Torque motor torque fluctuation coefficient detector and detecting method

A technology of torque fluctuation and torque motor, applied in the direction of torque measurement, instruments, measuring devices, etc., can solve the problem of unreliable test results, and achieve the effect of good man-machine interface, simple and convenient operation, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

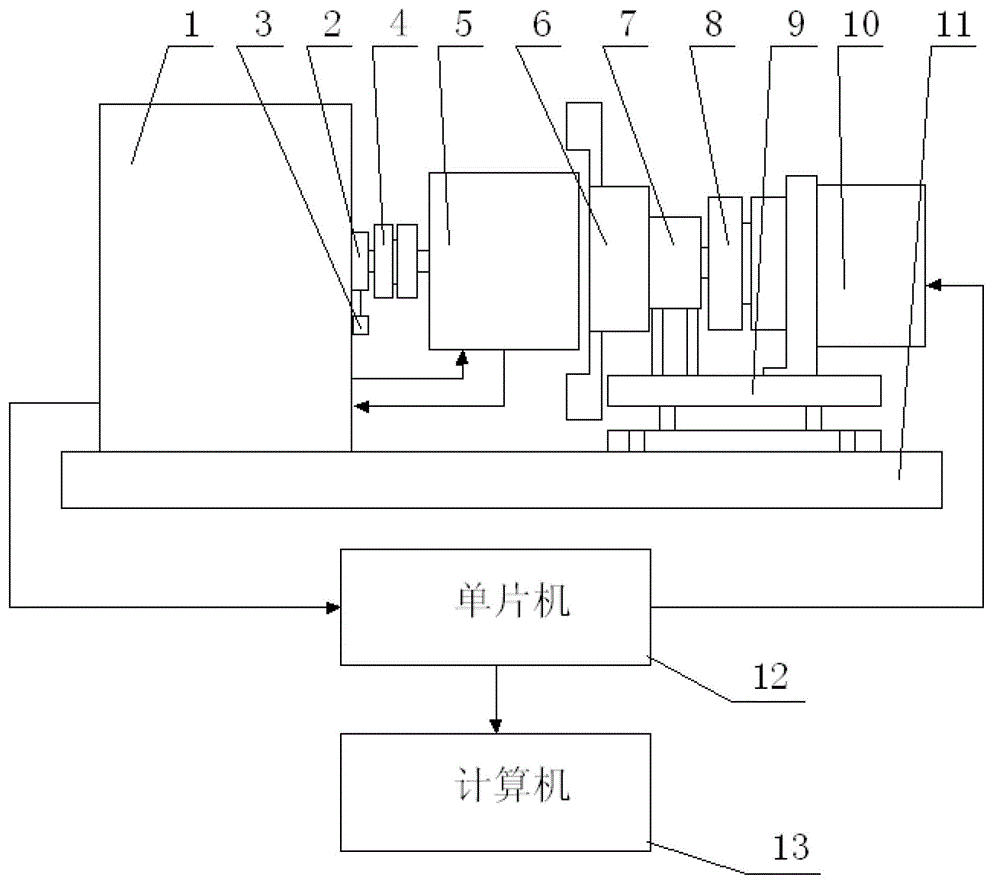

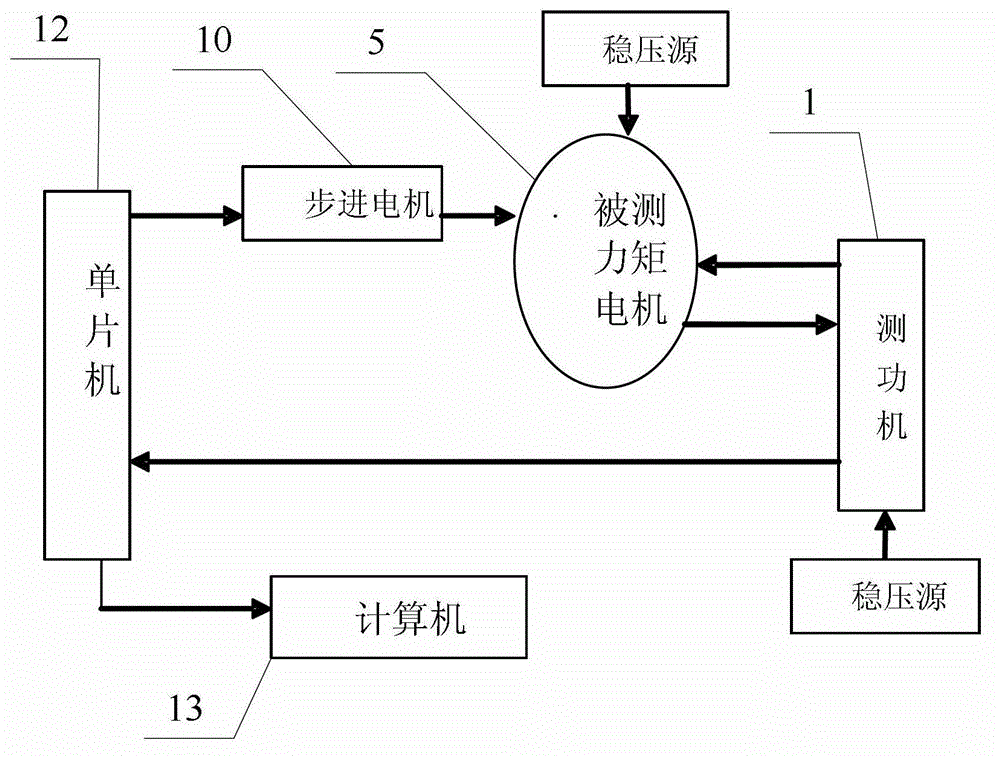

[0029] Specific implementation mode one: the following combination Figure 1 to Figure 3 Describe this embodiment, the torque motor torque fluctuation coefficient detector described in this embodiment includes a dynamometer 1, and is characterized in that: it also includes a calibration assembly, a first shaft coupling 4, a measured torque motor 5, a card Disk manipulator 6, bearing bearing 7, second shaft coupling 8, position adjustment base 9, stepper motor 10, stable base 11, single-chip microcomputer 12 and computer 13,

[0030] The dynamometer 1 is fixed on the stable base 11, the output shaft of the dynamometer 1 passes through the calibration assembly and is connected with the rotating shaft of the rotor of the torque motor 5 under test through the first coupling 4,

[0031] The power output shaft of the stepper motor 10 is connected to the central axis of the chuck manipulator 6 through the second shaft coupling 8, and the chuck manipulator 6 is used to firmly clamp th...

specific Embodiment approach 2

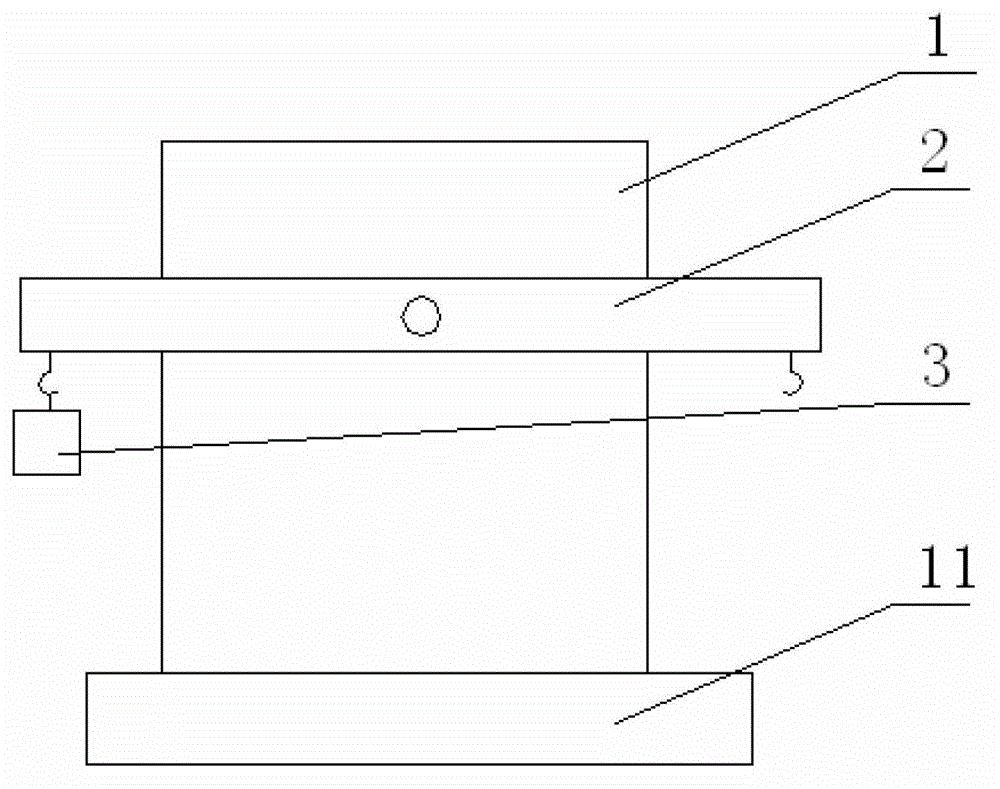

[0039] Specific implementation mode two: the following combination figure 1 and figure 2 Describe this embodiment. This embodiment is a further description of Embodiment 1. The calibration assembly is composed of a calibration lever 2 and a weight 3. The calibration lever 2 is arranged on the output shaft of the dynamometer 1, and the output shaft passes through Through the center of the calibration lever 2, the weight 3 is suspended at one end of the calibration lever 2.

[0040] The dynamometer 1 is the main body of sensory measurement, and the external central axis of the dynamometer 1 is connected to the calibration lever 2 for initial calibration, and the initial calibration is performed through the weight 3 .

specific Embodiment approach 3

[0041] Specific implementation mode three: the following combination Figure 1 to Figure 3 Describe this embodiment, this embodiment is based on the detection method of the torque motor torque fluctuation coefficient detector described in Embodiment 1 or 2, and it comprises the following steps:

[0042] Step 1: Initially calibrate the dynamometer 1 using a calibration assembly consisting of a calibration lever 2 and a weight 3;

[0043] Step 2: Adjust the chuck manipulator 6 so that it firmly clamps the stator of the torque motor 5 under test;

[0044]Step 3: Power up the measured torque motor 5 to generate torque, and make the working voltage of the measured torque motor 5 continuously adjustable under the condition of not higher than the rated voltage of the motor; at the same time, the dynamometer 1 The current torque of 5 adds corresponding reverse torque to it, so that the measured torque motor 5 stops rotating; the continuous peak stall time of the measured torque motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com