Chip structure product aoi testing equipment

A technology for testing equipment and products, applied to measuring devices, instruments, optical devices, etc., can solve problems such as low measurement accuracy and low measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

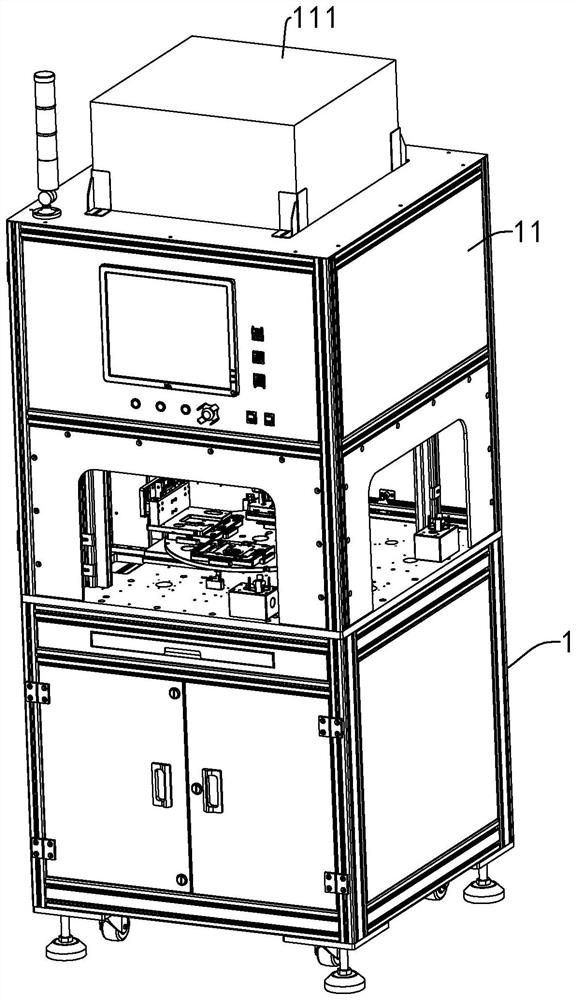

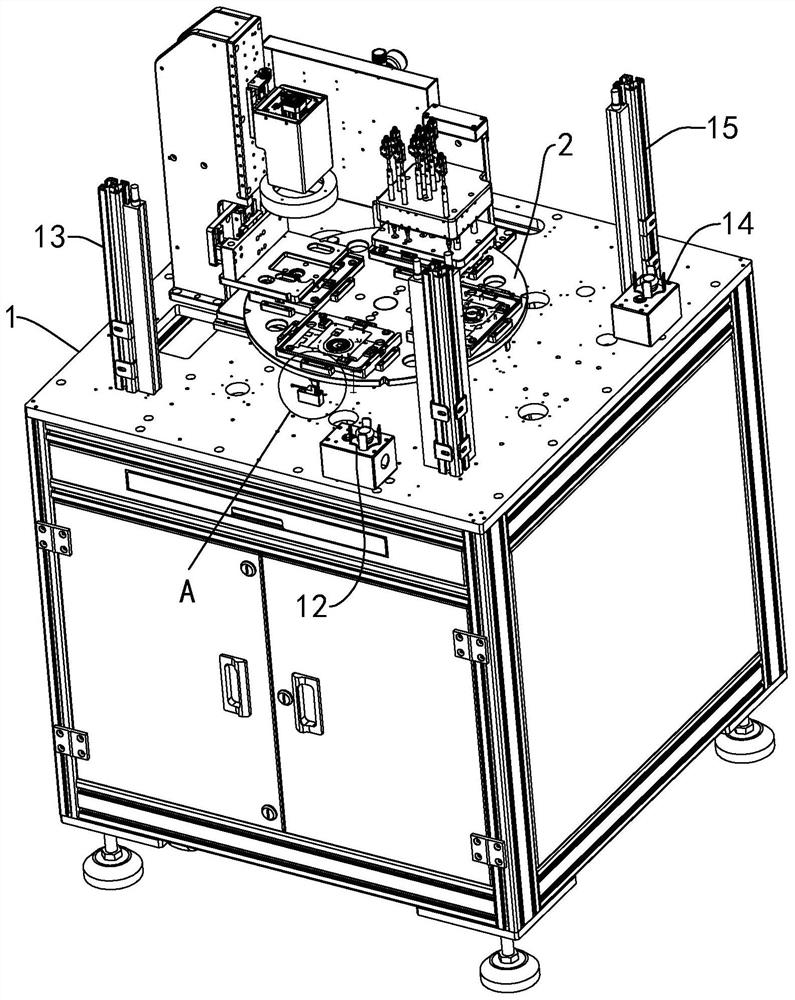

[0050] refer to figure 1 , is a piece-type structure AOI detection equipment disclosed in the present invention, including a frame 1, an upper machine cover 11 is arranged on the frame 1, and an air purification system 111 is arranged on the upper machine cover 11, and the air purification system 111 is used for filtering Fine dust in the air inside the equipment.

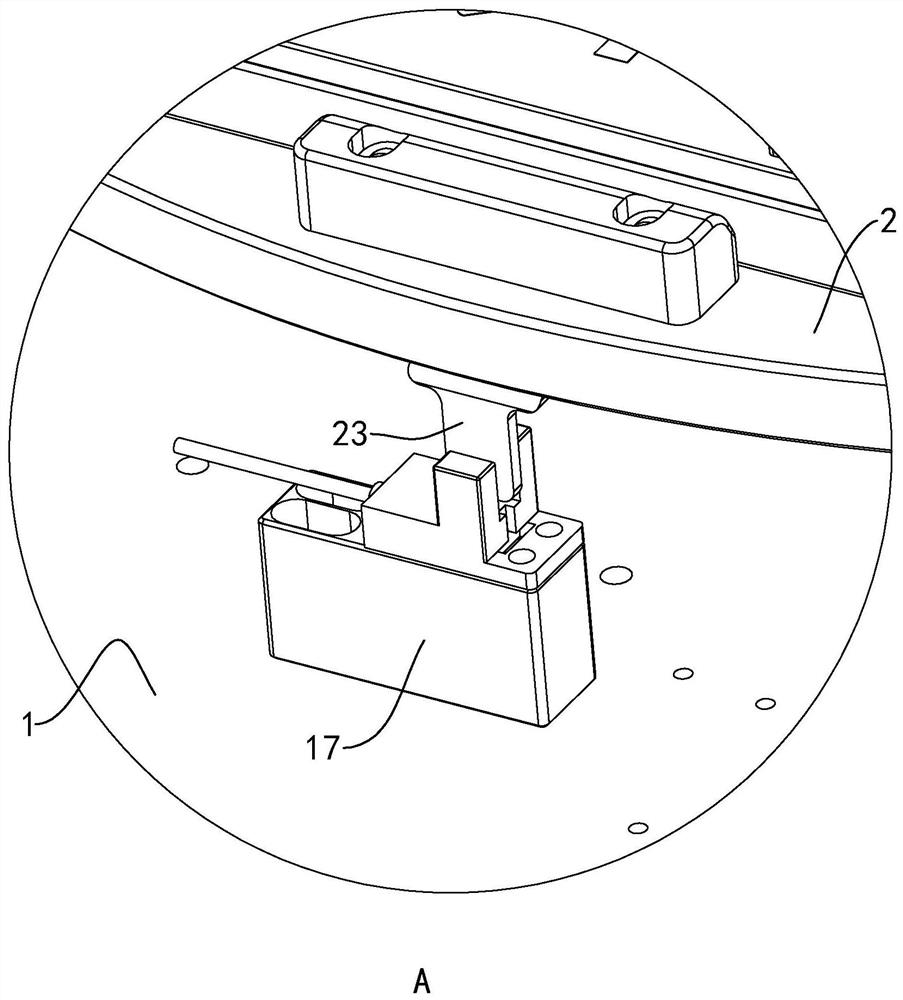

[0051] join figure 2 and Figure 4 , the frame 1 is provided with a transfer tray 2, and the frame 1 is sequentially provided with a feeding station 51, a plane inspection station 52, a thickness inspection station 53, and a discharge station 54 along the outer circumference of the transfer tray 2, A jig 4 is provided on the transfer tray 2, and the jig 4 is used to place the product to be tested. The products tested in this embodiment are the upper film, the lower film and the conductive graphite sheet in the wireless charging device.

[0052] refer to Figure 10 and Figure 11 , The jig 4 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com