Patents

Literature

37 results about "Conical pendulum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A conical pendulum consists of a weight (or bob) fixed on the end of a string or rod suspended from a pivot. Its construction is similar to an ordinary pendulum; however, instead of swinging back and forth, the bob of a conical pendulum moves at a constant speed in a circle with the string (or rod) tracing out a cone. The conical pendulum was first studied by the English scientist Robert Hooke around 1660 as a model for the orbital motion of planets. In 1673 Dutch scientist Christiaan Huygens calculated its period, using his new concept of centrifugal force in his book Horologium Oscillatorium. Later it was used as the timekeeping element in a few mechanical clocks and other clockwork timing devices.

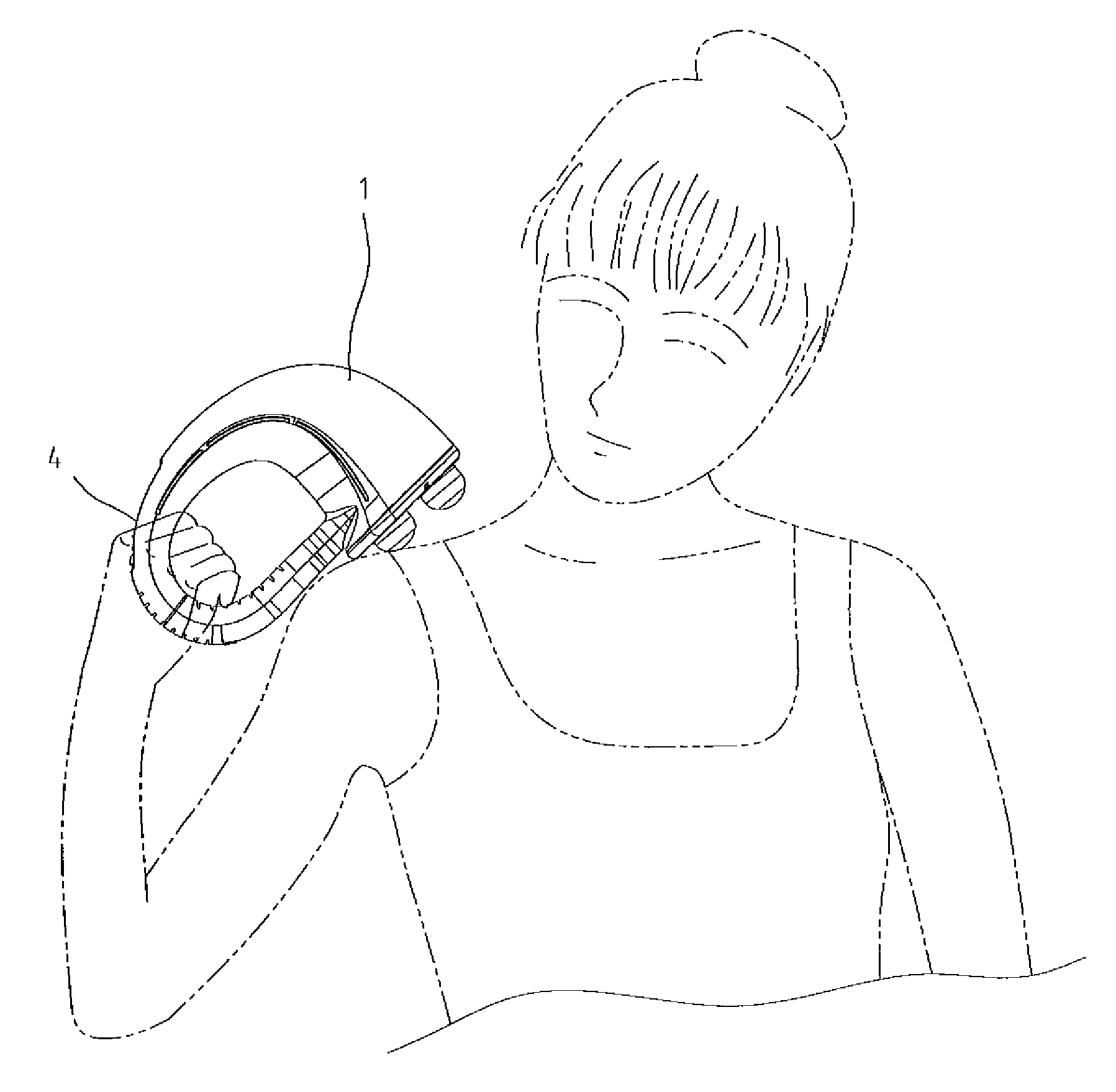

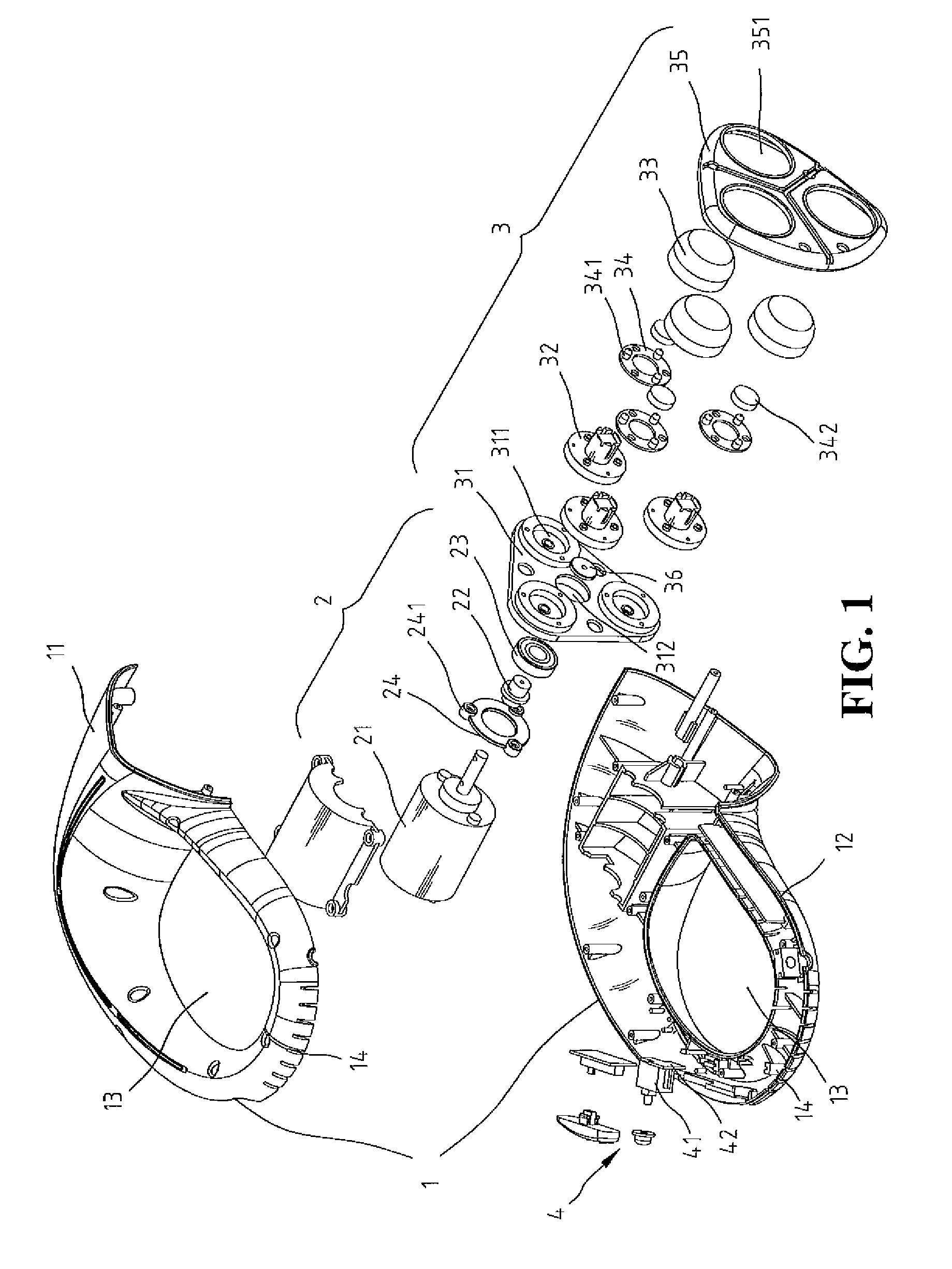

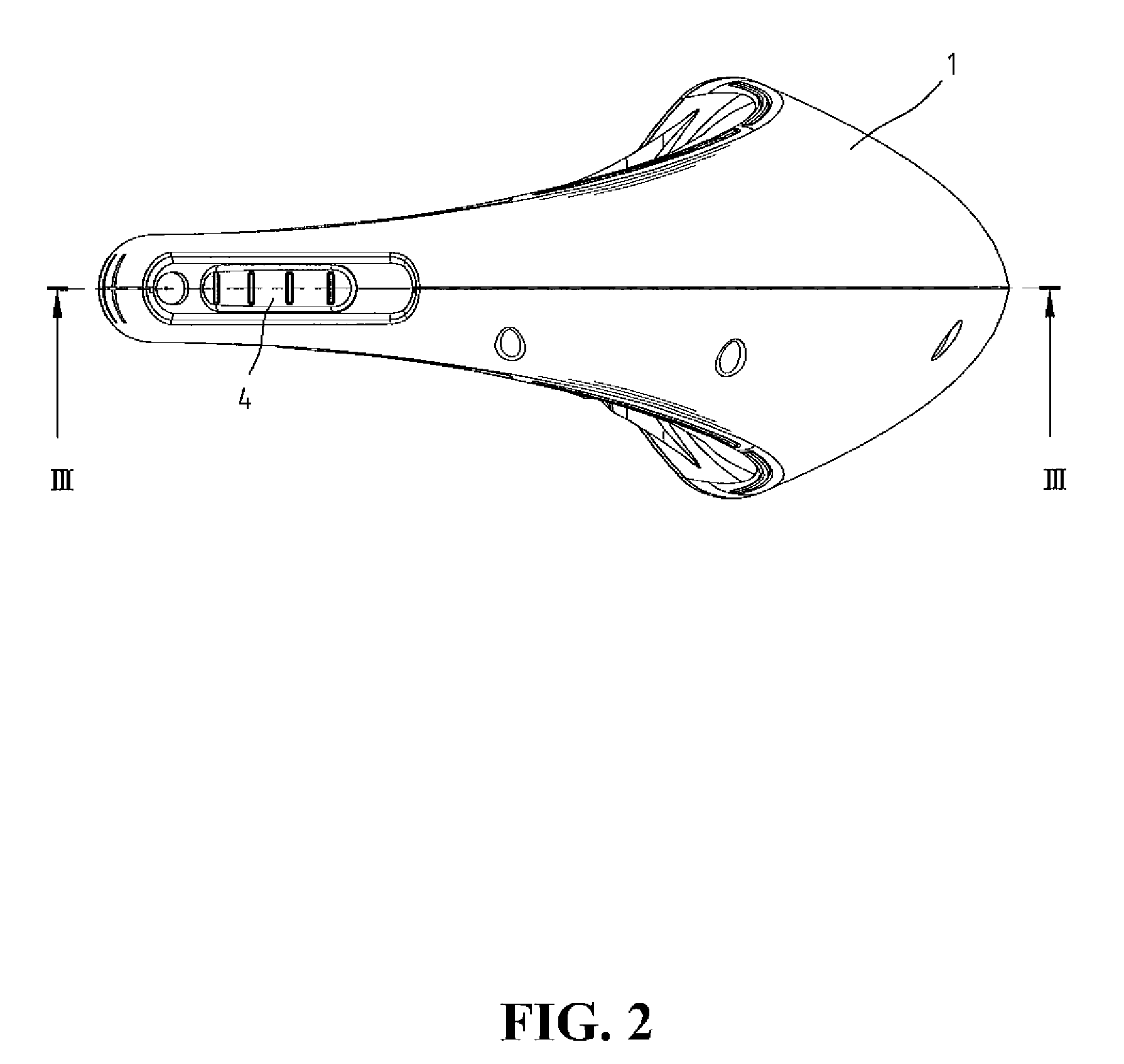

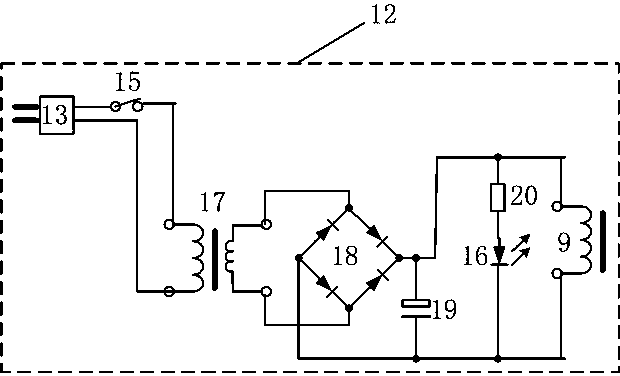

Handheld massage device

InactiveUS20100145242A1Convenient grippingGuaranteed uptimeVibration massageGenitals massageMassageHand held

A handheld massage device includes an actuator mechanism and a massage unit received in an outer housing. The actuator includes a motor, a bearing and a tilting piece having a first shaft coupled with the motor and a second shaft fitted into the bearing. The crank-shaped first and second shafts do not lie on a straight line. The massage unit has a base plate and massage elements mounted on the base plate. The massage elements protrude from one end of the outer housing. The bearing is fitted in the base plate. Because the first and second shafts form an angle therebetween, the base plate is tilted and swings like a conical pendulum. Therefore, the massage elements on the base plate move back and forth along a direction of an axle of the motor, thereby providing kneading and percussion massages on the user's body.

Owner:TSAI MING WEI

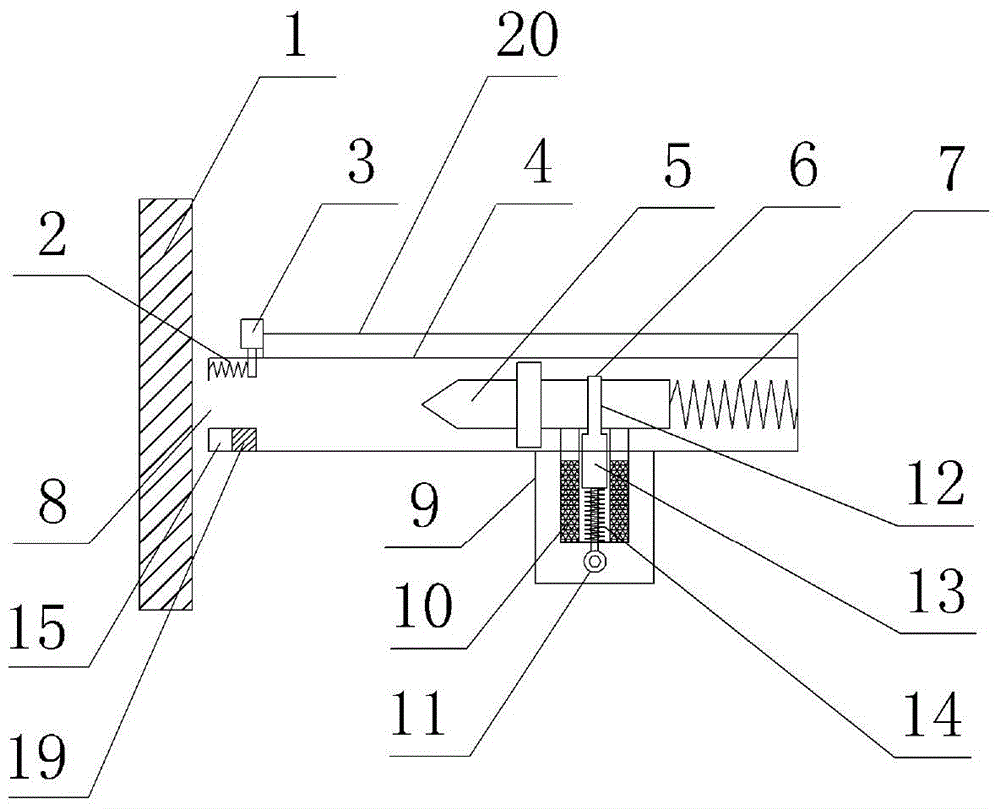

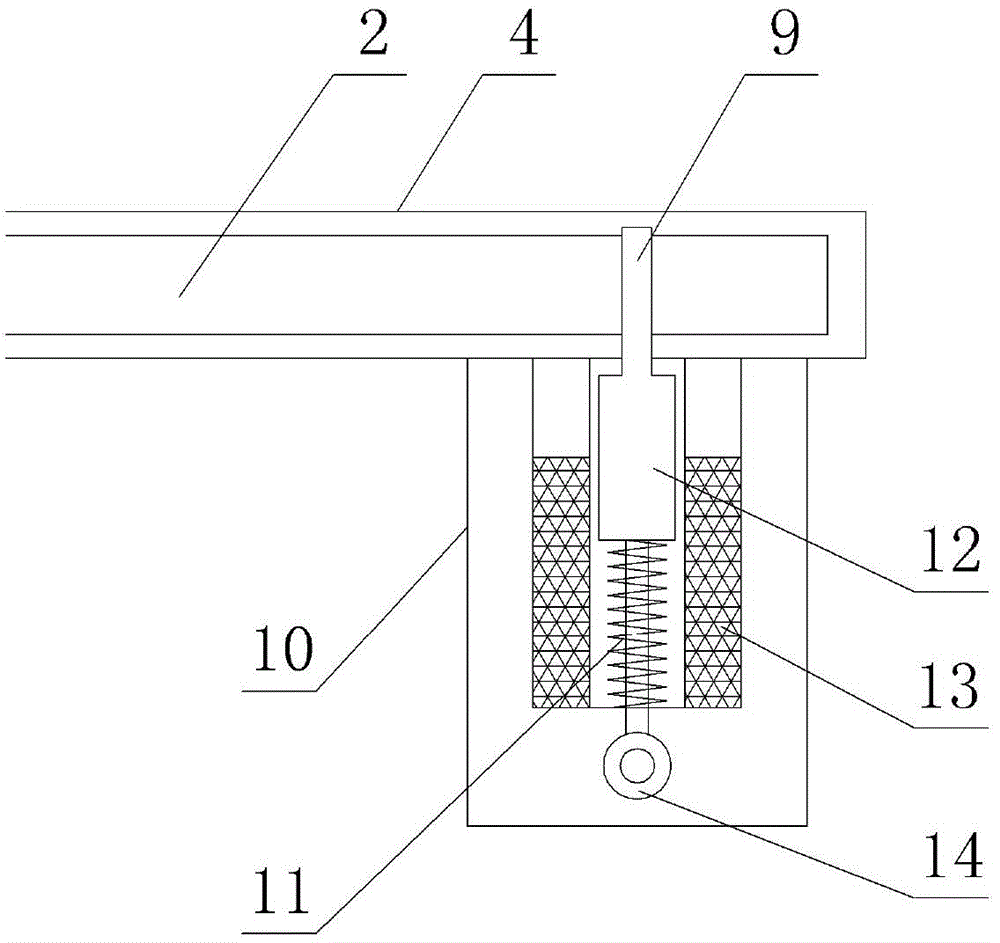

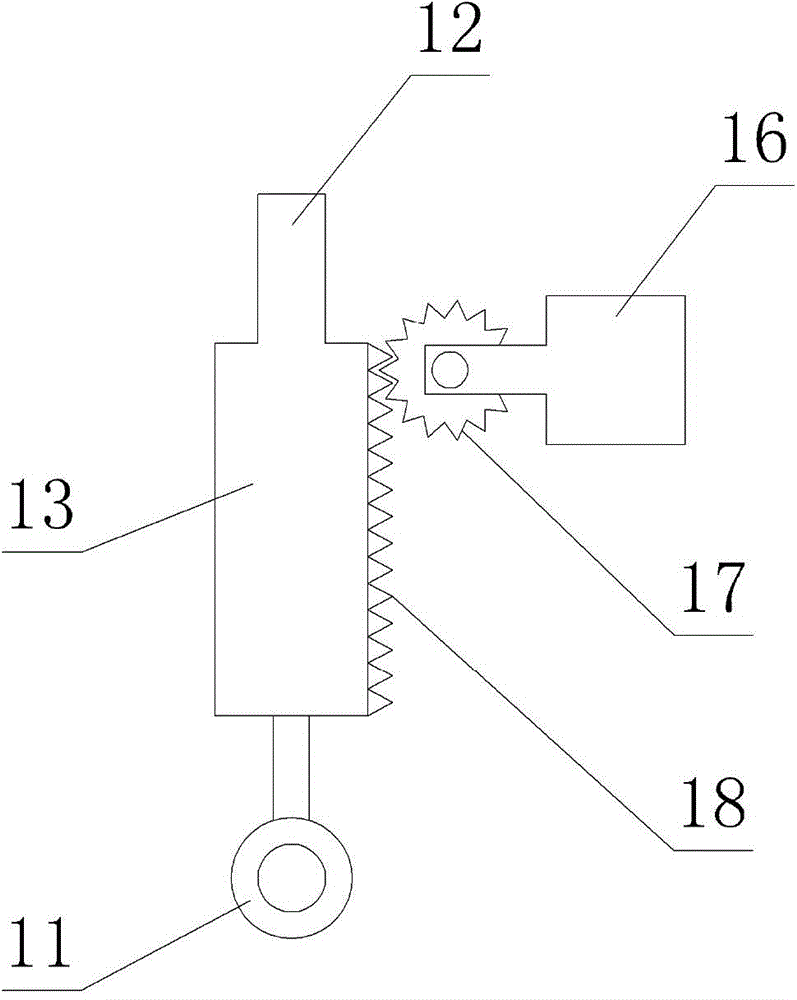

Window breaker

InactiveCN105752018ANot easy to loseImprove reliabilityPedestrian/occupant safety arrangementConical pendulumEngineering

The invention relates to a window breaker, which comprises a conical pendulum hammer, a spring, a trigger switch and a window breaker box, wherein the spring can be used for enabling the conical pendulum hammer to be horizontally ejected; the trigger switch is used for limiting and triggering the conical pendulum hammer to be horizontally ejected; the window breaker box is used for guiding the conical pendulum hammer to be horizontally ejected; the conical pendulum hammer and the spring are arranged in the window breaker box; the trigger switch is arranged outside the window breaker box; one end of the conical pendulum hammer is connected with the spring; the other end of the conical pendulum hammer is connected with the trigger switch; one side, which is close to a glass window, of the window breaker box is provided with a window breaking hole through which the conical pendulum hammer can pass; the other side, which is close to a glass window, of the window breaker box is provided with the spring. The window breaker has the characteristics that the loss is difficult, the reliability is good, the repeated percussion can be carried out, the operation is convenient, and further, the operating time is short.

Owner:XIAN BLUE DIAMOND ELECTRONICS

Automatically levelled theodolite device

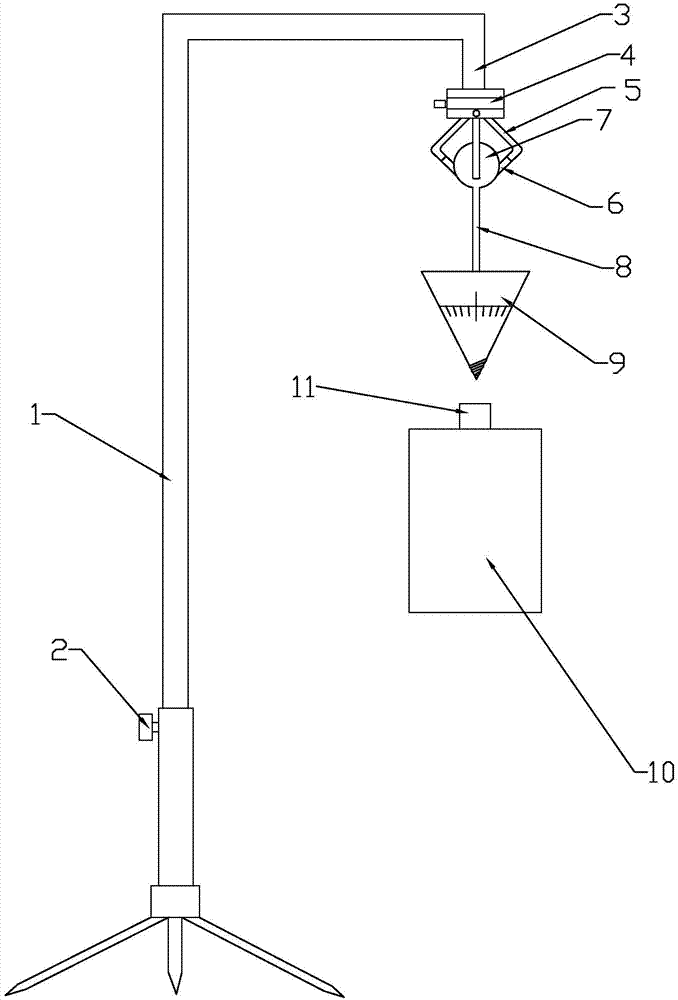

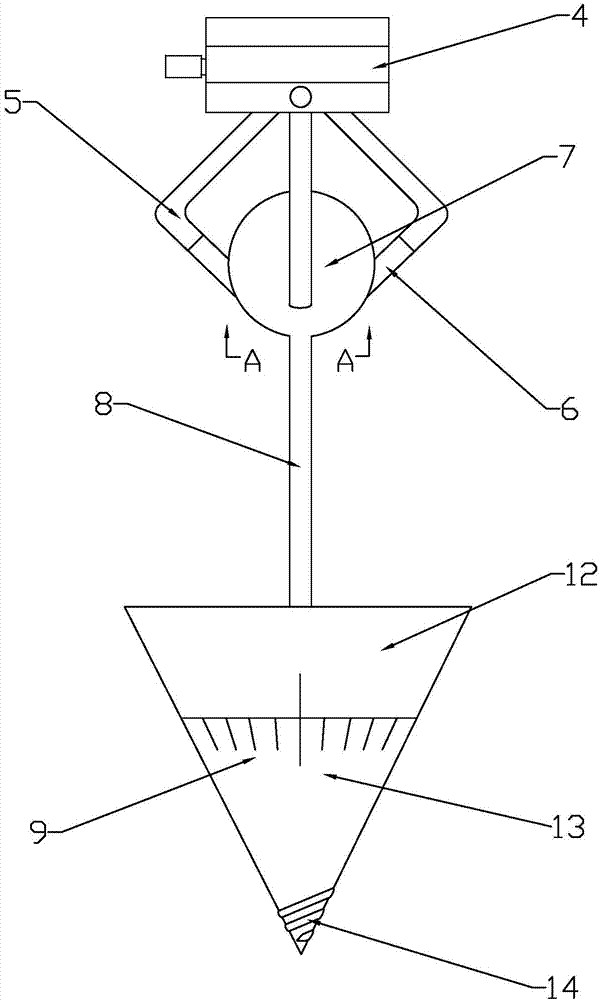

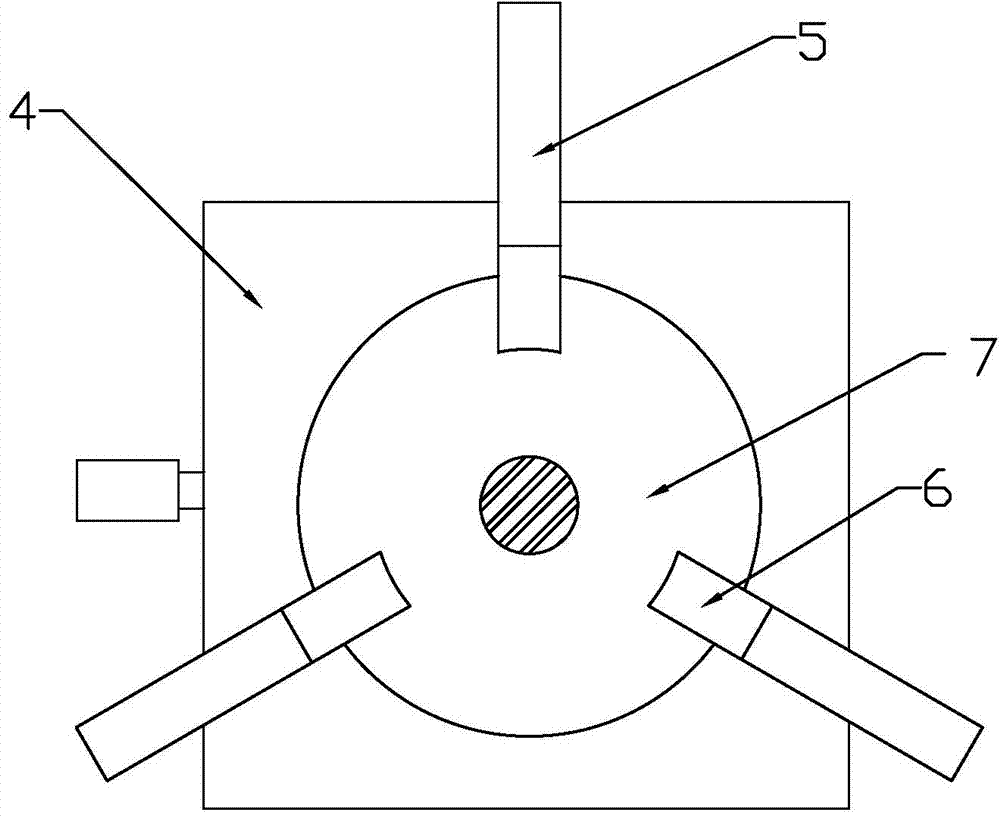

The invention discloses an automatically levelled theodolite device. The automatically levelled theodolite device comprises a theodolite body and a support, wherein the support comprises a suspension arm and a theodolite body levelling and centering mechanism, the theodolite body levelling and centering mechanism comprises a horizontal fine turning component the bottom of which is connected with the tail end of the suspension arm, as well as a gravity pendulum bob, the horizontal fine turning component is connected with the gravity pendulum bob in a manner of holding a spherical pendulum head of the gravity pendulum bob by virtue of multiple extending downward ball claws which are arranged on the working platform of the horizontal fine turning component, a locating component which can fix the position of the spherical pendulum head is arranged on each ball claw, the gravity pendulum bob also comprises a conical pendulum body, the gravity center of the conical pendulum body is located on the central axis of the conical pendulum body, the vertebral point of the conical pendulum body is arranged downward and is provided with an external screw thread structure, a screw hole matched with an external screw thread structure is formed in the top of the theodolite body, and the central axis of the screw hole is coincided with the vertical axis of the theodolite body. The automatically levelled theodolite device has the advantages that automatic levelling and locating can be realized, and centering is convenient, so that operation is relatively easy and relatively conveniently.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

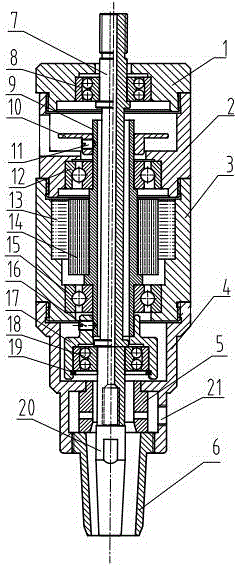

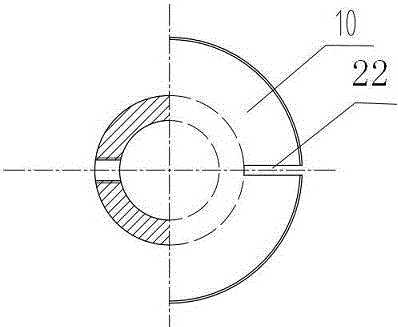

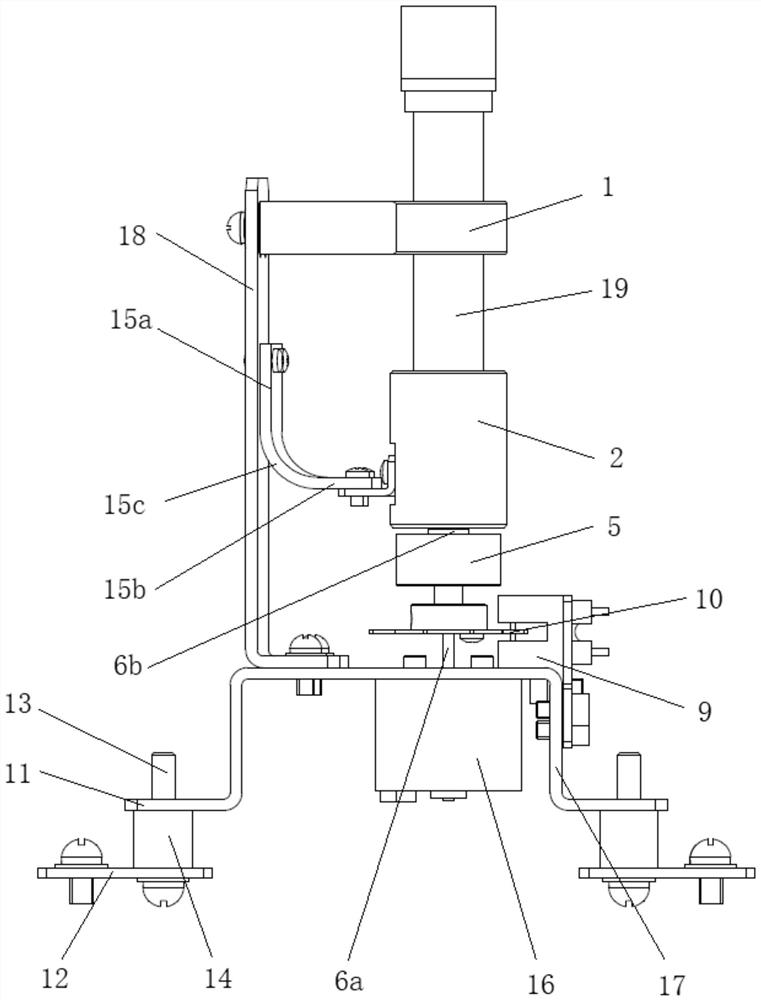

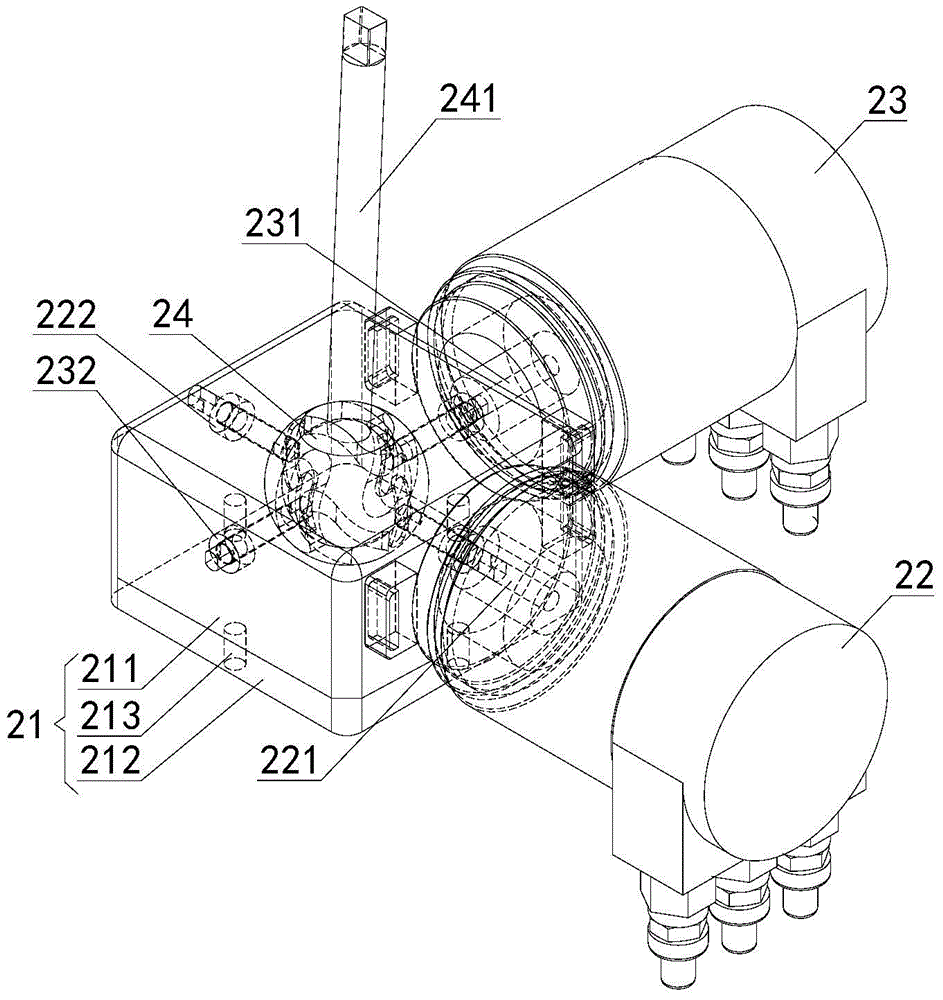

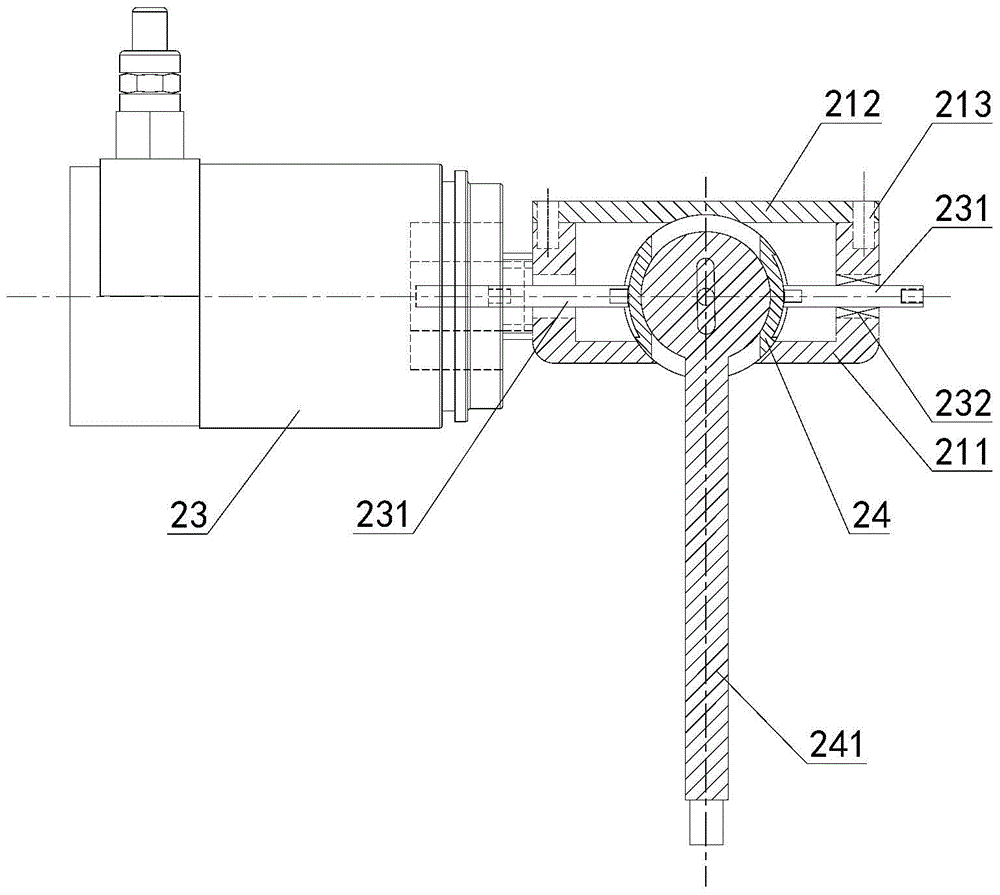

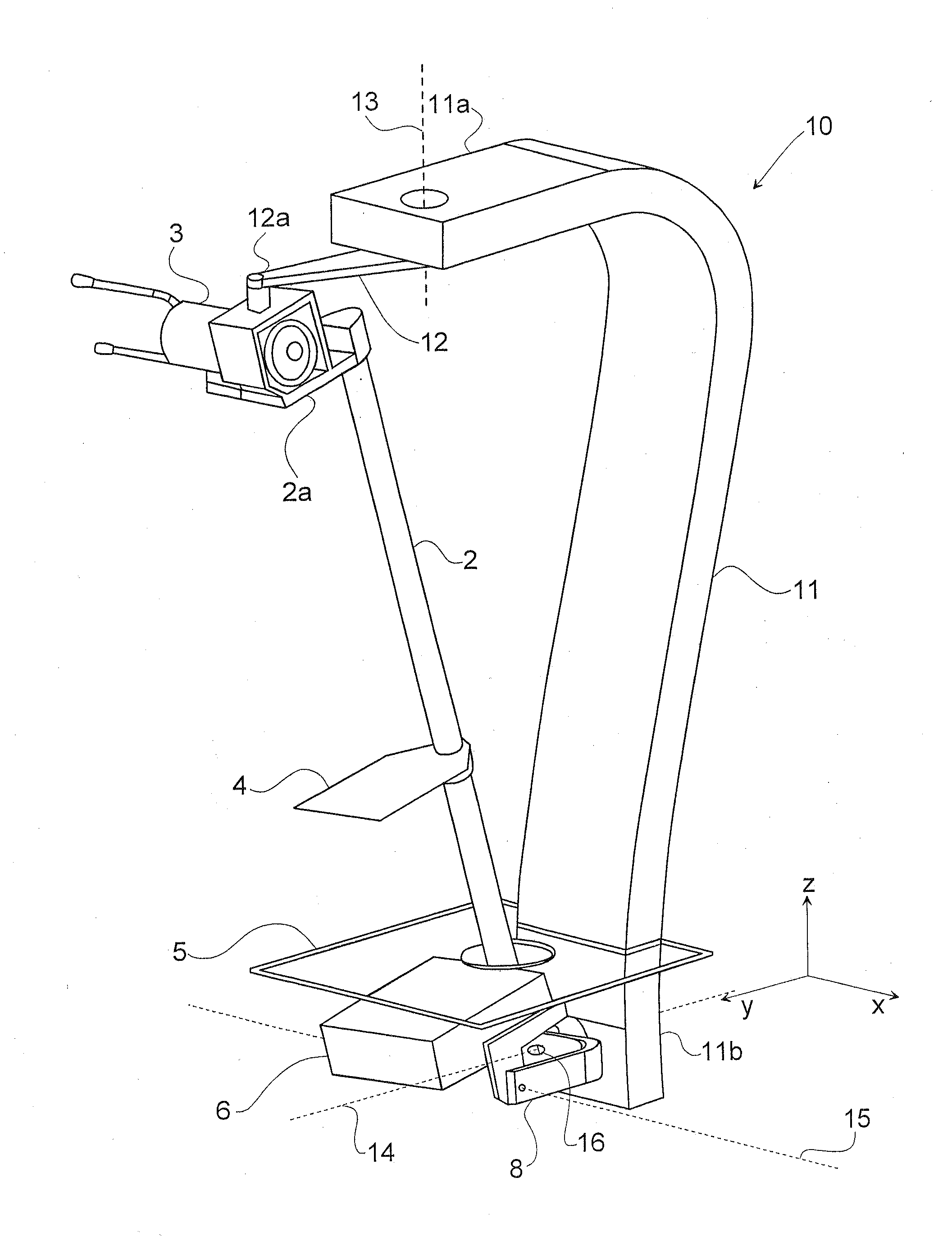

Rotating arc sensor for gas shielded welding

InactiveCN105817741AReduce vibrationCompact structureWelding protection meansConical pendulumDrive motor

The invention discloses a rotating arc sensor for gas shielded welding. The rotating arc sensor for gas shielded welding is composed of two parts, that is, a shell and a rotor assembly. A conical pendulum scheme is adopted for the rotating arc sensor disclosed by the invention, and because a hollow shaft is directly installed on a rotor of a drive motor, a transmission device is reduced; and the sensor is small in vibration, compact in structure, small in size, high in accessibility, wider in application range, and convenient to use.

Owner:NANCHANG UNIV

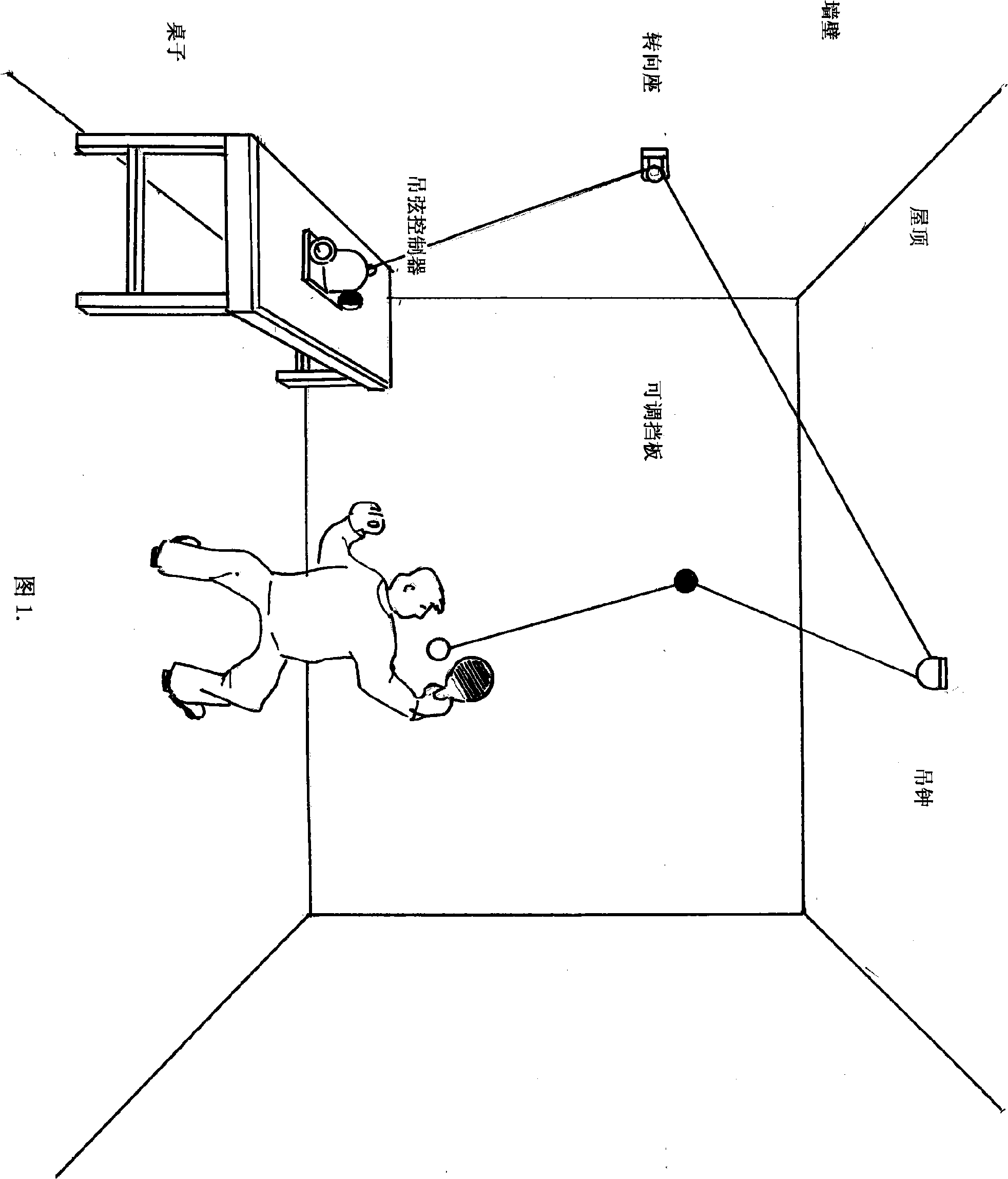

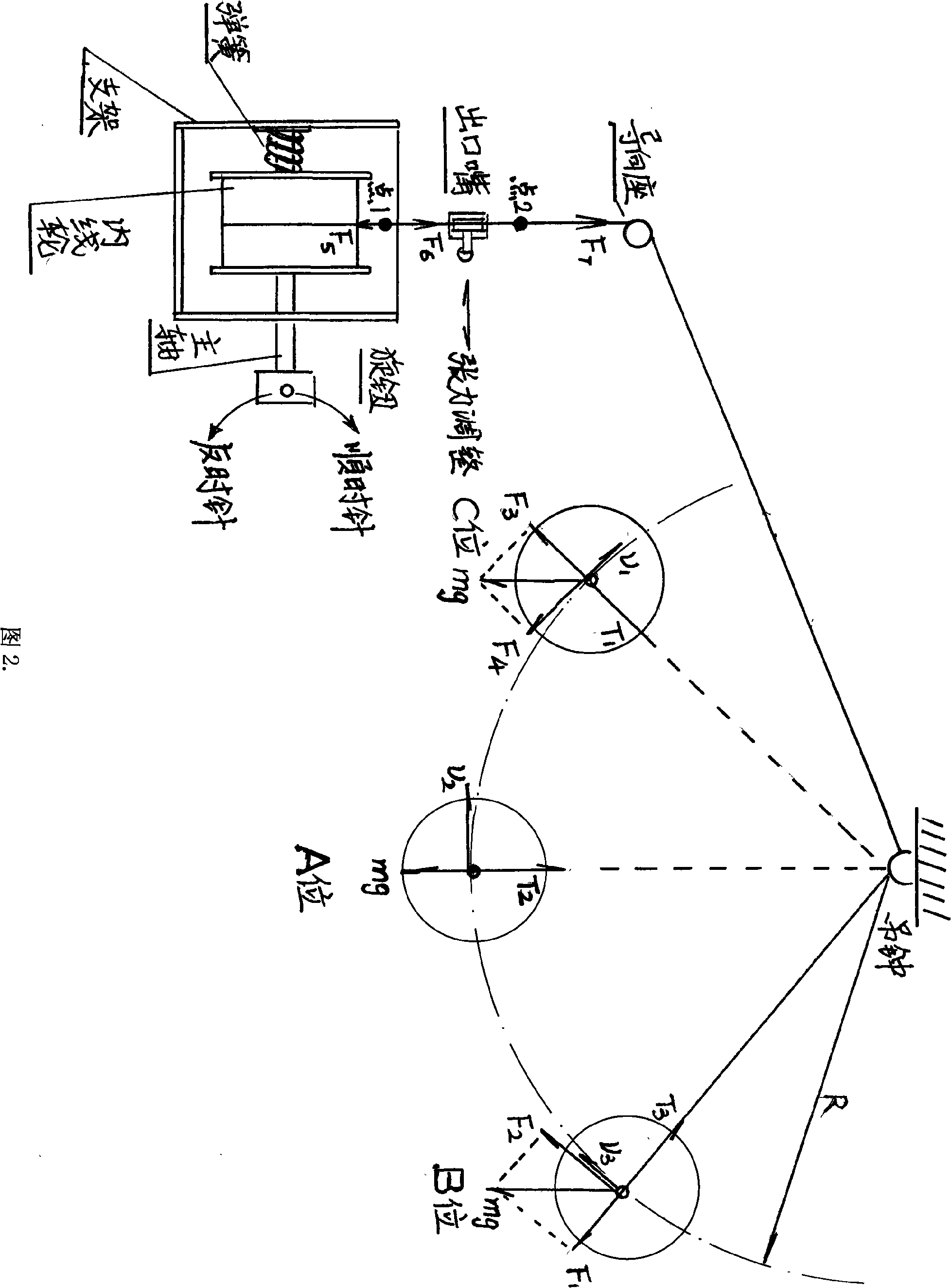

Simulation ball

InactiveCN101357264APrevention of myopiaIncreased systolic functionSport apparatusTraining - actionGeneral family

A simulative magic ball is a simulative batting device for training actions and skills of a plurality of competitive balls with simulative batting method for the first time. The simulative magic ball belongs to the field of family physical exercise or game toys. A plurality of ball exercises can be enjoyed in an ordinary home. The simulative batting method is easily mastered and the skills of the competitive balls are quickly improved. The simulative magic ball can strengthen the body, train strong basic skills, and provide great joys. Taking simulative table tennis as example, specific skills such as push and block, cut, lift, drive, sidespin, loop drive, and the like, can be practiced. The simulative magic ball can be used for training badminton, foot shuttlecock skills, etc. The device can be extended to play skill games, the batting difficulty and entertainment fun can be increased by a compound pendulum and a conical pendulum. In the simulative batting and games, physical knowledge is combined. Teenagers can deeply understand and research into the corresponding physical phenomena, get relieved from muscle and bone, prevent from short sight, and release pressure. The simulative magic ball has the advantages of physical training, physics learning and eyes exercise, and is applied to family sports and student exercise.

Owner:刘培林

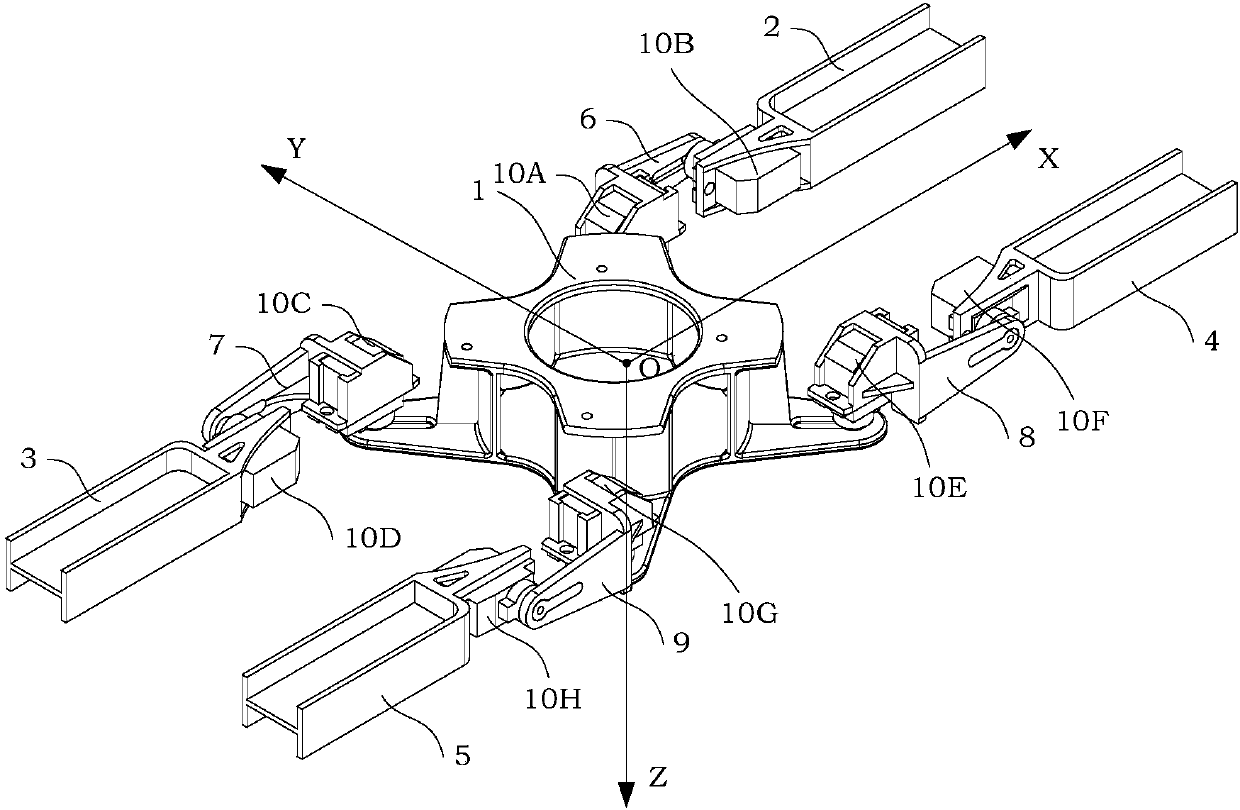

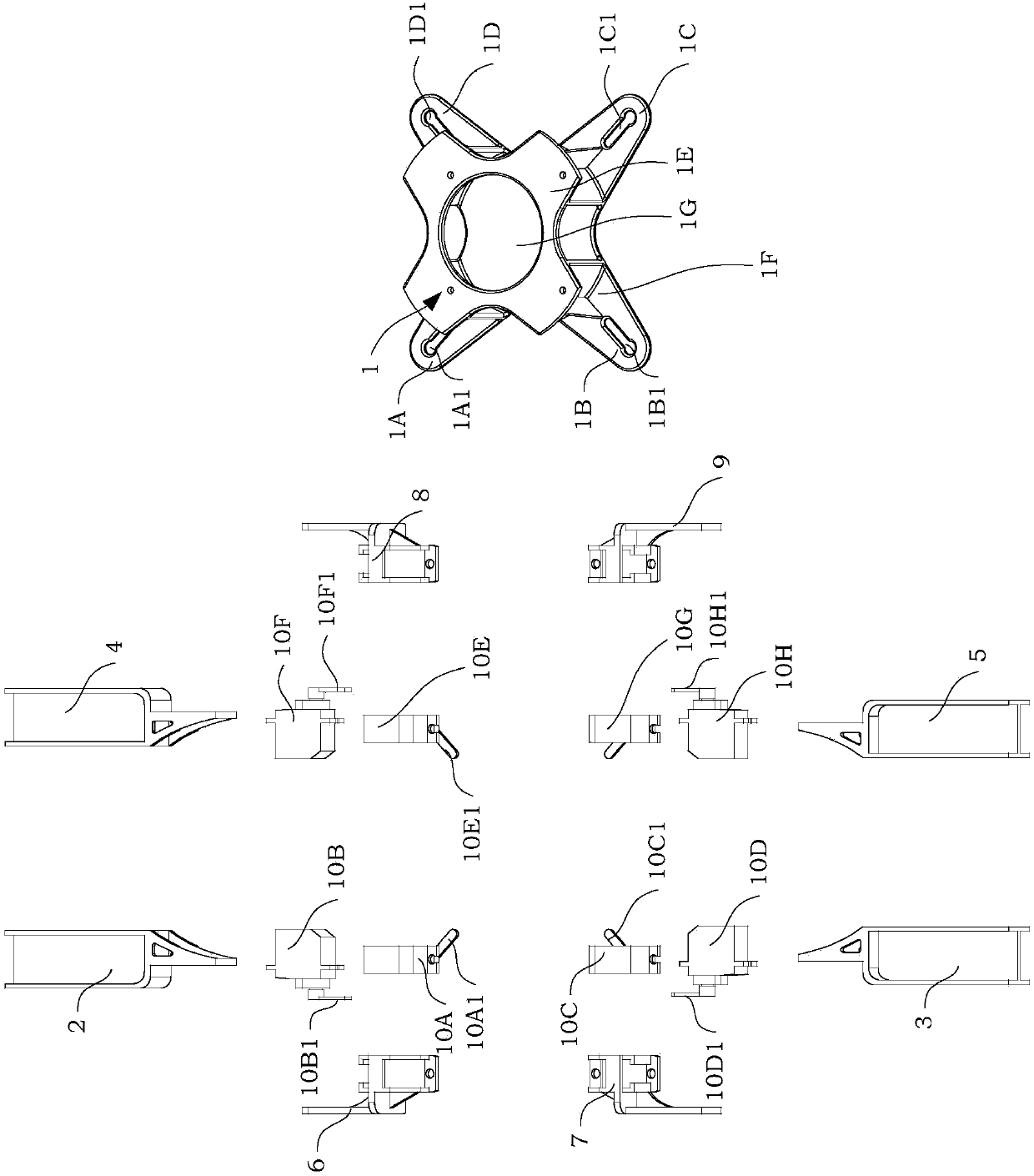

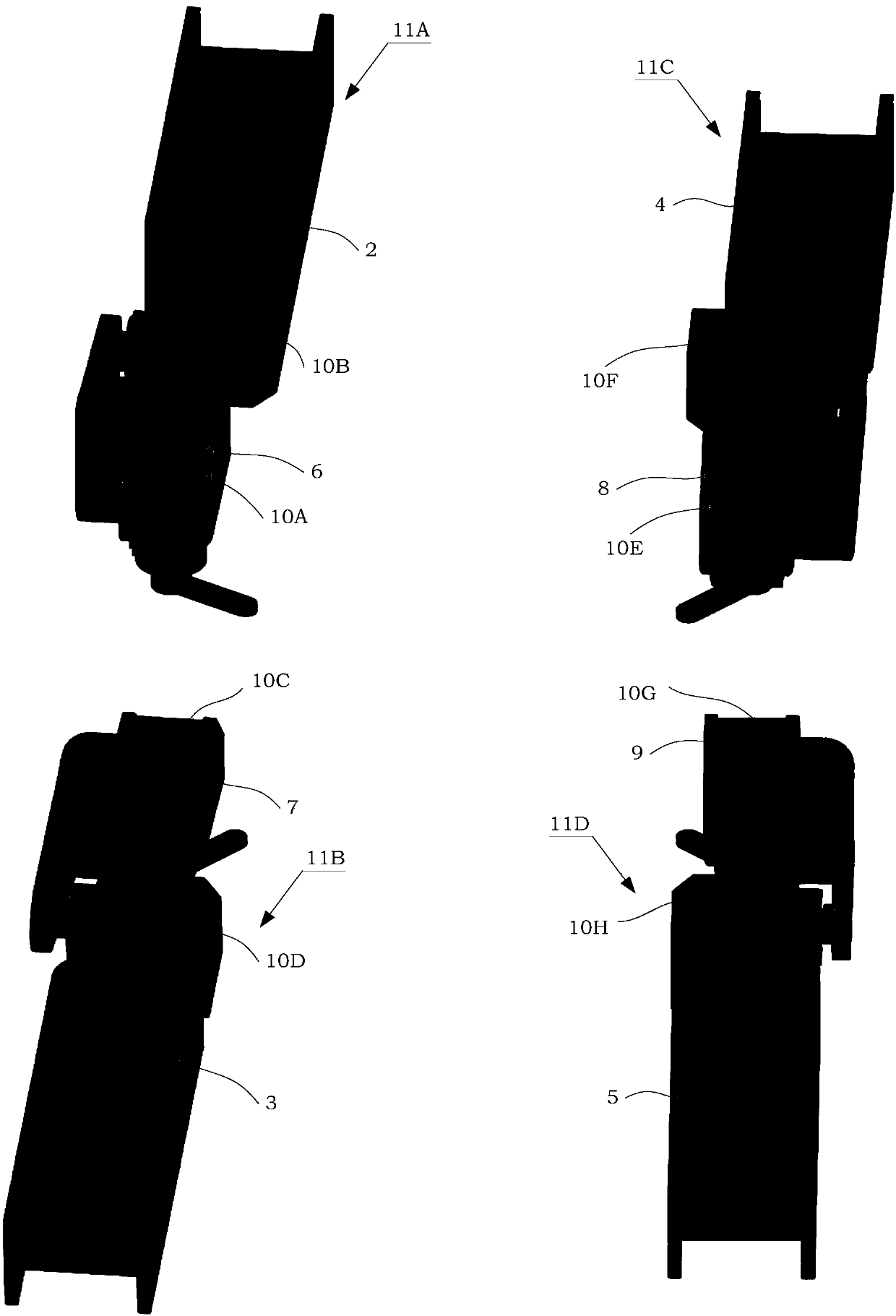

Quadruped robot self-adjusted from any posture in air to landing posture

InactiveCN108214519ASimple and lightweight designEasy to controlProgramme-controlled manipulatorJointsConical pendulumTwo degrees of freedom

The invention discloses a quadruped robot self-adjusted from any posture in the air to a landing posture. The robot comprises a steering engine control unit, steering engines and a quadruped robot body, wherein the quadruped robot body comprises a trunk body and leg units capable of carrying out spatial two-degree-of-freedom motion; through conical pendulum motion in different directions of the leg units, any posture in the air can be adjusted into the landing posture to enable the robot body to reach the ground; the four leg units of the quadruped robot body are provided with the steering engines respectively, and the steering engines are controlled by steering engine commands output by the steering engine control unit; and the steering engine control unit carries out control on the steering engines by adopting an adjusting sequence from an X axis to a Y axis and to a Z axis. According to the quadruped robot self-adjusted from any posture in the air to the landing posture, when the quadruped robot is adopted to bear a satellite structure body, posture adjustment of smooth and stable landing of the satellite structure body can be achieved without external force action.

Owner:BEIHANG UNIV

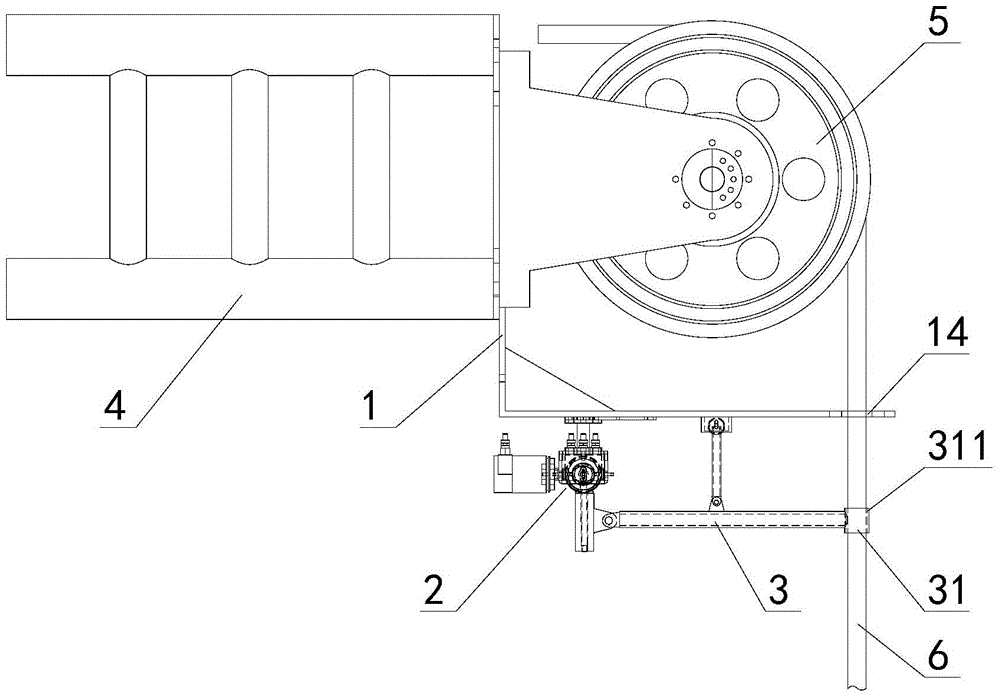

Small mobile welding robot

InactiveCN106735782AReduce volumeLight in massElectrode holder supportersEngineeringConical pendulum

The invention relates to the technical field of welding robots, in particular to a small mobile welding robot. The small mobile welding robot comprises a wheeled mobile platform, a welding torch adjusting mechanism and an arc sensor, the wheeled mobile platform is of a three-wheeled differential driving structure, an adjustable magnetic adsorbability is mounted at the bottom, and a controller is integrated on the mobile platform. The welding torch adjusting mechanism is composed of a cross slider and a welding torch connecting device, the cross slider is driven by two motors respectively, and horizontal and vertical accurate tracking of welds is realized; the arc sensor adopts a conical pendulum form and is designed with a welding gun integrally, and convenience in use is achieved. The robot meets the requirements of bend weld tracking, and is good in welding quality, small in size, lightweight, convenient to use and the like, and the requirements on welding robots in narrow space are met.

Owner:柳州振业焊接机电设备制造有限公司

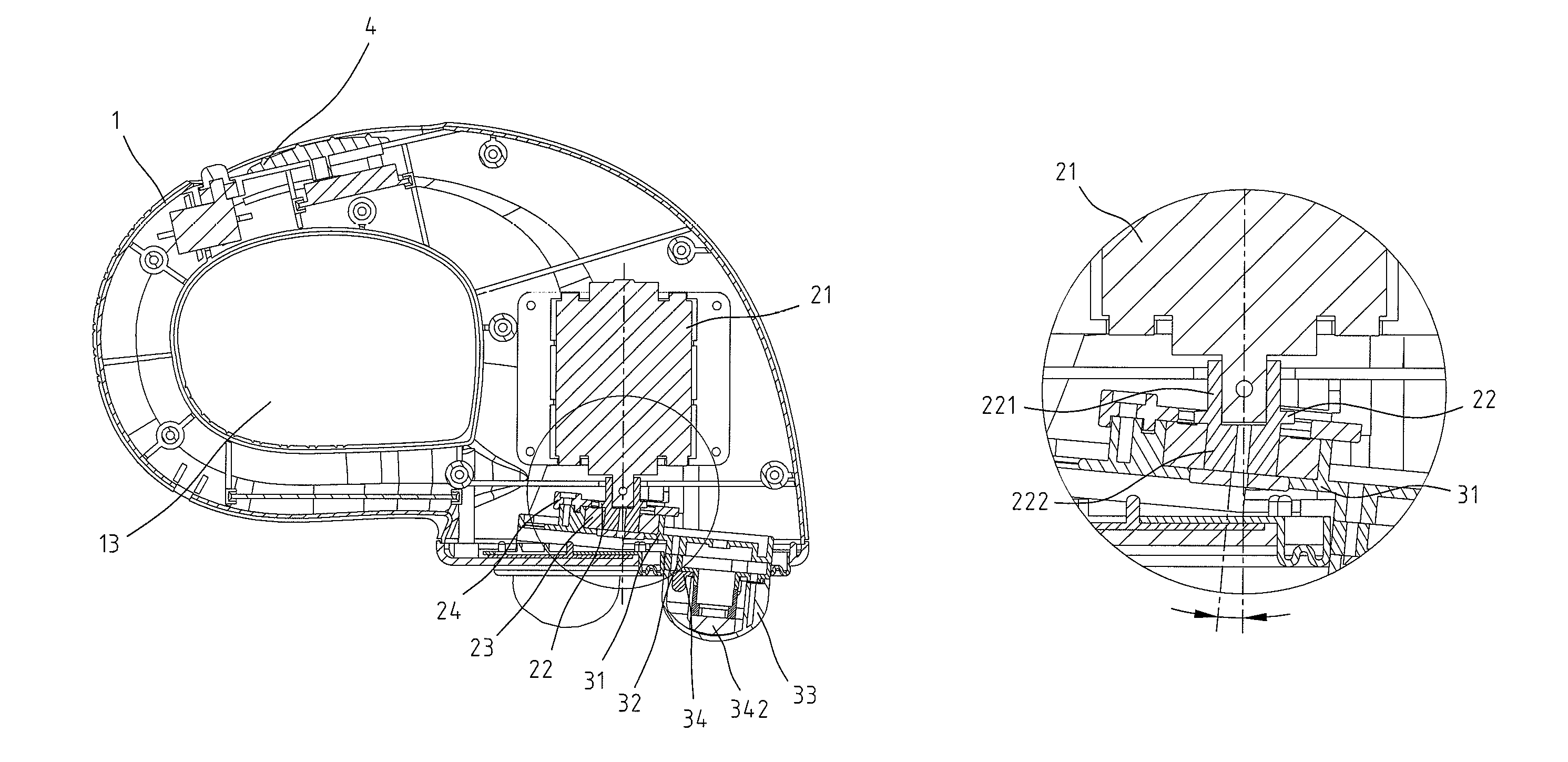

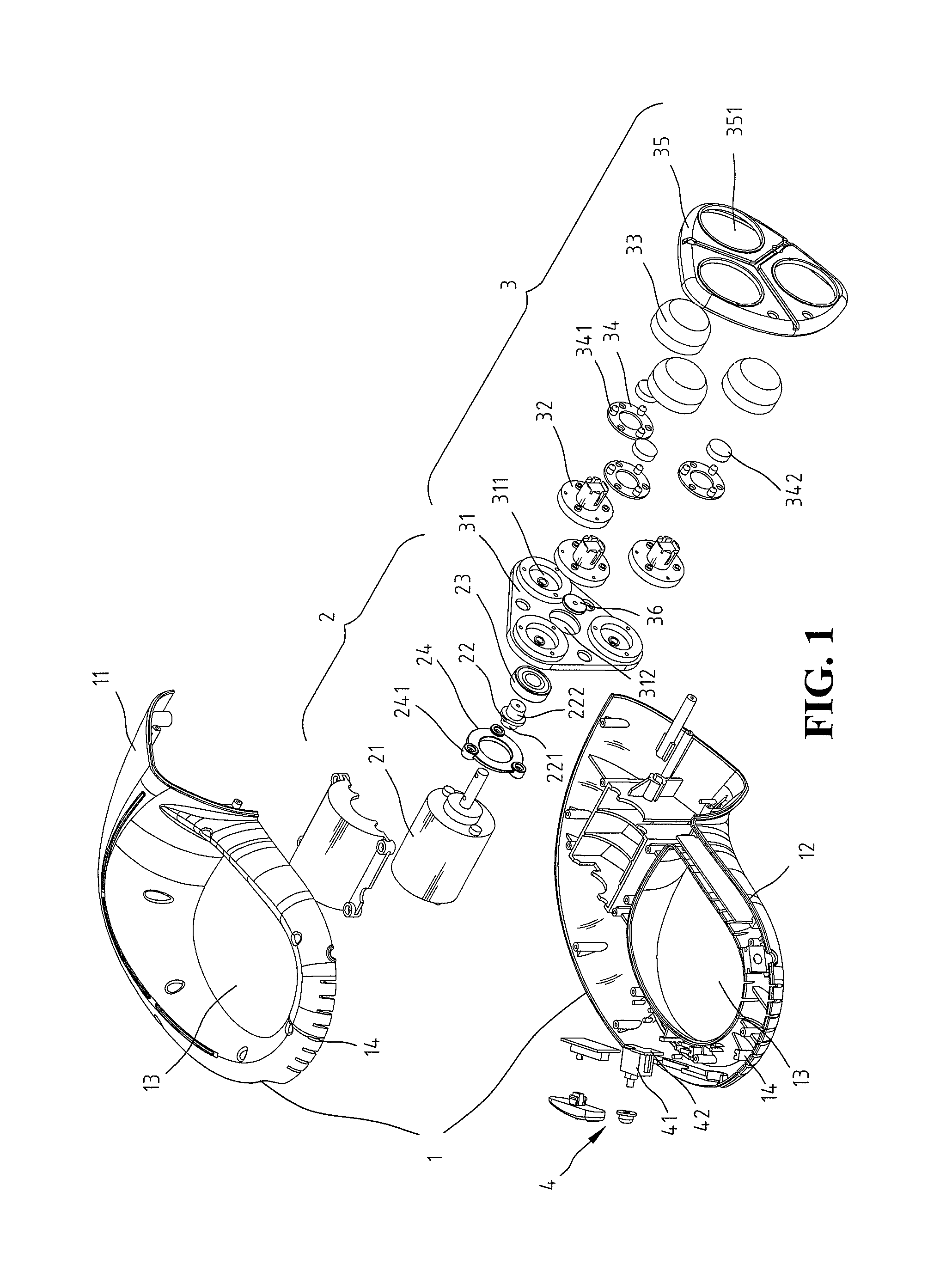

Handheld massage device

InactiveUS8777881B2Convenient gripping and operationImprove aestheticsChiropractic devicesVibration massageMassageEngineering

A handheld massage device includes an actuator mechanism and a massage unit received in an outer housing. The actuator includes a motor, a bearing and a tilting piece having a first shaft coupled with the motor and a second shaft fitted into the bearing. The crank-shaped first and second shafts do not lie on a straight line. The massage unit has a base plate and massage elements mounted on the base plate. The massage elements protrude from one end of the outer housing. The bearing is fitted in the base plate. Because the first and second shafts form an angle therebetween, the base plate is tilted and swings like a conical pendulum. Therefore, the massage elements on the base plate move back and forth along a direction of an axle of the motor, thereby providing kneading and percussion massages on the user's body.

Owner:TSAI MING WEI

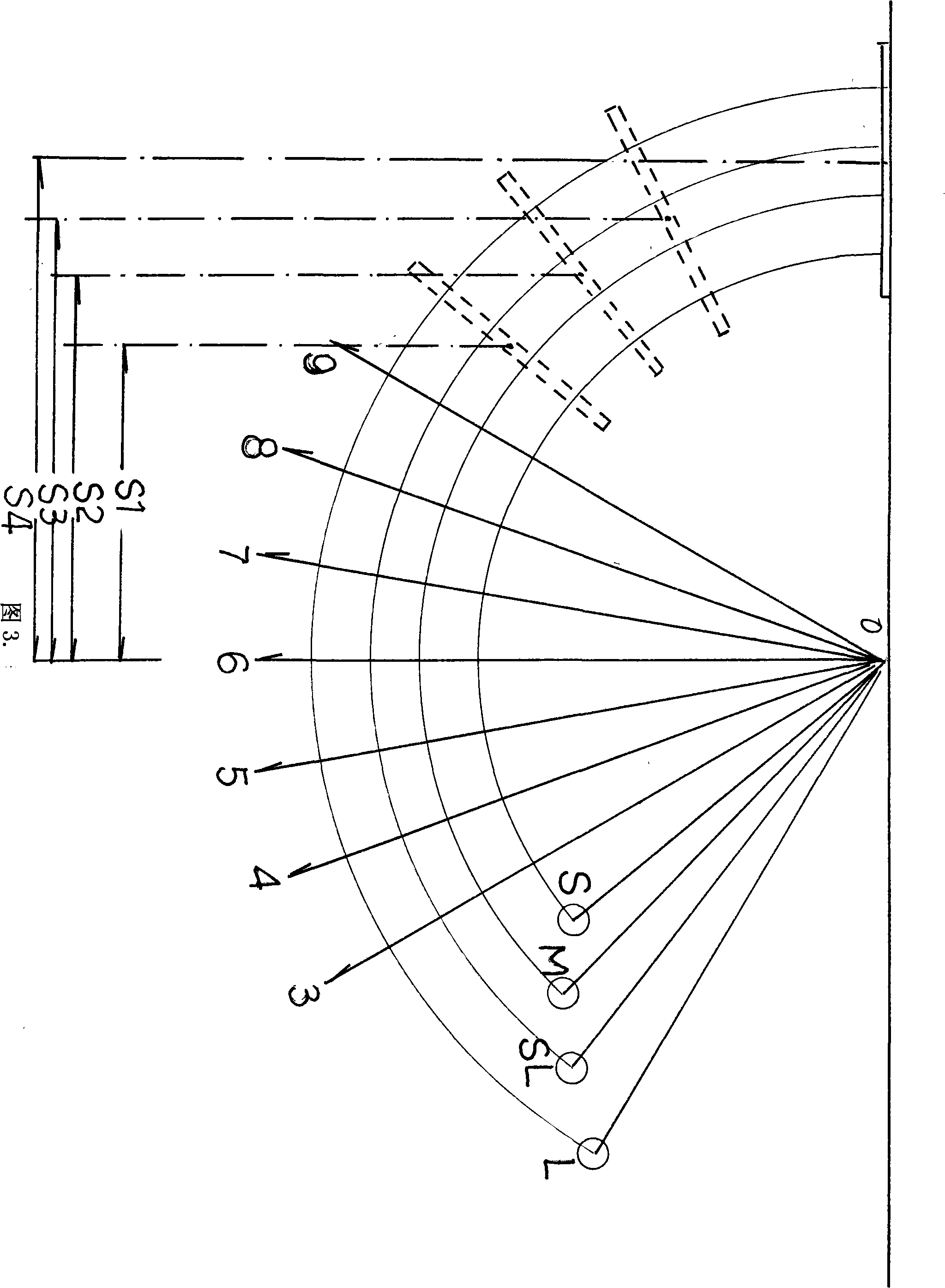

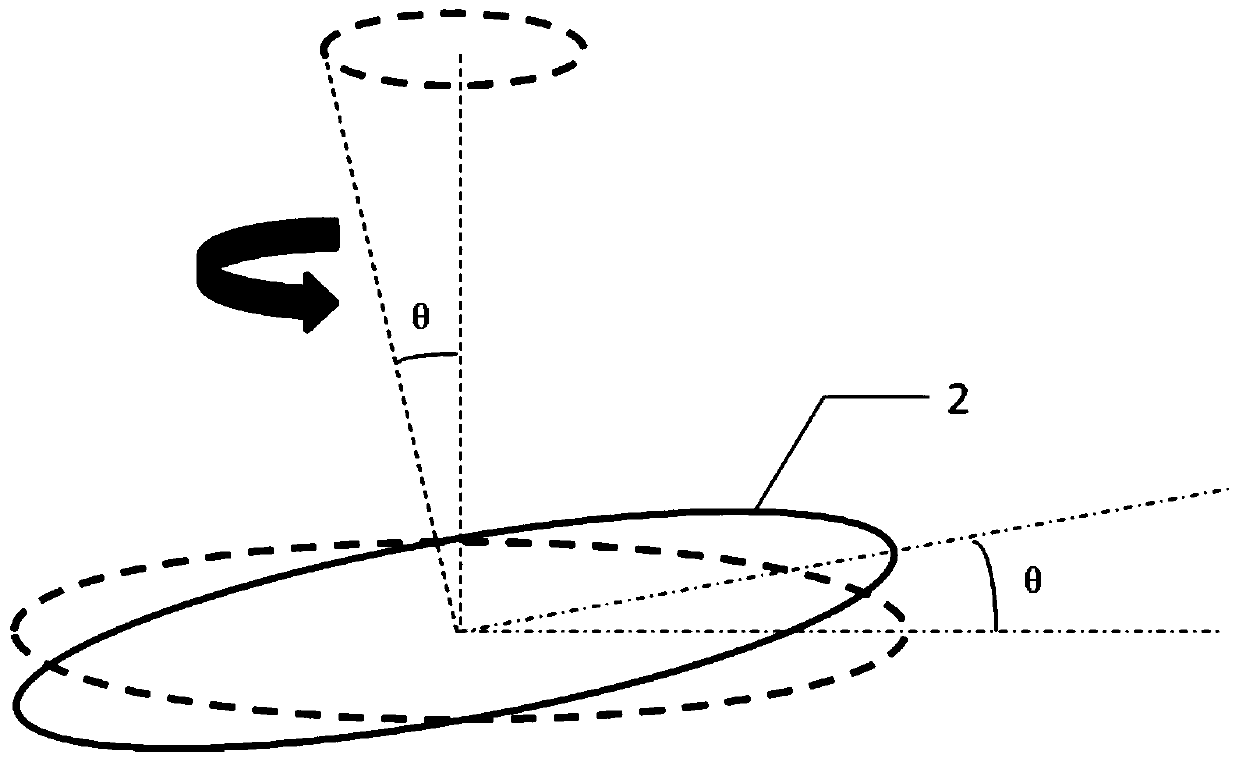

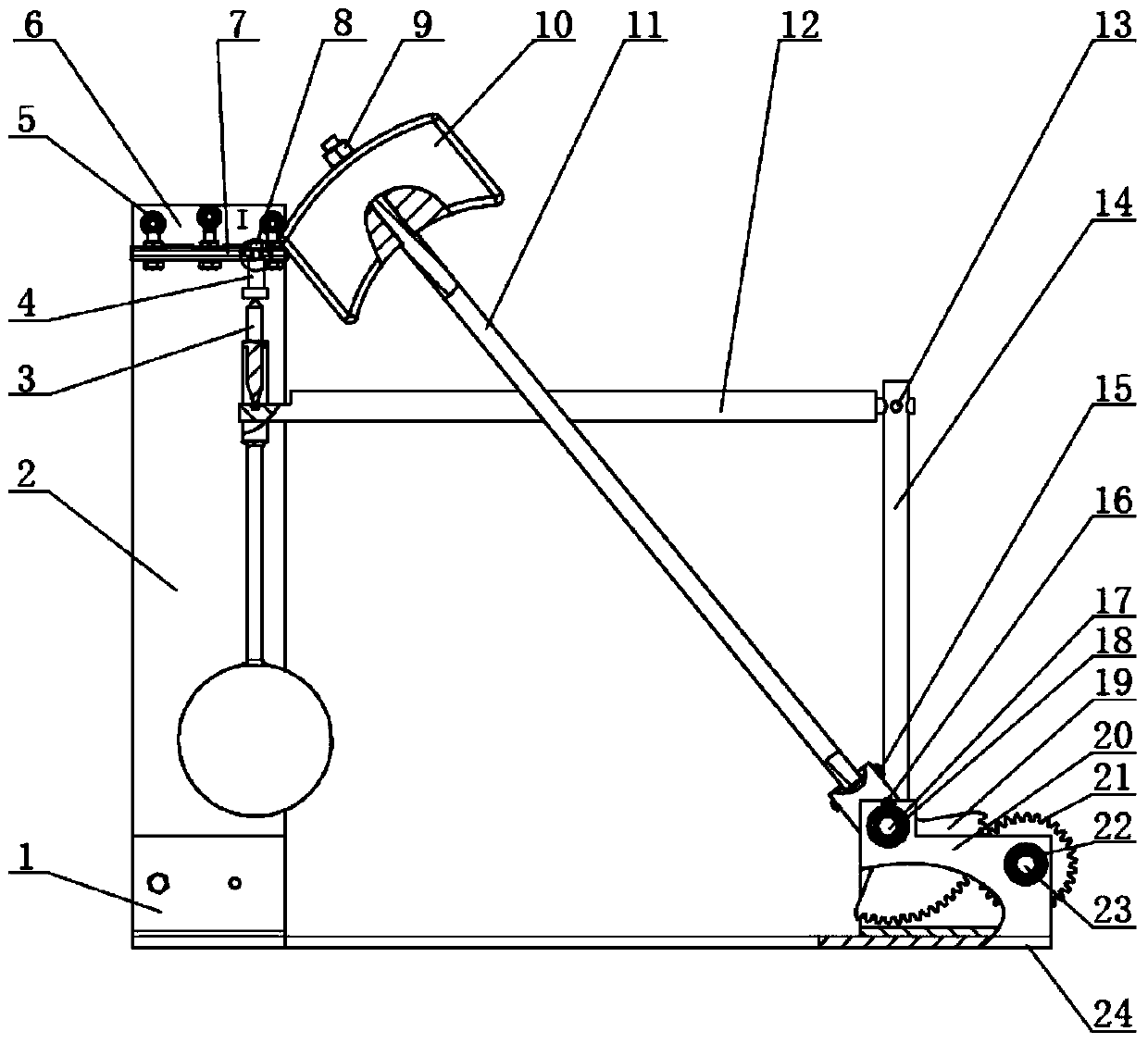

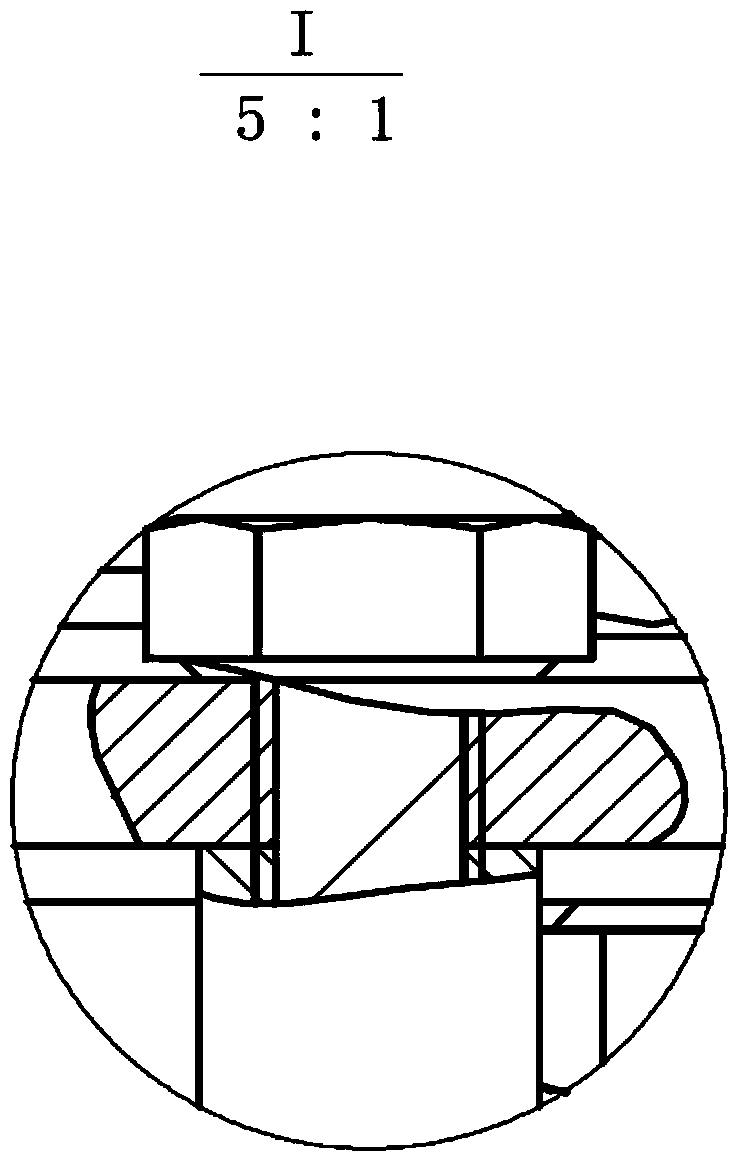

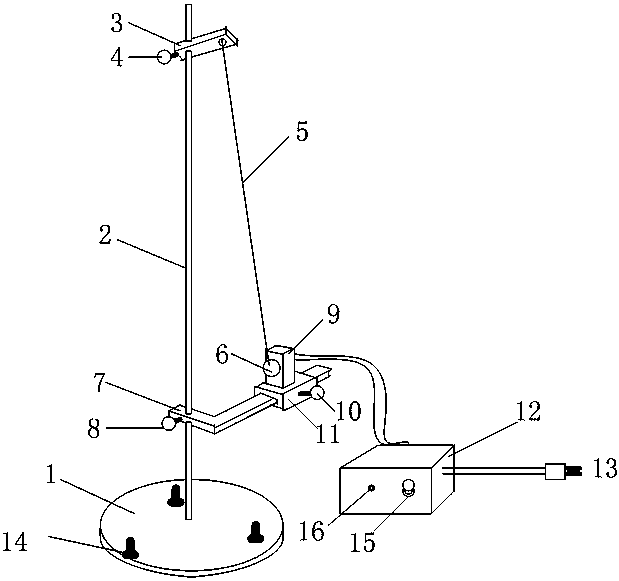

Method for measuring gravitational acceleration by using conical pendulum

InactiveCN104020504AGuaranteed uptimeMeasurement results have no effectEducational modelsGravitational wave measurementAerodynamic dragEngineering

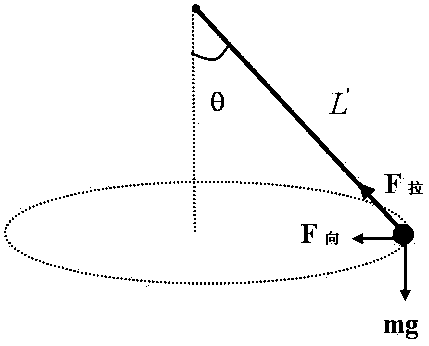

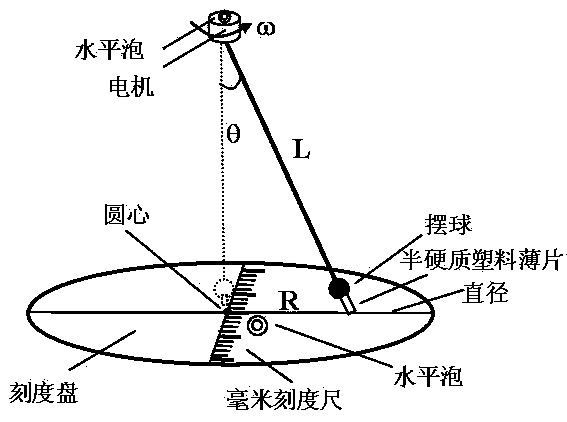

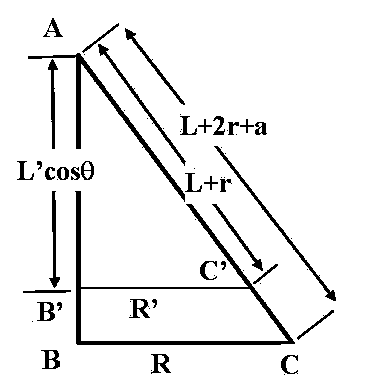

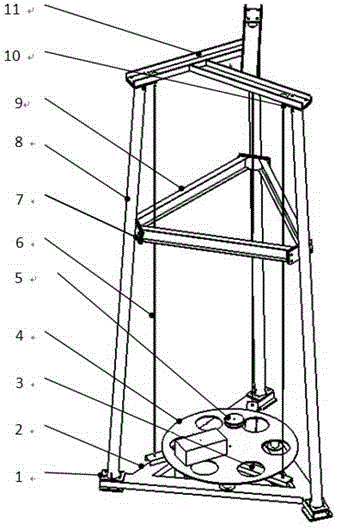

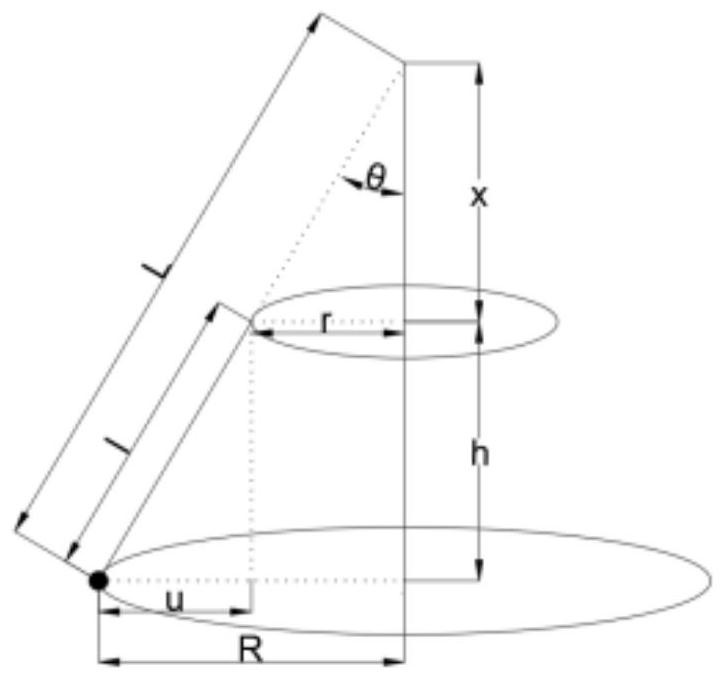

The invention provides a method for measuring gravitational acceleration by using a conical pendulum and relates to the field of physical parameter measurement. The method is novel for measuring the gravitational acceleration. According to the technical scheme, the length of a cycloid of a simple pendulum is L, the radius of a pendulum ball is r, and a semi-hard plastic sheet with the length a is fixed to the other side opposite to the cycloid in the diameter direction, where the cycloid is located, of the pendulum ball. The pendulum ball of the simple pendulum is driven by a rotating shaft to do the circular motion, the included angle theta of the cycloid and the vertical direction and a swing cycle T of the pendulum ball are measured, and thus the gravitational acceleration g=(2pi / T)2*L'cos theta, wherein pi=3.1415926. The method for measuring the gravitational acceleration by using the conical pendulum has the advantages that the novel method for measuring the gravitational acceleration is proposed, students are guided to correctly understand errors; compared with the mode that the inclination angle amplitude of the simple pendulum is gradually reduced due to air resistance, driving of a motor is adopted in the method, and stable operation at the constant speed can be ensured; the cyclic formula of the simple pendulum is an approximation, the inclination angle is required to be within five degrees, and the requirement is avoided in the method.

Owner:SICHUAN UNIV

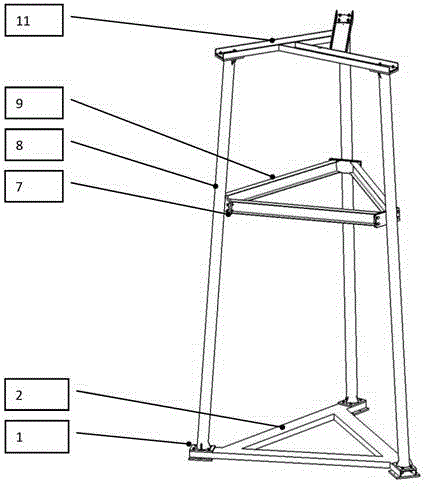

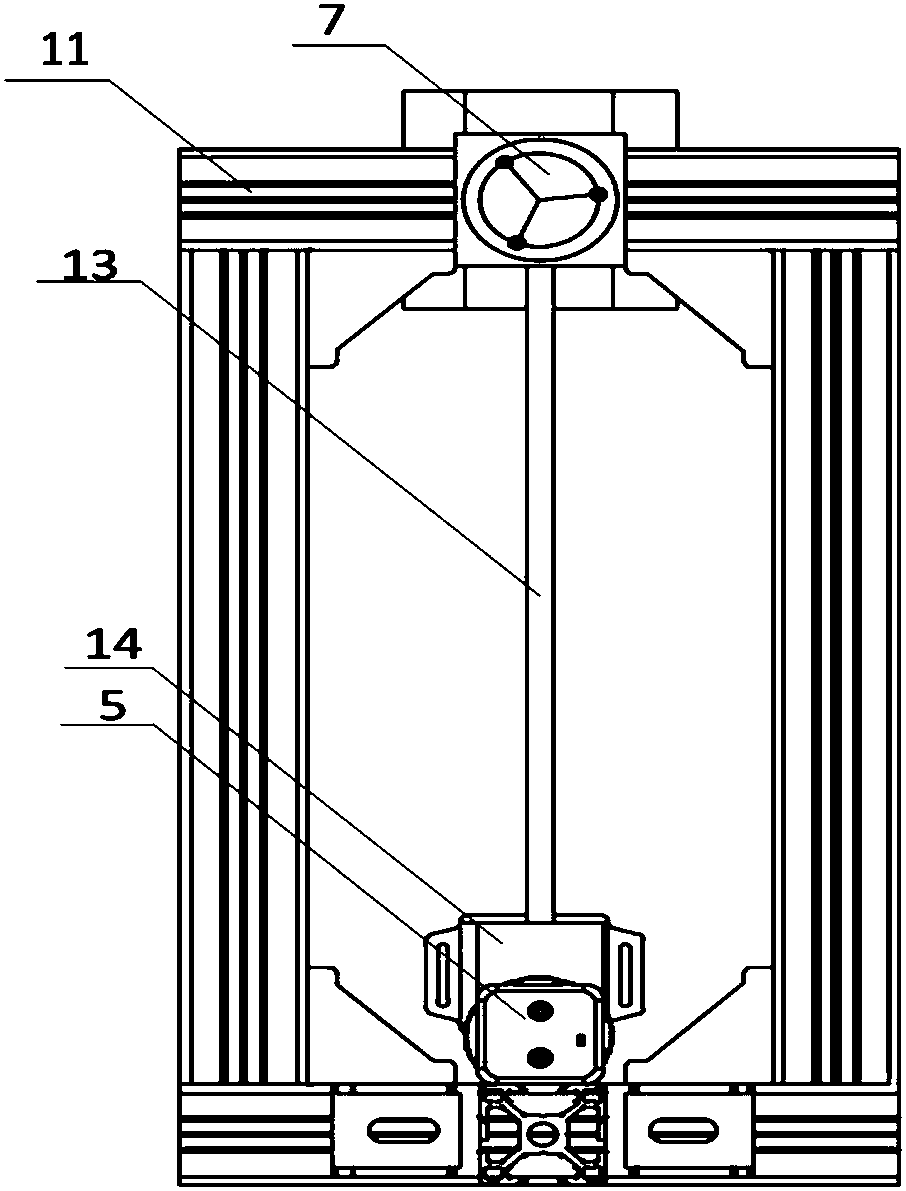

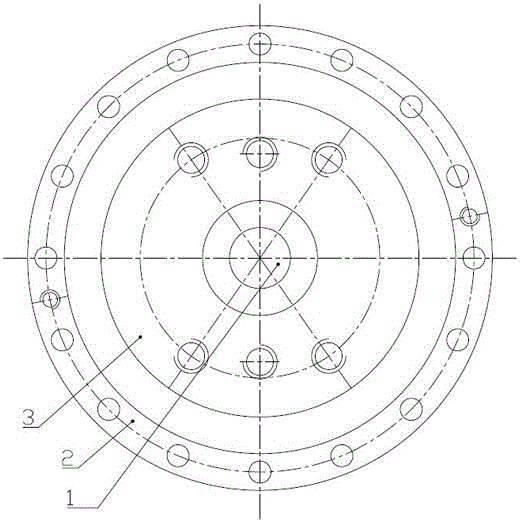

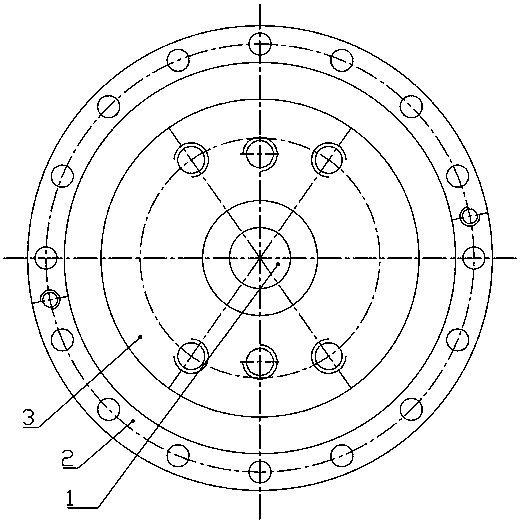

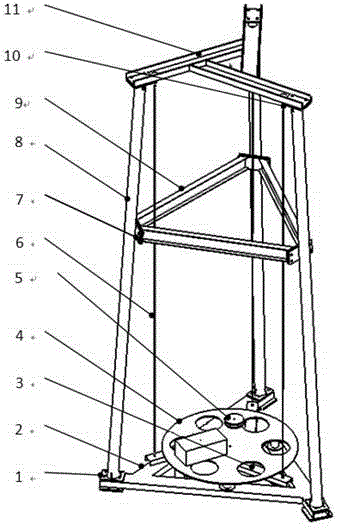

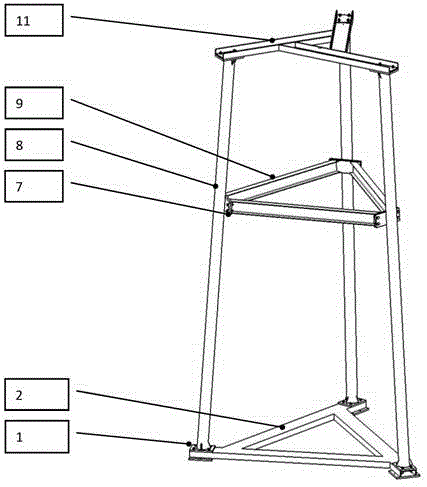

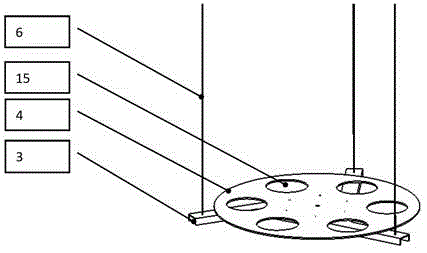

Three-wire torsional pendulum method rigid body dynamic parameter test console

ActiveCN103148984AConvenient for repeated liftingEasy to placeStatic/dynamic balance measurementJackscrewEngineering

The invention provides a three-wire torsional pendulum method rigid body dynamic parameter test console which comprises a test console chassis, a cycloid curve and a tray and is characterized in that a lifting device and a centering device are arranged on the test console chassis, wherein the lifting device comprises three jacks; the jacks are circumferentially and uniformly distributed through taking the center of the chassis as the center of a circle; the centering device is positioned at the center of the chassis and comprises a jack and a centering shaft; and the centering shaft is installed at the upper end of a jack piston in the centering device and ascends or descends along with the piston. The three-wire torsional pendulum method rigid body dynamic parameter test console has the beneficial effects that through the lifting device of the test console, the tray can be conveniently and repeatedly lifted for multiple times, measured objects are convenient to put, load and unload, the tray can be fixedly arranged and put in a non-test state, and the service lives of the cycloid curve and the sensor can be prolonged; and through the centering device, the tray can be enabled to carry out pure torsion vibration around a central lead vertical axis without generating mixed pendulum or conical pendulum movement, so that the measurement precision and the measurement efficiency are improved.

Owner:UNIV OF SCI & TECH BEIJING

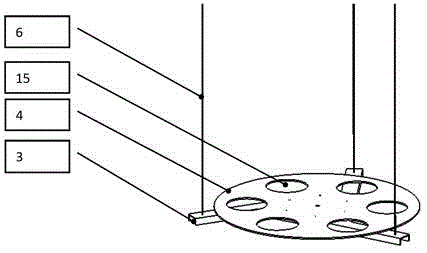

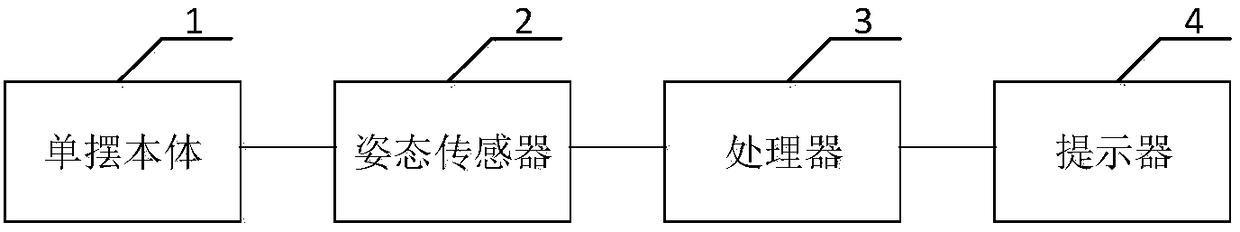

Simple pendulum system

PendingCN108492685AImprove accuracyHigh degree of automationEducational modelsBody measureConical pendulum

The invention discloses a simple pendulum system. The system comprises a simple pendulum body, an attitude sensor, a processor and a prompting device. The simple pendulum body is connected to the attitude sensor. The processor is connected to the attitude sensor and the prompting device. The processor is used to prompt the three-dimensional motion attitude of the single pendulum body measured by the attitude sensor during moving through the prompting device. In the invention, the processor can prompt the three-dimensional motion attitude of the single pendulum body measured by the attitude sensor during moving through the prompting device; compared with naked eye observation, the three-dimensional motion attitude of the single pendulum body measured by the attitude sensor during moving canbe used to greatly improve the accuracy of judgment; and a user can learn and know a conical pendulum phenomenon and an automation degree is increased.

Owner:GUANGDONG UNIV OF TECH

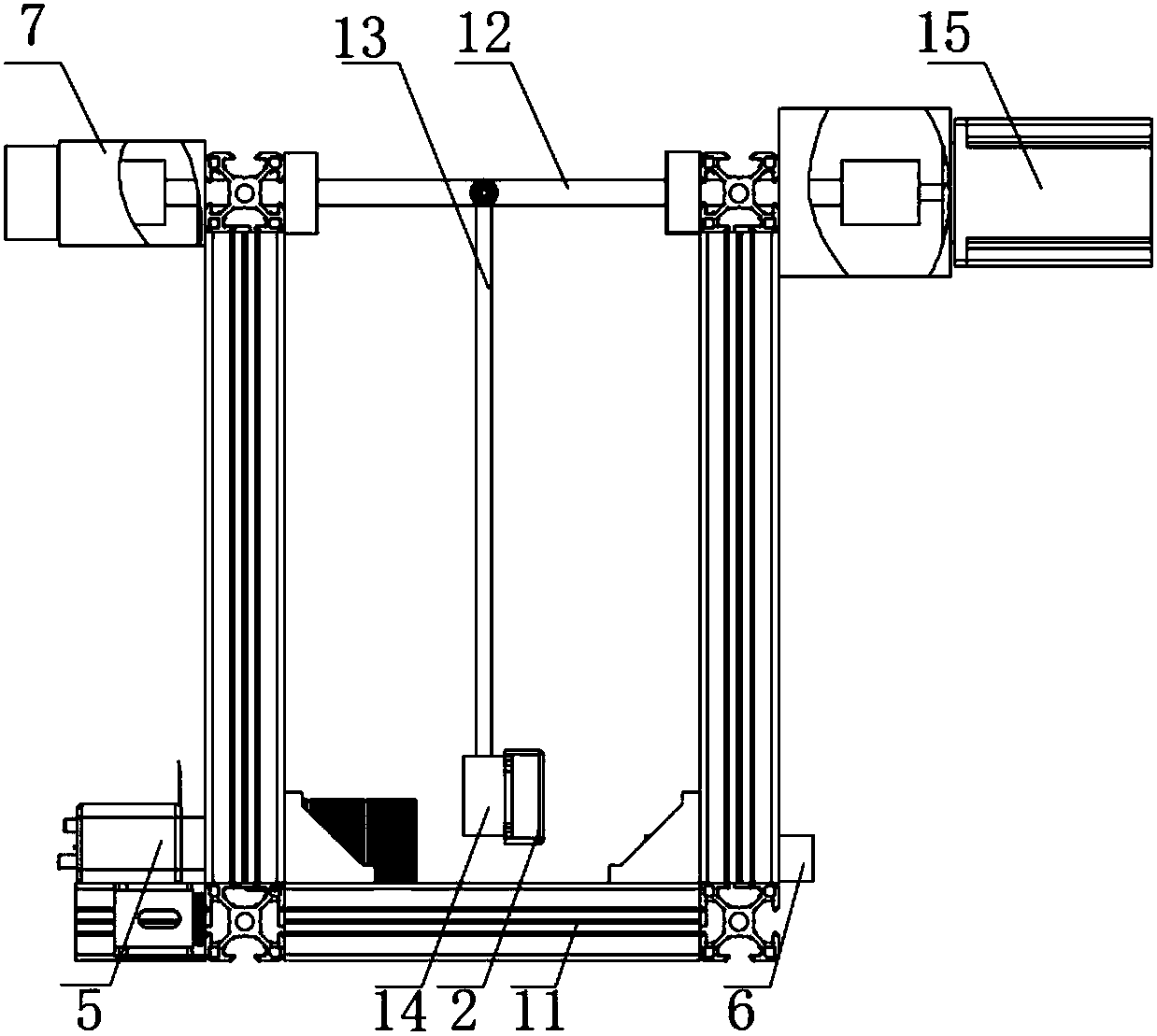

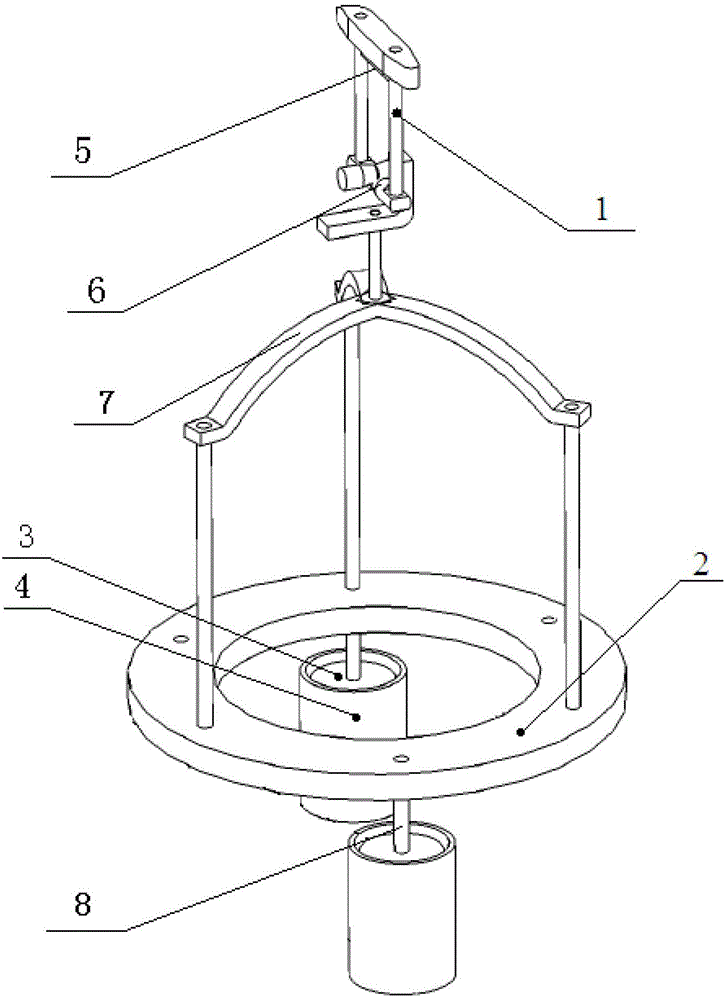

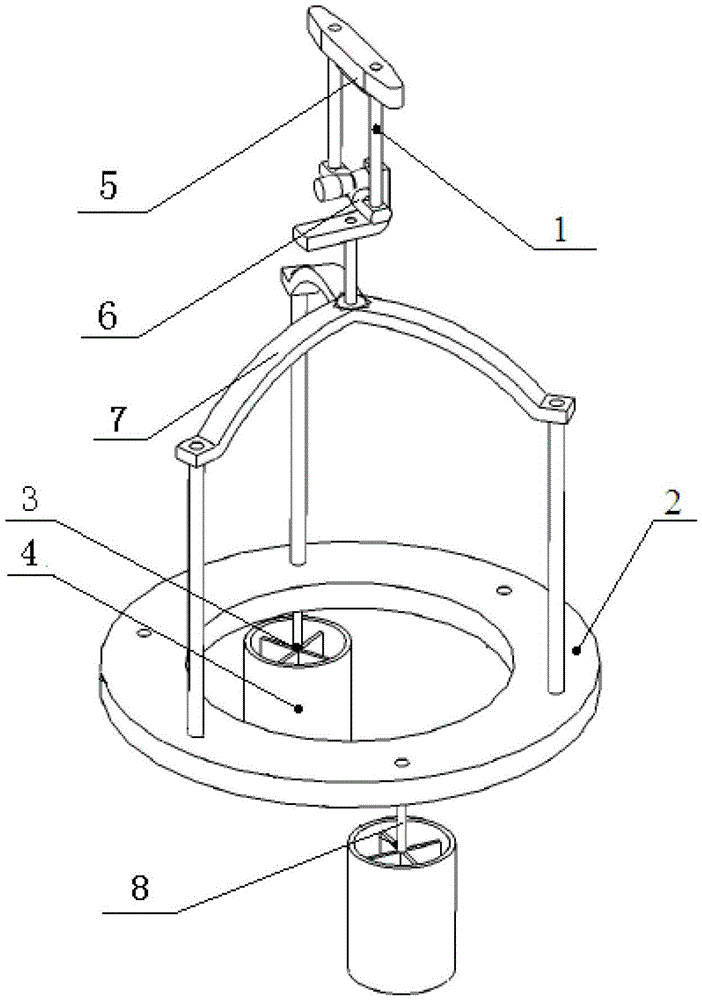

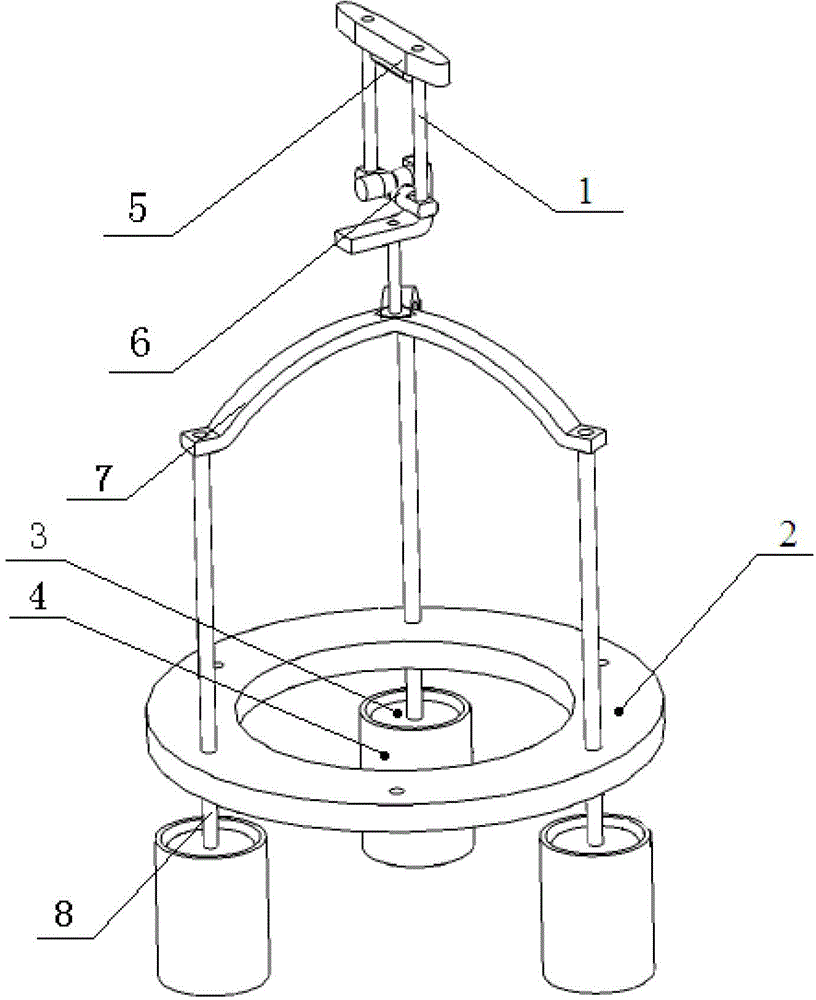

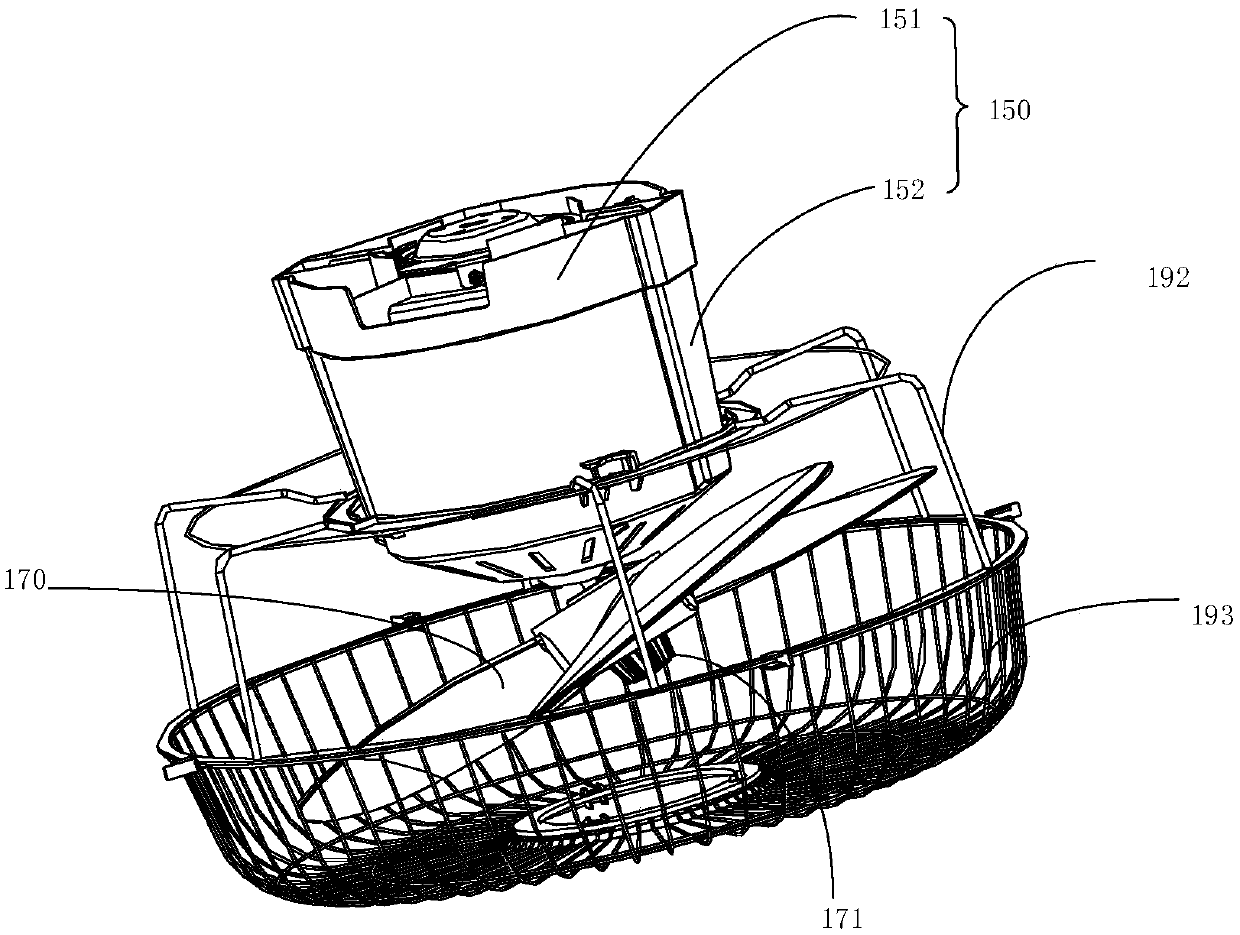

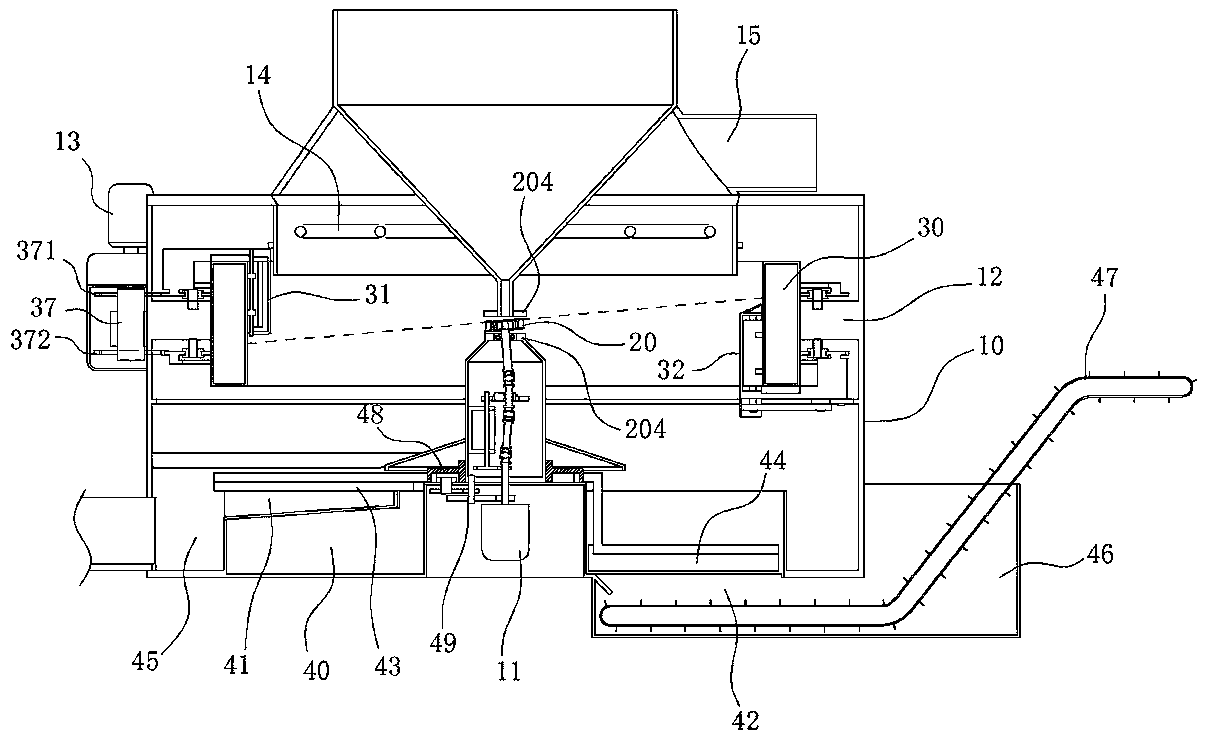

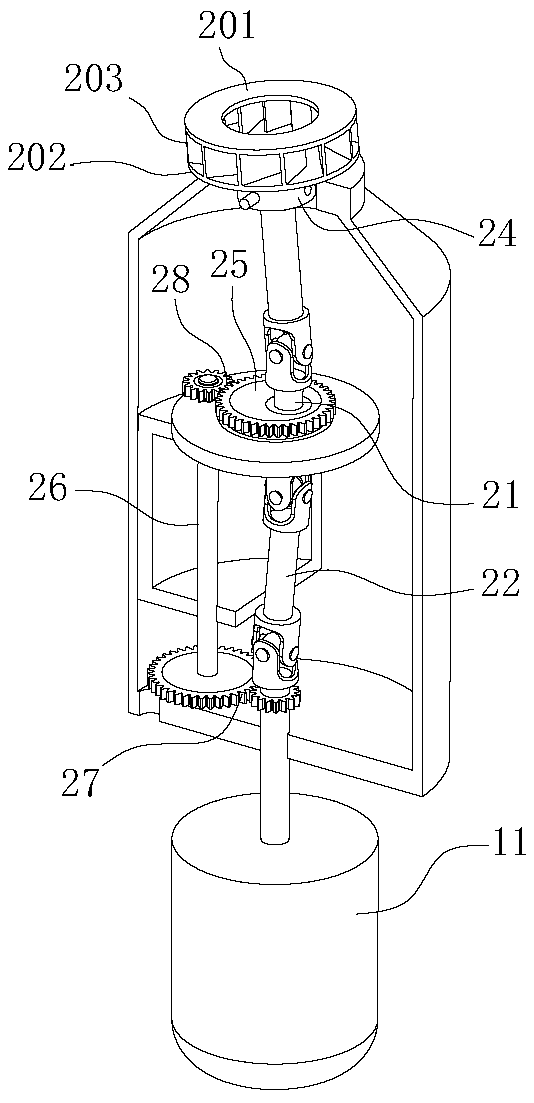

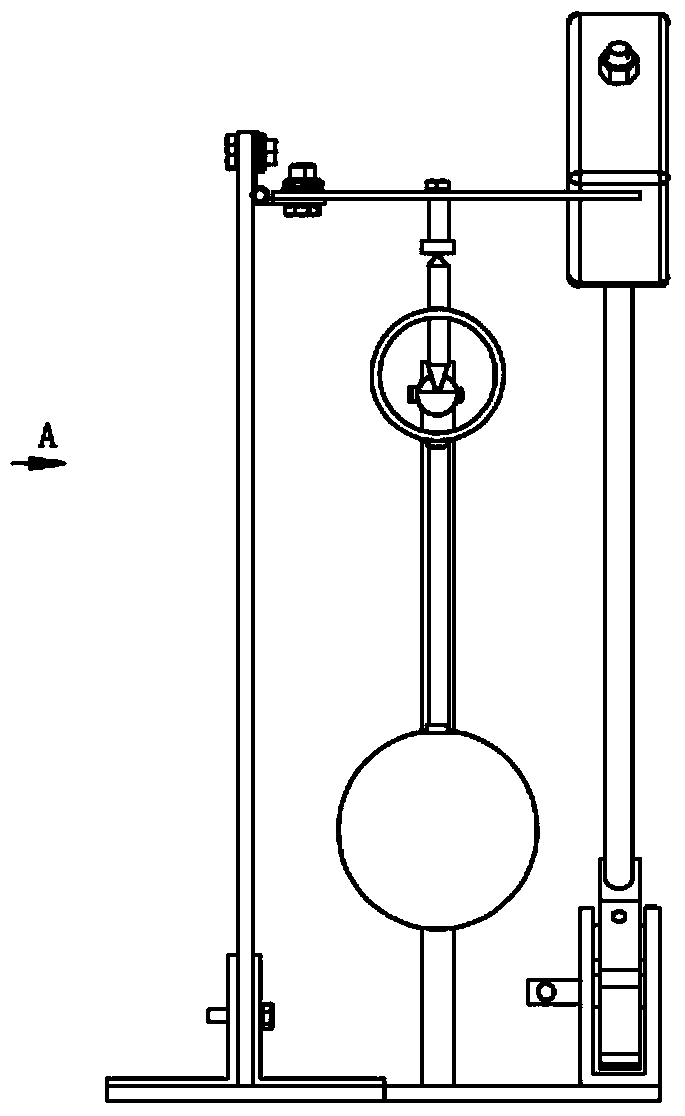

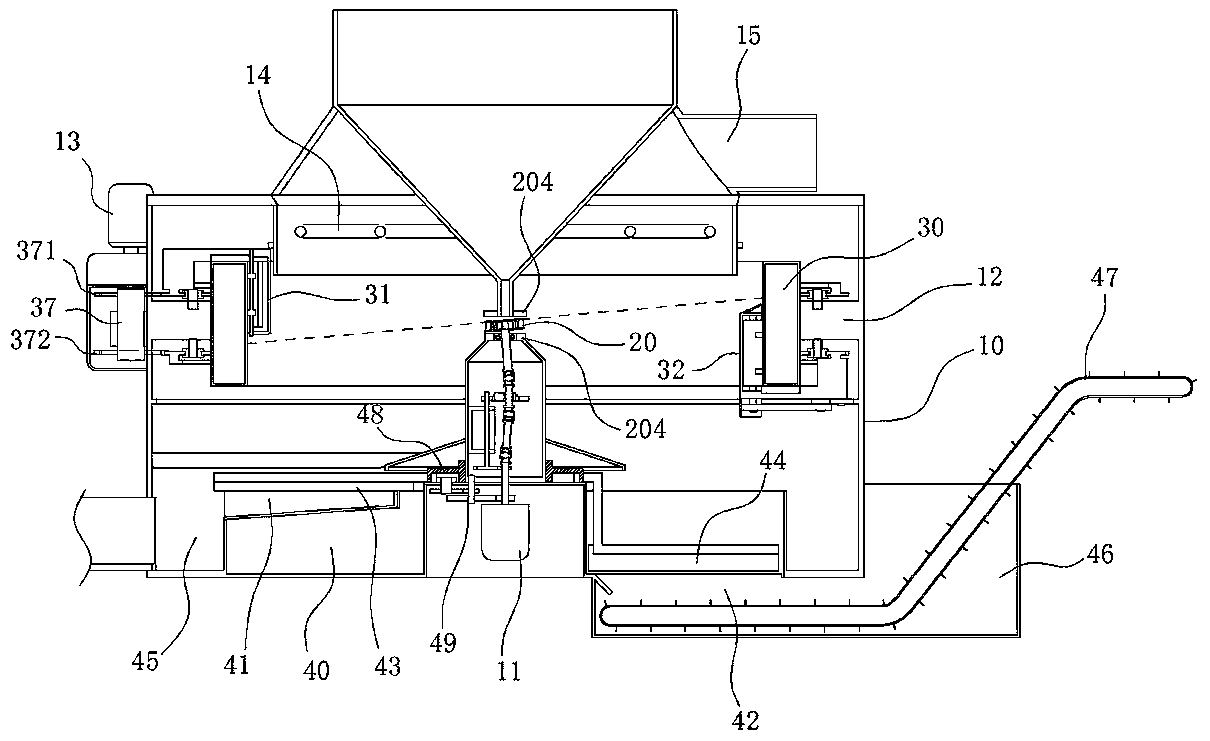

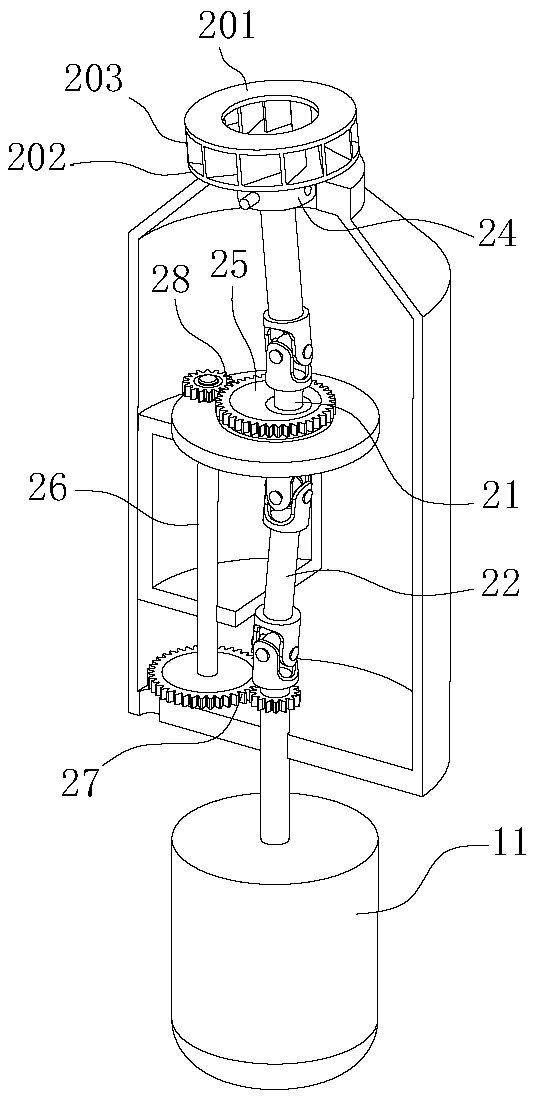

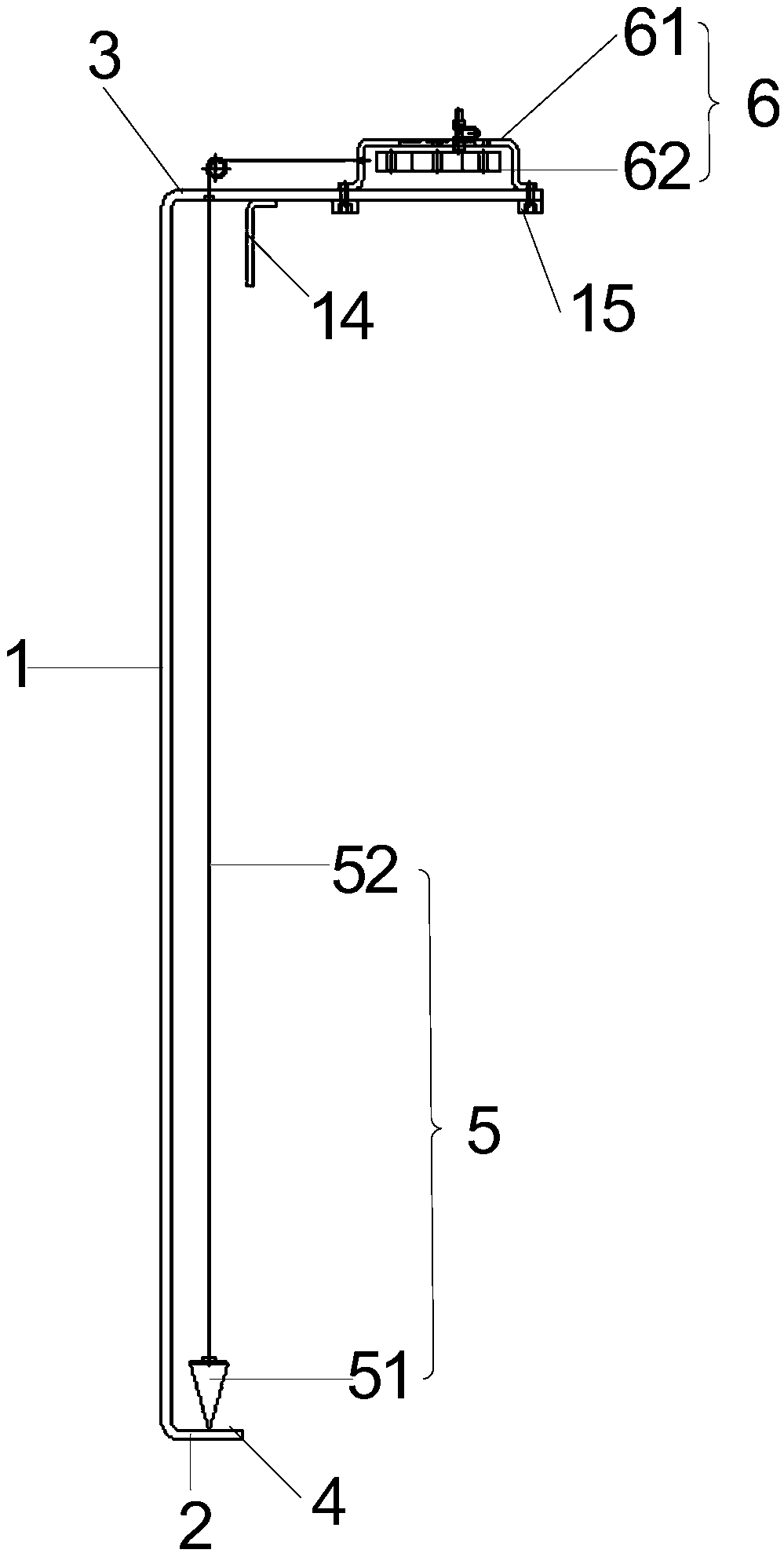

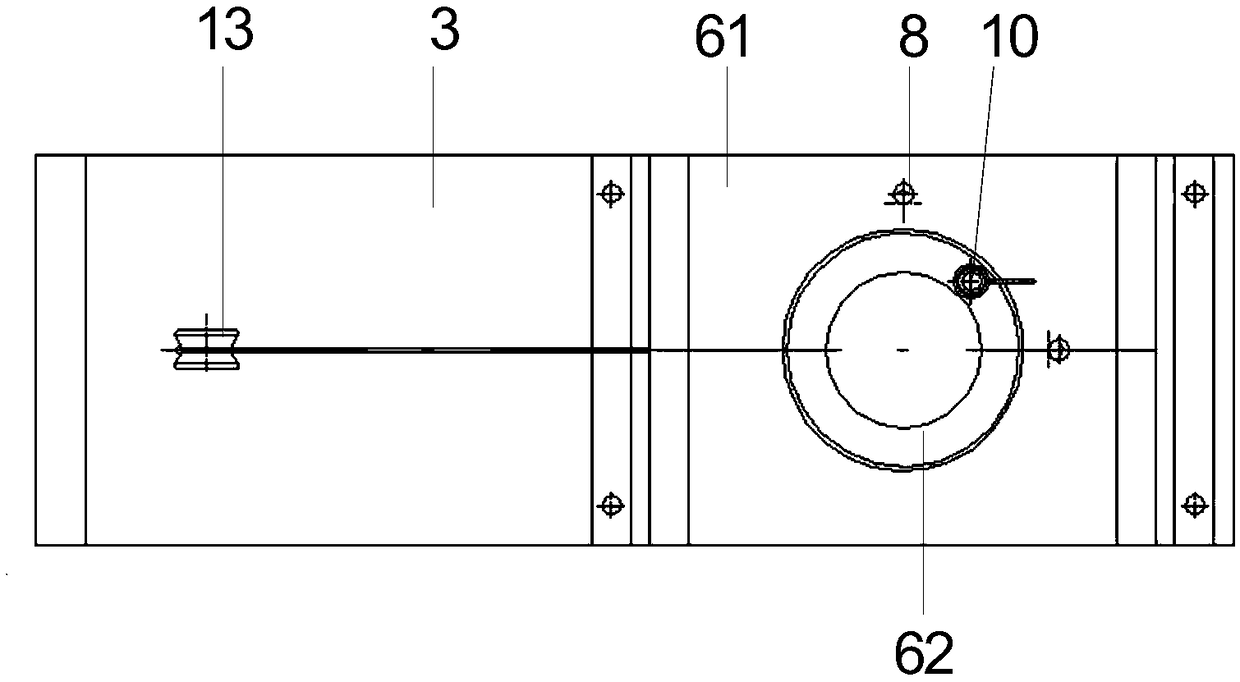

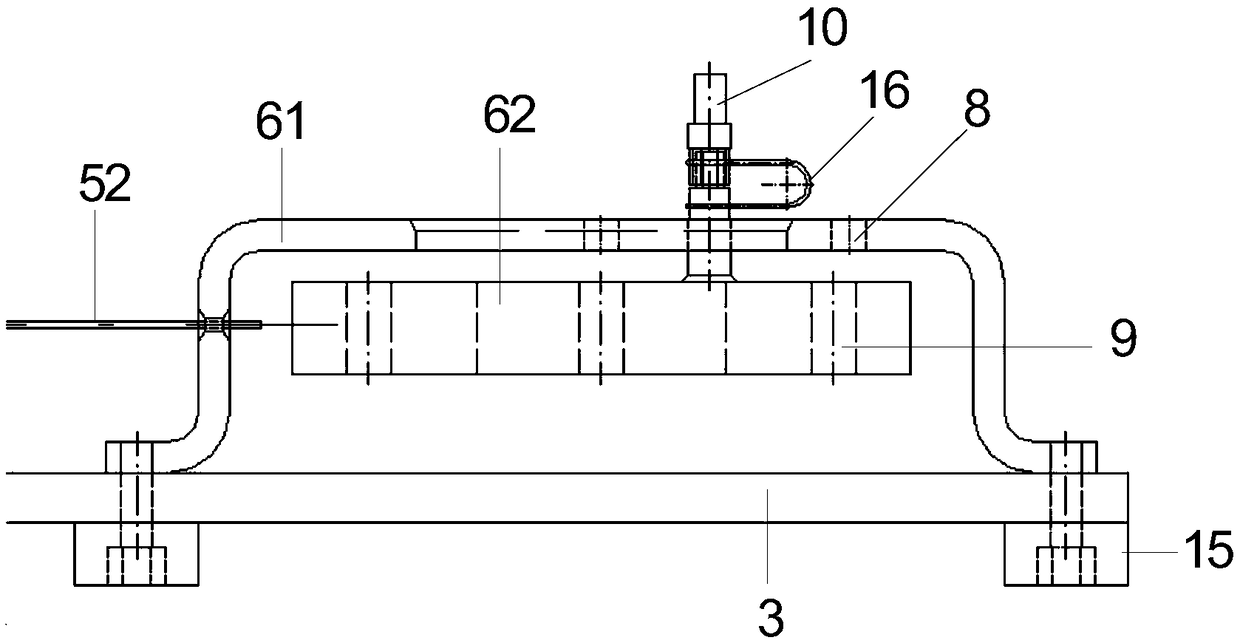

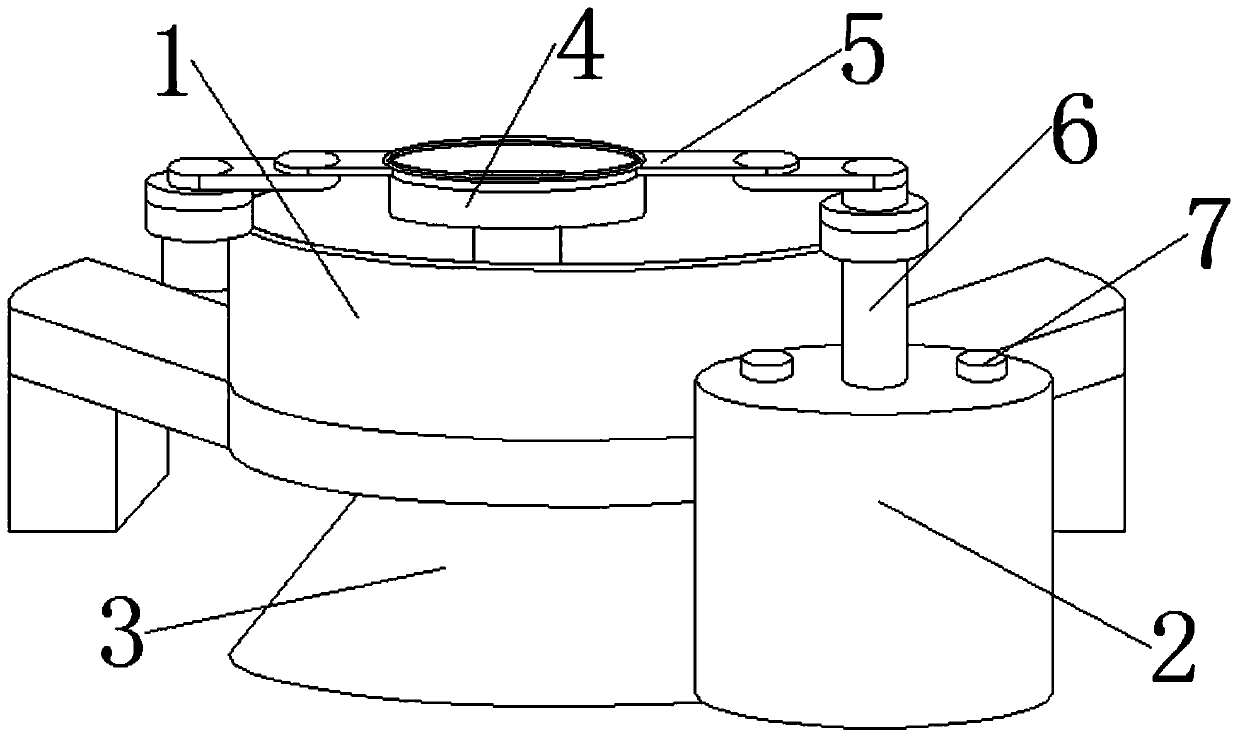

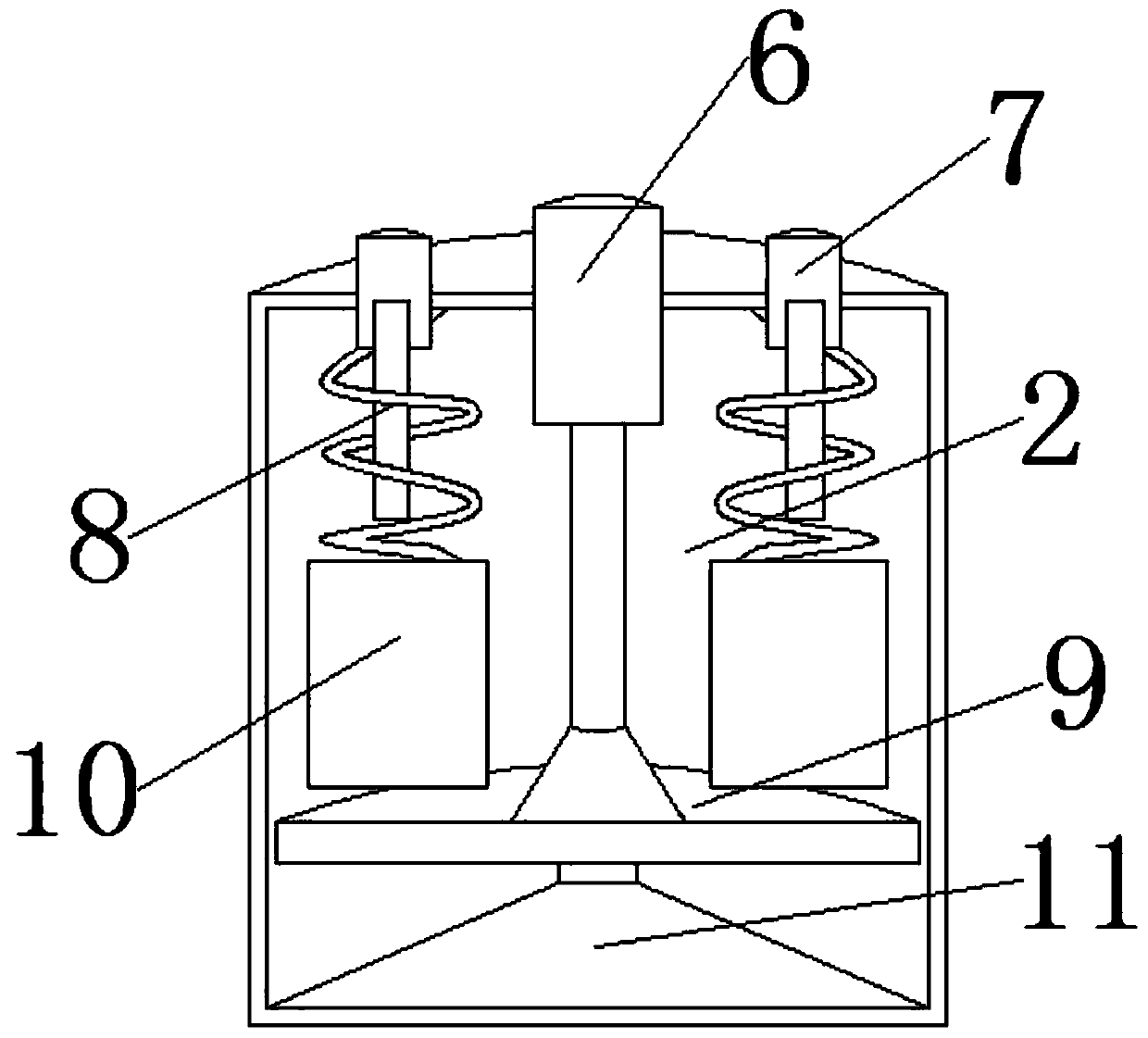

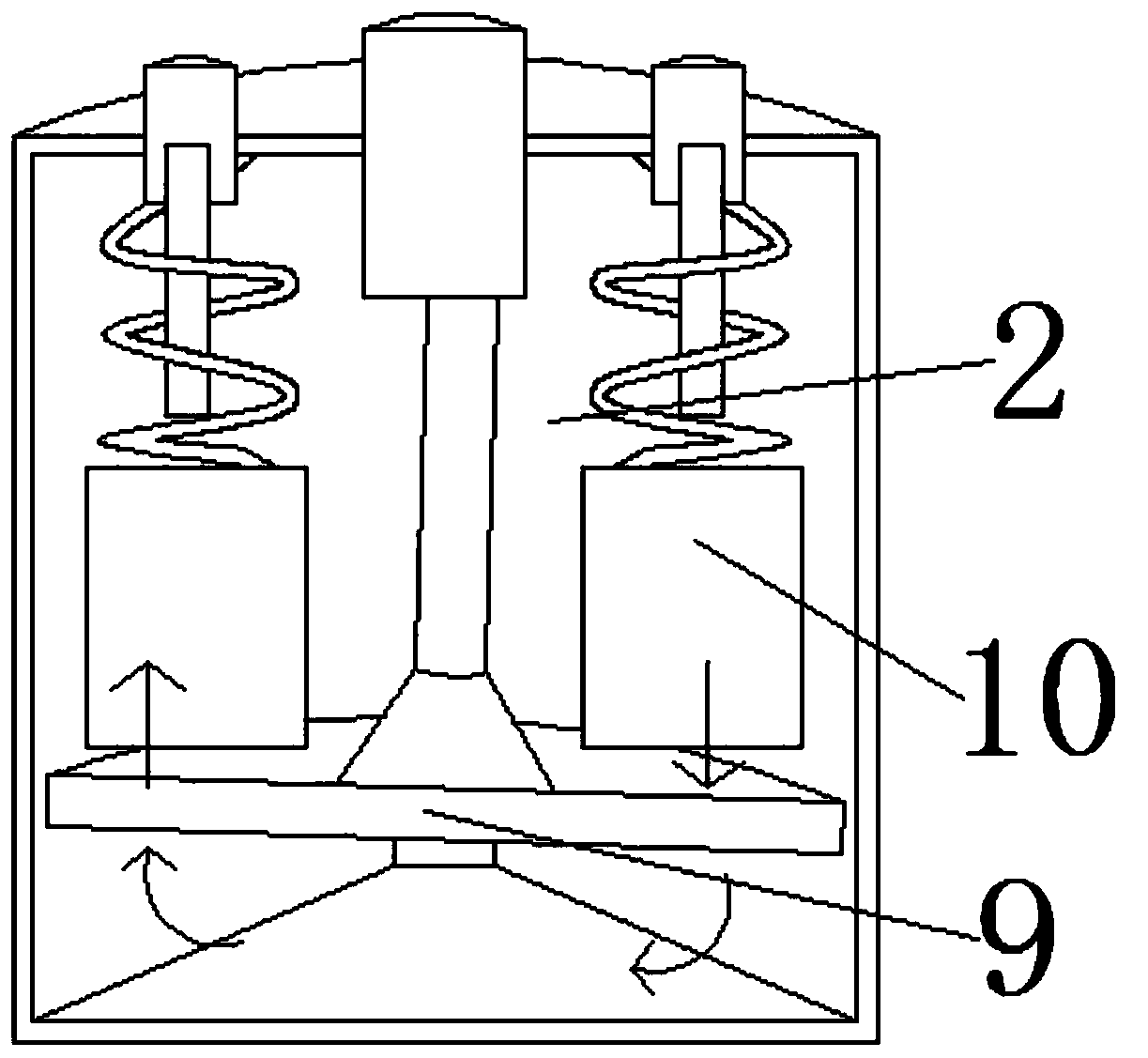

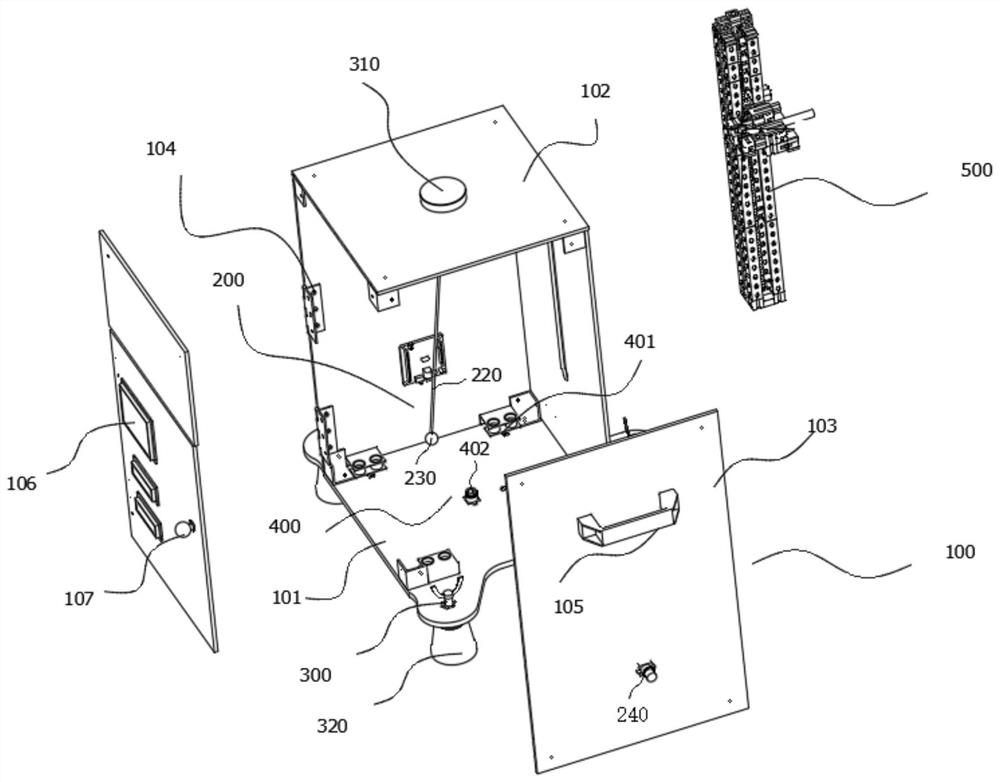

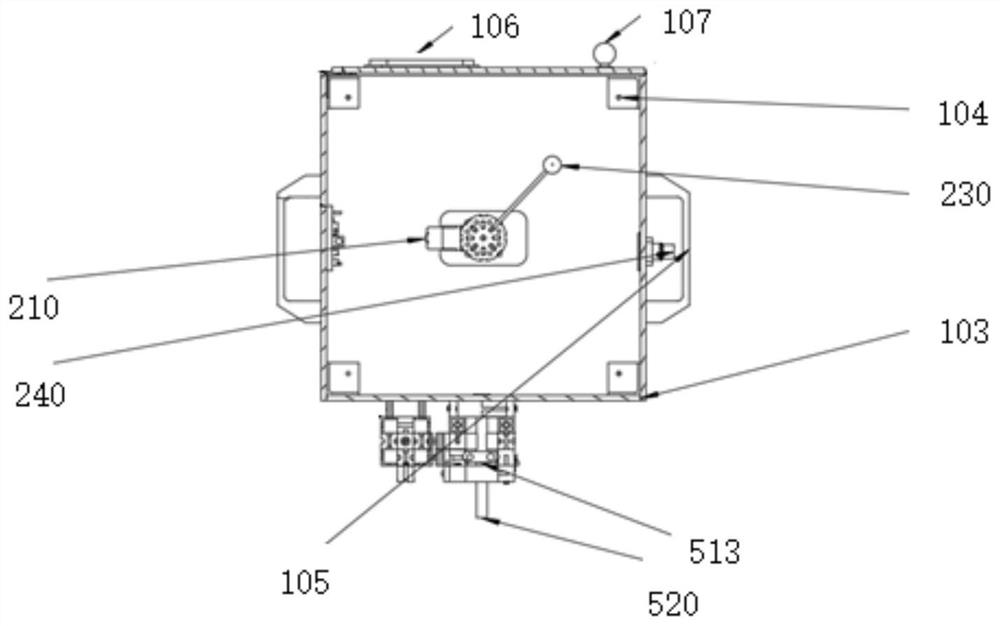

Sample uniform mixing mechanism

ActiveCN113588393AMixing to achieveImprove mixing efficiencyRotating receptacle mixersShaking/oscillating/vibrating mixersEngineeringConical pendulum

The invention discloses a sample uniform mixing mechanism, which comprises a support, wherein the support is provided with a sample container seat used for placing a sample container; and a uniform mixing driving mechanism, which is used for driving the sample container to do conical pendulum motion. The mechanism also comprises an anti-rotation mechanism used for preventing the sample container from rotating around the axis of the sample container in the process of performing the conical pendulum motion. According to the sample uniform mixing mechanism disclosed by the invention, the uniform mixing driving mechanism is arranged to drive the sample container to do the conical pendulum motion, so that samples in the sample container generate eddy current to realize sample mixing, but if the sample container rotates in the conical pendulum motion process, the eddy current may be weakened or even cannot be generated, the uniform mixing effect is reduced, and even the samples cannot be uniformly mixed; by arranging the anti-rotation mechanism, the sample container can be prevented from generating rotation or only generating slight rotation in the process of performing conical pendulum motion, so that eddy current in the sample container is not influenced by rotation, and the sample uniform mixing efficiency and the uniform mixing effect can be effectively improved.

Owner:ZYBIO INC

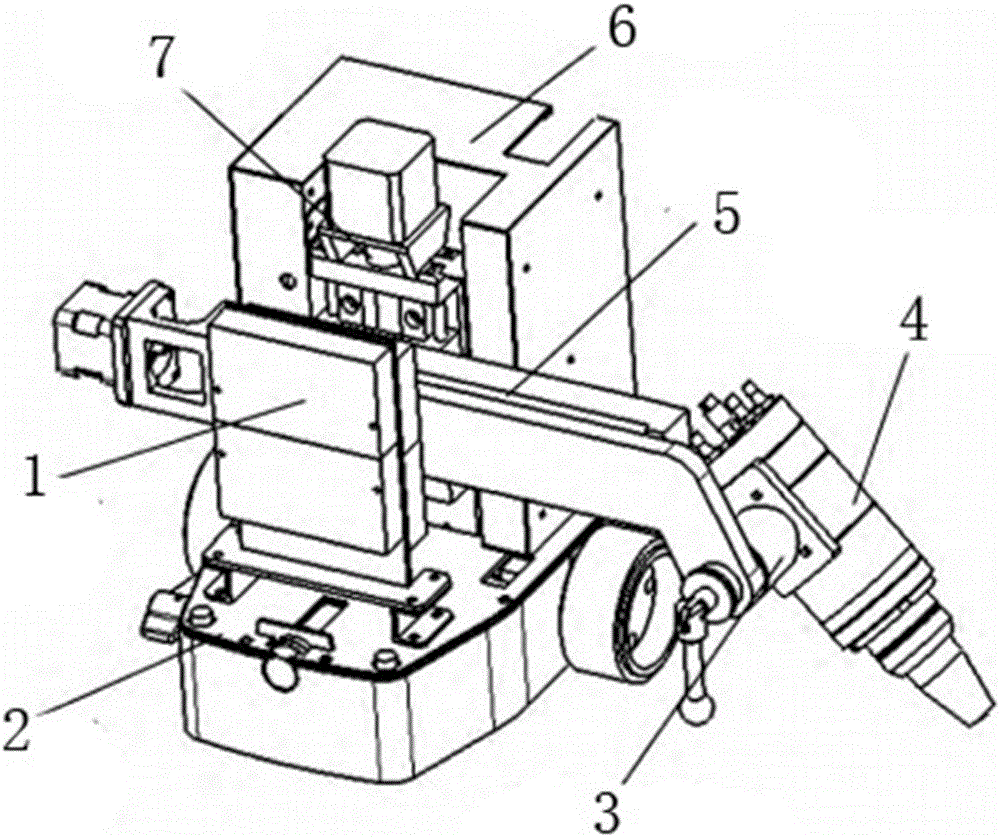

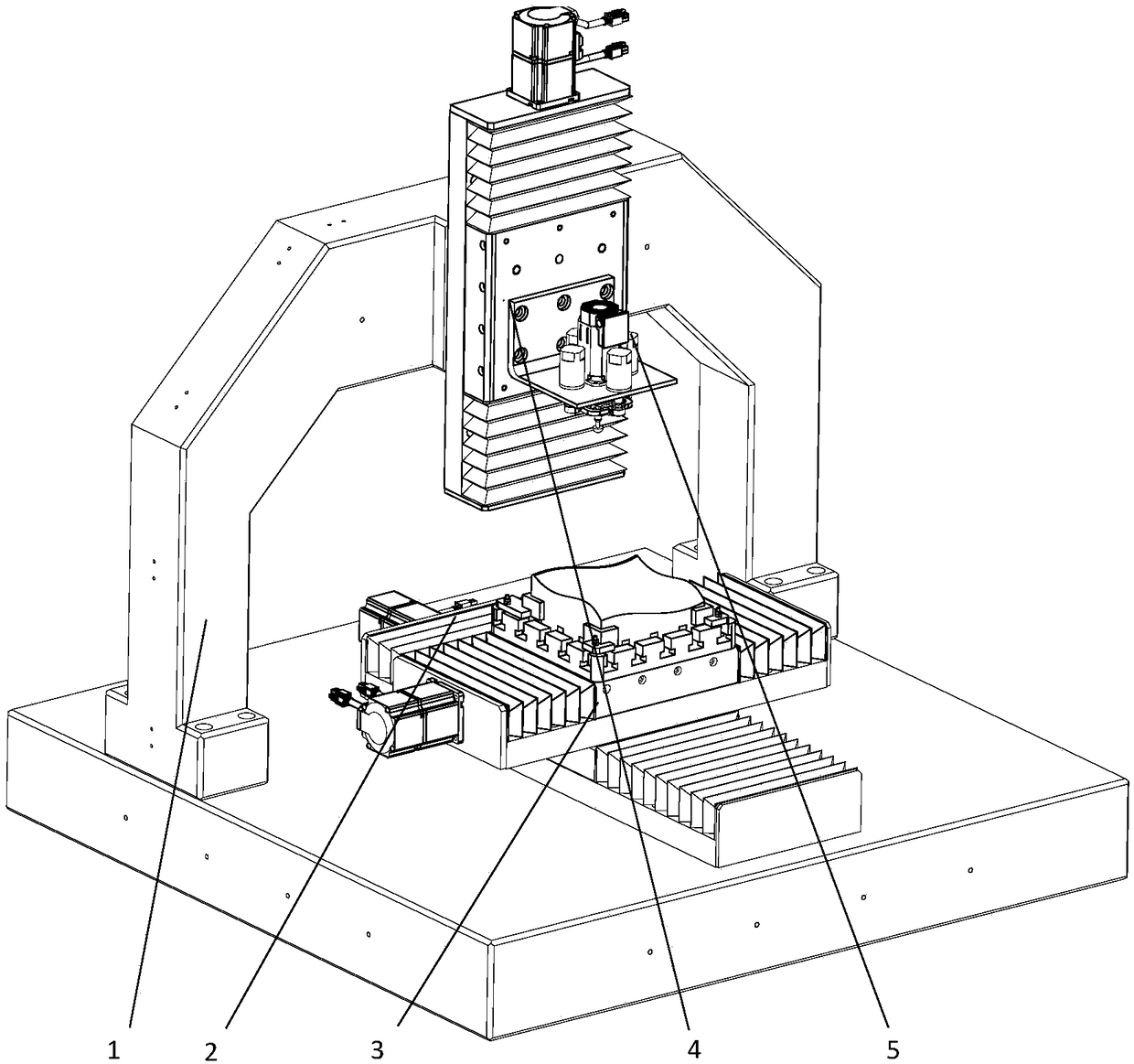

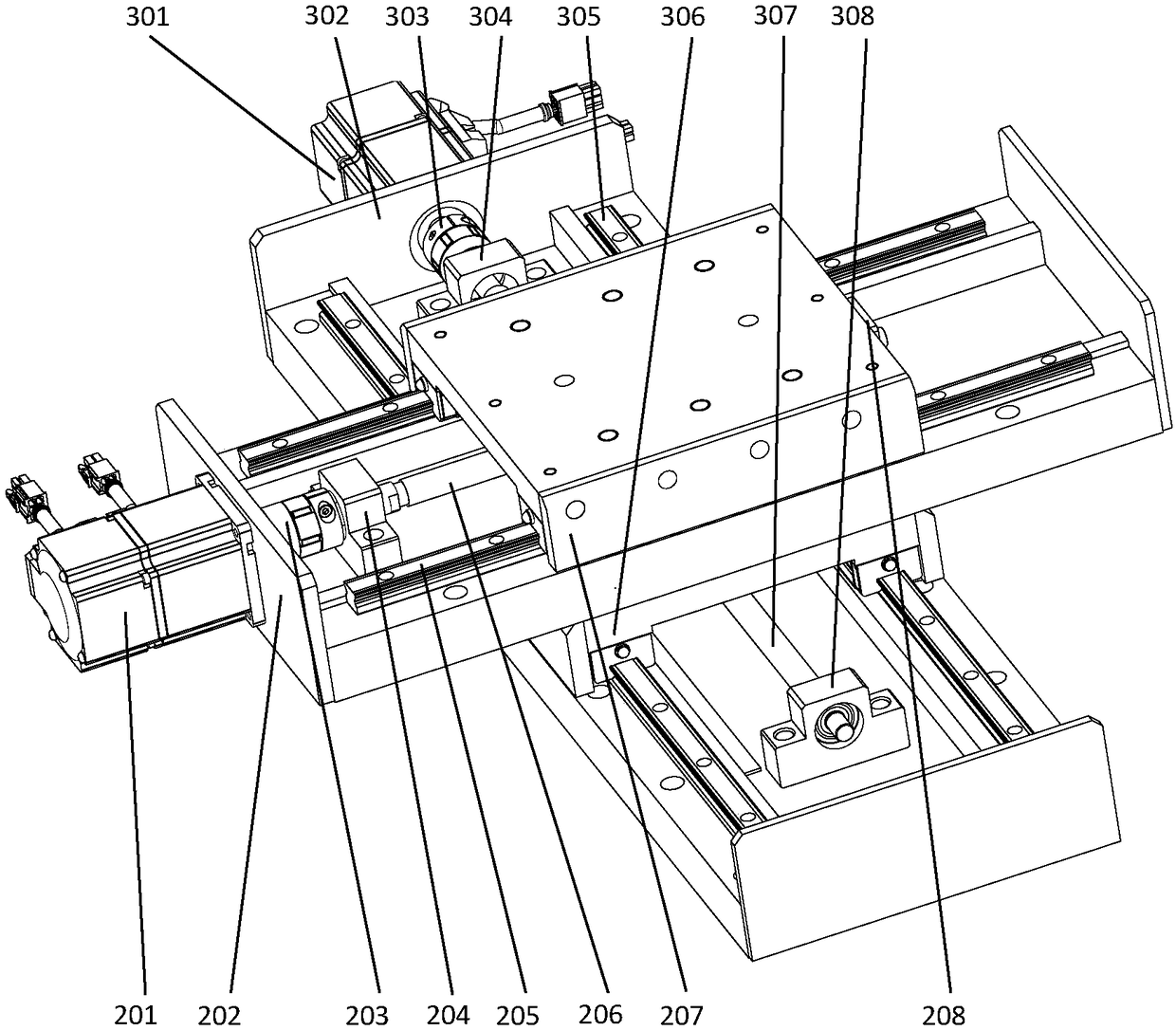

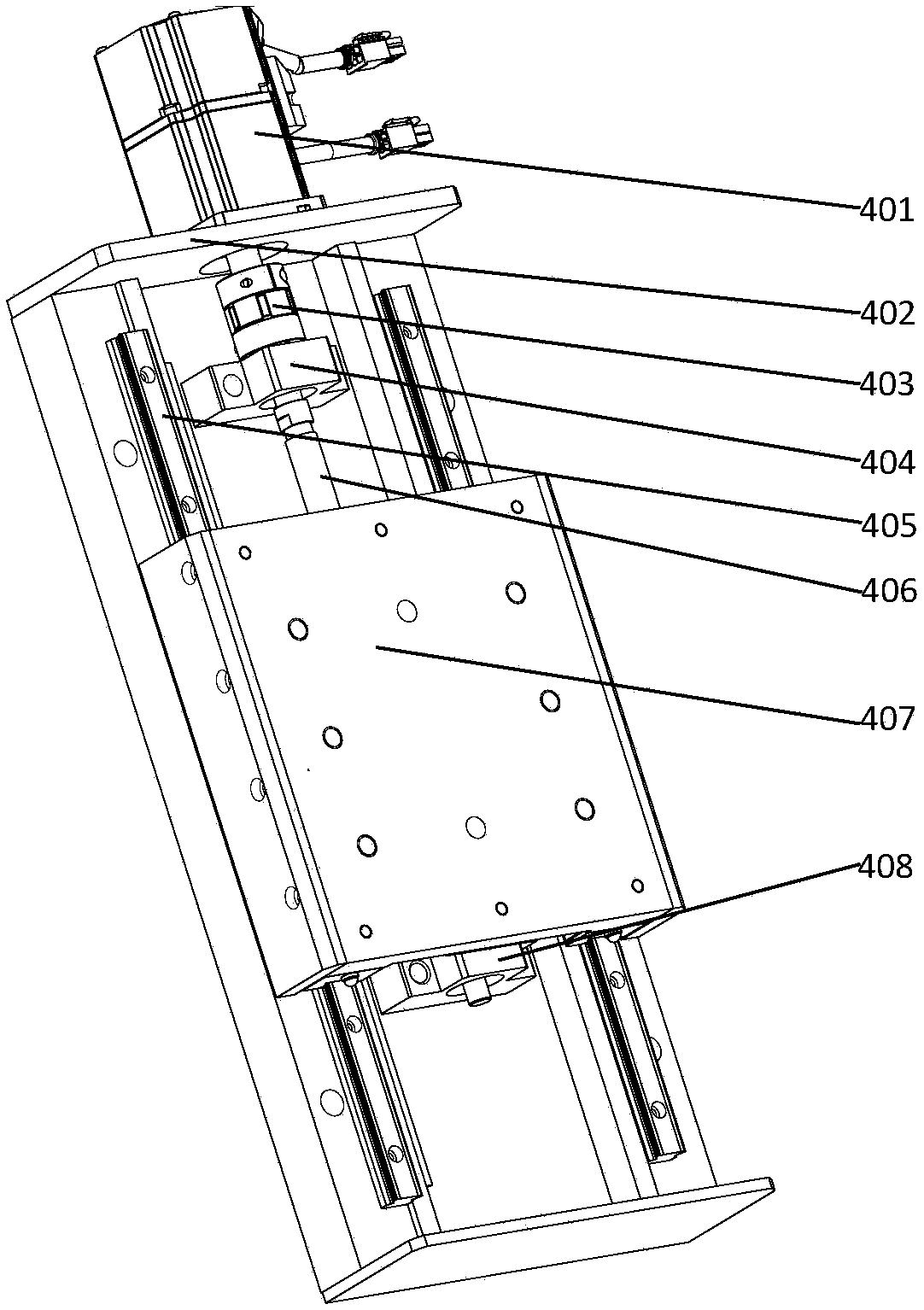

Multifunctional supersonic vibration auxiliary machining machine tool and control method thereof

ActiveCN108436490AAchieve axial vibrationIncrease productivityAutomatic control devicesFeeding apparatusEngineeringUltrasonic vibration

The invention relates to a multifunctional supersonic vibration auxiliary machining machine tool and a control method thereof. Compared with an ordinary machining mode, supersonic vibration auxiliarymachining can effectively reduce cutting force, reduce tool abrasion, improve the surface machining precision of workpieces, improve the machining efficiency and the like. Most of traditional supersonic vibration is in a single vibration mode, with continuous expansion of the application fields of a supersonic vibration auxiliary machining technology, traditional supersonic vibration auxiliary machining machine tools cannot meet the actual production requirements, and in order to solve the problems, the multifunctional supersonic vibration auxiliary machining machine tool and the control method thereof can achieve axial vibration, circumferential vibration, conical pendulum vibration and tool rotary speed fluctuation at the same time, provide convenience for further using supersonic vibration auxiliary machining to reduce cutting force and improve the machining efficiency in the cutting process, and have great application value.

Owner:JILIN UNIV

Window breaker

InactiveCN105752017ANot easy to loseImprove reliabilityPedestrian/occupant safety arrangementConical pendulumOperating time

The invention relates to a window breaker, which comprises a window breaker box, a conical pendulum hammer, an elastic device and a trigger switch, wherein the elastic device can be used for enabling the conical pendulum hammer to rotate; the trigger switch is used for limiting and triggering the rotation of the conical pendulum hammer; the conical pendulum hammer and the elastic device are arranged in the window breaker box; the trigger switch is arranged outside the window breaker box; one end of the conical pendulum hammer is connected with the elastic device; the other end of the conical pendulum hammer is connected with the trigger switch; one side, which is close to a glass window, of the window breaker box is provided with a window breaking hole through which the conical pendulum hammer can pass. The window breaker has the characteristics that the loss is difficult, the reliability is good, the repeated percussion can be carried out, the operation is convenient, and further, the operating time is short.

Owner:XIAN BLUE DIAMOND ELECTRONICS

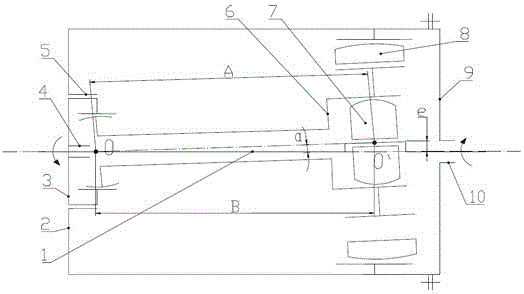

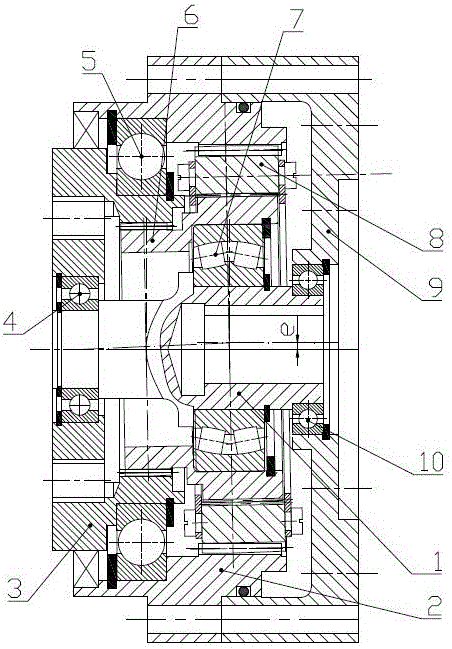

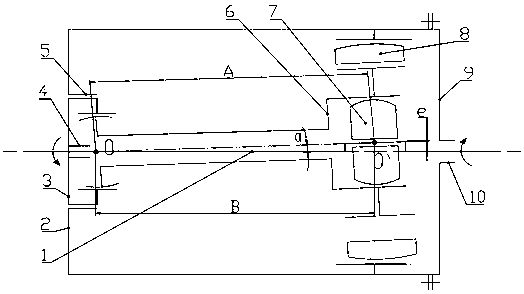

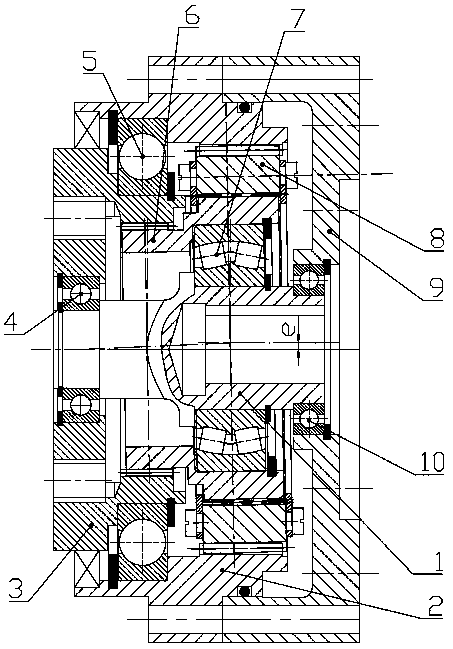

Conical pendulum type few tooth difference speed reduction device

The invention relates to a conical pendulum type few tooth difference speed reduction device. The conical pendulum type few tooth difference speed reduction device is characterized in that an output disc with a tooth ring on the inner side is arranged on one side of a machine shell through a bearing, the other side of the machine shell is provided with a fixing tooth ring and connected with a connection base, a tooth-ring gear is arranged in the fixing tooth ring, and an oscillating zero tooth difference gear coupler is formed by the tooth-ring gear and the fixing tooth ring; an input bent axle is arranged in the center of the machine shell, the two ends of the input bent axle transversely penetrate the machine shell and are borne by a center bearing of the output disc and a center bearing of the connecting base, and an eccentric shaft of the input bent axle is provided with an oscillating duplex gear through a self-aligning roller bearing; and one end of the duplex gear is engaged with a tooth ring of the tooth-ring gear to form a few tooth difference planetary transmission gear pair, and the other end of the duplex gear is matched with the tooth ring of the output disc to form an oscillating zero tooth difference gear coupler. The conical pendulum type few tooth difference speed reduction device is simple in structure, large in transmission ratio, small in size, small in weight, high in performance cost ratio and long in service life.

Owner:HUBEI SPACE DOUBLE RHOMBUS LOGISTICS TECH +1

Air damping type positioning device of energy balance suspension system

InactiveCN103063286AImprove stabilityEffective and stableWeighing apparatus using electromagnetic balancingWeighing apparatus detailsEnergy balancedConical pendulum

The invention provides an air damping type positioning device of an energy balance suspension system. The air damping type positioning device of the energy balance suspension system comprises at least two damping elements. One damping element is evenly distributed on the bottom of a current carrying coil (2) of an energy balance (1). Each damping element comprises a damper (3) and a damping box (4). The damper (3) is movable arranged in the damping box (4). The top of the damper (3) is connected with the bottom of the current carrying coil (2) in a hardwired mode through a connecting rod (8). The air damping type positioning device of the energy balance suspension system achieves the goal of measuring quality of weights from 100g-1000g, errors caused by simple pendulum, conical pendulum and rotational motion around a center shaft generated in the working process of the energy balance can be effectively reduced, and quasi-static measurement of the energy balance can be achieved.

Owner:NAT INST OF METROLOGY CHINA

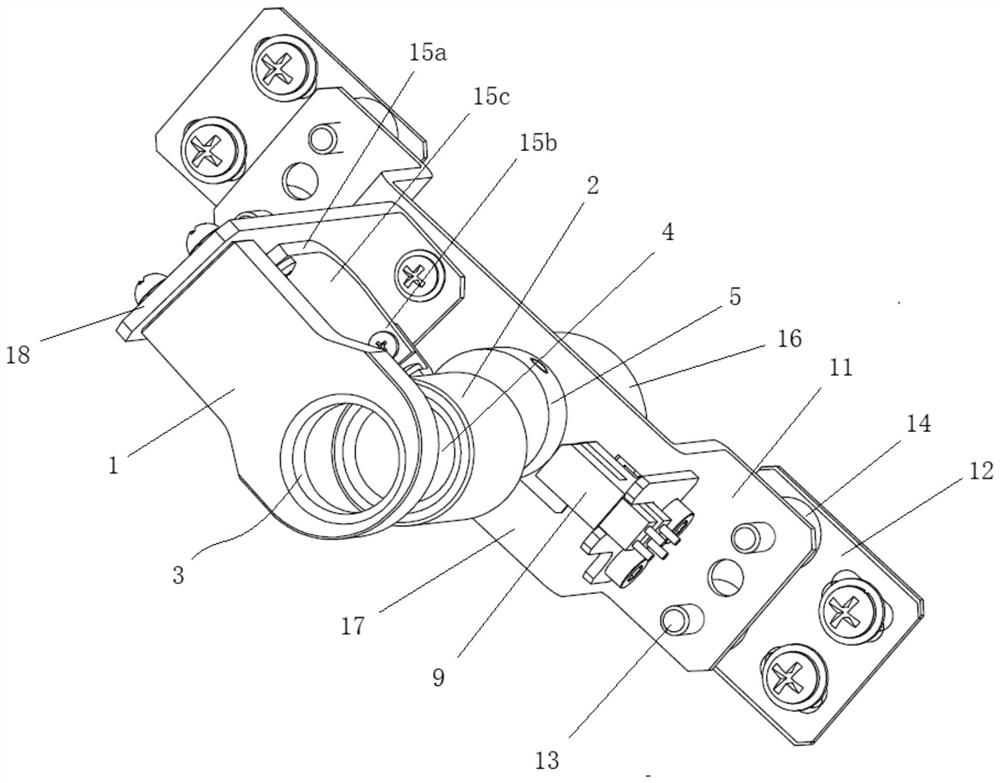

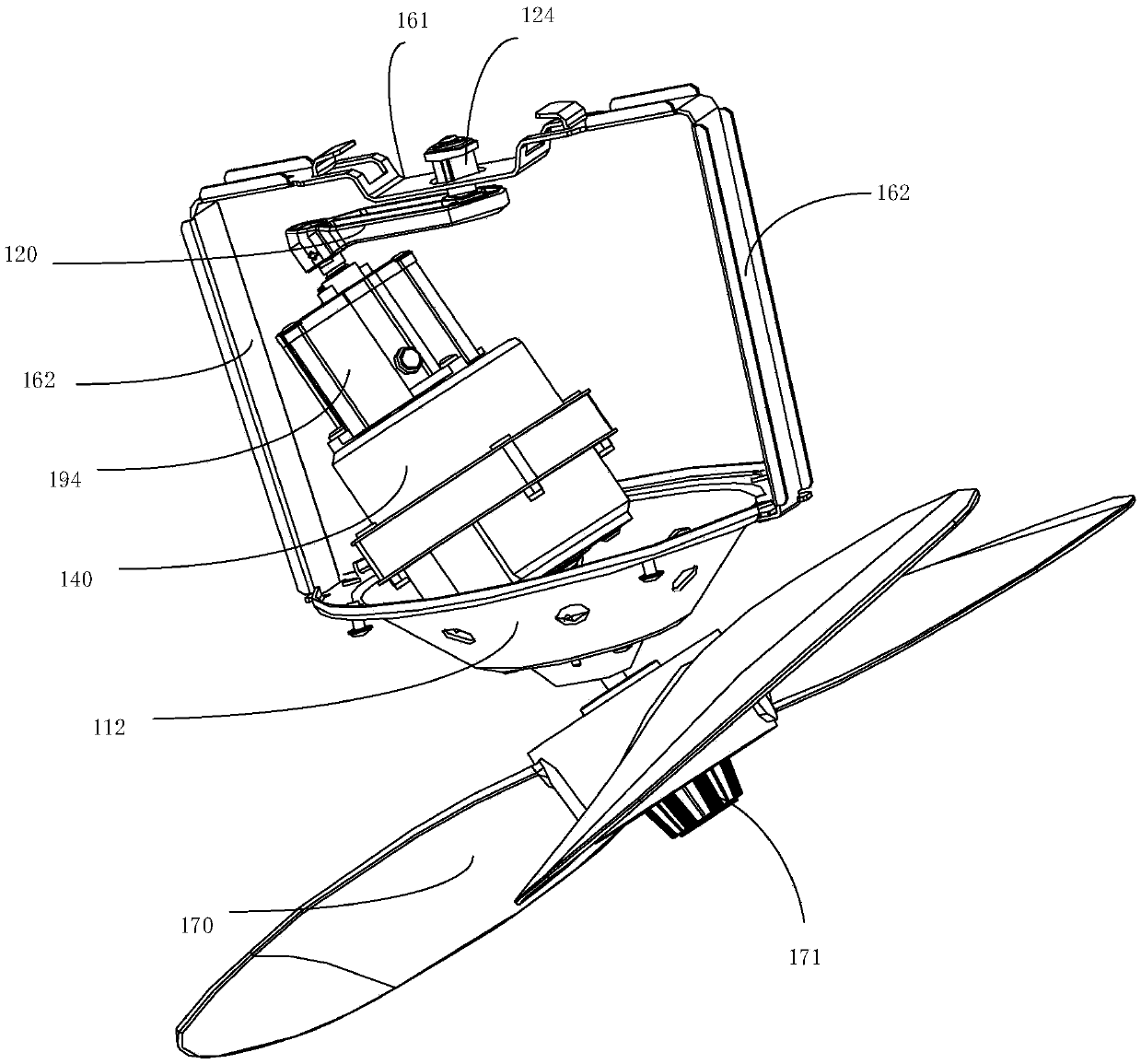

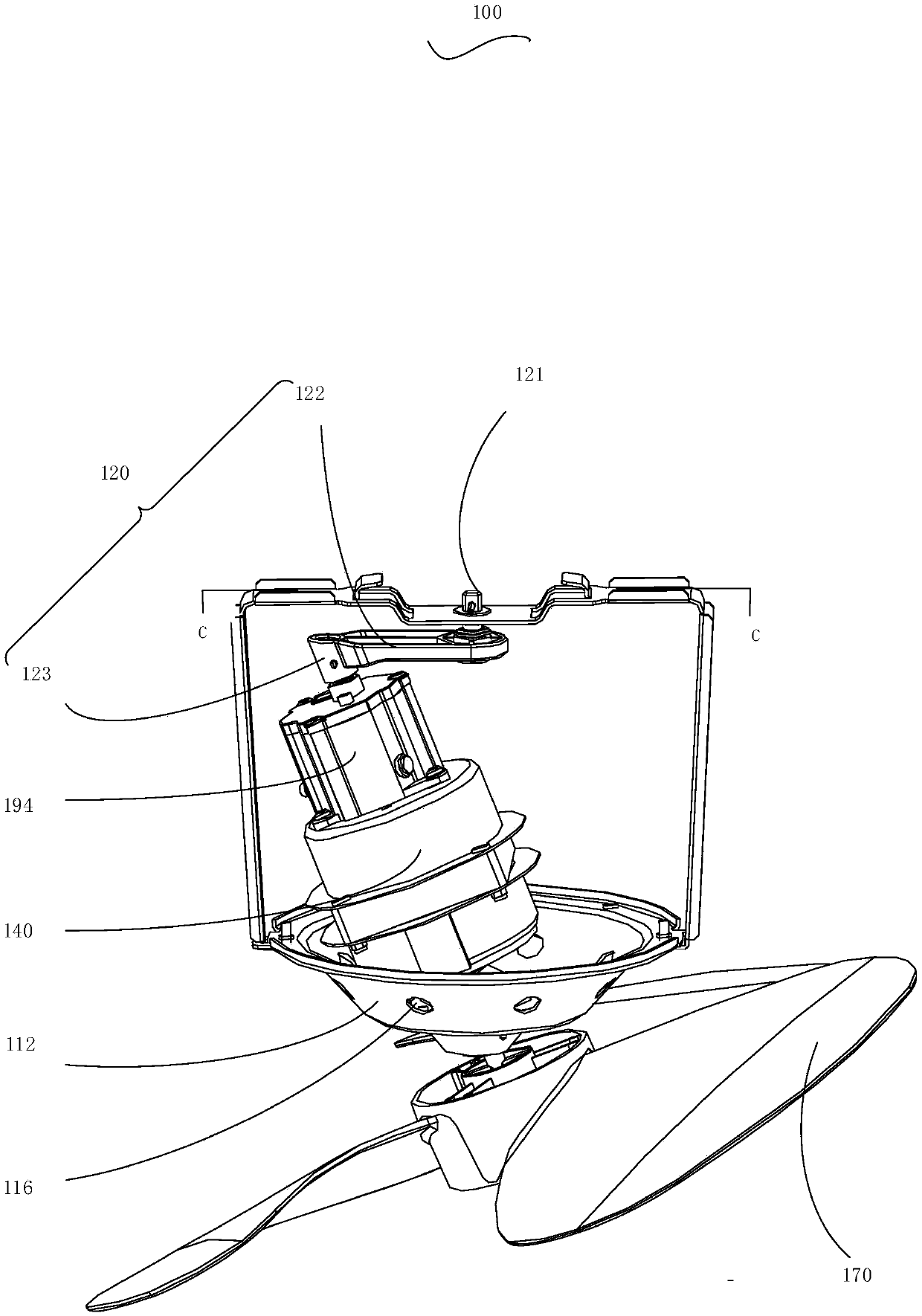

Conical pendulum mechanism and roof fan

InactiveCN111219348ARealize conical pendulum motionExpand the range of air supplyPump componentsPump installationsBall bearingClassical mechanics

The invention provides a conical pendulum mechanism and a roof fan provided with the conical pendulum mechanism. The conical pendulum mechanism comprises a support, a rotating shaft, a universal ballbearing, a connecting rod and a motor, wherein the universal ball bearing is arranged on the support, one end of the connecting rod is rotationally connected to the rotating shaft, the other end of the connecting rod is rotationally connected with the end, close to the rotating shaft, of an output shaft of the motor, the connecting rod is driven by the motor to conduct conical rotation around therotating shaft, the end, far away from the rotating shaft, of the output shaft of the motor penetrates through a universal ball of the universal ball bearing and is exposed outside the universal ballbearing, the rotating shaft is fixed to the position, avoiding the universal ball bearing, of the support, the support is used for fixing the conical pendulum mechanism to an external fixed object, orthe rotating shaft is used for being directly fixed to the external fixed object. According to the mechanism, the universal ball bearing is arranged on the support, so that the conical pendulum motion of the whole conical pendulum mechanism is realized, when the conical pendulum mechanism is used for an oscillating mechanism of the roof fan, the air supply range of the roof fan can be further expanded, and various requirements of users are met.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

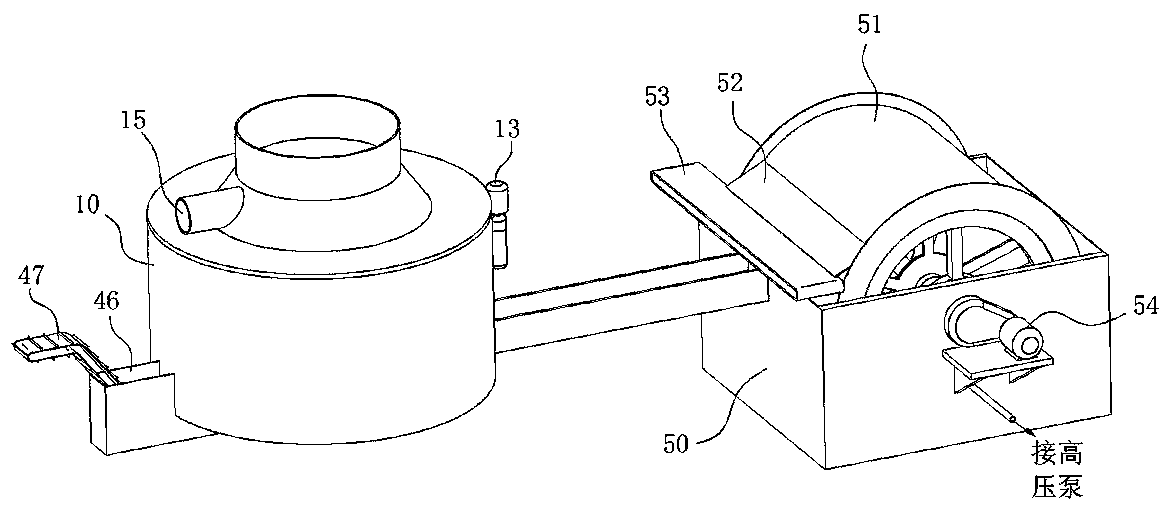

Slag water separation apparatus

ActiveCN110090488AImprove recycling efficiencyAvoid pollutionRecycling and recovery technologiesProcess efficiency improvementSlagWastewater

The invention belongs to the technical field of steel metallurgy, and concretely relates to a slag water separation apparatus. The apparatus comprises a slag tank, a centrifuging disc is arranged at the center of the slag tank, the centrifuging disc can rotate along the self axis, a first driving motor for driving the centrifuging disc to rotate is arranged in the slag tank, the inner wall of theslag tank is provided with a cooling water jacket, a spraying device is arranged at the top of the slag tank, the centrifuging disc is assembled to be able to perform conical pendulum movement along avertical axis, and a driving mechanism for driving the centrifuging disc to perform conical pendulum movement is arranged in the slag tank; and a slag water collecting pool is arranged at the bottomof the slag tank, an overflow member is arranged at the upper end of the slag water collecting pool, a sediment tank is arranged at the lower end of the slag water collecting pool, a slag dredging mechanism is arranged in the sediment tank, and an aeration tube is arranged at the bottom of the slag water collecting pool. The slag water separation apparatus has the advantages of directness in collection of steel slag and wastewater generated in the slag granulation process, implementation of cleaning and separating works in the first time, improvement of the recycling efficiency of the steel slag, compact structure and small occupied space.

Owner:安徽中巨机电设备有限公司

Optical fiber coating even shaking device and method

PendingCN110368857AWell mixedReduce coating defectsShaking/oscillating/vibrating mixersTransportation and packagingConical pendulumEngineering

The invention discloses an optical fiber coating even shaking method. The optical fiber coating even shaking method includes the following steps that under the condition of heat preservation, a container containing an optical fiber coating is fixed to an even shaking table to control the even shaking table to move, so that an axis of the even shaking table moves in an inverted conical pendulum mode, and thus the optical fiber coating in the container is shaken evenly; and the axis is a straight line vertically penetrating through the geometric center of the even shaking table, the angle between the axis and the vertical direction is 10-20 degrees, and a conical pendulum moves at the speed of 10-30 rpm. The invention further discloses an optical fiber coating even shaking device. Accordingto the optical fiber coating even shaking method, the optical fiber coating can be shaken evenly and quickly, the pre-treatment time of the optical fiber coating is decreased, production energy consumption is reduced, and the production cost is lowered.

Owner:JIANGSU HENGTONG OPTICAL FIBER TECH +1

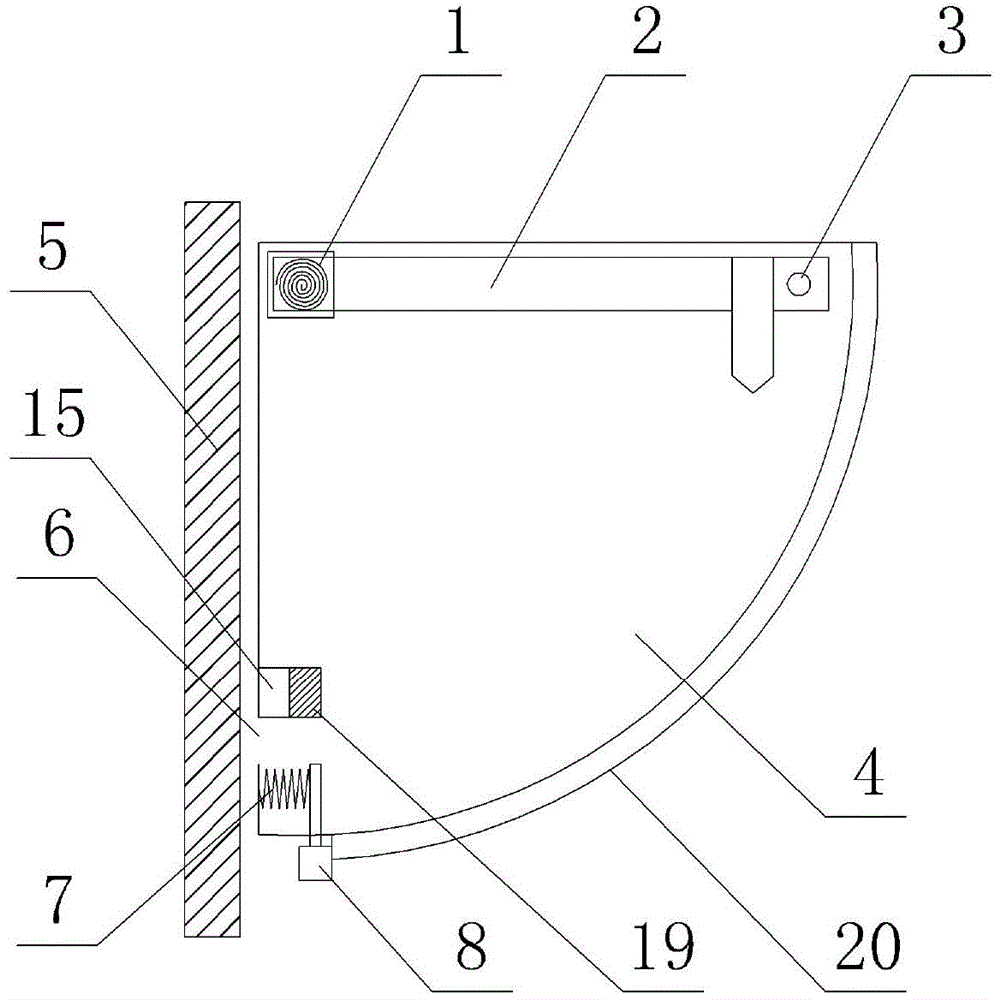

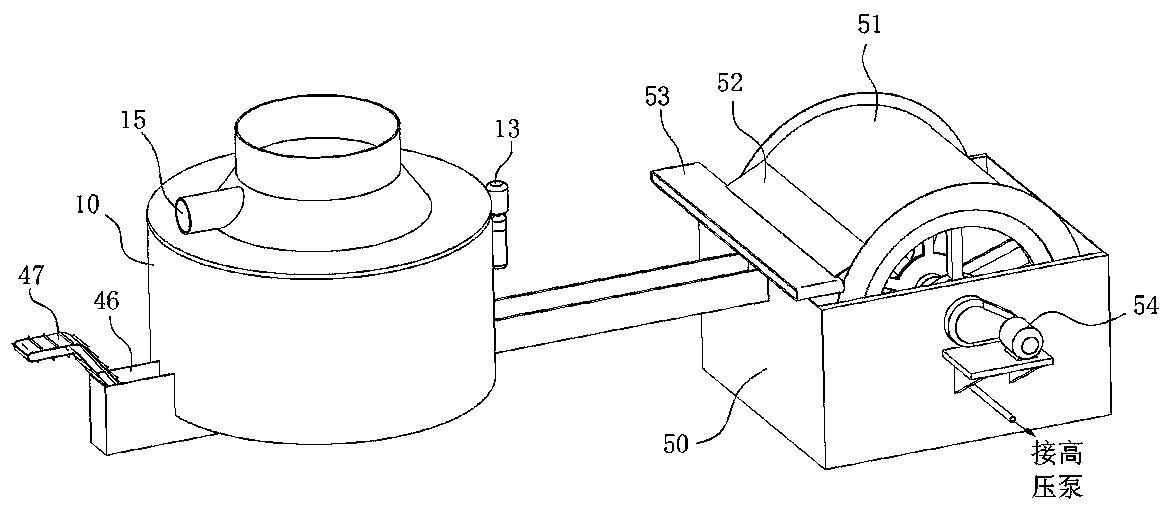

Mechanical earthquake self-detection device

InactiveCN103439737ARealize all-round automatic detectionGood prevention effectSeismic signal receiversInertial effectProtection mechanism

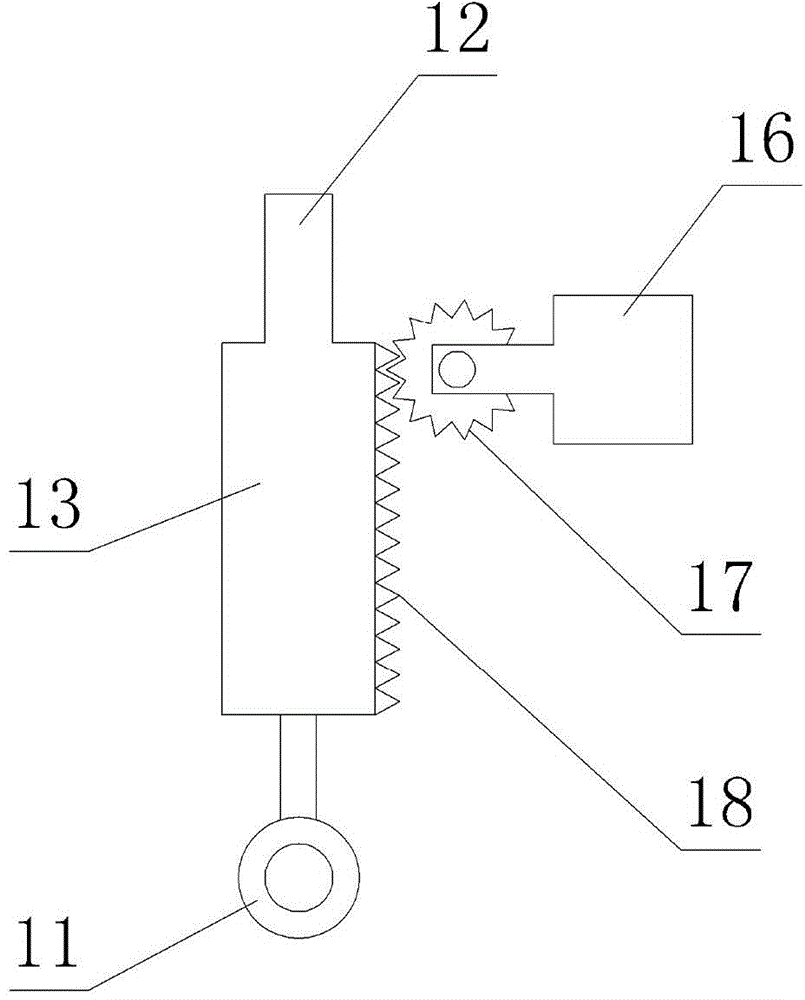

The invention discloses a mechanical earthquake self-detection device which comprises an earthquake amplitude control plate, a pointed conical pendulum supporting frame, a pendulum bob and a ground fixed connecting plate. The pointed conical pendulum supporting frame is located between the earthquake amplitude control plate and the pendulum bob. The earthquake amplitude control plate, the pointed conical pendulum supporting frame and the pendulum bob are fixedly installed on the upper portion of the ground fixed connecting plate in a mutually-parallel mode. When an earthquake occurs, the pointed conical pendulum supporting frame is installed on the ground fixed connecting plate, therefore, a pointed conical pendulum will swing at the frequency same as that of the ground under the inertial effect of gravity swinging, when swinging of the pointed conical pendulum reaches the certain amplitude, a convex cone at the upper end of the pointed conical pendulum is separated from an earthquake amplitude control circular truncated cone, a pendulum bob head on the earthquake amplitude control plate loses supporting, the pendulum bob head drives a pendulum rod to drop in an overturn mode, a sector gear at the other end of the pendulum rod is in meshed transmission with a cylindrical gear externally connected with a control mechanism, a protection mechanism, connected with the cylindrical gear, in the control mechanism is driven to be started instantaneously, 360-degree earthquake wave all-dimensional automatic detection is achieved, and the prevention effect on sudden disasters is good.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Steel slag centrifugal granulation device

InactiveCN110142002AUniform splash pathSplash path avoidanceGranulation in rotating dishes/pansRecycling and recovery technologiesSlagCooling effect

The invention belongs to the technical field of ferrous metallurgy, and specifically relates to a steel slag centrifugal granulation device. A centrifugal disc is set to have a conical pendulum structure so that the splashing route of melted steel slag fluctuates periodically, thus all areas of a cooling water sleeve can be evenly impacted by steel slag, the cooling effect becomes more uniform, and at the same time, the service life of a slag tank is prolonged. A first cleaning head and a second cleaning head are arranged on the valley and peak of a steel slag splashing route; then the rotation speed of the cleaning heads is set to be identical with the speed of the conical pendulum of the centrifugal disc; thus the first and second cleaning heads can always avoid the steel slag splashingroute; and real-time online washing of the cooling water sleeve in the slag tank is realized. A slag-water separating device can directly collect steel slag and wastewater generated during the steel slag granulation process and carries out cooling, washing, and separating immediately. The steel slag recovering and utilizing efficiency is improved. The steel slag is not piled up, waste heat or smoke is not generated, and the environment is protected.

Owner:安徽中巨机电设备有限公司

Cone Pendulum Reducer with Small Tooth Difference

The invention relates to a conical pendulum type few tooth difference speed reduction device. The conical pendulum type few tooth difference speed reduction device is characterized in that an output disc with a tooth ring on the inner side is arranged on one side of a machine shell through a bearing, the other side of the machine shell is provided with a fixing tooth ring and connected with a connection base, a tooth-ring gear is arranged in the fixing tooth ring, and an oscillating zero tooth difference gear coupler is formed by the tooth-ring gear and the fixing tooth ring; an input bent axle is arranged in the center of the machine shell, the two ends of the input bent axle transversely penetrate the machine shell and are borne by a center bearing of the output disc and a center bearing of the connecting base, and an eccentric shaft of the input bent axle is provided with an oscillating duplex gear through a self-aligning roller bearing; and one end of the duplex gear is engaged with a tooth ring of the tooth-ring gear to form a few tooth difference planetary transmission gear pair, and the other end of the duplex gear is matched with the tooth ring of the output disc to form an oscillating zero tooth difference gear coupler. The conical pendulum type few tooth difference speed reduction device is simple in structure, large in transmission ratio, small in size, small in weight, high in performance cost ratio and long in service life.

Owner:HUBEI SPACE DOUBLE RHOMBUS LOGISTICS TECH +1

Horizontal detection apparatus

The invention discloses a horizontal detection apparatus. The horizontal detection apparatus comprises an apparatus body, wherein the apparatus body comprises a bracket; the bracket comprises a bottomplate and a top plate; the bottom plate is provided with a dial scale; a conical pendulum with an adjustable pendulum length is hoisted on the top plate; when the top plate or the bottom plate is located on the horizontal plane, a pendulum needle of the conical pendulum is aligned to the central position of the dial scale. In an actual utilization process of the horizontal detection apparatus, the top plate or the bottom plate is placed on a floor surface of a vehicle and the adjustable pendulum length adjusted so that the top of the pendulum needle of the conical pendulum gets close to the dial scale; when the conical pendulum does not swing, the pendulum length is adjusted again so that the top of the pendulum needle of the conical pendulum slightly abuts against the dial scale; a numerical value on the dial scale is read, is a distance, deviated from the center of the dial scale, of the pendulum needle and then is recorded. The maximum deviation amount delta of a vehicle accordingto a similar triangle principle, and delta is equal to (L / S)*h. The horizontal detection apparatus only needs to be placed on a measurement point to read and calculate; the horizontal detection apparatus is very convenient to use and a detection position is flexible and diverse, so that the detection precision is greatly improved.

Owner:CHONGQING CRRC RAILWAY VEHICLES CO LTD

Three-wire torsional pendulum method rigid body dynamic parameter test console

ActiveCN103148984BConvenient for repeated liftingEasy to placeStatic/dynamic balance measurementJackscrewConical pendulum

The invention provides a three-wire torsional pendulum method rigid body dynamic parameter test console which comprises a test console chassis, a cycloid curve and a tray and is characterized in that a lifting device and a centering device are arranged on the test console chassis, wherein the lifting device comprises three jacks; the jacks are circumferentially and uniformly distributed through taking the center of the chassis as the center of a circle; the centering device is positioned at the center of the chassis and comprises a jack and a centering shaft; and the centering shaft is installed at the upper end of a jack piston in the centering device and ascends or descends along with the piston. The three-wire torsional pendulum method rigid body dynamic parameter test console has the beneficial effects that through the lifting device of the test console, the tray can be conveniently and repeatedly lifted for multiple times, measured objects are convenient to put, load and unload, the tray can be fixedly arranged and put in a non-test state, and the service lives of the cycloid curve and the sensor can be prolonged; and through the centering device, the tray can be enabled to carry out pure torsion vibration around a central lead vertical axis without generating mixed pendulum or conical pendulum movement, so that the measurement precision and the measurement efficiency are improved.

Owner:UNIV OF SCI & TECH BEIJING

Single pendulum experiment instrument

InactiveCN110853465AAvoid experimental errorLow structural costEducational modelsClassical mechanicsElectrical connection

The invention discloses a single pendulum experiment instrument. The single pendulum experiment instrument comprises a base and bottom foot screws, wherein the upper part of the base is provided witha vertical column; the upper end of the vertical rod is provided with a hanging bracket; the hanging bracket is provided with a hanging bracket screw; the upper end of a cycloid is mounted on the hanging bracket, and the lower end of the cycloid is connected with a swing ball; a bracket is adjustably mounted on the vertical rod through a bracket screw; an electromagnet movable bracket is arrangedon the bracket in a sleeving manner; an electromagnet is mounted on the electromagnet movable bracket; and the electromagnet and a power supply are electrically connected with each other. The single pendulum experiment instrument overcomes the defect that a single pendulum experiment instrument in the prior art is prone to conical pendulum during the experiment process, and the experiment precision is improved. The single pendulum experiment instrument can be used for the single-pendulum experiments in college physical experiments.

Owner:吴玉珍

Crane pull rope shaking motion conversion device and crane

Owner:SANY MARINE HEAVY IND

Conical pendulum bearing type sorting device for perfect circle granular plastic product

InactiveCN110238991ABig-amplitudeAvoid reply moveGas current separationMedial rotationConical pendulum

The invention provides a conical pendulum bearing type sorting device for a perfect circle granular plastic product. The sorting device comprises a sorting shell and a driving box, the driving box is mounted on one side of the sorting shell, driving frames are rotationally arranged on the two sides of the upper end of the sorting shell, rotating discs are rotationally arranged on the inner sides of the driving frames, inner bearings are rotationally arranged at the lower ends of the rotating discs, fan blades surround the outer sides of the inner bearings, penetrating grooves penetrate through one sides of the fan blades, and rotating rails are arranged at one ends of the inner bearings in a sliding manner; the inner part of the sorting shell is provided with a bottom plate, a penetrating opening penetrates through the middle part of the bottom plate, and a sorting groove penetrates through one end of the penetrating opening; and a bottom cone and a movable disc are arranged to be combined into a pendulum bearing type structure, so that when an elastic column flips in the vertical direction through a spring, downward gravity of the elastic column drives the movable disc to swing left and right in the horizontal direction, the amplitude of the movable disc during swing can be increased through the bottom cone, and the rotating column can be automatically driven by the movable disc to rotate.

Owner:张其斌

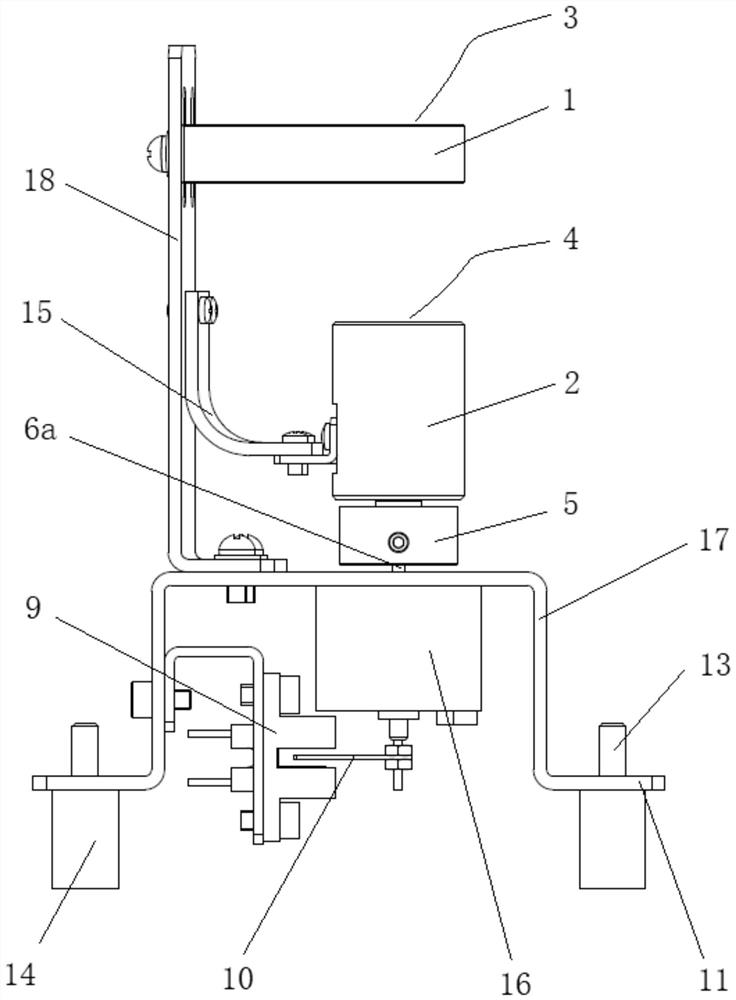

Intelligent gravitational acceleration measuring instrument based on conical pendulum

PendingCN112505794AMonitor stabilityAvoid measurement effectsGravitational wave measurementMeasuring instrumentClassical mechanics

The invention discloses an intelligent gravitational acceleration measuring instrument based on a conical pendulum, which comprises a shell, a conical pendulum body which is mounted on the shell and can perform conical pendulum motion for measuring gravitational acceleration, a levelness adjusting device which is arranged on the shell and is used for adjusting the levelness of the shell, a monitoring device which is installed in the shell and used for monitoring the specification of the shell and the position change state of a pendulum ball in the conical pendulum body, and a measuring devicewhich is arranged on the shell and is used for measuring the height and the rotation period of the pendulum ball and calculating the gravitational acceleration. The motion state of the pendulum ball and the position of the rack can be measured and monitored, and what is ensured is that the experimental environment of the rack and the pendulum ball is in the most ideal state.

Owner:HEFEI UNIV OF TECH

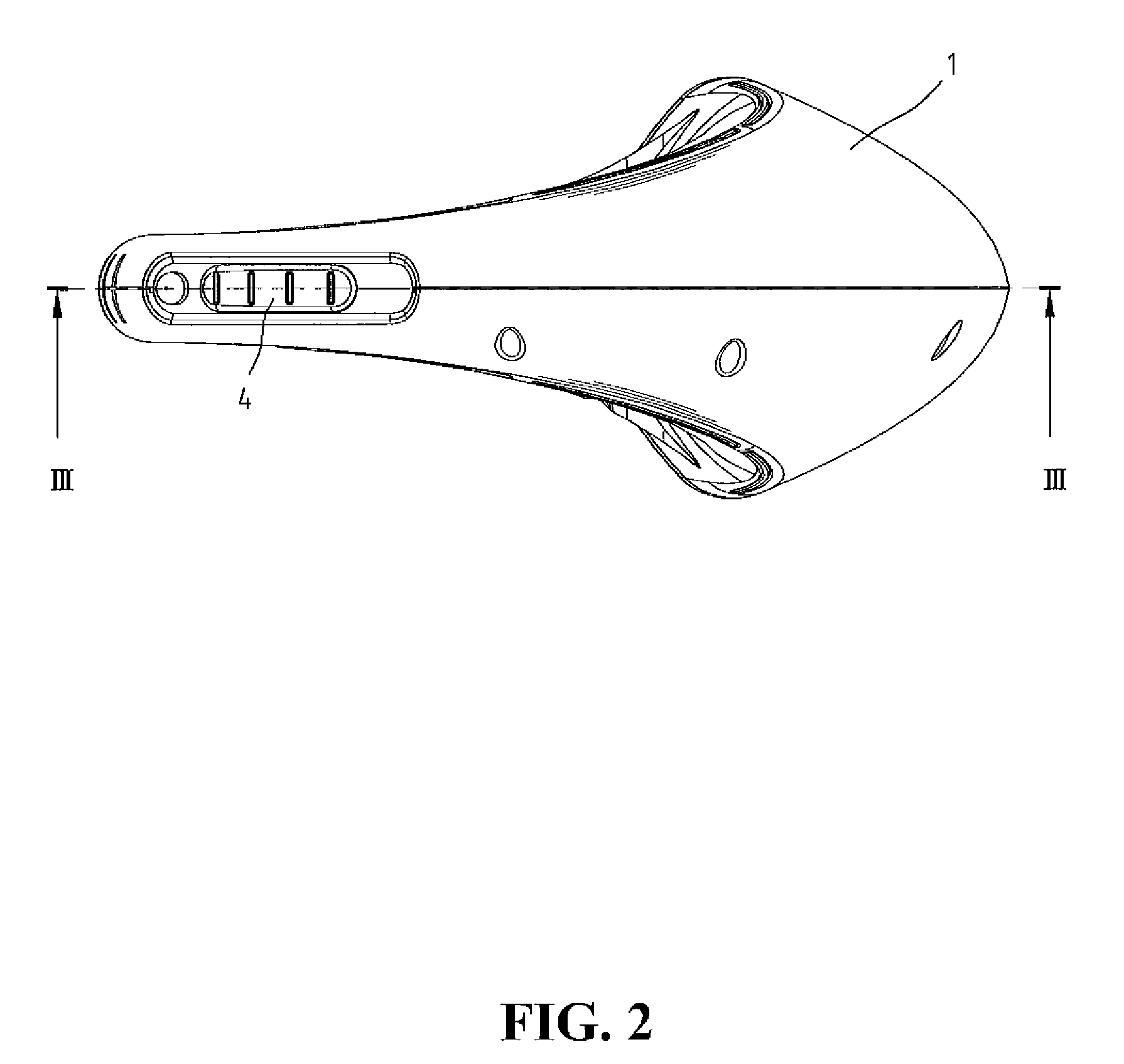

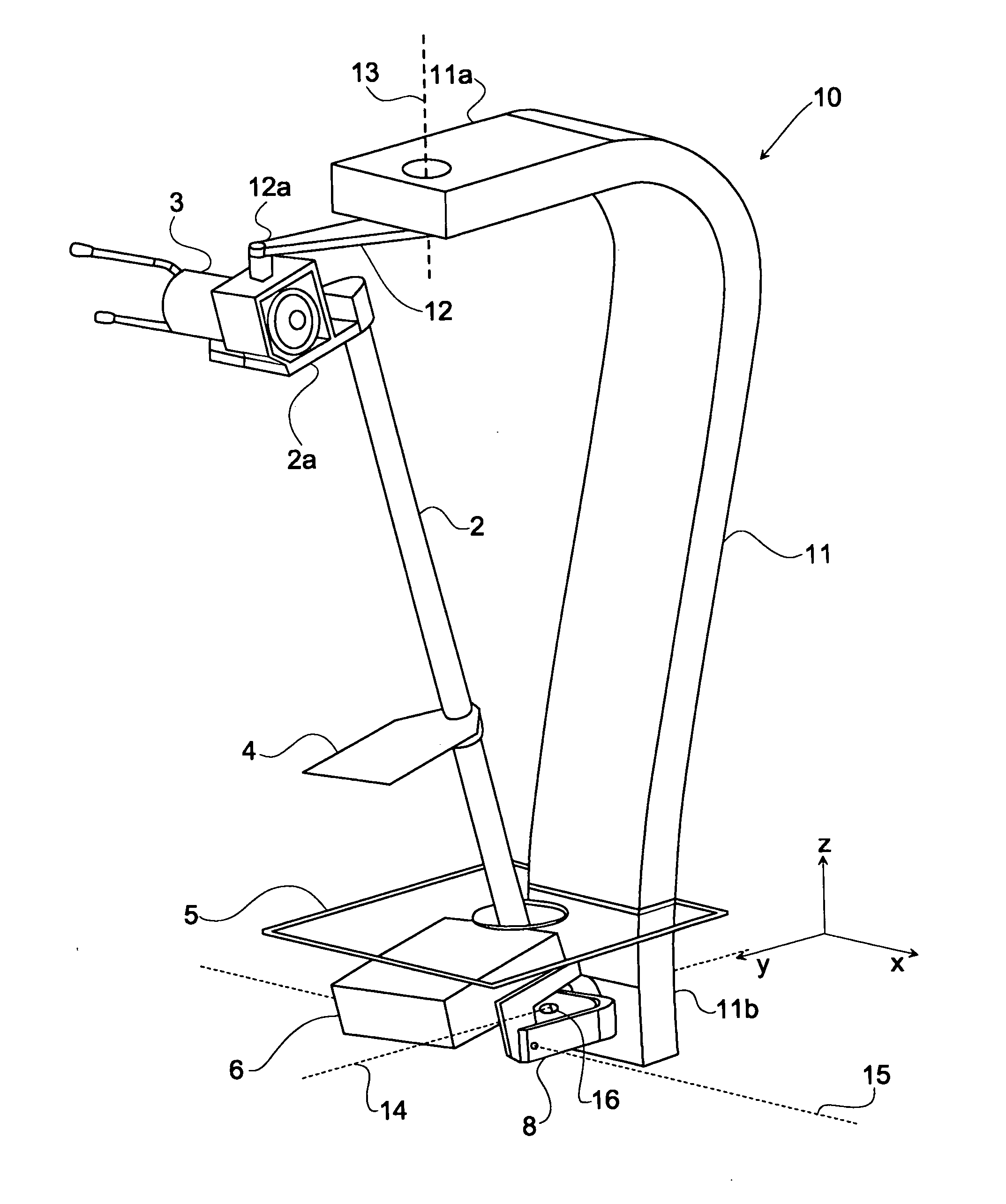

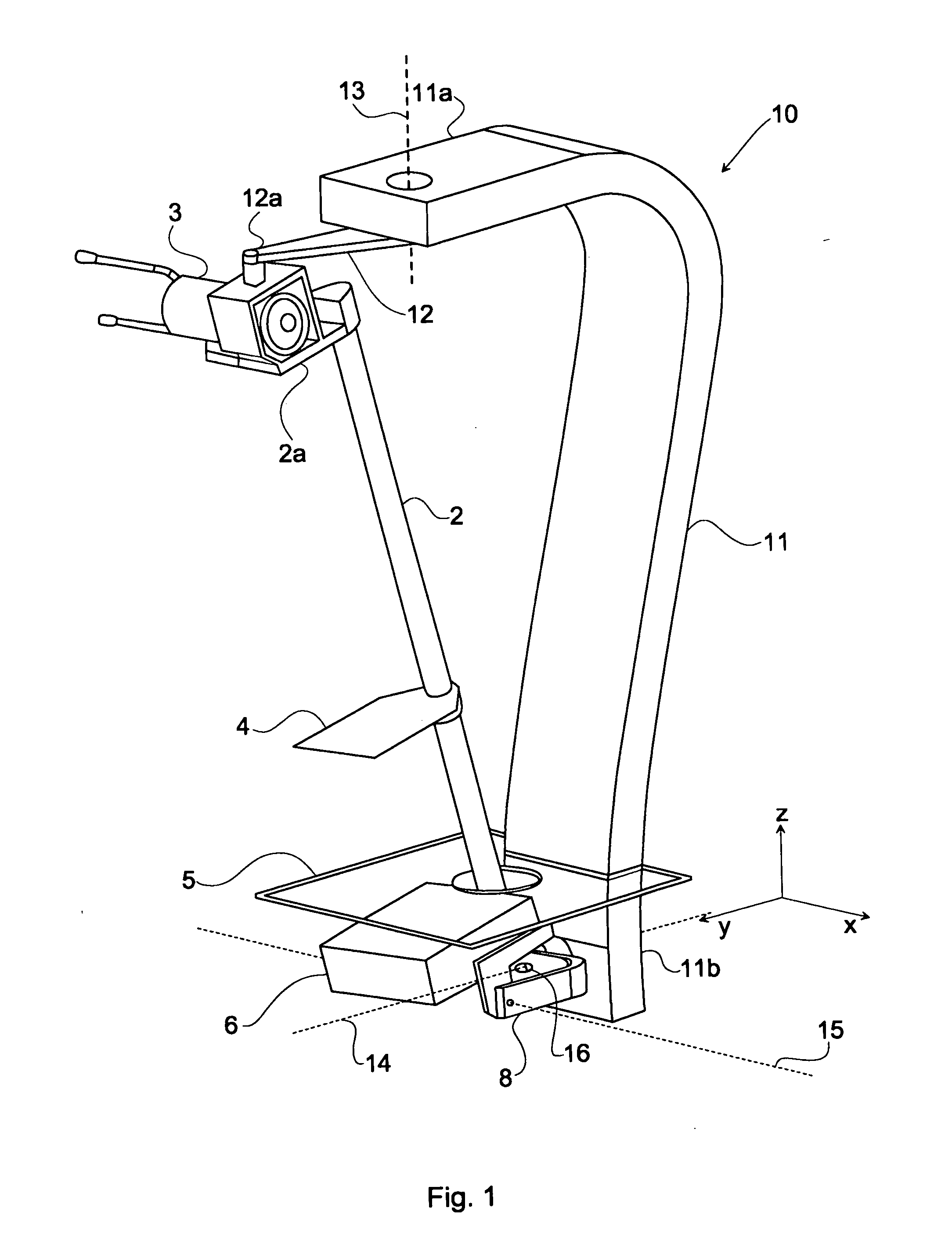

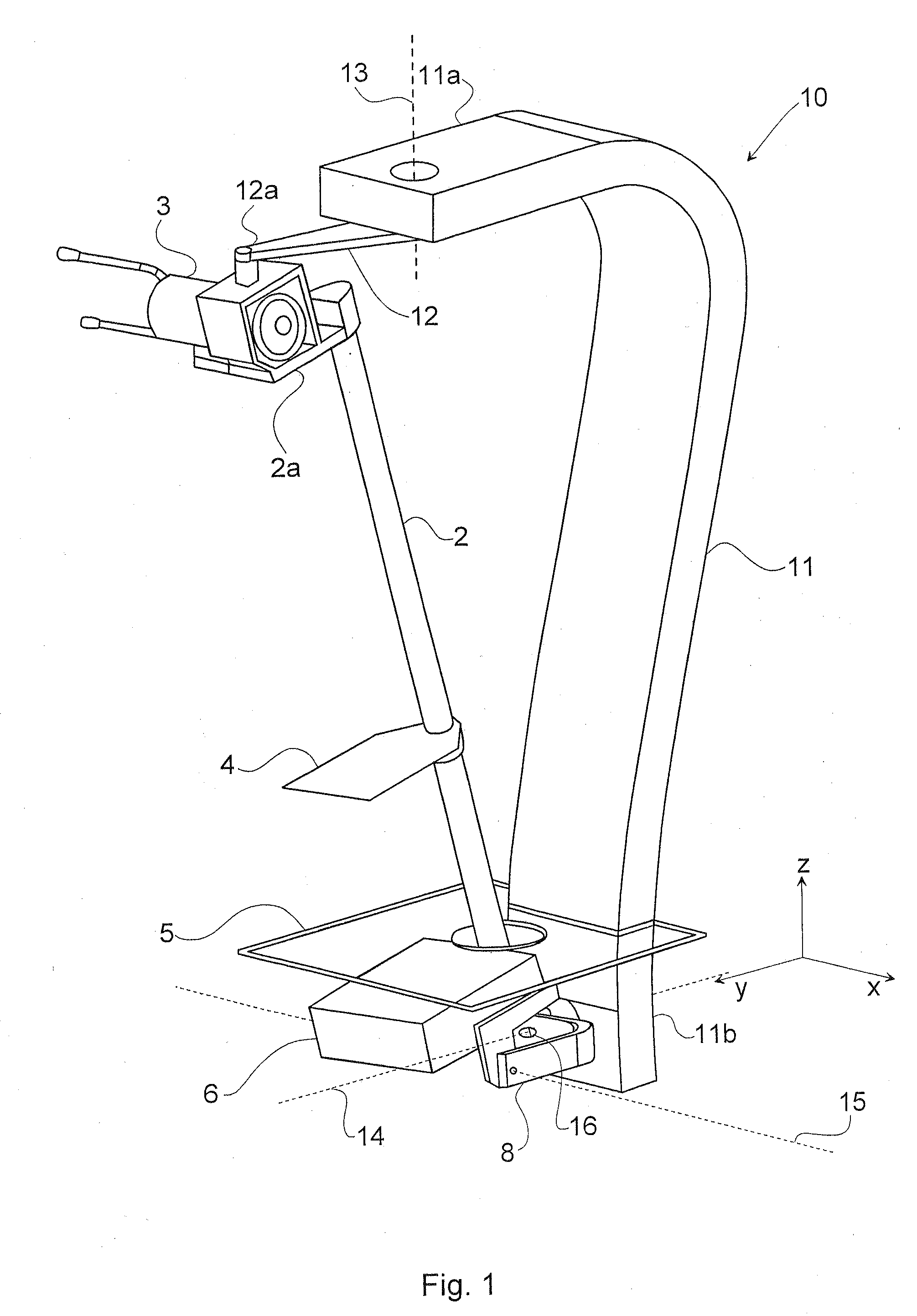

Apparatus and method for recording radiation image data of an object

InactiveUS20090092226A1Reliable and accurate and inexpensiveImprove spatial resolutionX-ray/infra-red processesMaterial analysis using wave/particle radiationConical pendulumImaging data

An apparatus for recording radiation image data of an object comprises a radiation source arrangement provided for emitting radiation; an object holder arranged in the radiation path of the emitted radiation and provided for housing the object during the recordation of the radiation image data; a detector arrangement for detecting radiation which has interacted with the object; a support structure, to which the radiation source and detector arrangements are secured; and a scanning device provided for moving either one of the support structure or the object holder with respect to the other one of the support structure or the object holder in a conical pendulum movement while the detector arrangement is provided for detecting radiation which has interacted with the object.

Owner:XCOUNTER

Apparatus and method for recording radiation image data of an object

InactiveUS20100215145A1Improve spatial resolutionHigh resolutionMaterial analysis using wave/particle radiationRadiation/particle handlingConical pendulumImaging data

An apparatus for recording radiation image data of an object comprises a radiation source arrangement (3) provided for emitting radiation; an object holder (5) arranged in the radiation path of the emitted radiation and provided for housing the object during the recordation of the radiation image data; a detector arrangement (6) for detecting radiation which has interacted with the object; a support structure (2), to which the radiation source and detector arrangements are secured; and a scanning device (1) provided for moving either one of the support structure or the object holder with respect to the other one of the support structure or the object holder in a conical pendulum movement while the detector arrangement is provided for detecting radiation which has interacted with the object.

Owner:XCOUNTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com