Rotating arc sensor for gas shielded welding

A technology of gas shielded welding and rotating arc, which is applied in the direction of arc welding equipment, welding protection devices, welding equipment, etc. It can solve the problems of difficult to reduce the volume structure, poor sensor practicability, and affecting the accessibility of the welding torch, etc., and achieves a compact structure , Good accessibility, small vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In conjunction with the accompanying drawings, the description is as follows:

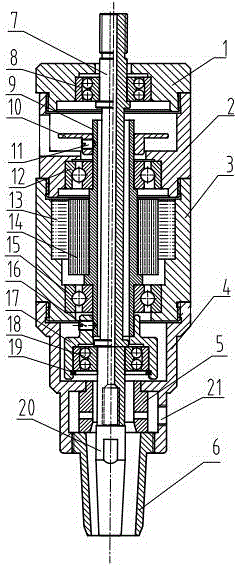

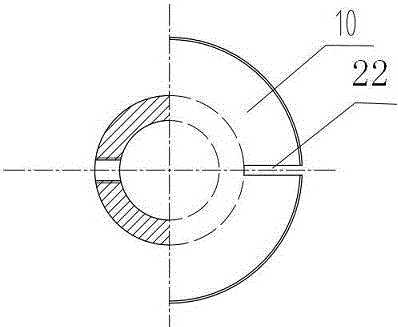

[0024] The rotating arc sensor of the present invention is composed of a housing and a rotor assembly, wherein the housing includes an end cover (1), a speed measuring chamber (2), a power chamber (3), an eccentric chamber (4), and an air chamber (5) and the gas cover (6), the parts are connected by threads; the rotor assembly includes a conductive rod (7), two self-aligning bearings (8) (18), a hollow shaft (9), an optical code disc (10), Two deep groove ball bearings (12) (15), drive motor, eccentric block (17) and welding tip (20).

[0025] The upper part of the conductive rod (7) is installed in the end cover (1) through a self-aligning bearing (8), the lower part is installed on the eccentric block by a self-aligning bearing (18), and a welding rod is installed on the conductive rod (7). Nozzle (20), the welding wire penetrates into the welding nozzle (20) from the conductive rod (7). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com