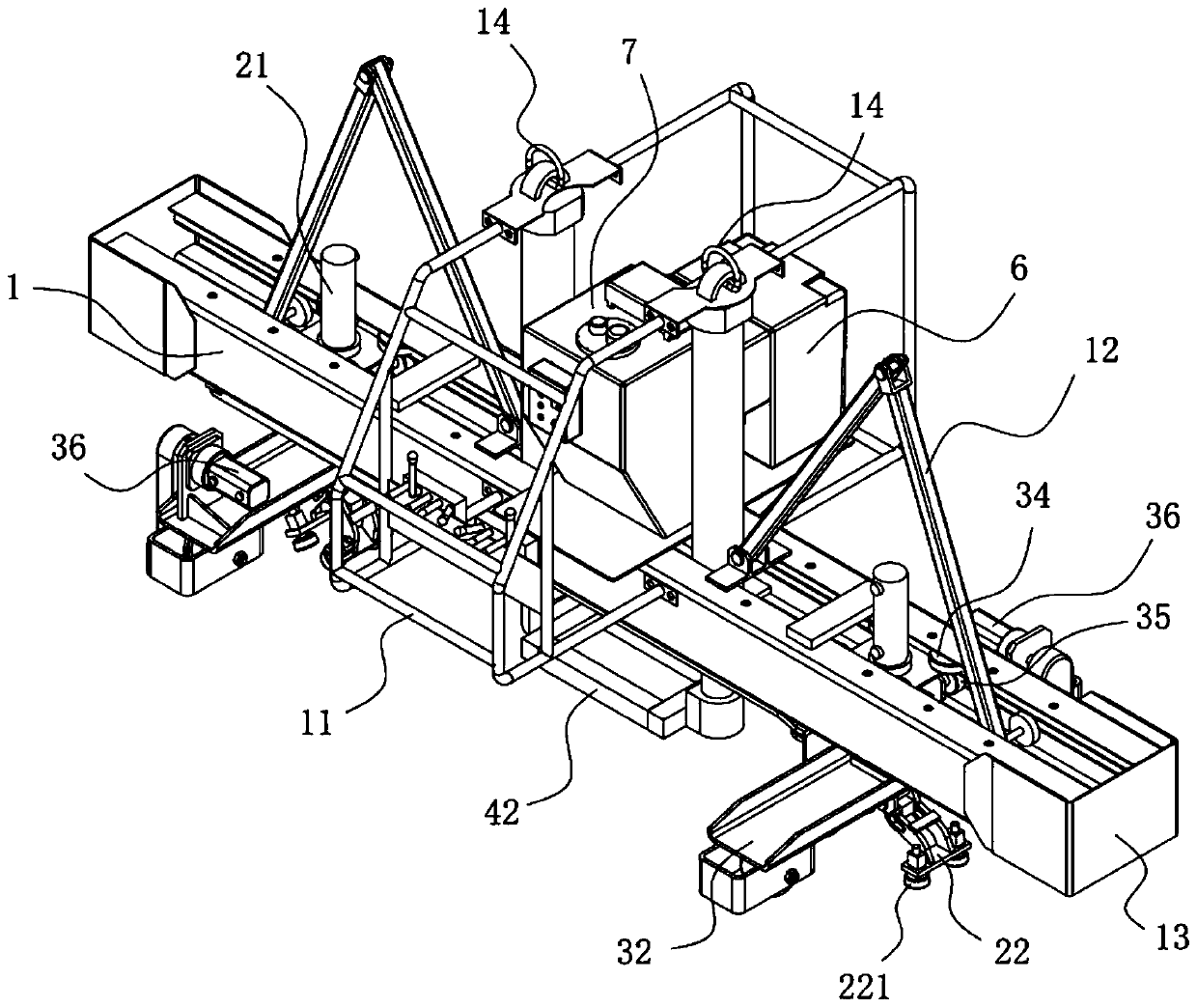

Hydraulic track changer

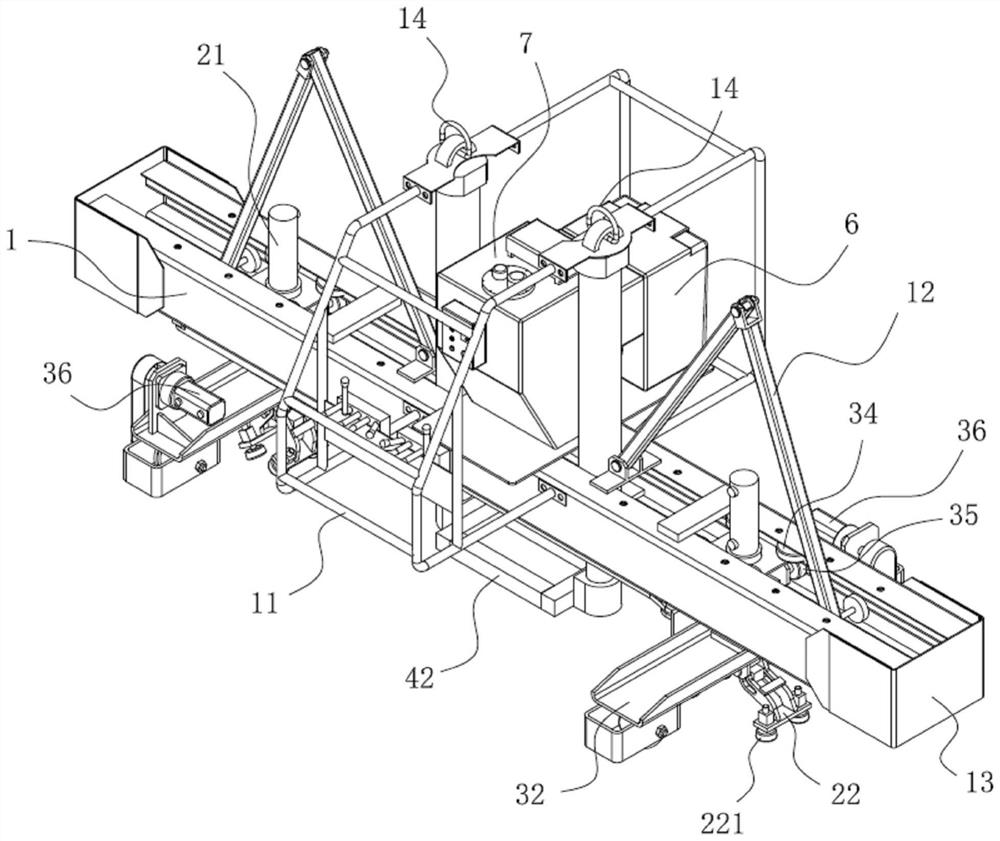

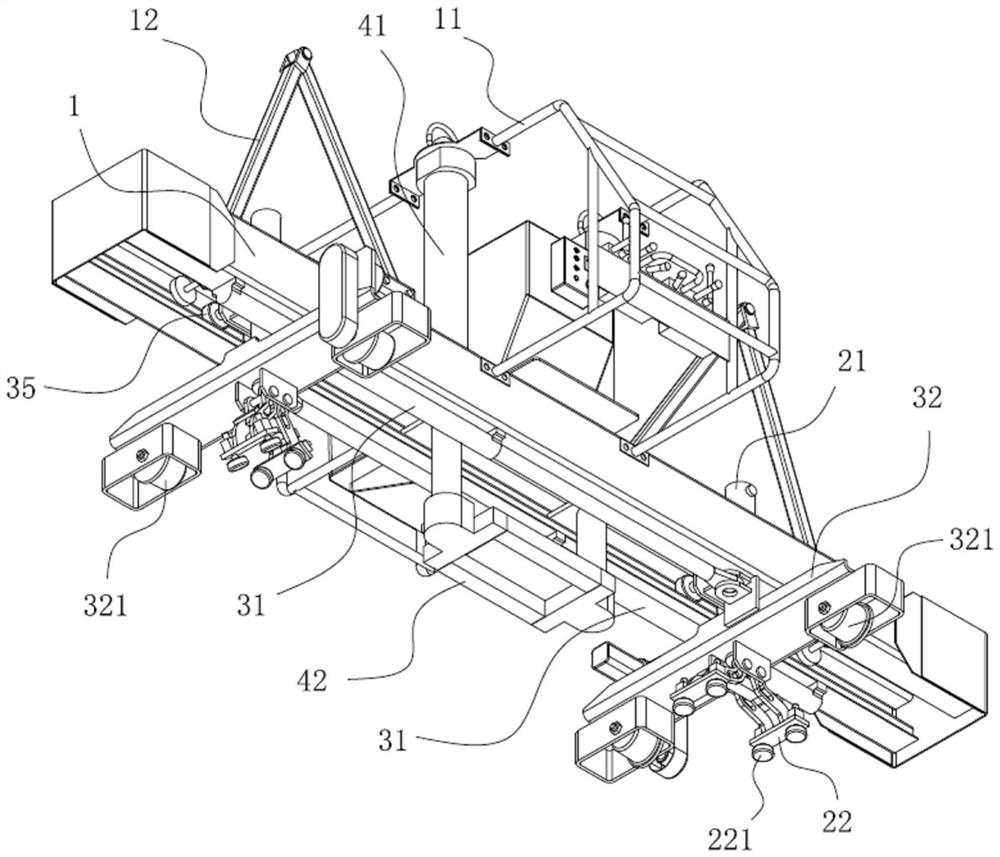

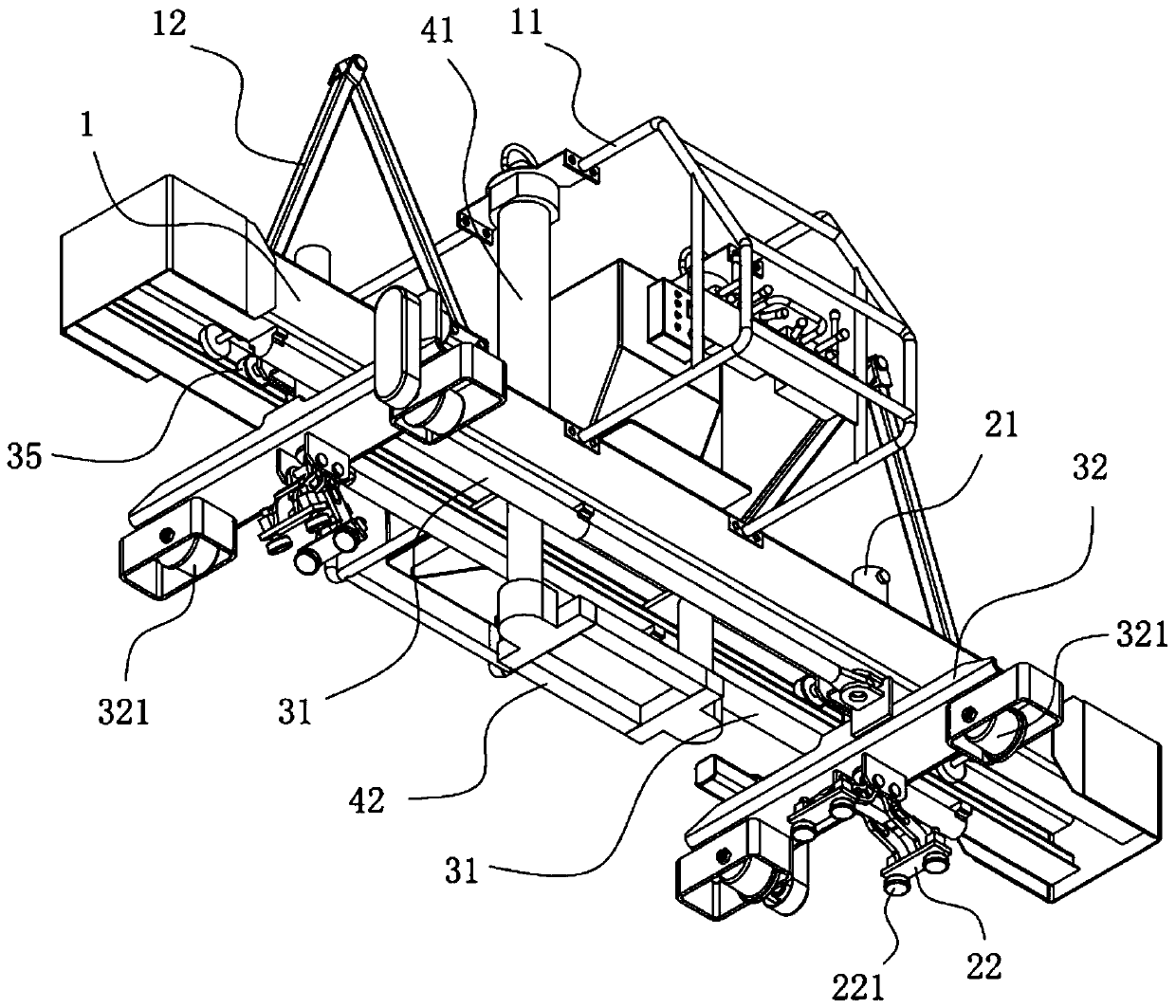

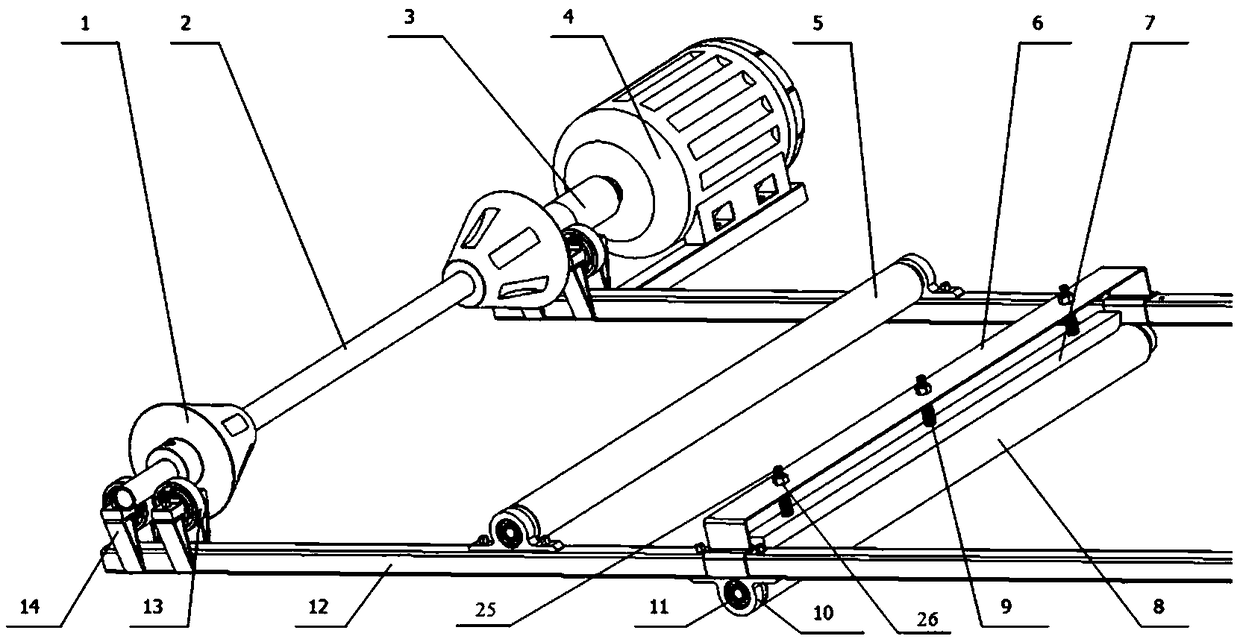

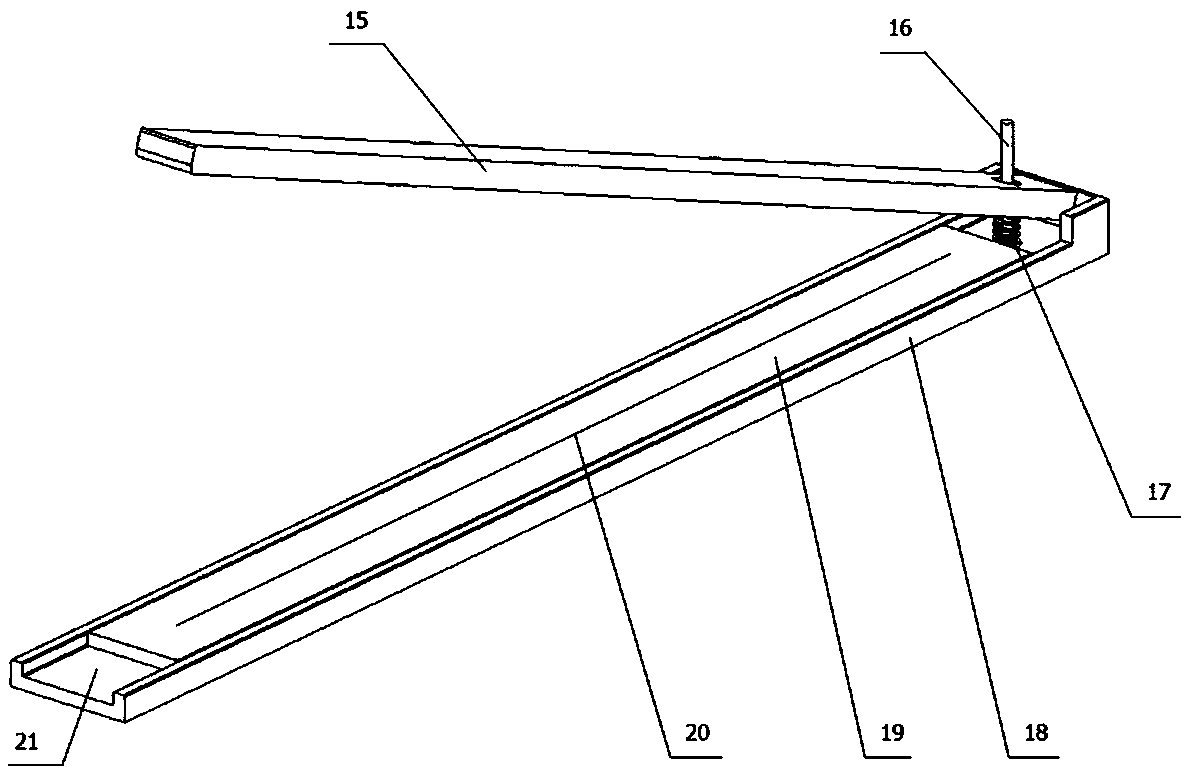

ActiveCN109898375BFlexible useEconomical to useRailway track constructionHydraulic cylinderHydraulic ram

The invention discloses a hydraulic rail-changing machine, which belongs to the technical field of rail-changing devices and is designed to solve the problems of inconvenient use of existing large-scale rail-changing devices and low efficiency of manual rail-changing work. The hydraulic rail changing machine of the present invention comprises a main frame arranged horizontally, on which are installed a clamping assembly for clamping the rail to be replaced, a translation assembly for carrying the rail to be replaced and a lifting assembly for lifting and lowering the rail to be replaced, The clamping assembly can move horizontally along the main frame; the clamping assembly, translation assembly and lifting assembly are all driven by hydraulic cylinders, and the clamping assembly, translation assembly and lifting assembly are controlled independently by different hydraulic control valve groups. The hydraulic rail changing machine of the present invention can quickly remove and lay steel rails during rail changing operations in public works. Compared with large-scale rail changing vehicles, the hydraulic rail changing machine is more flexible, more economical, and can be used in a wider range; compared with manual operations, the hydraulic rail changing machine has high working efficiency, can reduce manpower and labor intensity.

Owner:华夏高铁技术有限公司

Supersonic speed dry-wet combined spiral bladeless dust collection and removal system and dust removal method thereof

ActiveCN113685224AEfficient captureNot easy to settle naturallyDust removalFire preventionDust controlEngineering

The invention relates to a supersonic speed dry-wet combined spiral bladeless dust collection and removal system. The supersonic speed dry-wet combined spiral bladeless dust collection and removal system comprises an outer shell, a Laval supersonic speed airflow generation device, an airflow reversal acceleration device, an inner shell and a spiral airflow generation device, and an internal thread hole is formed in the joint of the outer shell and the first end of the inner shell so that the Laval supersonic speed airflow generation device can be arranged; the interior of the cylindrical section of the joint of a second end is connected with the airflow reversal acceleration device, the internal threaded hole serves as a first air inlet, an air outlet of the airflow reversal acceleration device serves as a first air outlet, and the spiral airflow generation device is located at the joint of the outer shell and the second end of the inner shell and connected with the first air outlet, and a dust removal method is provided. Accroding to the supersonic speed dry-wet combined spiral bladeless dust collection and removal system and the dust removal method thereof, by utilizing a Laval supersonic speed negative pressure dust collection technology, dust escaping from a coal mine transfer point can be effectively captured, the whole structure is simple, the dust can be removed after dust collection, the operation is safe, the efficiency is high, and the supersonic speed dry-wet combined spiral bladeless dust collection and removal system and the dust removal method thereof is more suitable for coal mines.

Owner:国家卫生健康委职业安全卫生研究中心 +1

Power regeneration type braking and boosting integrated device used for locomotive

InactiveCN102085855BImprove recycling efficiencySafe and smooth brakingBraking action transmissionHigh pressureAir compressor

Owner:SHANGHAI LANXIN ENERGY SAVING TECH

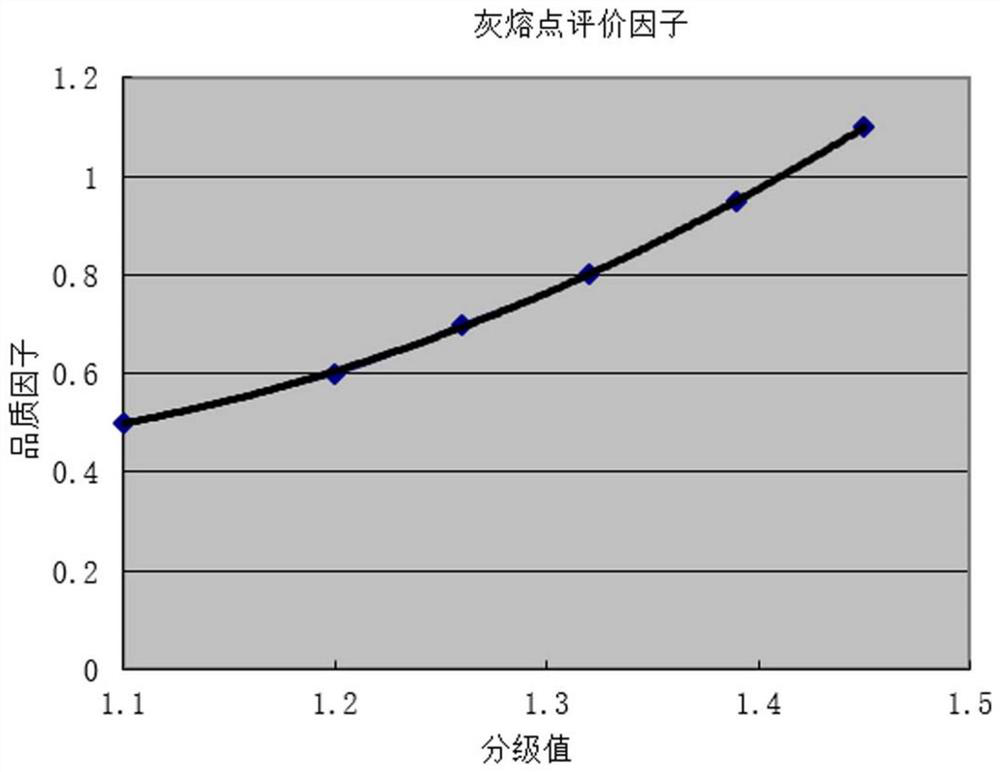

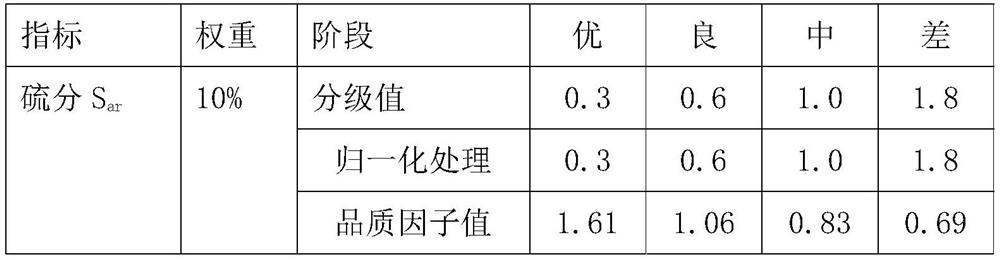

Coal quality evaluation method

PendingCN114004445AEliminate single evaluation factorsWide range of useResourcesComplex mathematical operationsProcess engineeringCoal

The invention discloses a coal quality evaluation method. The coal quality evaluation method comprises the following steps: setting coal evaluation indexes, and establishing a coal evaluation index analysis model; acquiring evaluation index parameters of the coal, and grading the evaluation index parameters according to a comprehensive evaluation index; setting a quality factor and a grading value for the evaluation index, and obtaining an evaluation factor through a calculation model of the evaluation index; setting the weight of the evaluation index; and performing weighted synthesis on the evaluation factors according to the weights of the evaluation indexes to obtain a final quality evaluation result. The coal quality evaluation method has the beneficial effects that by establishing the quality evaluation model and utilizing the scientific method, quality grading and scoring are carried out after coal quality characteristic numerical values are normalized, quantitative quality factor values are given, quality grading and scoring can be carried out on coal from multiple dimensions, and finally the comprehensive evaluation result of the coal is obtained; the coal quality factor is fully and completely considered, the application range is wide, and the method is diversified for users.

Owner:HUANENG (GUANGDONG) ENERGY DEV CO LTD

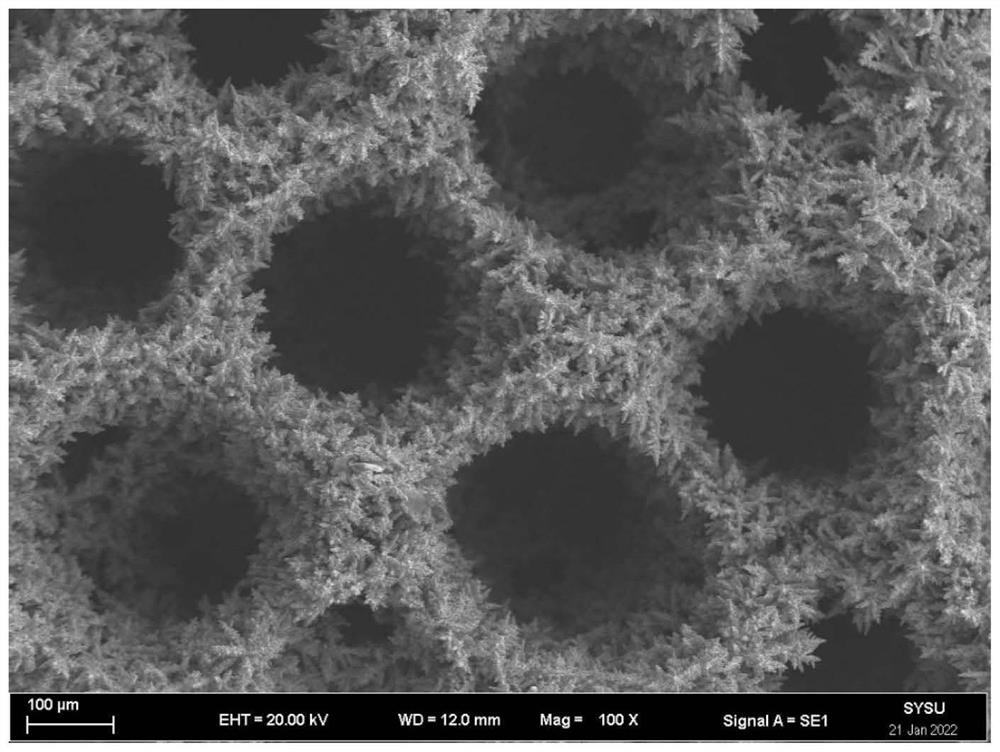

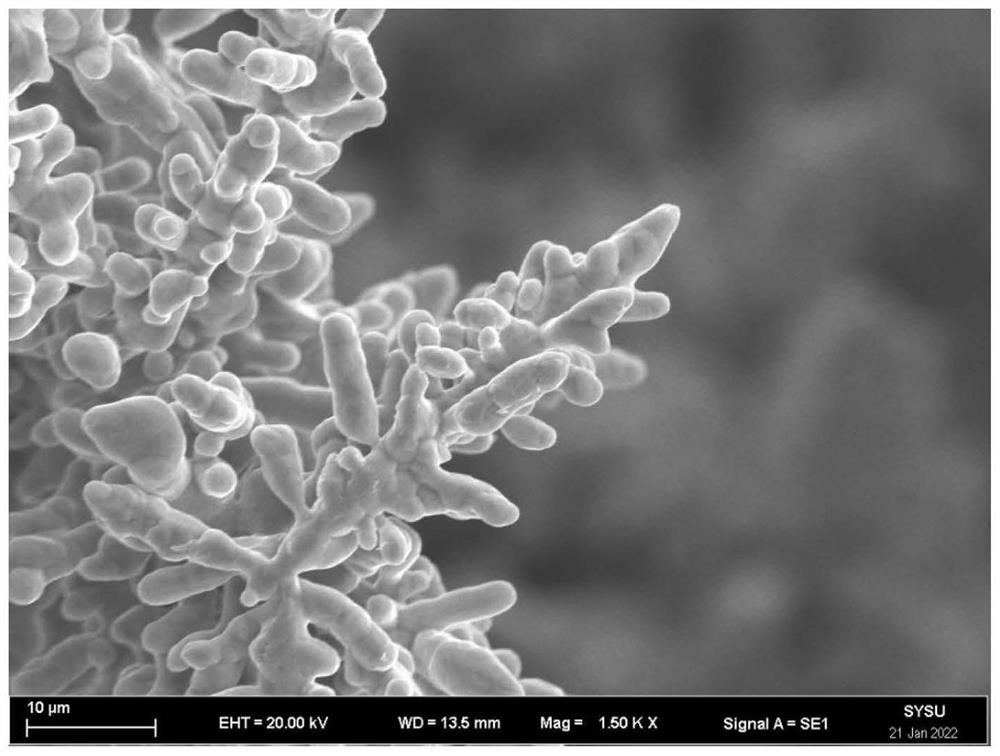

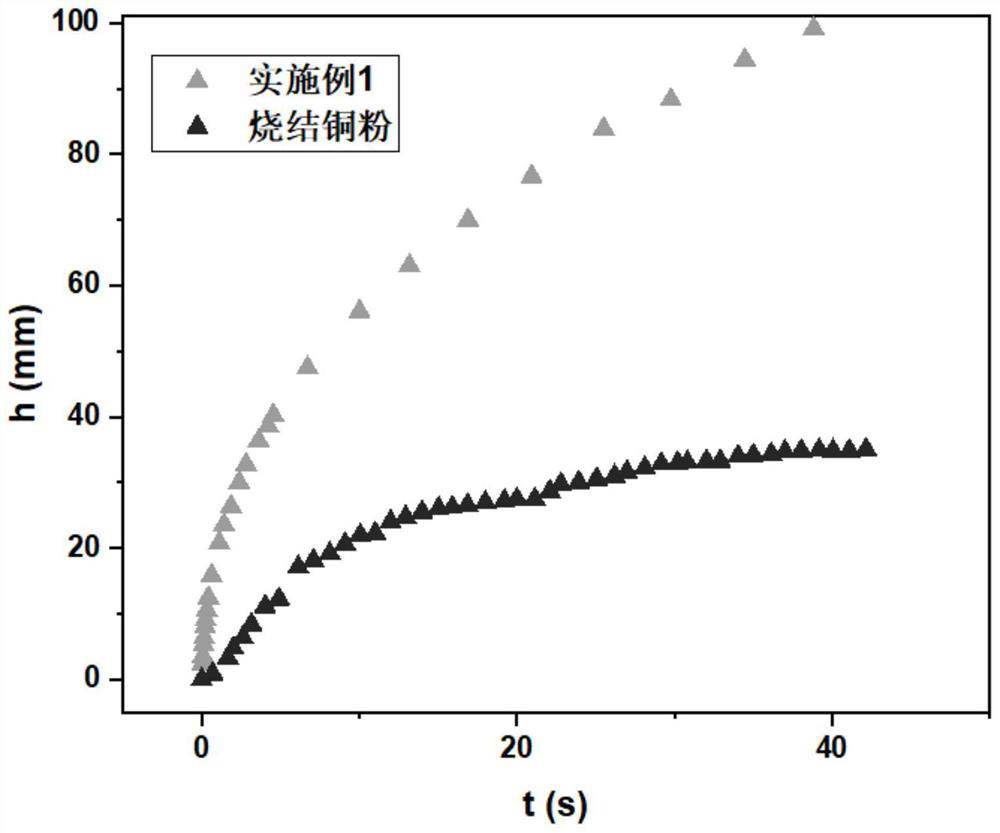

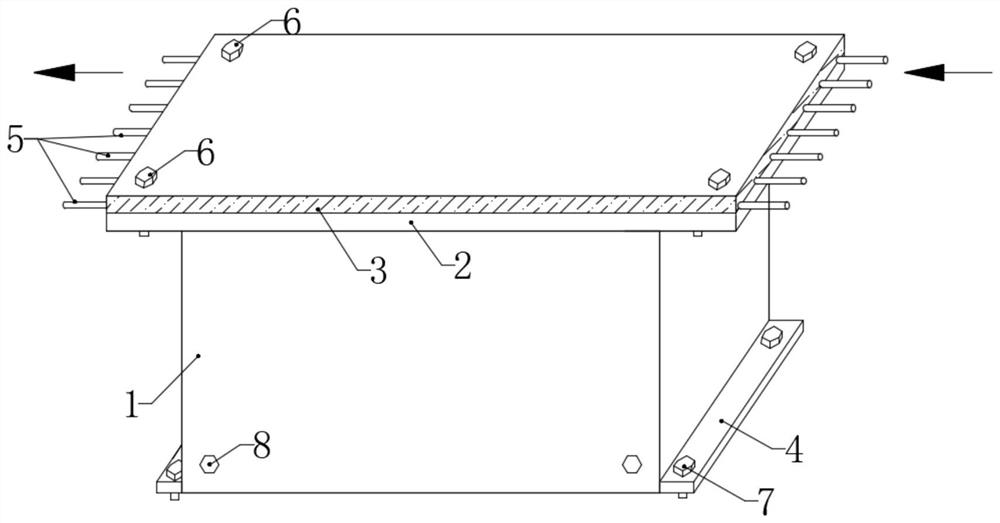

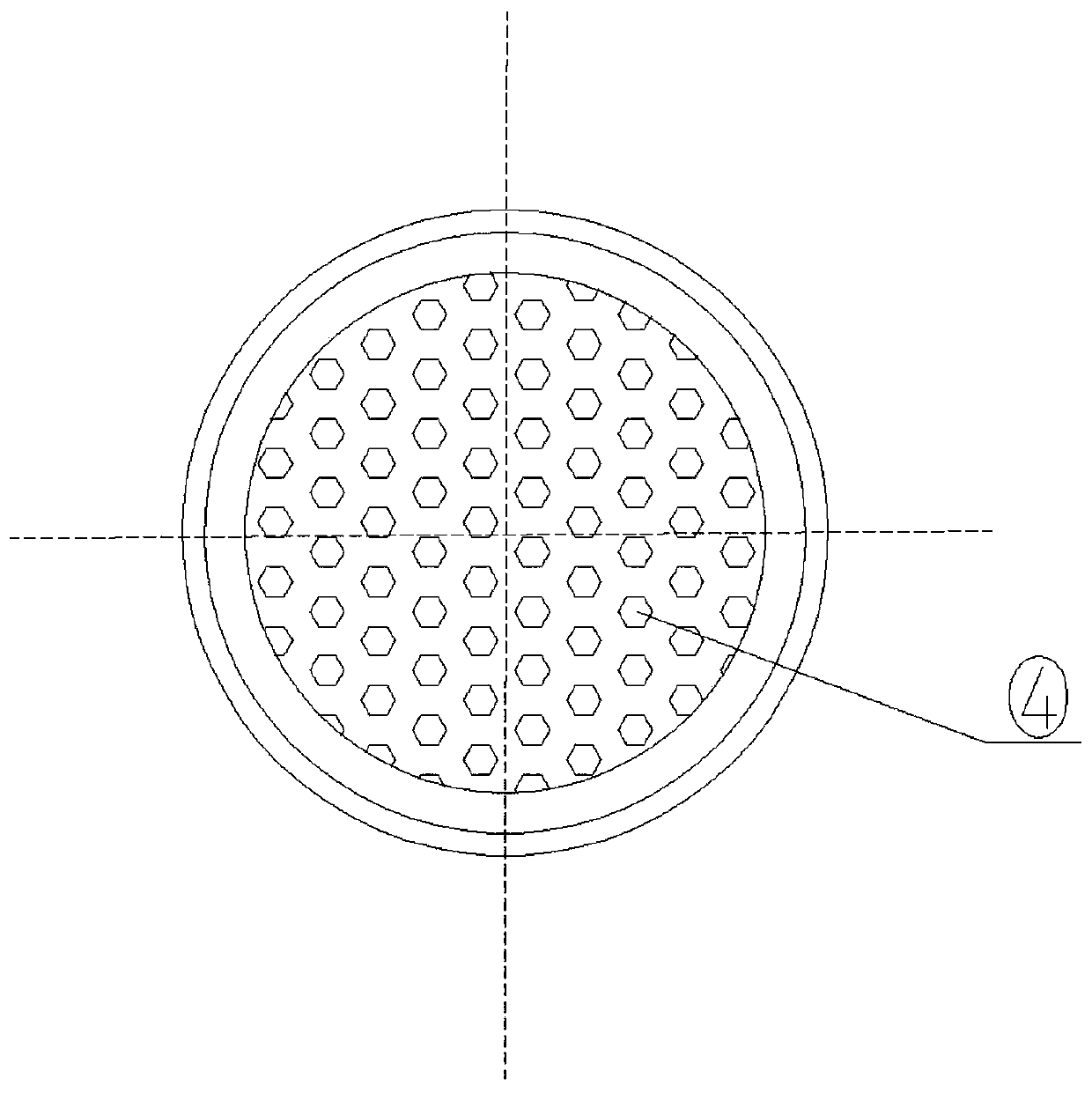

Porous structure surface with high capillary performance and high boiling heat transfer performance and preparation method thereof

The invention discloses a porous structure surface with high capillary performance and high boiling heat transfer performance and a preparation method thereof. The surface structure is a honeycomb-shaped porous copper structure and is provided with holes with micro-nano-scale pore diameters, hole walls are composed of copper crystal branches, staggered channel structures are formed between main trunks of the crystal branches, and due to the existence of micron-scale honeycomb holes, the flowing resistance of a working medium is reduced; and abundant branches of the crystal dendrites form nano-scale holes to provide capillary force, so that high capillary performance is presented. Holes of different sizes provide a large number of bubble nucleation sites and bubble separation paths respectively, meanwhile, a hole-shaped structure directly communicated with a substrate enables two-phase heat exchange to occur in a position closer to the substrate so as to obtain a smaller wall surface superheat degree, and a liquid working medium is continuously supplemented due to the high capillary liquid absorption characteristic of the hole-shaped structure. The drying of the surface caused by high heat flux is reduced, and the film-like boiling is delayed, so that the heat transfer of the boiling surface is further enhanced.

Owner:SUN YAT SEN UNIV

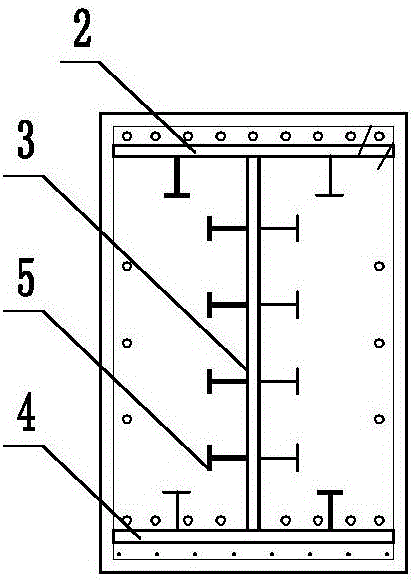

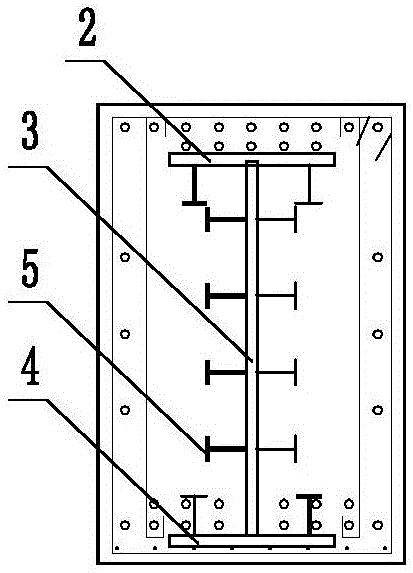

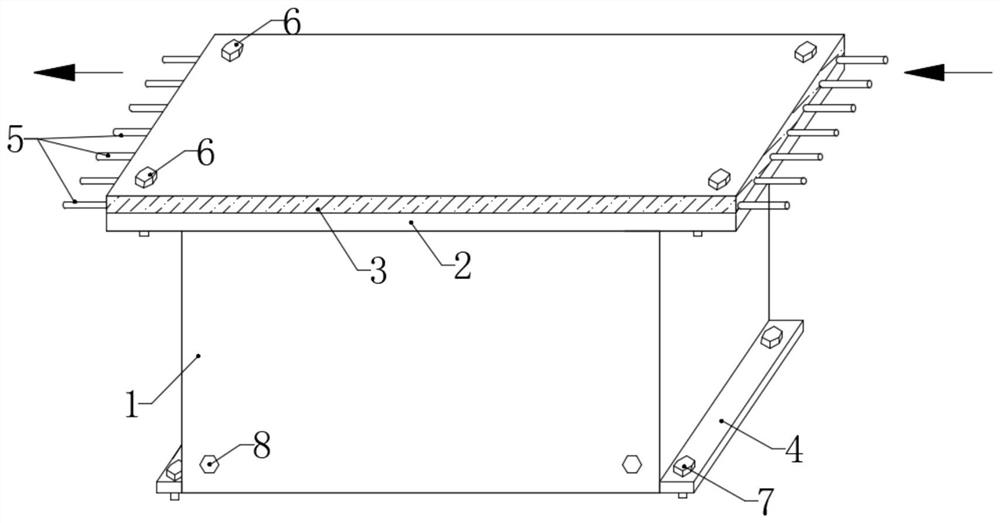

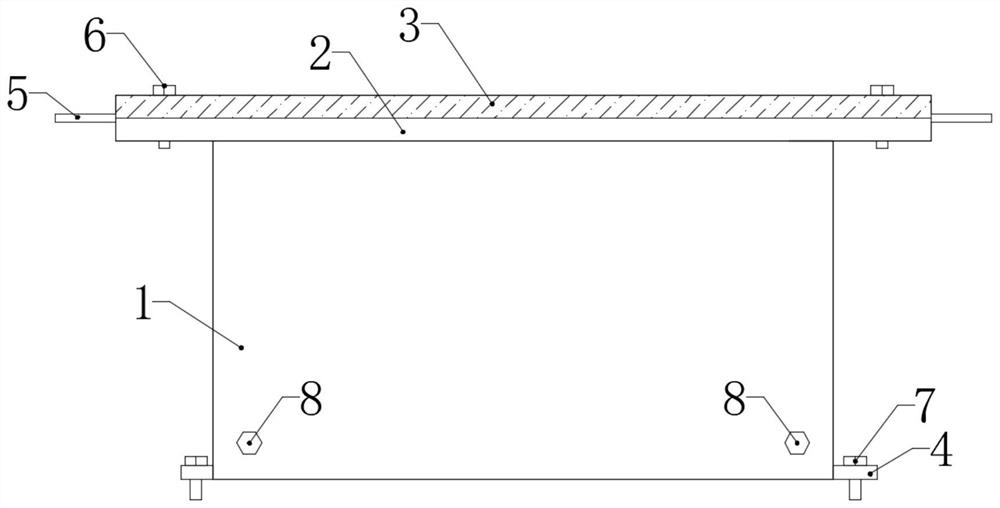

A cable bracket for computer network engineering construction wiring

ActiveCN112134219BSeparate and neatly collectedOrderly rowsApparatus for laying cablesStructural engineeringMechanical engineering

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Hydraulic rail changing machine

ActiveCN109898375AFlexible useEconomical to useRailway track constructionUltimate tensile strengthHydraulic control

The invention discloses a hydraulic rail changing machine, and belongs to the technical field of rail changing operation devices, aiming to solve the problems of existing large rail changing devices,such as inconvenience in use and low efficiency in manual rail changing work. The hydraulic rail changing machine comprises a horizontal main frame. A clamping component, a translation component and alifting component are mounted on the main frame; the clamping component is used for clamping a to-be-changed steel rail; the translation component is used for carrying the to-be-changed steel rail; the lifting component is used for lifting and dropping the to-be-changed steel rail; the clamping component can horizontally move along the main frame; the clamping component, the translation componentand the lifting component are driven by a hydraulic oil cylinder, and can be independently controlled by different hydraulic control valve groups. The hydraulic rail changing machine can rapidly remove and lay steel rails during public rail changing. Compared with large-scale rail changing vehicles, the hydraulic rail changing machine has the advantages of flexibility in use, economy, and wide application range; compared with manual work, the hydraulic rail changing machine has the advantages of high working efficiency, reduced manpower and reduced labor intensity.

Owner:华夏高铁技术有限公司

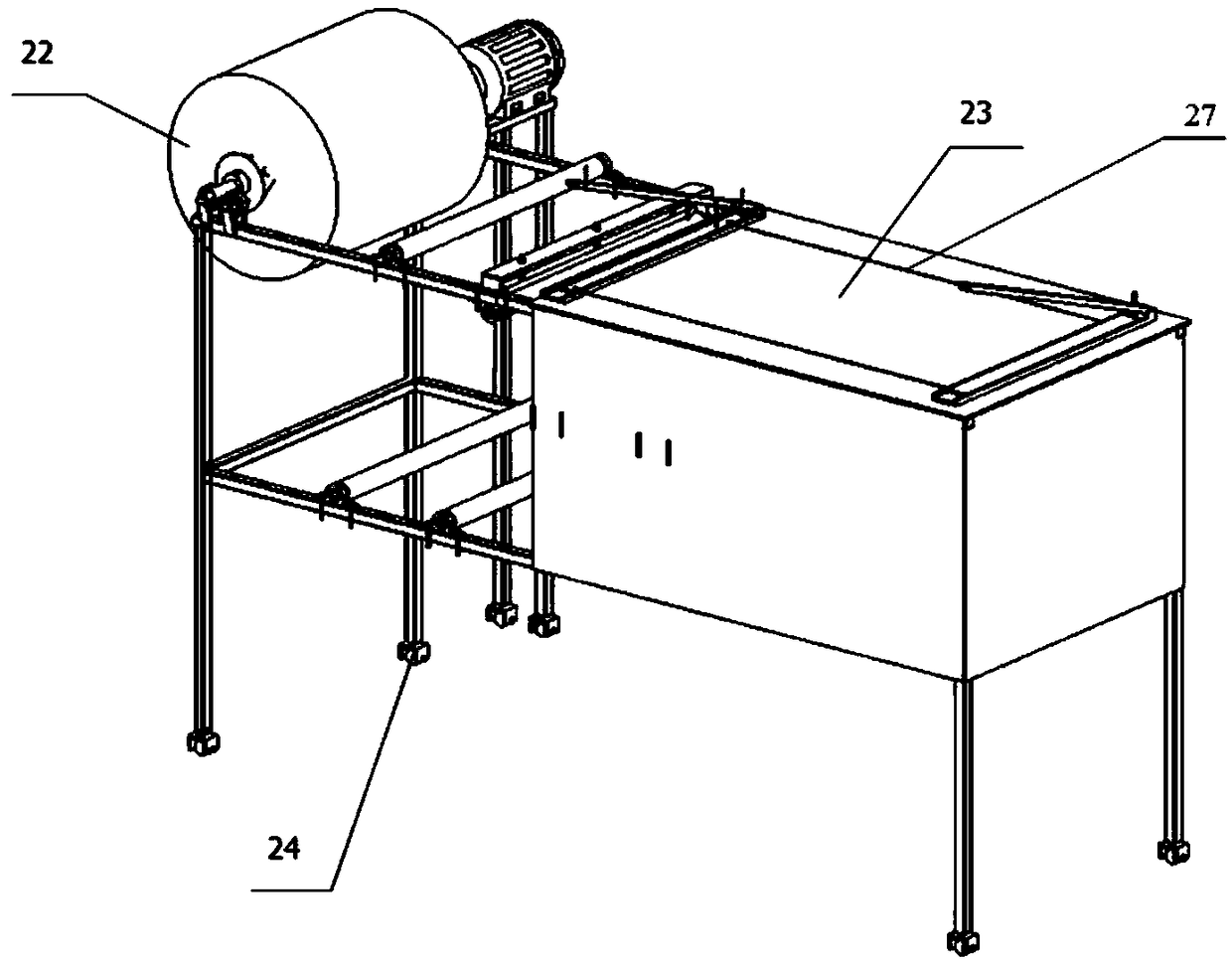

A mobile hand-pressed packaging machine

ActiveCN106553800BQuick sealImprove work efficiencyWrapper twisting/gatheringElectric machineryEngineering

The invention discloses a movable hand-pressed packaging machine, which is composed of a frame, a motor, a packaging bag feeding mechanism, a sealing mechanism, a workbench, a circuit control part, wheels and a whole tube of packaging materials. The invention uses a circuit to control the conveying speed of the packaging bag and the heating rate of the thermal fuse, and can seal the packaging bag faster. According to the size of the packaged goods, the packaging bags of the corresponding size are cut out, which saves more materials and is green and environmentally friendly. Simultaneously, the overall structure of the present invention is relatively simple and light, stable in operation, excellent in performance, simple and durable in structure.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Touch screen device and its anti-mis-touch recognition system and anti-mis-touch recognition method

ActiveCN107329613BImprove experienceSolve the problem of easy false alarm and anti false touchInput/output processes for data processingEngineeringScreens (device)

The invention discloses a false touch prevention recognition method, which includes: when the touch screen detects that the distance between one or several areas on its surface and an external object is less than or equal to a preset distance threshold, then the touch screen detects and judges the distance of the area. Light sensitivity value; when the touch screen detects that the light sensitivity value of this area is less than or equal to the preset light sensitivity value threshold, the touch screen triggers its anti-mistouch operation. In the process of anti-mistouch identification, the present invention adds the judgment of the light sensitivity value of the touch screen surface, and when the touch screen detects that the surface light sensitivity value is less than or equal to the preset light sensitivity value threshold, it is judged to trigger the anti-mistouch operation of the touch screen device , to solve the situation that the surface of the touch screen is disturbed by oil pollution or the distance sense structure is slightly deformed, the distance sense detection of the touch screen will mistakenly believe that there is an external object approaching the mobile phone, resulting in false alarms and false touch prevention when the touch screen is bright The other problem is to reduce the probability of anti-false touch and false alarm by judging the light sensitivity value, and improve the user experience.

Owner:SHANGHAI TRANSSION CO LTD

A kind of preparation method of vegetable tanned shrinkage top layer leather

ActiveCN104762422BUnique shapeCan be used in a wide rangeTanning treatmentPre-tanning chemical treatmentTanninEngineering

The invention provides a manufacturing method of tanned shrunk grain top layer leather. In the method, crust leather is successively subjected to following processes: degreasing, re-tanning, neutralization, filling, dyeing, fat-liquoring, stacking, vibration-softening, leather grinding, painting-decoration and roll-burnishing. In the re-tanning process, by means of addition of sodium carbonate, the pH value of liquid in a drum machine is regulated to be 8-10 and meanwhile the temperature of the liquid is adjusted to be 33-35 DEG C, and then the crust leather is added with a shrunk grain agent to generate patterns on the crust leather, and finally when the processes are finished, the liquid in the drum machine is drained completely. In the invention, the shrunk grain agent is added at special pH value and temperature for generate bull-shoulder pattern on the crust leather, so that the tanned shrunk grain top layer leather is unique in appearance and is wider in available range when compared with a tanned leather prepared through a conventional technology. Meanwhile, by means of addition of a tannin extract in a special manner and at a special proportion during the filling process, the bull-shoulder pattern on the crust leather can be shaped to form a pattern shrinking effect.

Owner:FENGAN LEATHER

Blasting dust falling device and implementation method thereof

InactiveCN109780955ACan be used in a wide rangeSimple operation techniqueUsing liquid separation agentBlastingSpray nozzleEngineering

The invention discloses a blasting dust falling device and an implementation method of the blasting dust falling device. The blasting dust falling device comprises a device body and a pipe end spray nozzle device. The device body is a concrete pump truck. The pipe end spray nozzle device is installed on an end opening hose or the tail end of the hose of the concrete pump truck, and comprises a spray nozzle device connector (1) and a spray nozzle device body (2). The spray nozzle device body comprises tail end long-strip-shaped outlets (3) and tail end inward concave surface water outlet holes(4). The spray nozzle device connector and a hose connector are consistent. One end of the spray nozzle device connector is used for enabling the spray nozzle device to be fixed to the end opening hose or the tail end of the hose of the concrete pump truck, and the spray nozzle device body is arranged at the other end of the spray nozzle device connector. The spray nozzle device body and the spraynozzle device connector are fixedly connected, the spray nozzle device body is cylindrical, the multiple long-strip-shaped outlets are formed in the tail end of the spray nozzle device body in the transverse direction of the cylindrical surface, and the bottom surface of the spray nozzle device body is inwards concave. The blasting dust falling device can conduct dust falling operation at the high position on the site after engineering blasting is accomplished, the range of action is broad, and the dust falling effect is good.

Owner:ANHUI UNIV OF SCI & TECH

a chain hoist

ActiveCN104760898BCan be used in a wide rangeExtended service lifePortable liftingLong axisEngineering

Owner:CHONGQING VITAL ELEVATORING EQUIP

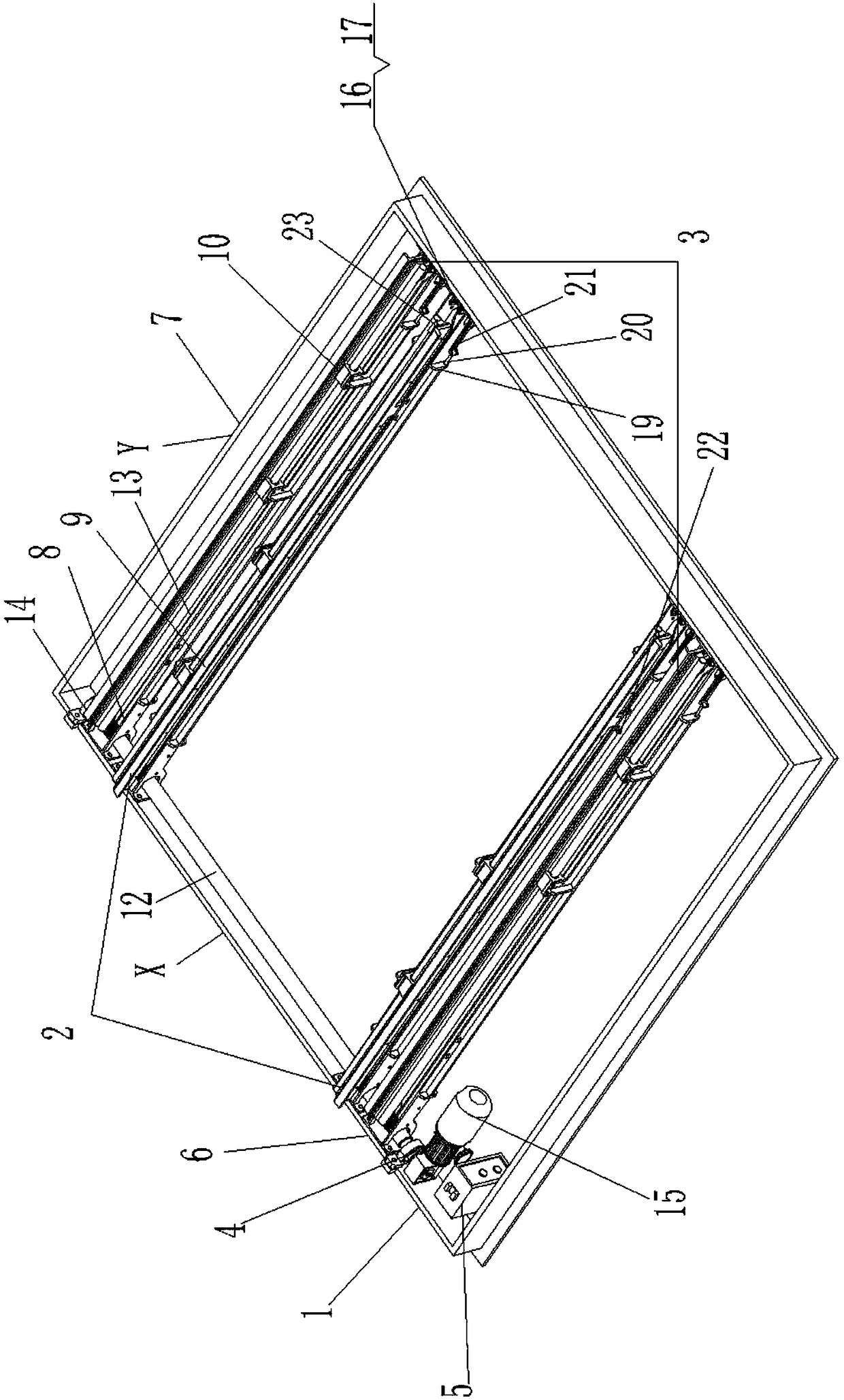

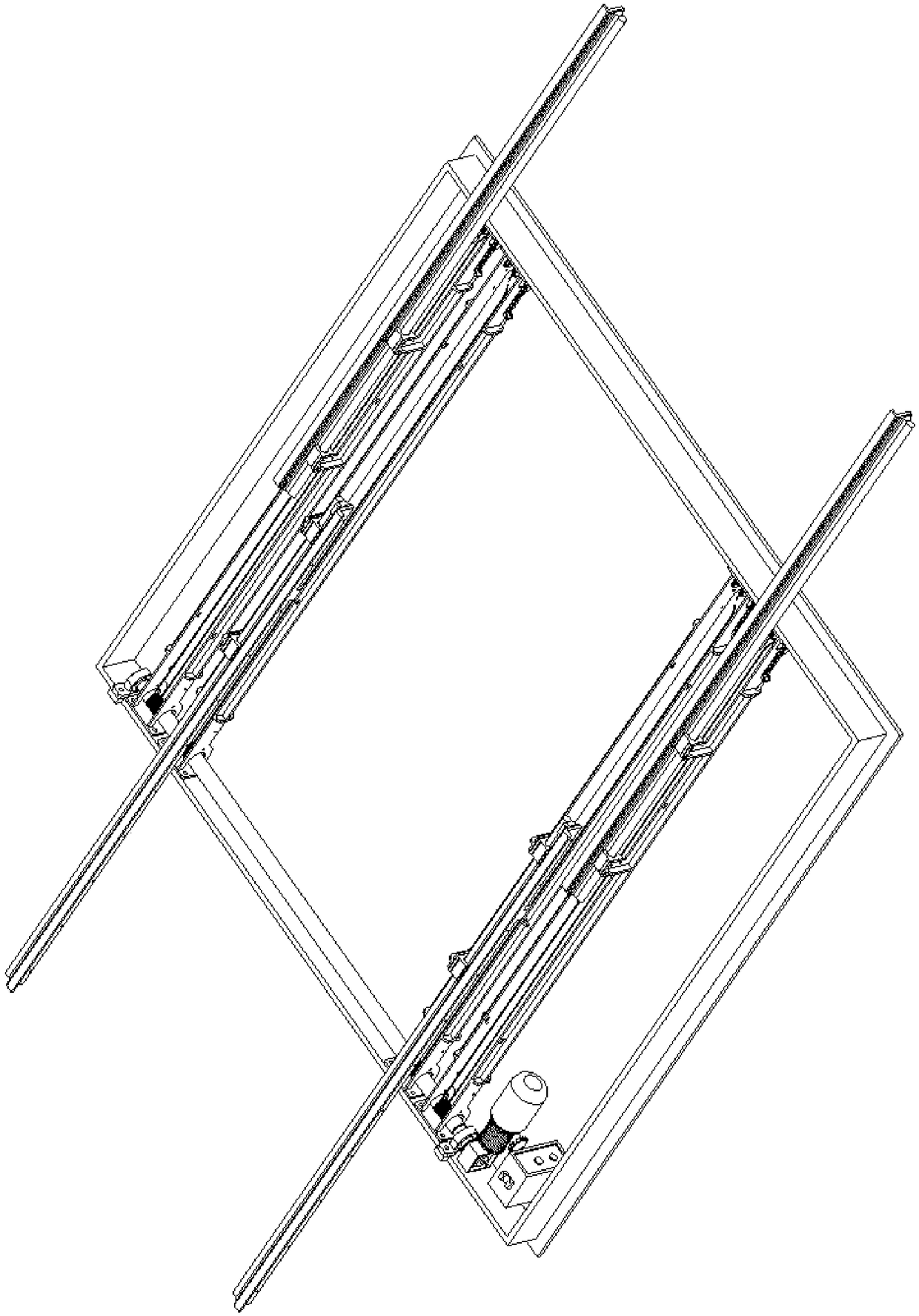

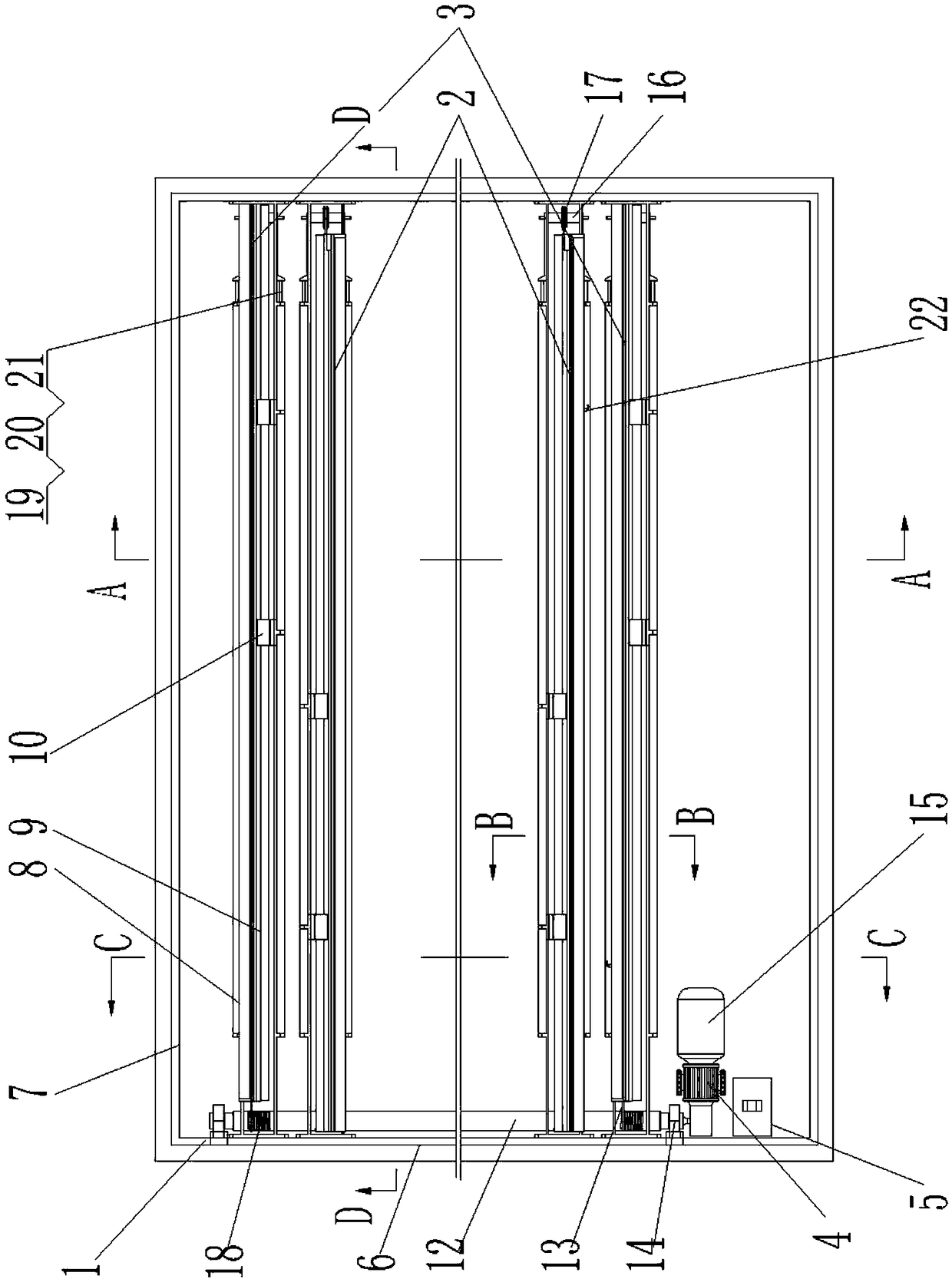

A horizontal pushing electric carriage device for side-opening doors

ActiveCN106948692BIncrease the effective pass sizeCompact structurePower-operated mechanismWing suspension devicesElectrical and Electronics engineeringEngineering

The invention particularly relates to a horizontal push electric carriage device for a hinged door. The device comprises a rectangular frame, an internal door opening and closing mechanism, an external door opening and closing mechanism, a transmission mechanism and a control box. The internal door opening and closing mechanism and the external door opening and closing mechanism are mounted on the rectangular frame; an internal door is mounted on the internal door opening and closing mechanism; an external door is mounted on the external door opening and closing mechanism; and the control box controls the transmission mechanism to drive the internal door and the external door to be opened and closed in the horizontal direction. Through the adoption of the structure, the horizontal push electric carriage device occupies a small space, and the effective passing size after the doors are opened can be increased maximally.

Owner:SHAANXI SIDA AVIATION SCI & TECH

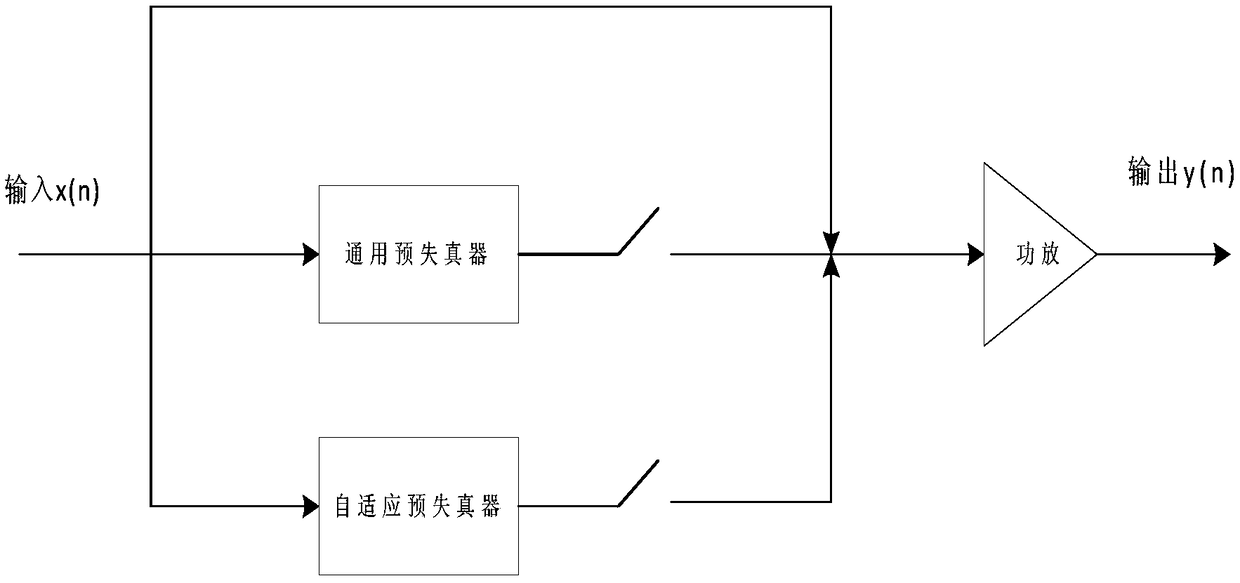

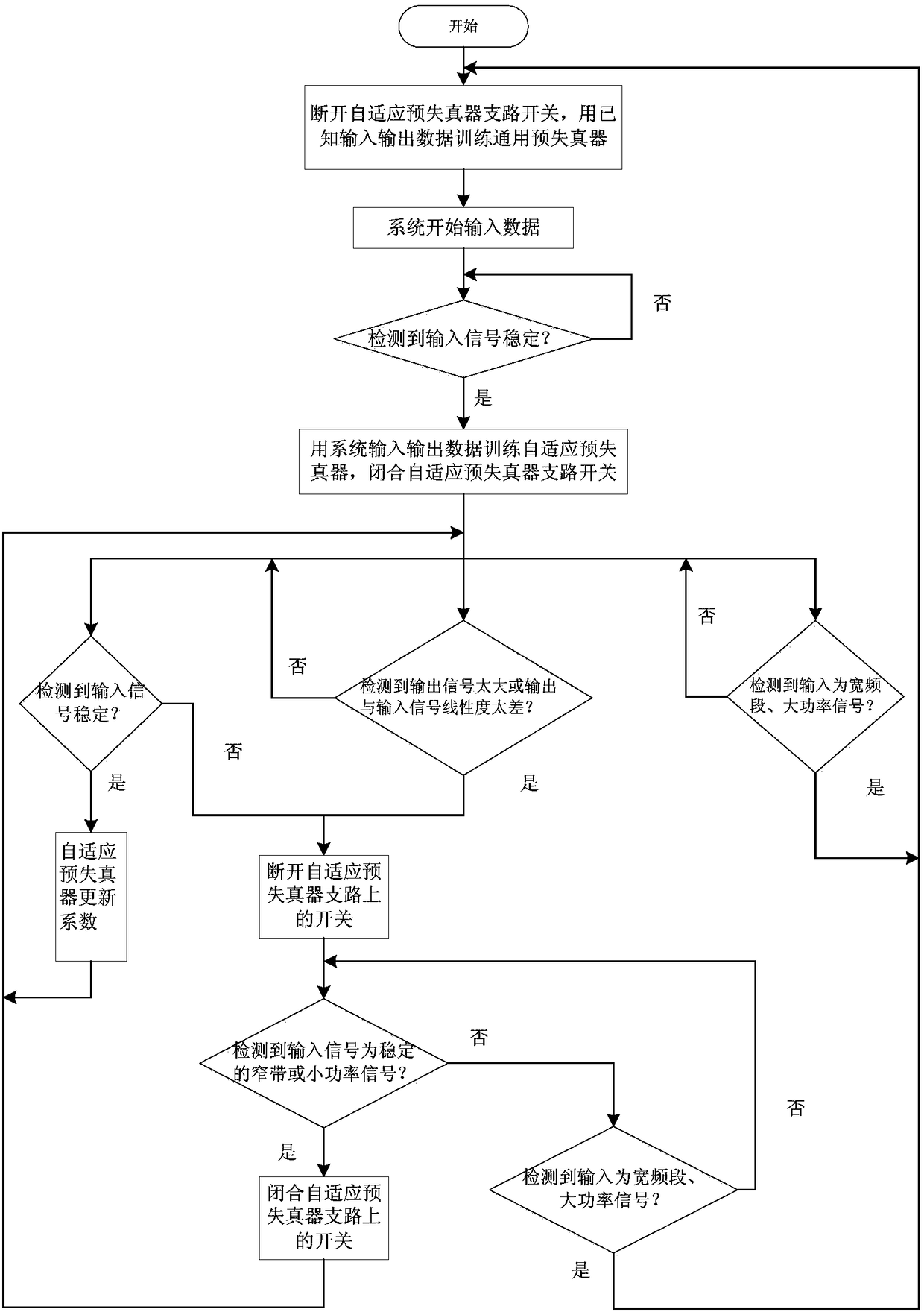

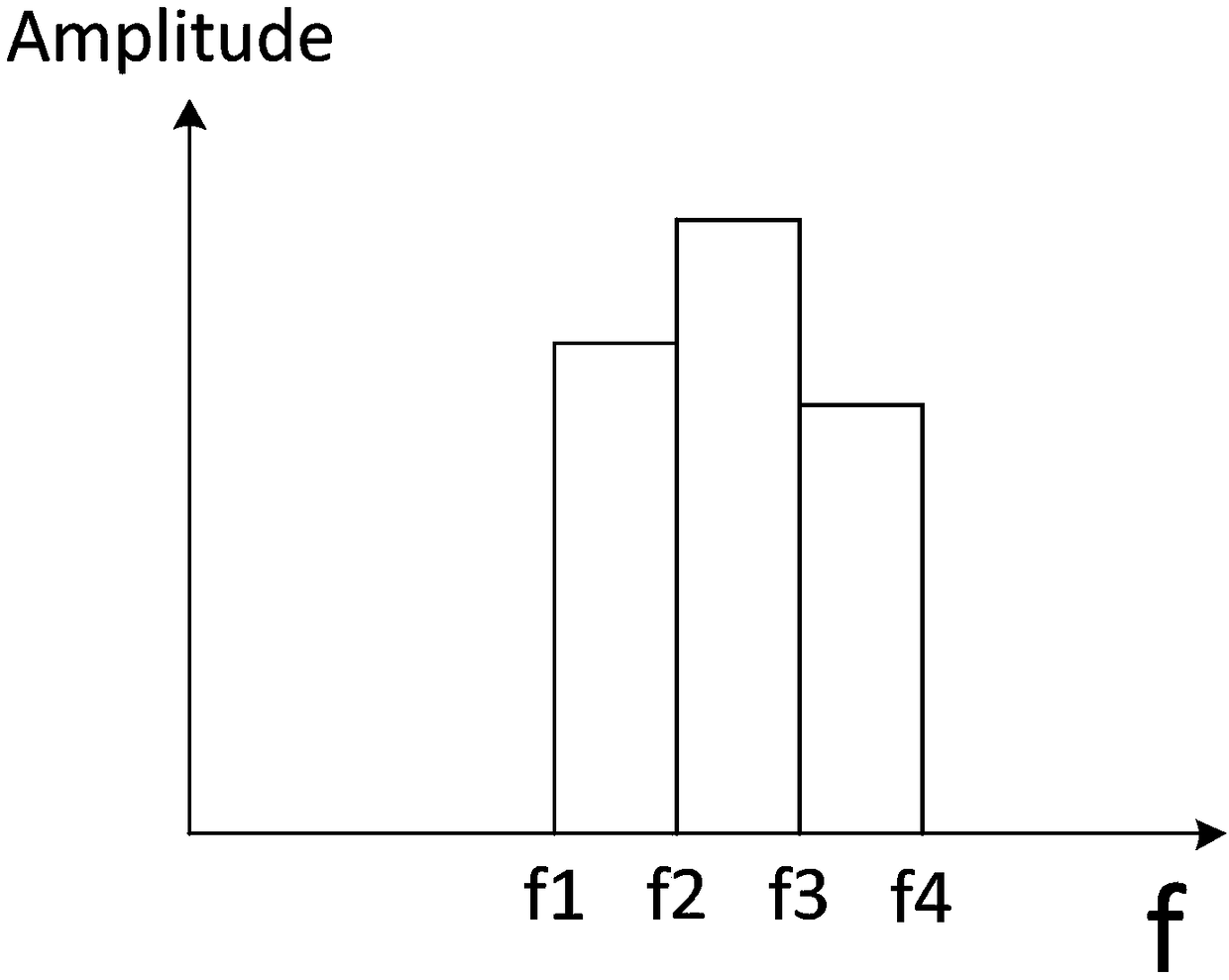

Predistortion processing method and system based on parallel structure

ActiveCN108449096AReduce nonlinear distortionExcellent pre-distortion performanceAmplifier modifications to reduce non-linear distortionTransmission monitoringStructure of Management InformationWide band

The invention discloses a predistortion processing method based on a parallel structure. The method includes the following steps: (1) inputting data into a system to obtain a universal predistortion coefficient; (2) when the input data is stable, enabling the system to obtain a predistortion coefficient, and turning off an adaptive predistorter branch switch; (3) when the input data is stable, enabling an adaptive predistorter to update the predistortion coefficient; when the input data is unstable, turning off the adaptive predistorter branch switch; and when the input data is a wide-band high-power signal, returning to the step (1); (4) when the input data is a narrow-band low-power signal, turning off the adaptive predistorter branch switch, and returning to the step (3); and (5) when the input data in the step (4) is a wide-band high-power signal, returning to the step (1). According to the scheme of the invention, the problems existing in a traditional predistortion method can besolved, more excellent predistortion performance can be realized, and the power amplifier output has better linearity.

Owner:SOUTH CHINA UNIV OF TECH

Cable arrangement support for wiring of computer network engineering construction

ActiveCN112134219AOrderly rowsCause damageApparatus for laying cablesStructural engineeringMechanical engineering

The invention discloses a cable arrangement support for wiring of computer network engineering construction, which comprises a cable arrangement box, wherein a lug plate is mounted on the outer side of the top end of the cable arrangement box, a cover plate is mounted on the upper side of the lug plate, a plurality of cable arrangement plates are arranged in the cable arrangement box, a cable arrangement groove is formed in one side of each cable arrangement plate, buckling grooves are symmetrically formed in the top wall of the lug plate and the bottom wall of the cover plate, wire bodies arejointly distributed in the cable arrangement groove and the buckling grooves, a plurality of rotatable blocking strips are installed on the side, which is provided with the cable arrangement groove,of the cable arrangement plate, each rotatable blocking strip comprises a rotating shaft and a blocking strip, one end of each rotating shaft is fixed to the cable arrangement plate, and the other endis rotationally mounted with one end of the blocking strip. According to the scheme, the network cables can be orderly arranged and fixed on the wall through the cable arrangement support, a plurality of network cables can be arranged, disordered arrangement of the network cables on the wall is avoided, later maintenance is facilitated, the operation process is simple, and the working efficiencyis improved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

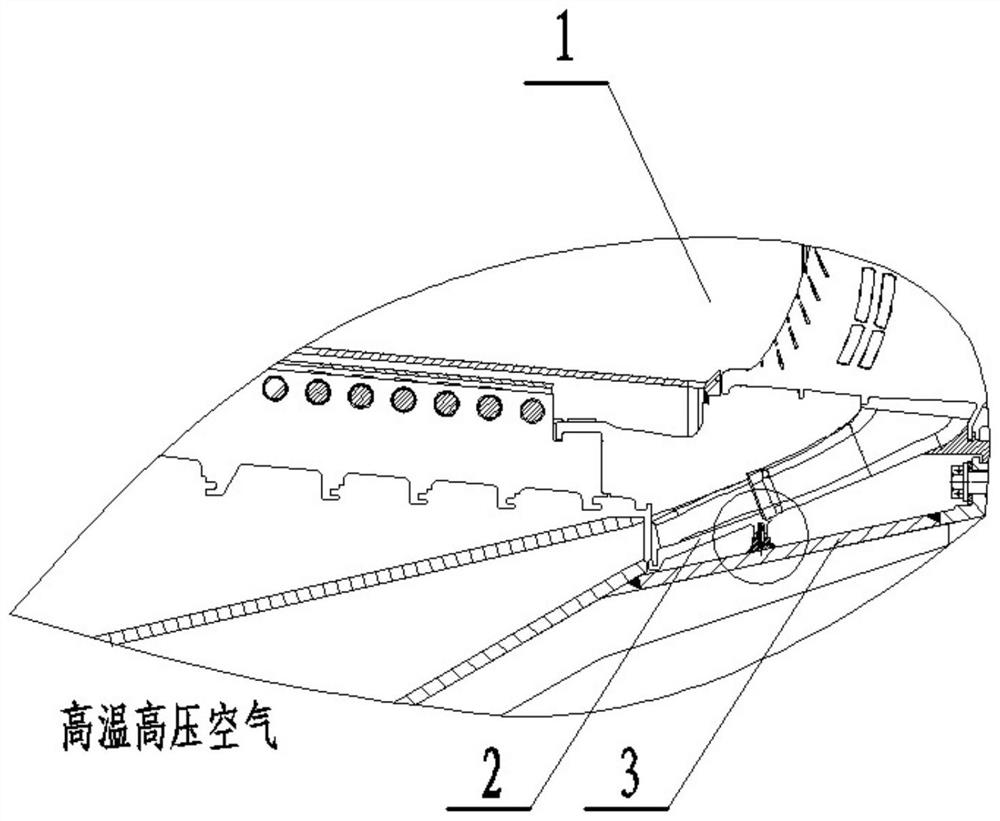

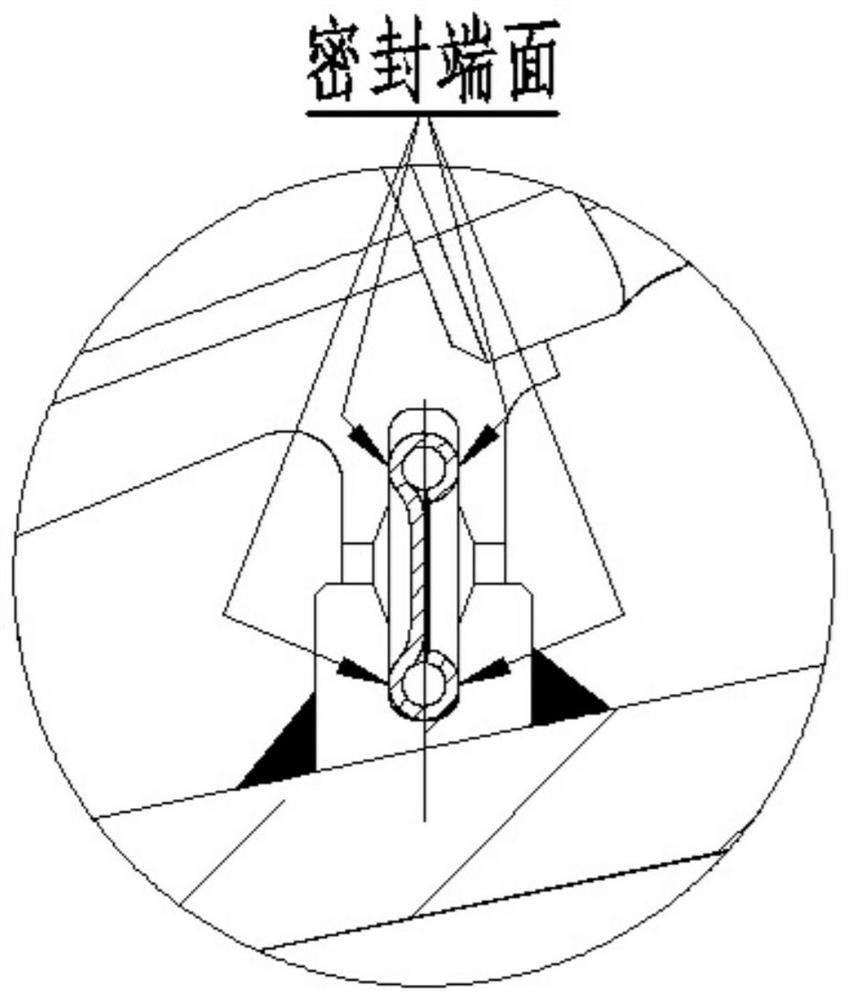

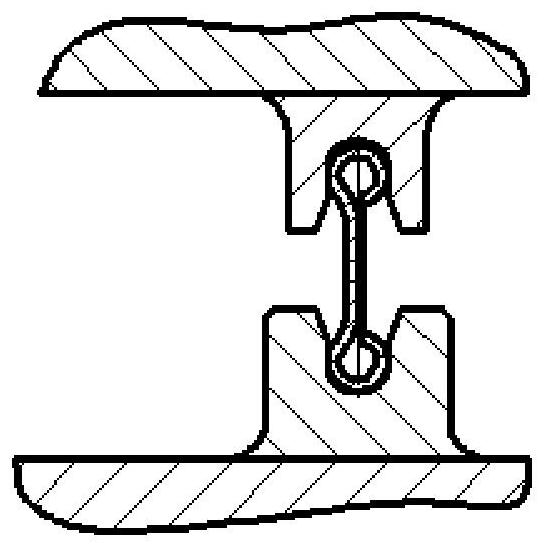

Inter-plane sealing assembly for high-temperature zone gap of gas turbine

InactiveCN112460630AAvoid the risk of breaking and damaging equipmentEasy to installContinuous combustion chamberCombustion chamberGas turbines

The invention aims to provide an inter-plane sealing assembly for a high-temperature zone gap of a gas turbine. The inter-plane sealing assembly comprises an upper groove clamping seat, a lower grooveclamping seat and a sealing clamping ring, the upper groove clamping seat and the lower groove clamping seat are fixed to the upper end face and the lower end face of a gap between a diffusion section at a compressed air inlet of a combustion chamber and a supporting plate correspondingly, and the two ends of the sealing clamping ring are installed in the upper groove clamping seat and the lowergroove clamping seat correspondingly; and the two ends of the sealing clamping ring are open circular rings, the diameter of the circular rings is larger than the inner size of the groove clamping seat, when the sealing clamping ring is installed in the upper groove clamping seat and the lower groove clamping seat, the circular rings contract and deform inwards, and inter-plane sealing is achievedthrough deformation and springback of a steel structure of the sealing clamping ring. The sealing assembly can be installed in a whole ring mode, fasteners do not need to be adopted for fastening, installation convenience is guaranteed, and meanwhile the risk that due to long-term operation of the gas turbine, the fasteners are broken and damage equipment is avoided; and the sealing assembly is not limited by the plane position, the groove clamping seat can be staggered, an included angle can be formed between the two planes, and the application range is extremely wide.

Owner:中国船舶重工集团公司第七0三研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com