Mechanical earthquake self-detection device

A self-detecting, mechanical technology, applied in the direction of seismic signal receivers, etc., can solve problems such as unreliability, damage to earthquake power facilities, explosion hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

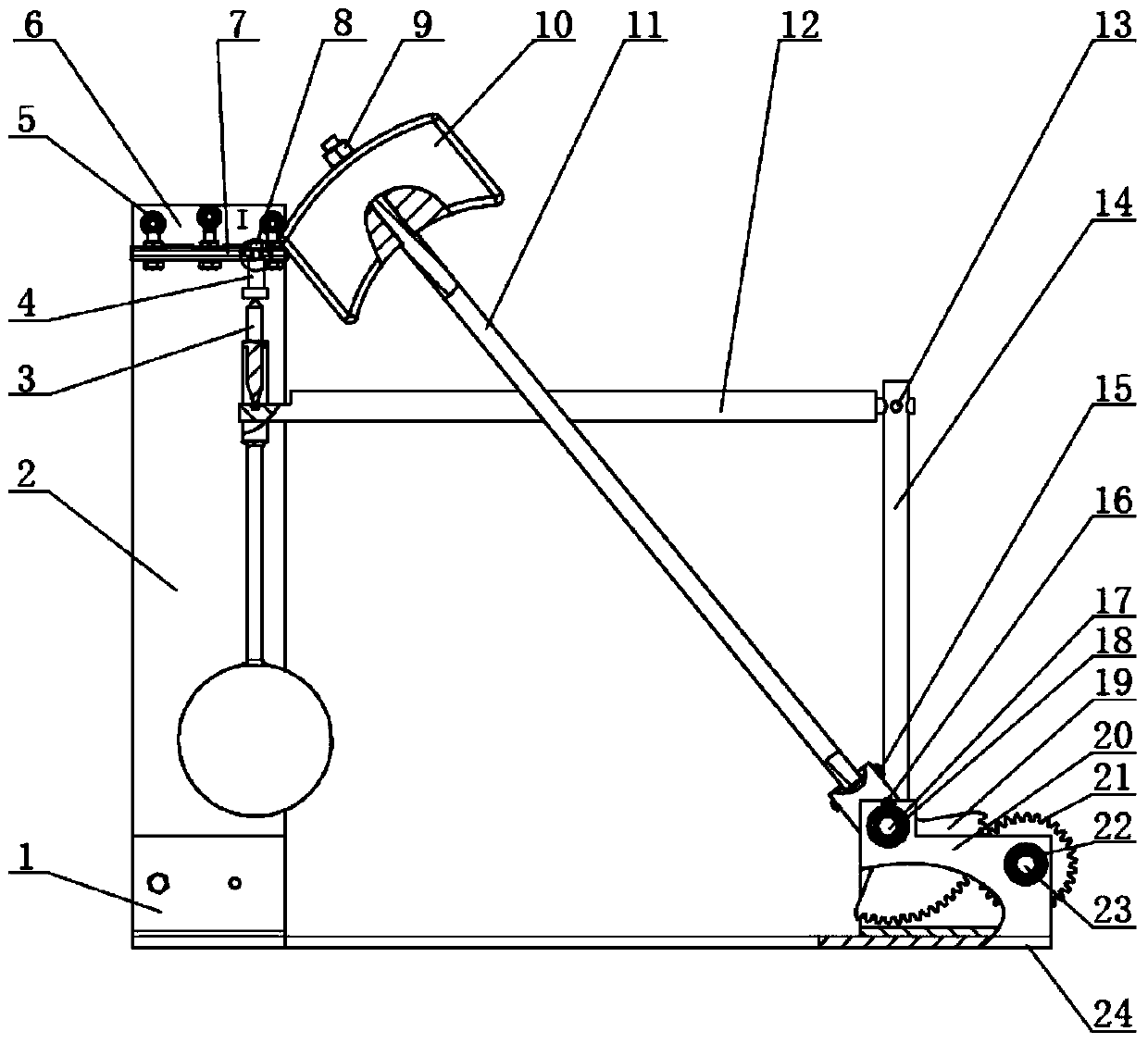

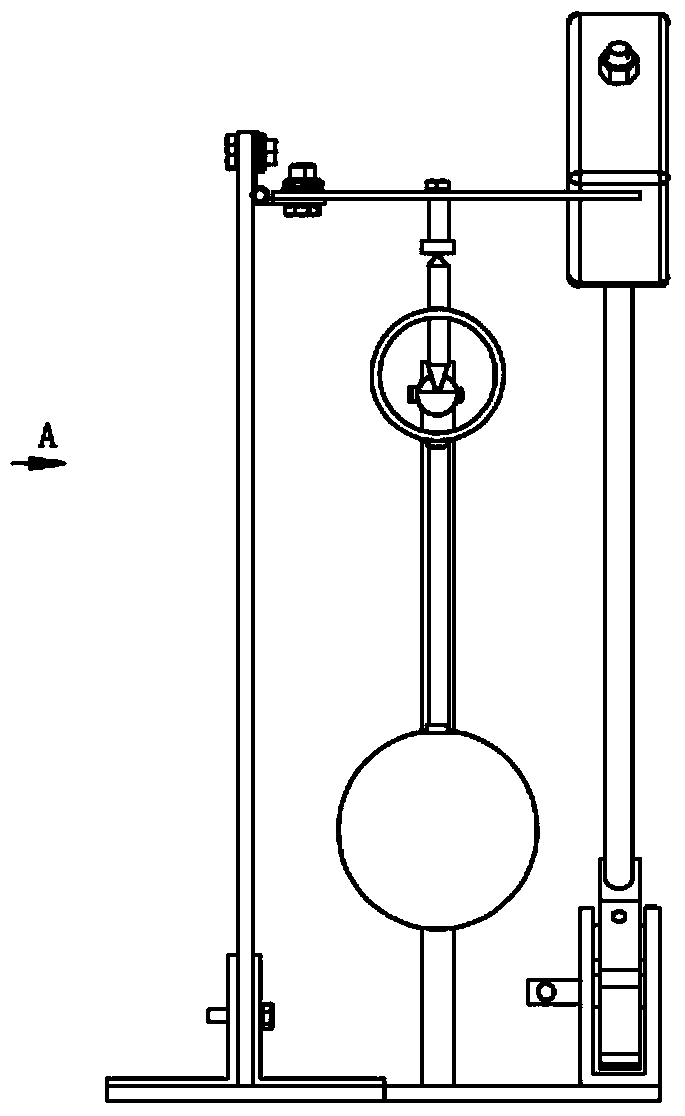

[0020] This embodiment is a mechanical self-detection device for earthquakes.

[0021] refer to Figure 1-Figure 5 , the mechanical earthquake self-detection device includes an amplitude control board, a pointed cone pendulum support frame, a pendulum, and a solid connection plate. The pointed cone pendulum support frame is located between the amplitude control plate and the pendulum. The pendulum support frame and the pendulum are parallel and fixedly installed on the solid connecting plate.

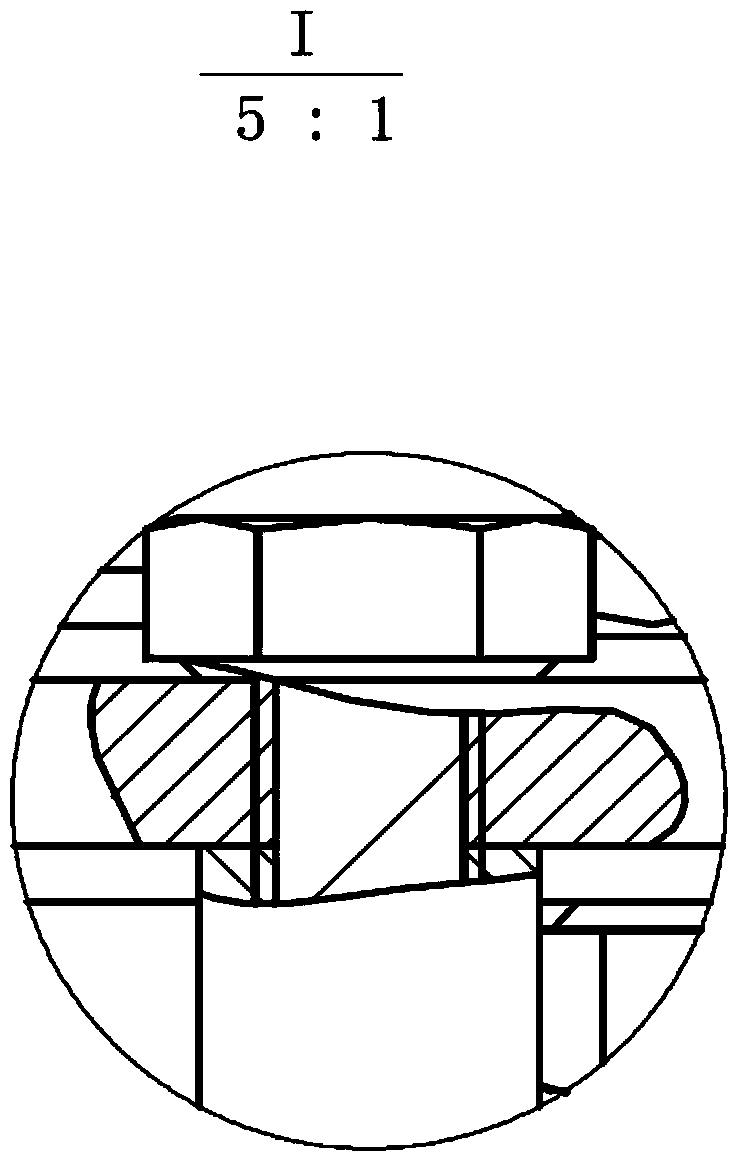

[0022] The amplitude control plate includes the amplitude control round table 4, the rectangular plate 7, the vertical fixed plate 2, the rib plate 1, the hinge 6, the bolt 8, the nut 5, one end of the vertical fixed plate 2 and the two rib plates 1 pass through the bolts Connection, the two ribs 1 and the solid connection plate 24 are fixedly connected by bolts. Rectangular plate 7 is installed on the side upper part of the other end of vertical fixed plate 2, and is perpendicular to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com