Patents

Literature

58results about How to "Measurement results have no effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

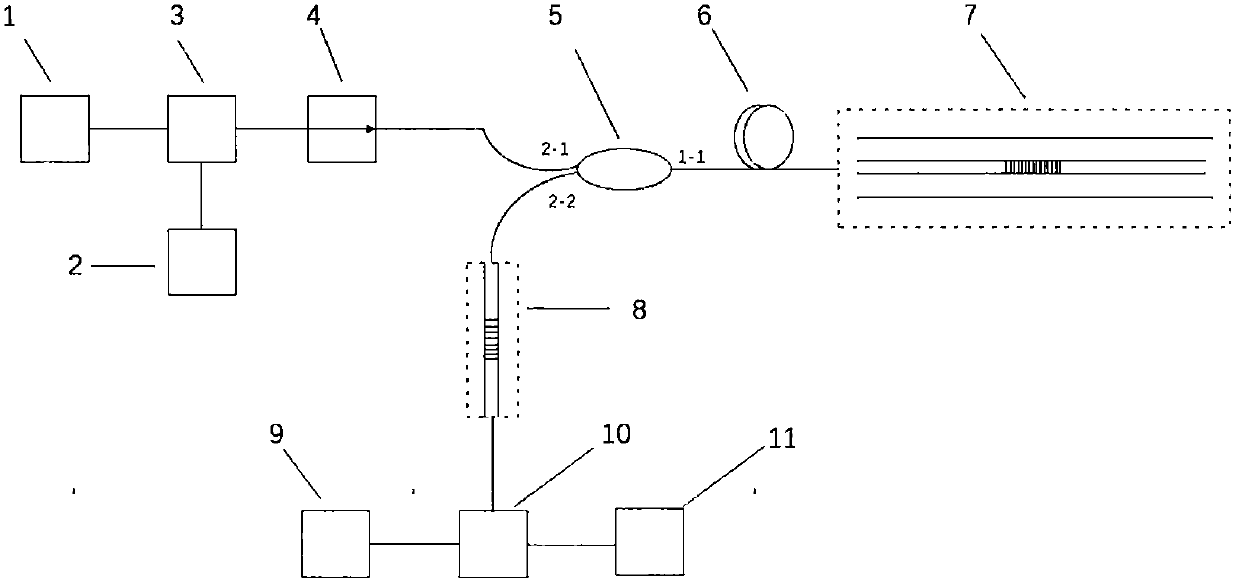

Method and device for measuring two-phase flow parameter based on double-end capacitance probe

InactiveCN101413911ANo electrolysisNo polarization problemFluid speed measurementMaterial capacitanceMeasurement deviceEngineering

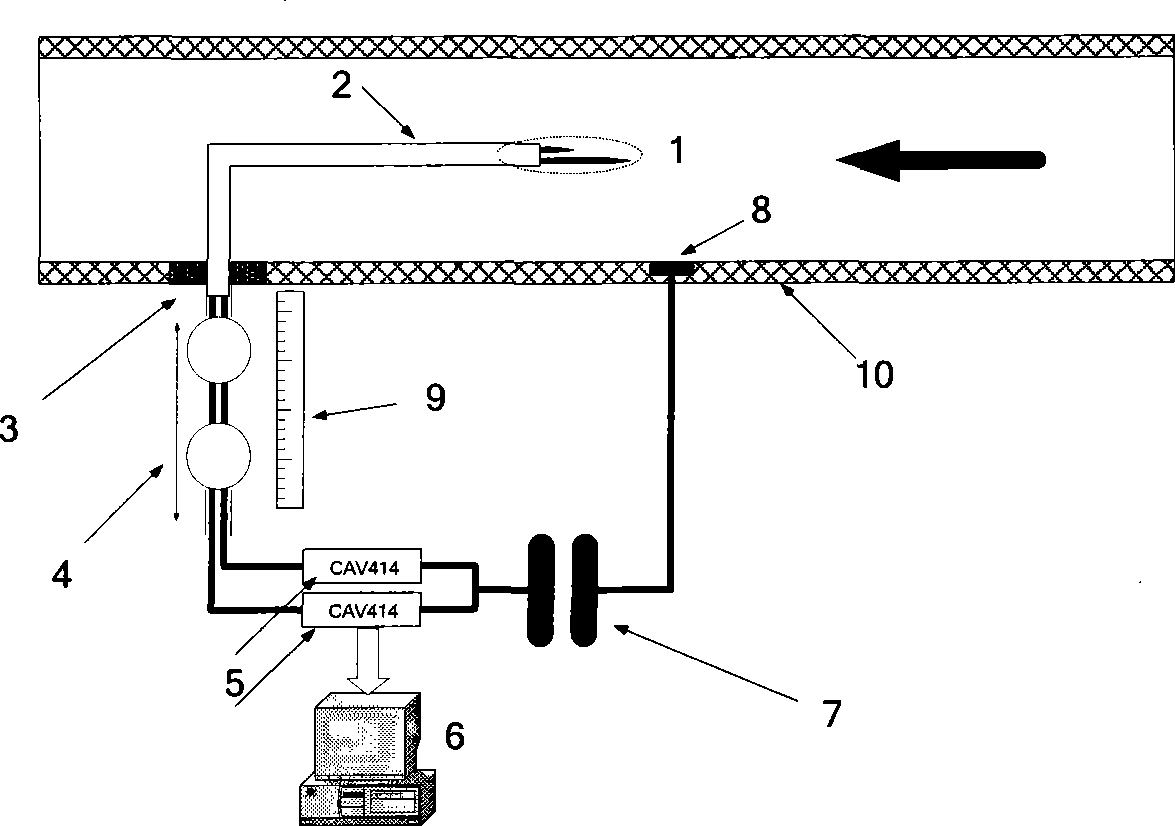

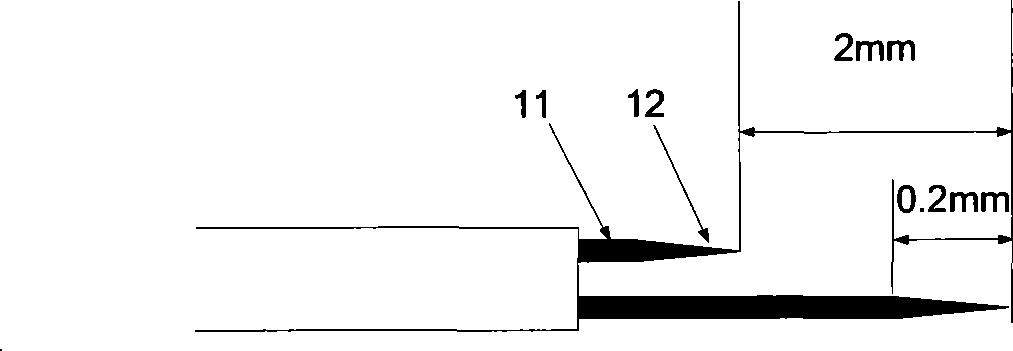

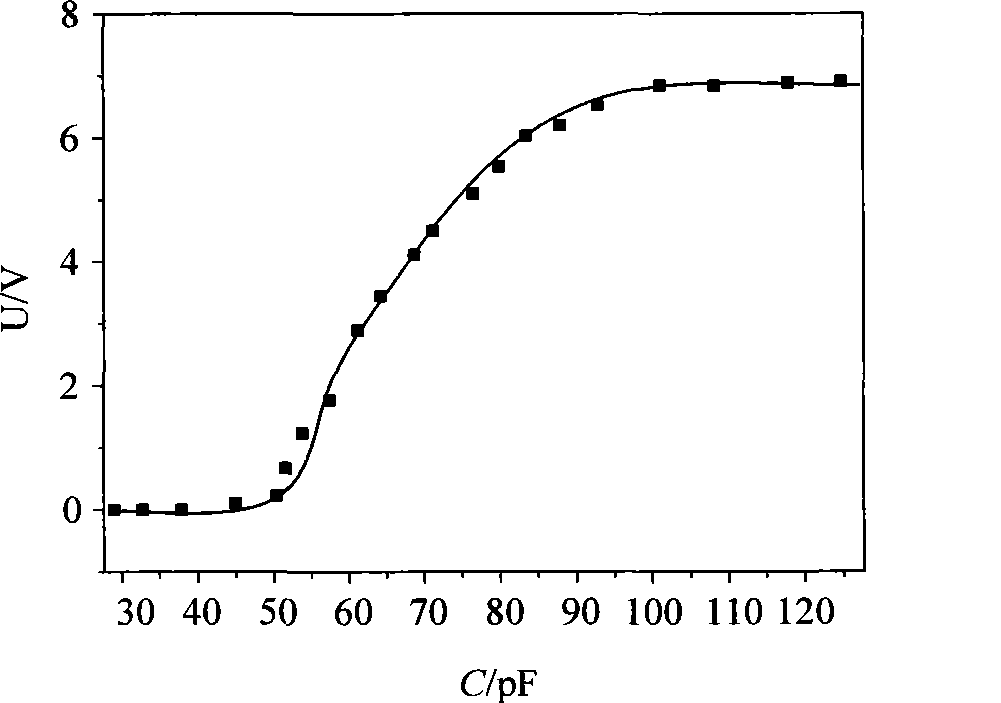

The invention provides a two-phase flow parameter measurement method based on a dual-head capacitance probe and a device thereof, belonging to the field of multi-phase flow testing technology. The device comprises the dual-head capacitance probe, a probe driving mechanism, two capacitance measurement circuits, a fixed capacitor, a slab electrode and a computer system; wherein, the dual-head capacitance probe system consists of two independent single-point capacitance probes and can carry out one-dimensional motion on the section of a pipeline. The method comprises the steps as follows: each single-point capacitance probe is used for recognizing fluid property; when the fluid passing through the head of the probe is conducted, the circuit is connected and the capacitance measurement device outputs high level, otherwise the circuit is cut off and the capacitance measurement device outputs low level. The level signal can obtain local phase holdup; the measurement result of the method is not affected by the conductivity of the fluid and the spacing of the probes. The local phase holdup and the flowing speed can be obtained by processing the two single-point capacitance probe signals by the threshold method and the correlation method; the flowing pattern information can be obtained by combining with two-phase flow knowledge, thus achieving the recognition of flow pattern on line.

Owner:SHANGHAI JIAO TONG UNIV

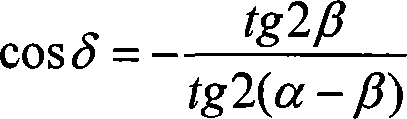

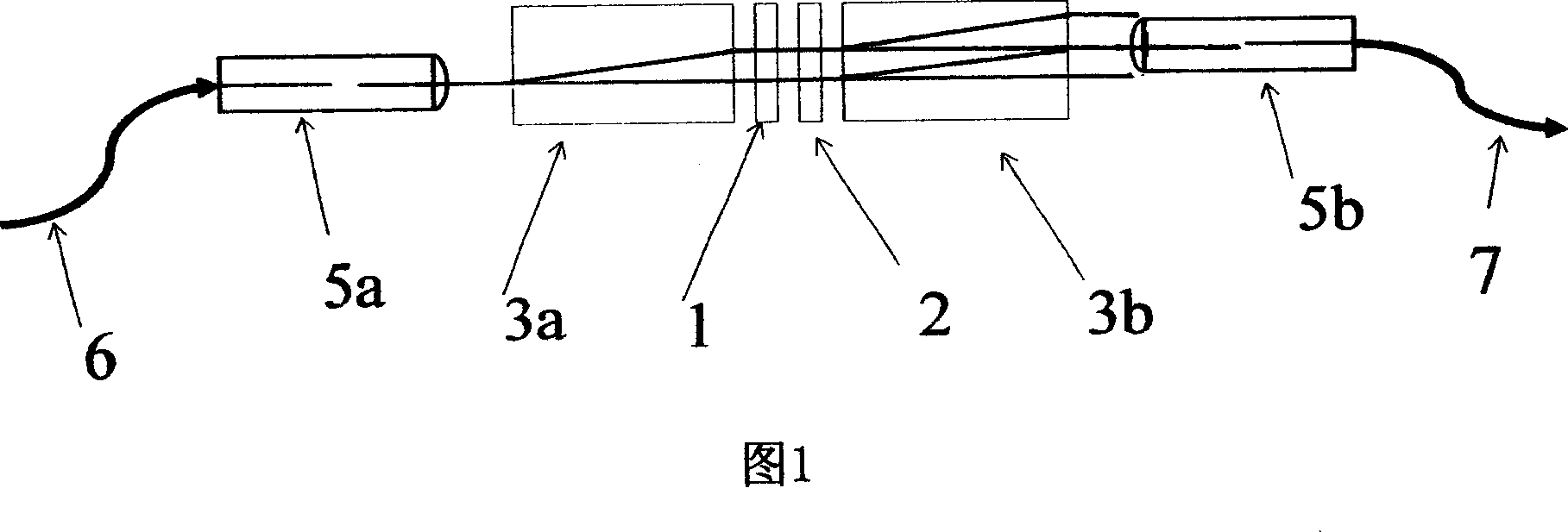

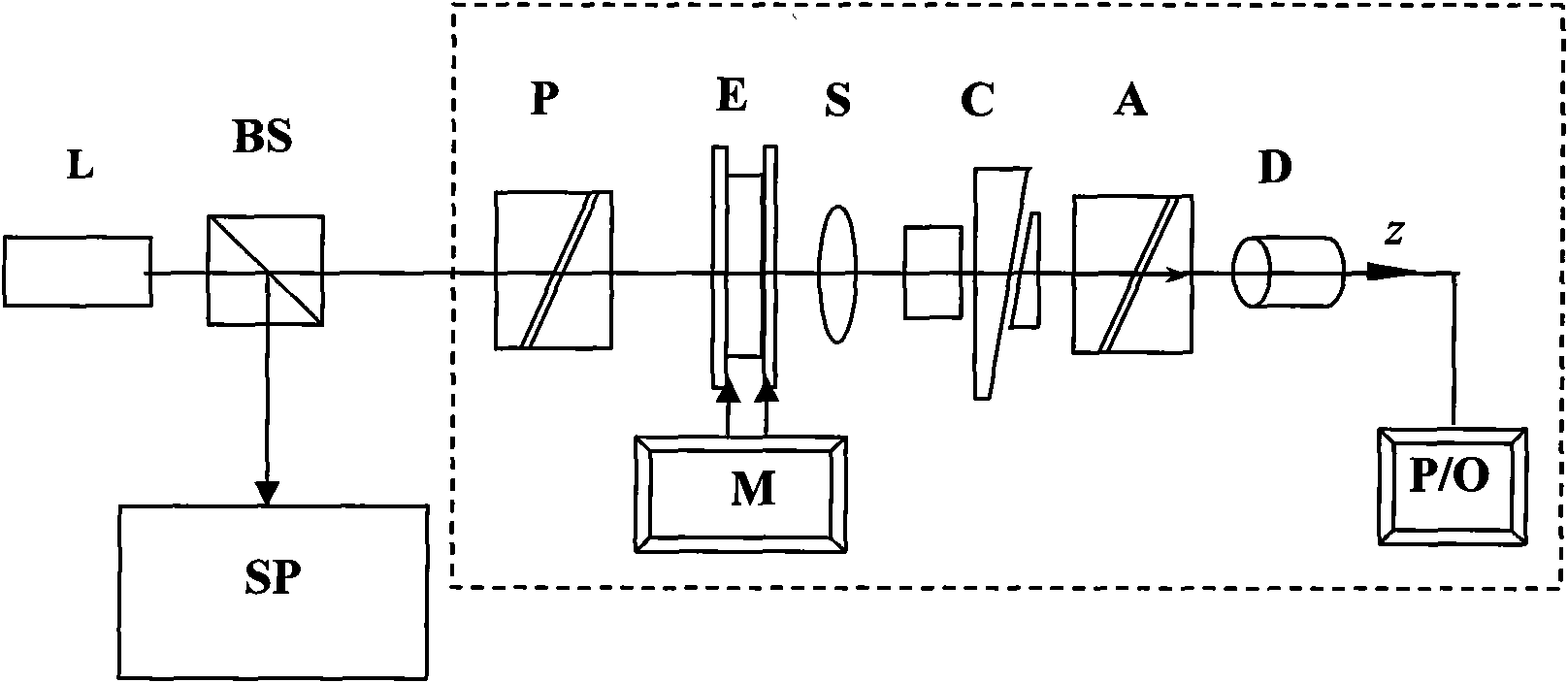

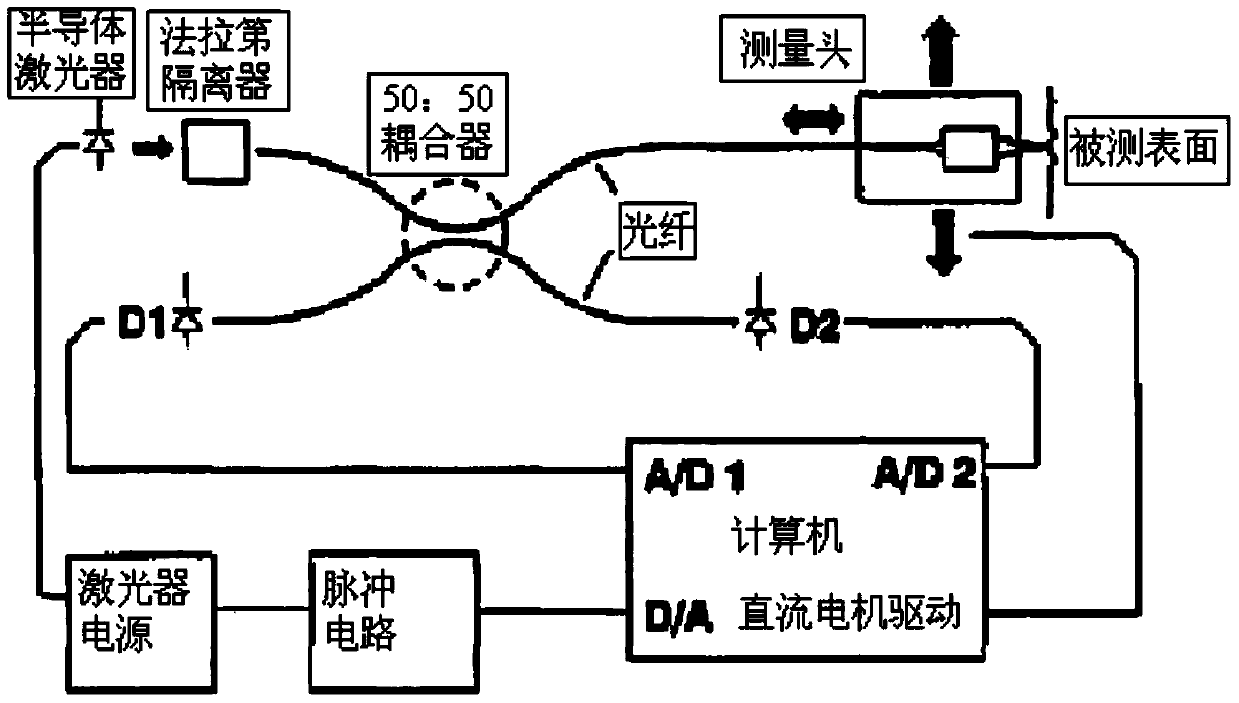

Optical phase put-off precision measurement method and system thereof

InactiveCN101183043AAdvantages of measurement accuracyEliminate unstable measurement resultsTesting optical propertiesPolarizerOptical path

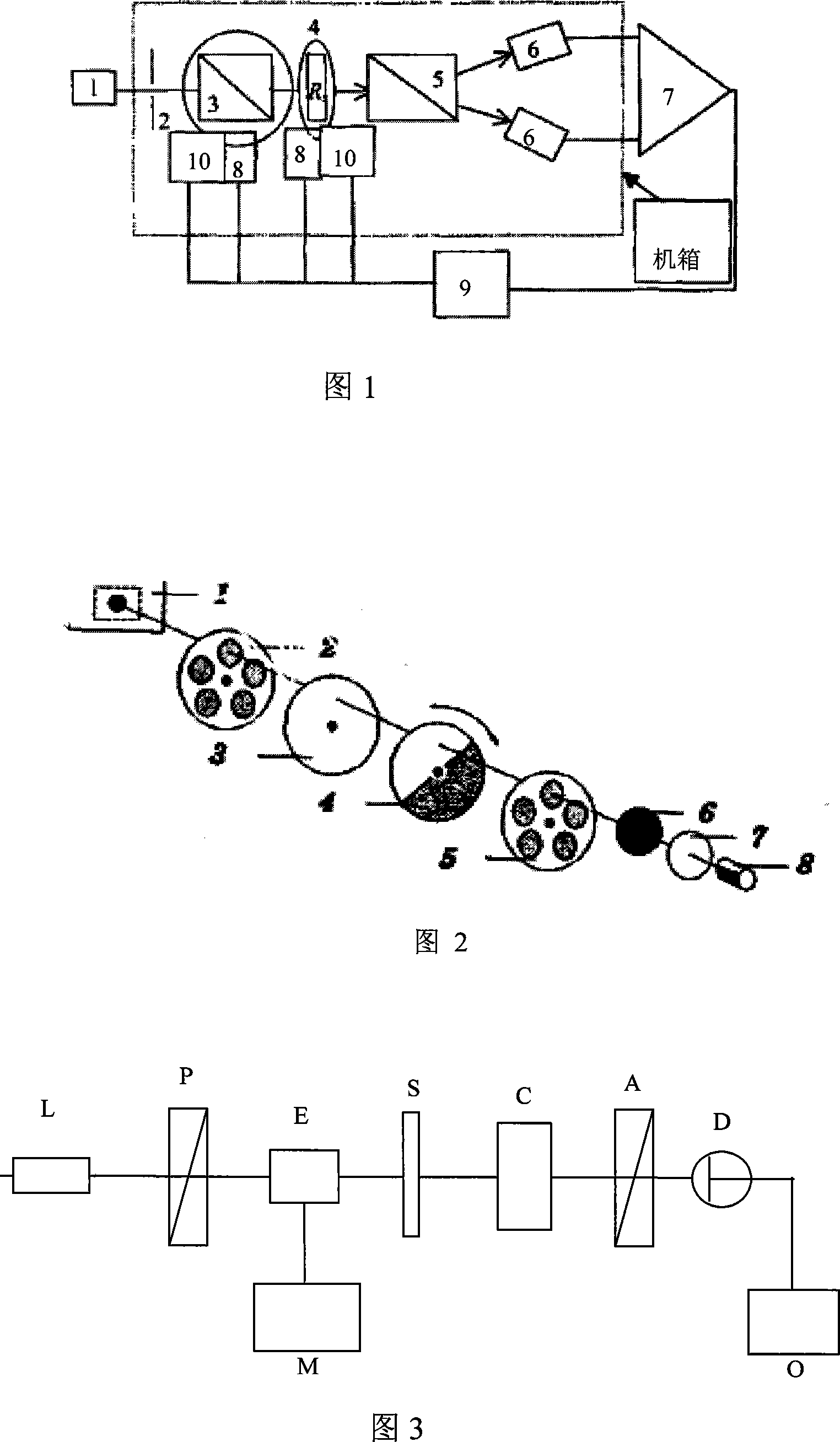

The invention discloses an optical phase delay precision measuring method and a system thereof. The system of the invention comprises a laser, a polarizer, a photo-modulator, a modulation signal source, a measuring phase retarder, a phase compensator, a polarization analyzer, an optical detector and a result output unit. The method of the invention is as follows that the optical modulator is added into a light path for optical modulation of detection polarized light and then modulation polarized light is generated; a result display unit realizes conversion from measurement of direct current zero point to measurement of alternate current zero point after conducting filtering process of the received signal, therefore, the position of an extreme point can be determined accurately and the measuring precision can be improved. The measurement of the invention is simple and convenient and the result is accurate and reliable, meanwhile, the precision is up to lambada / 300; the invention is suitable for production of a wave plate and other optical delay devices and detection of the product in the sales department.

Owner:大恒新纪元科技股份有限公司北京光电技术研究所

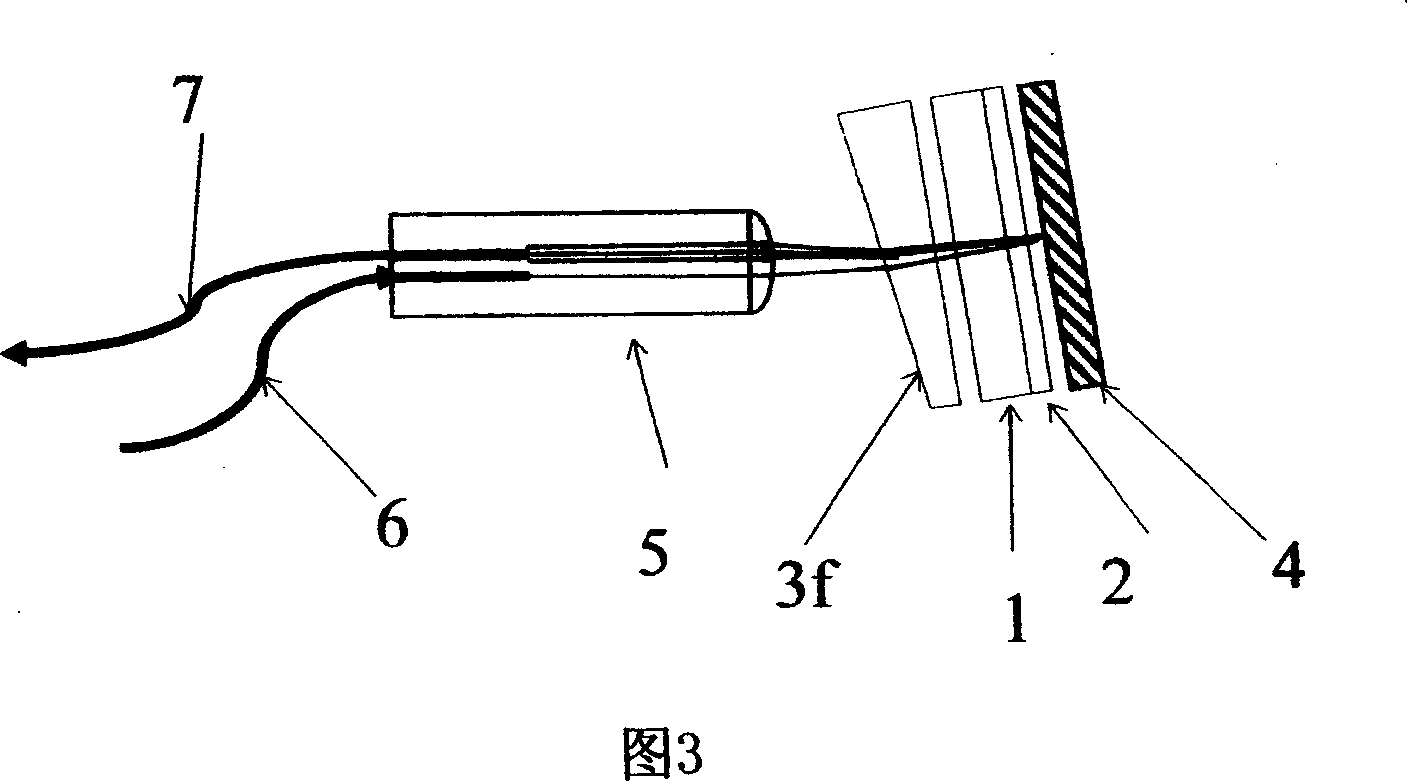

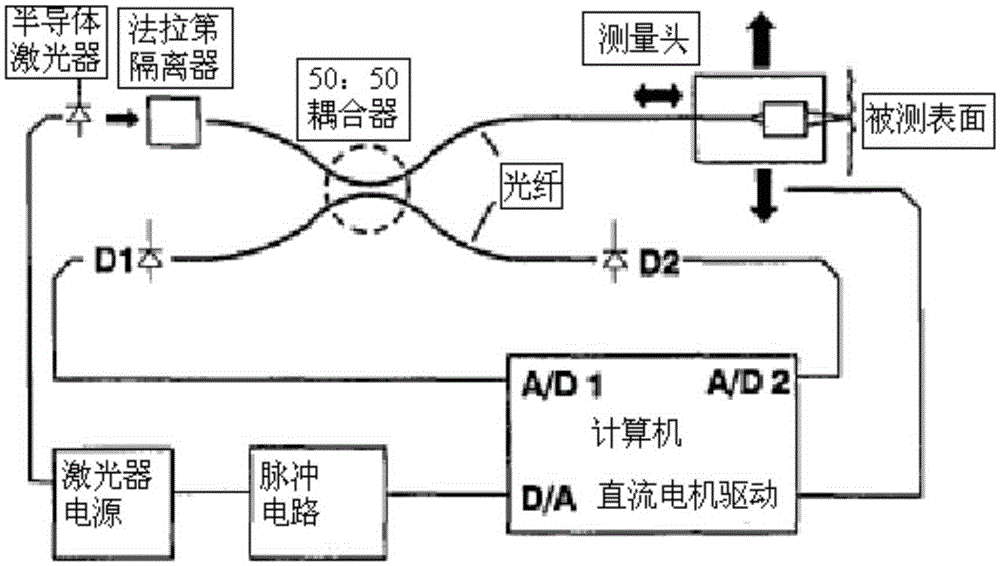

Fiber magnetic optical probe device and its usage system

InactiveCN101074983AMeasurement results have no effectReduce volumeVoltage/current isolationMagnetic field measurement using magneto-optic devicesFiberOptical polarization

A magnetic-optic probe of optical fiber consists of light being guided by optical fiber and Faraday magneto-optic rotator. It is featured as setting wave plate at back of Faraday magneto-optic rotator to use said wave plate to make rotation of polarization surface on two beams of output lights form said rotator and carrying out magneto-optic induction and polarization detection on two orthogonal polarization components simultaneously in equivalent way.

Owner:SIEYUAN ELECTRIC CO LTD

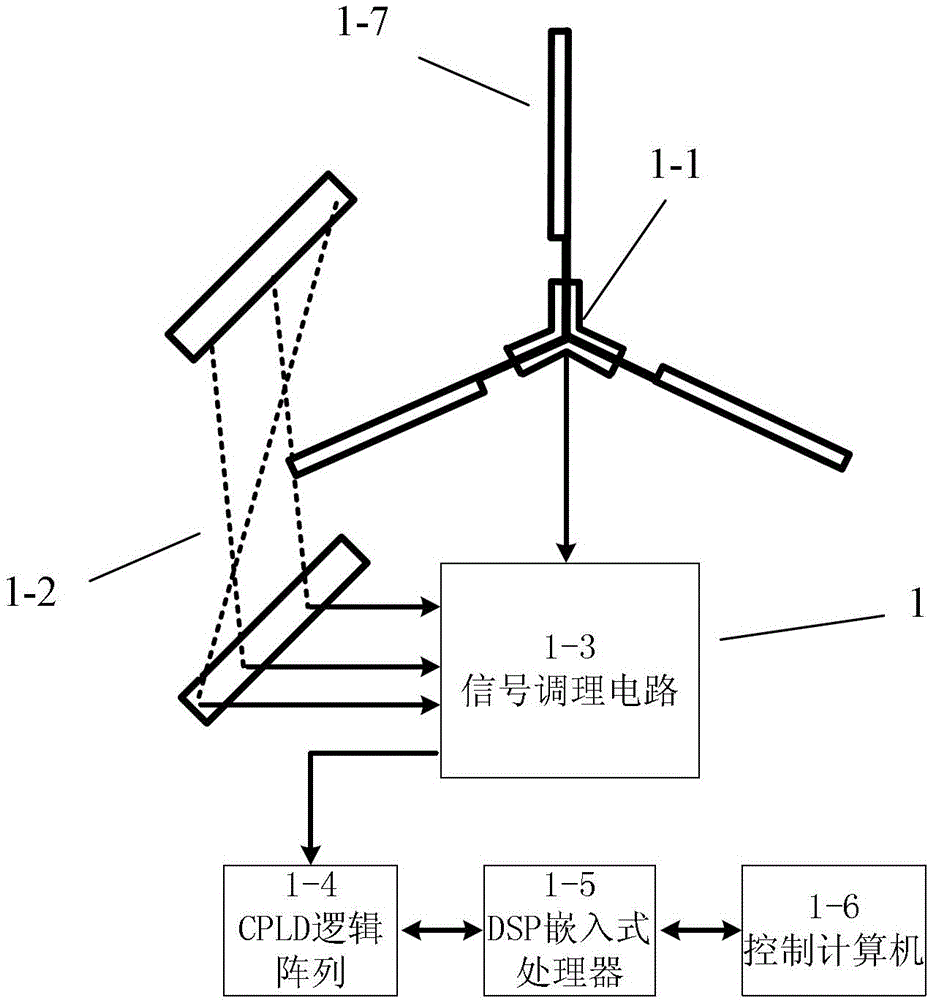

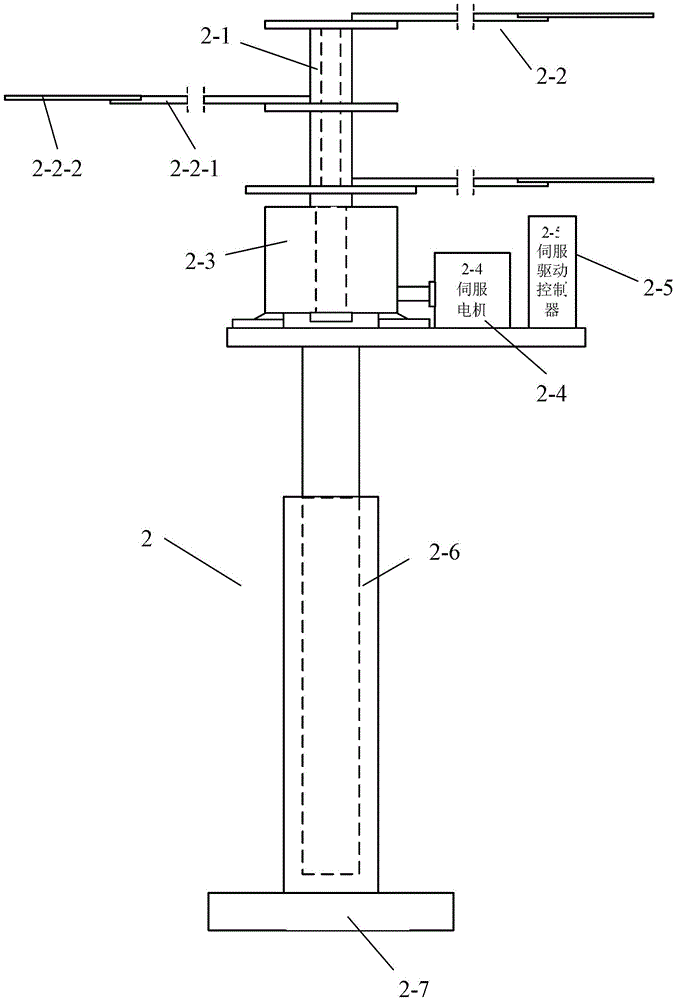

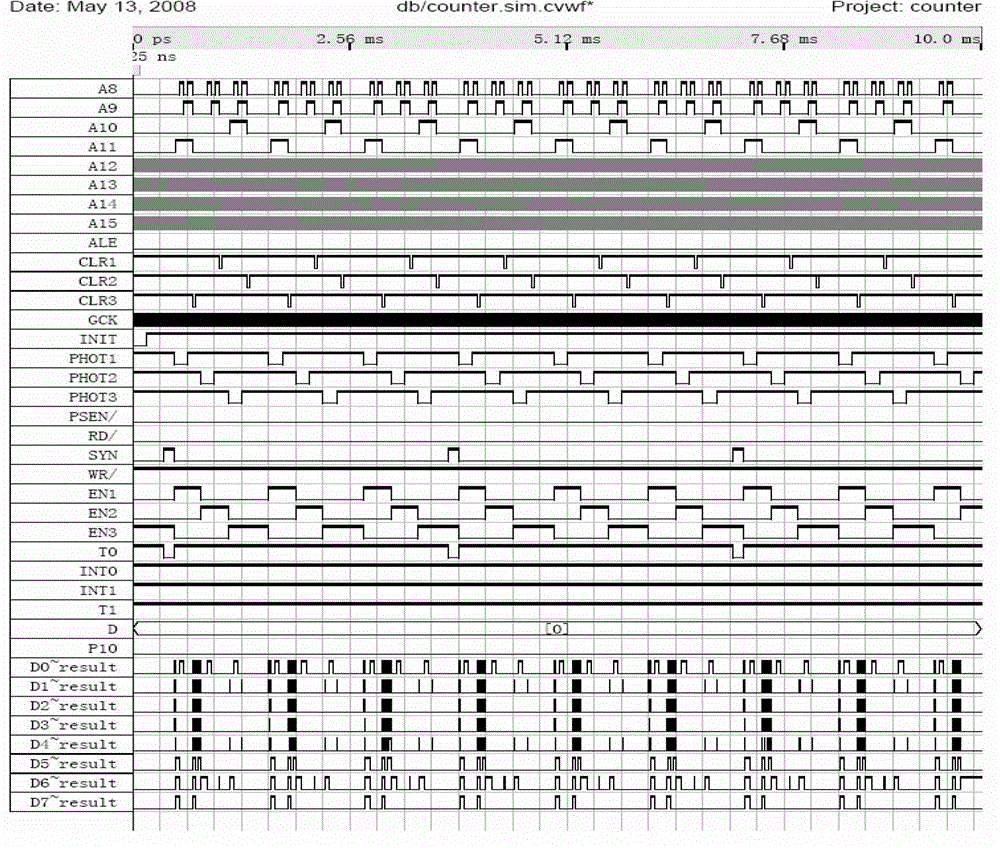

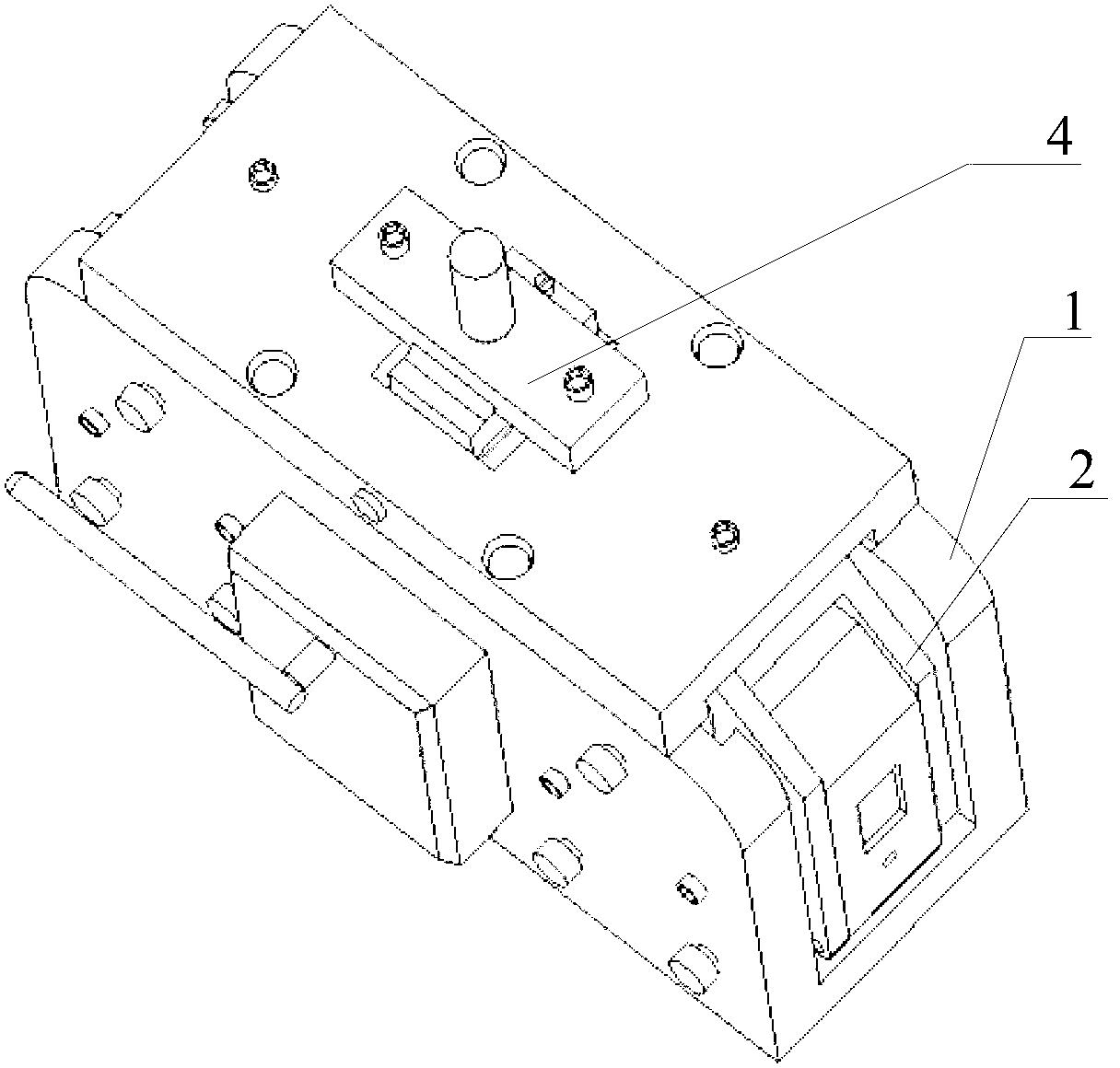

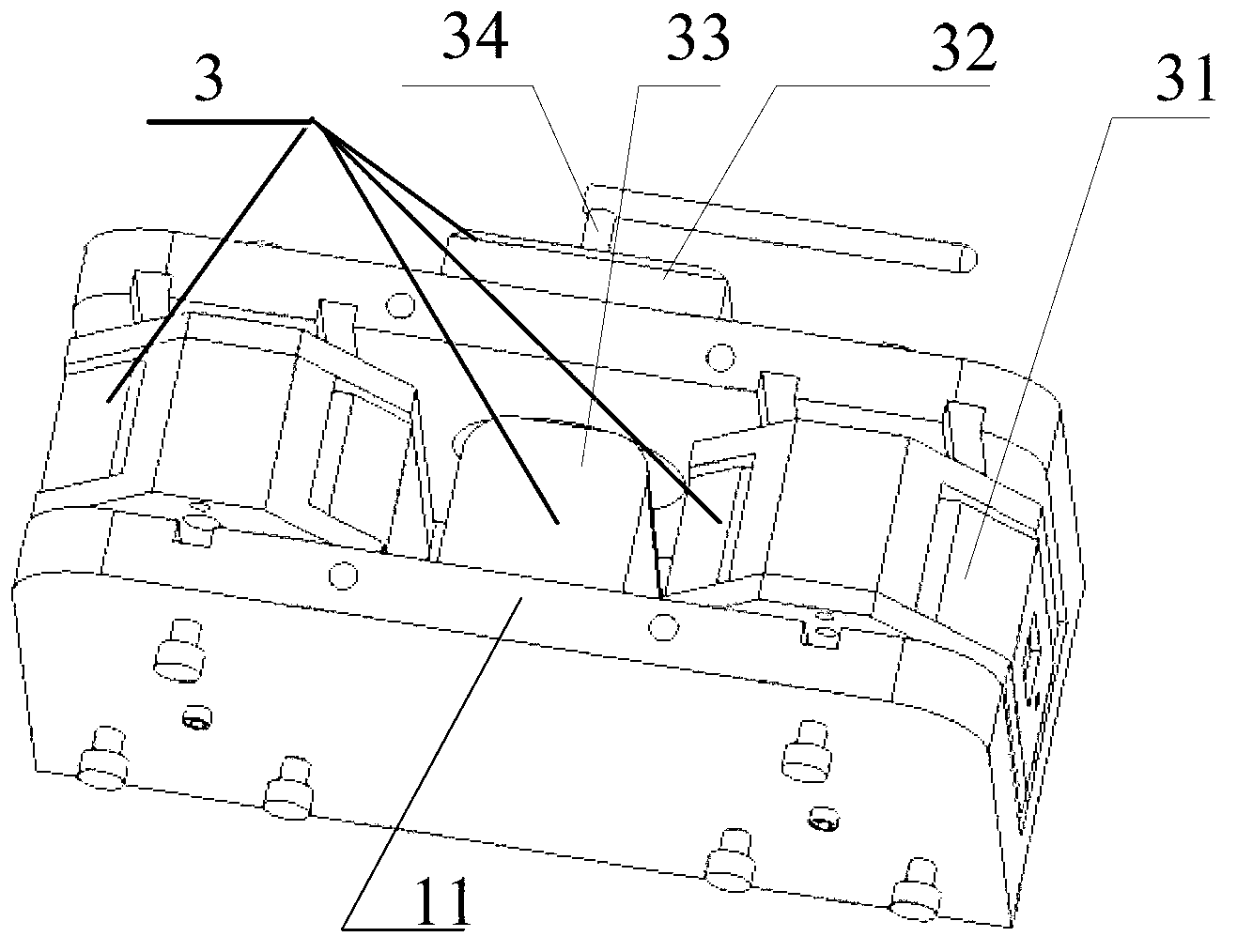

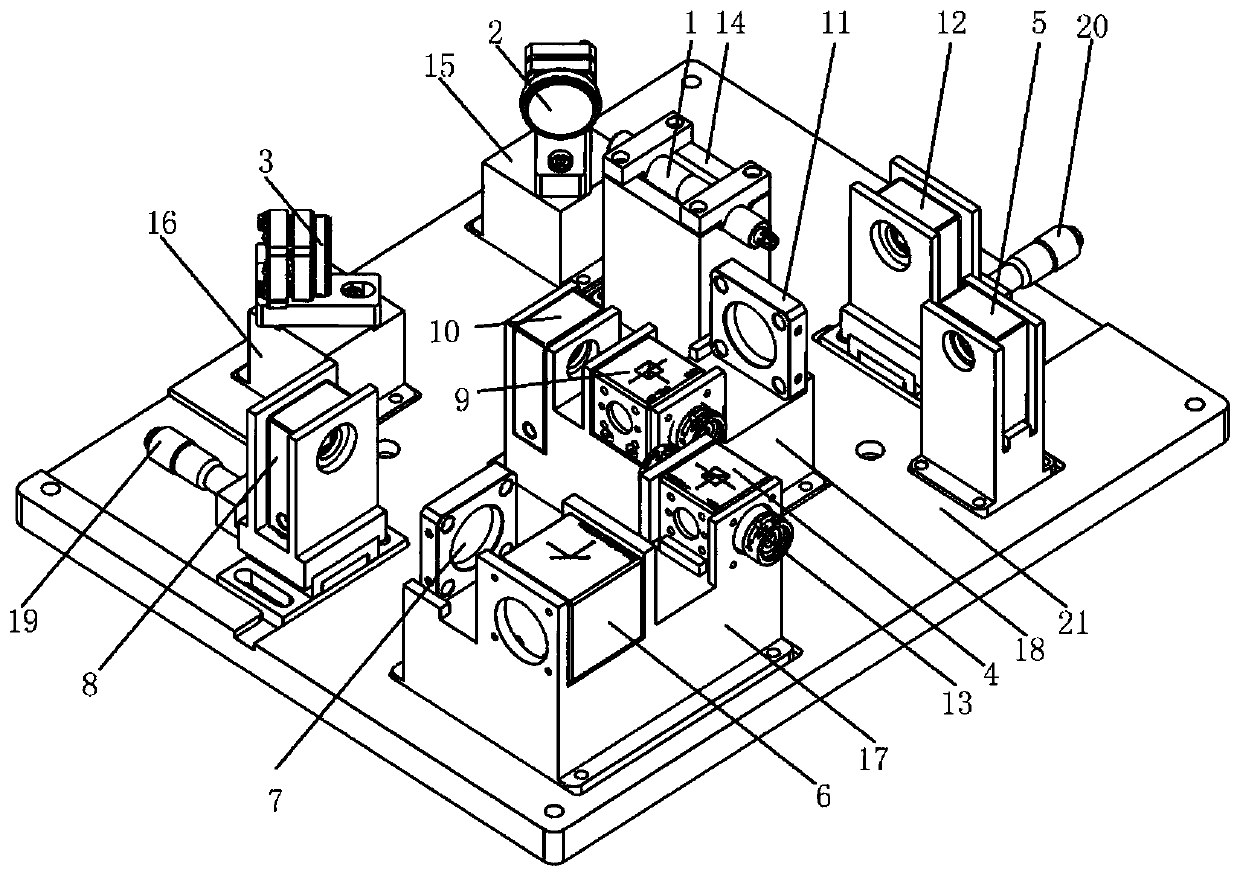

Device for calibrating dynamic balance parameter of helicopter rotor blade

InactiveCN102944361AMeasurement results have no effectGuaranteed accuracyStatic/dynamic balance measurementDynamic balanceComplex programmable logic device

The invention discloses a device for calibrating a dynamic balance parameter of a helicopter rotor blade and relates to a test and calibration technology of a helicopter rotor blade, and the device is used for solving the problems such as big error in measurement result and poor reliability in the dynamic balance test calibration of the helicopter rotor blade in the prior background art. A laser measurement platform is formed by a three-beam laser device of a dynamic balance test table; the flapping parameter of the rotor blade is measured in a non-contact way through a method of cutting laser beams by the blade; a pulse time sequence measuring and controlling system is designed by taking a CPLD (Complex Programmable Logic Device) and a DSP (Digital Signal Processor) as cores; and the flapping and shimmy characteristic parameters of the rotor blade are measured. A simulated blade with fixed height difference is adopted in a calibration device and rotated at a stable rotation speed through a servo motor, the dynamic balance test platform of the rotor blade is calibrated on site through a method of cutting the laser beams by the simulated blade, the calibration result is traced to national length standard, the accuracy and traceability of the measurement result are ensured, and a quality guarantee is provided for the development and test of the helicopter rotor blade.

Owner:HARBIN INST OF TECH

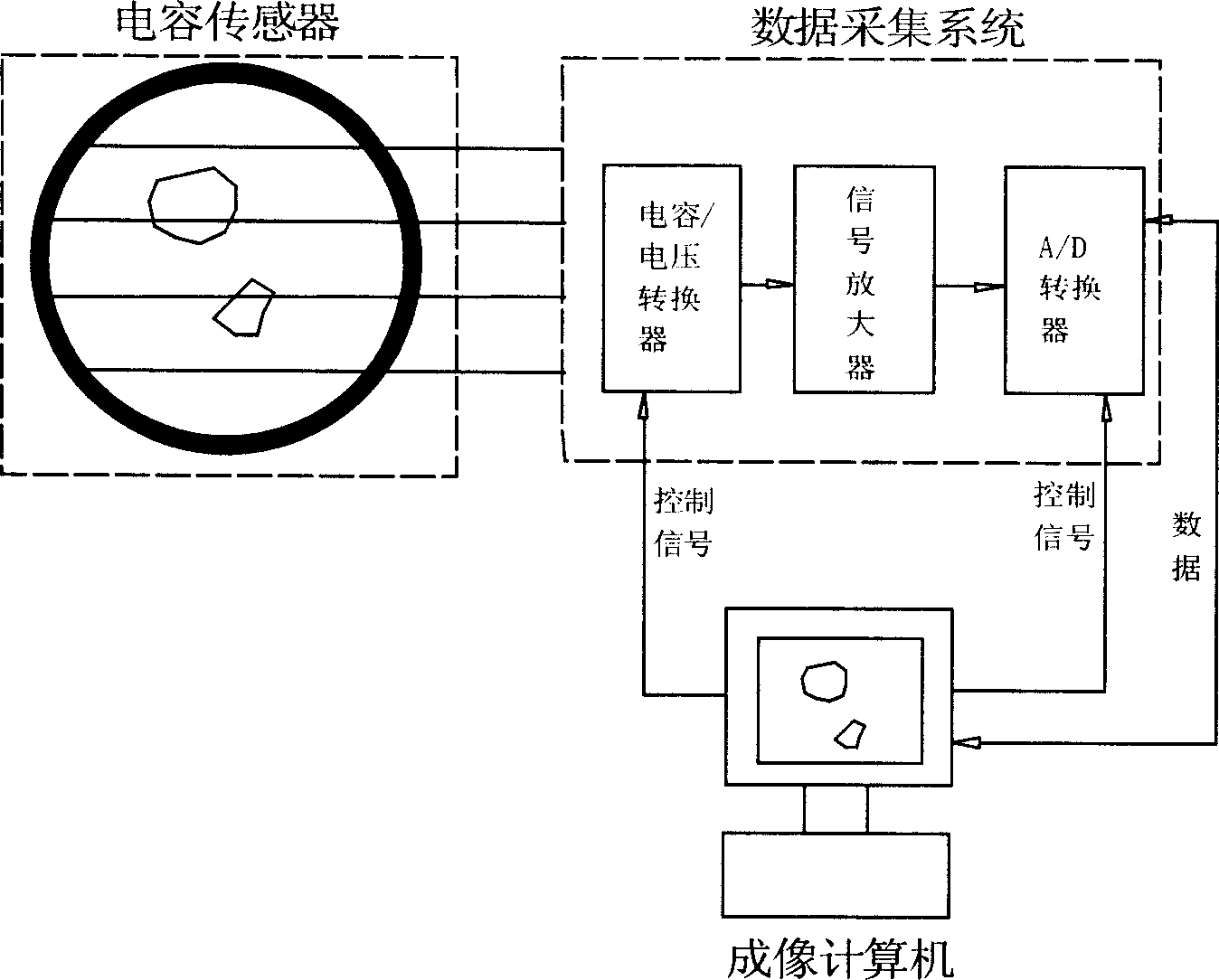

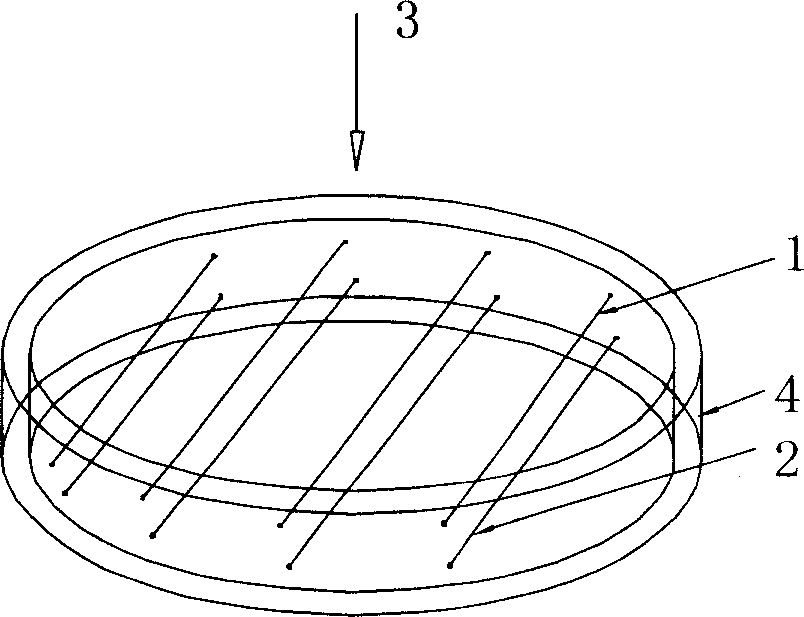

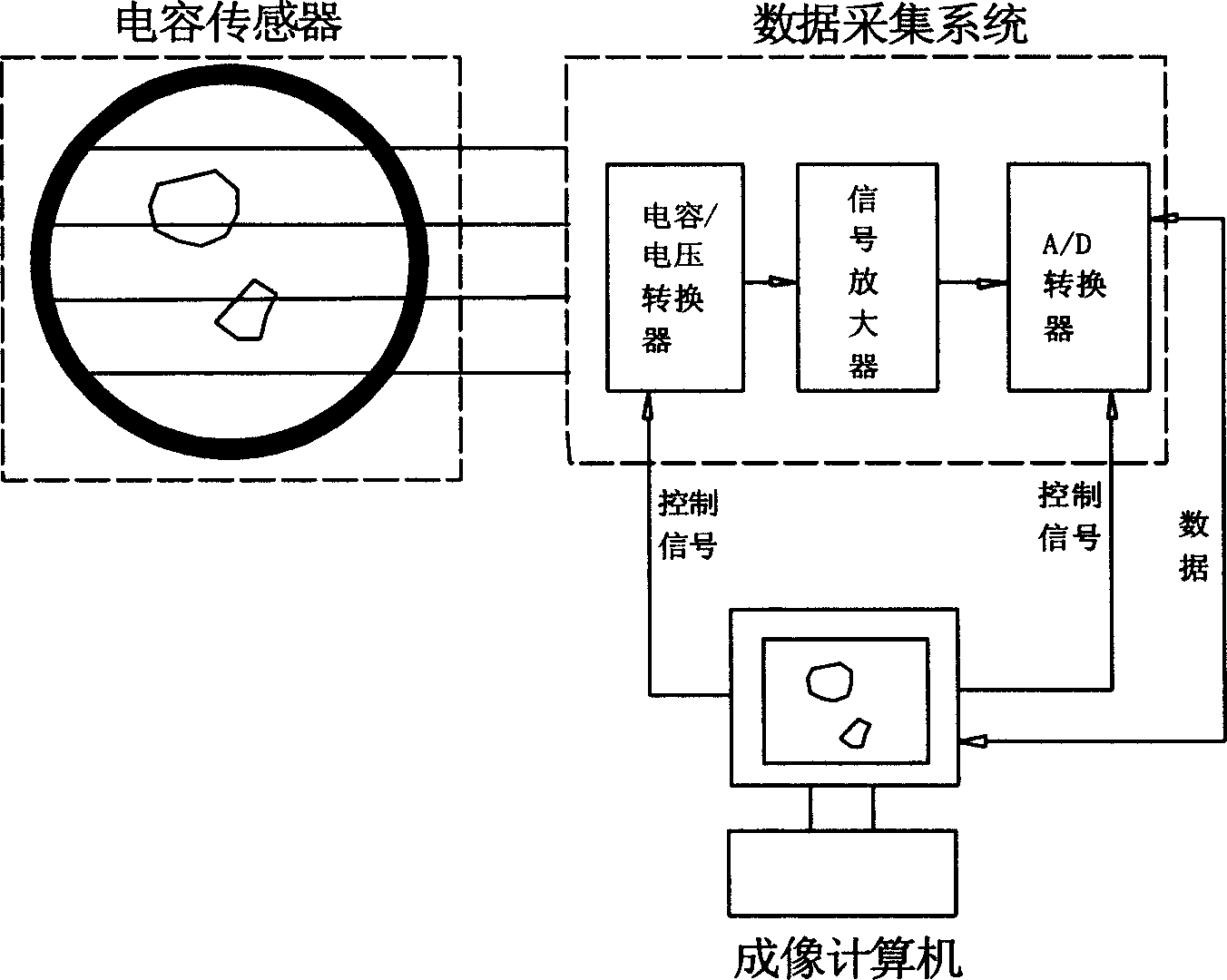

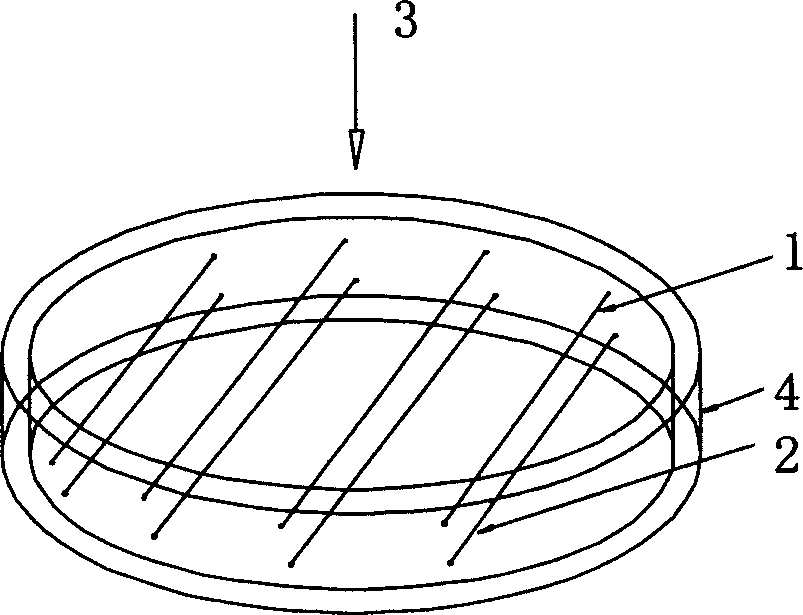

Two-phase fluid grid and capacitor chromatography imaging method

InactiveCN1854726AFlexible layoutHigh sensitivityResistance/reactance/impedenceMaterial capacitanceElectrical capacitance tomographyEngineering

A twine capacity chromatographic imaging method of two-phase fluid includes using metal core in insulation line as one electrode of said capacity and forming another electrode of it by conductive phase in two-phase fluid and contact surface of twine, using insulation layer at surface layer as insulator between electrodes and confirming its capacity value, using motor to drive transducer in insertion twine capacity type to carry out high speed scan on two-phase fluid in pipeline to obtain projection information of two-phase fluid at various directions on cross section of pipeline for having real time flowing image of said fluid.

Owner:XI AN JIAOTONG UNIV

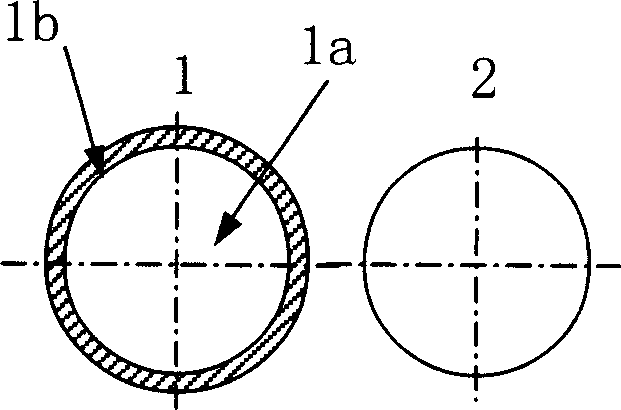

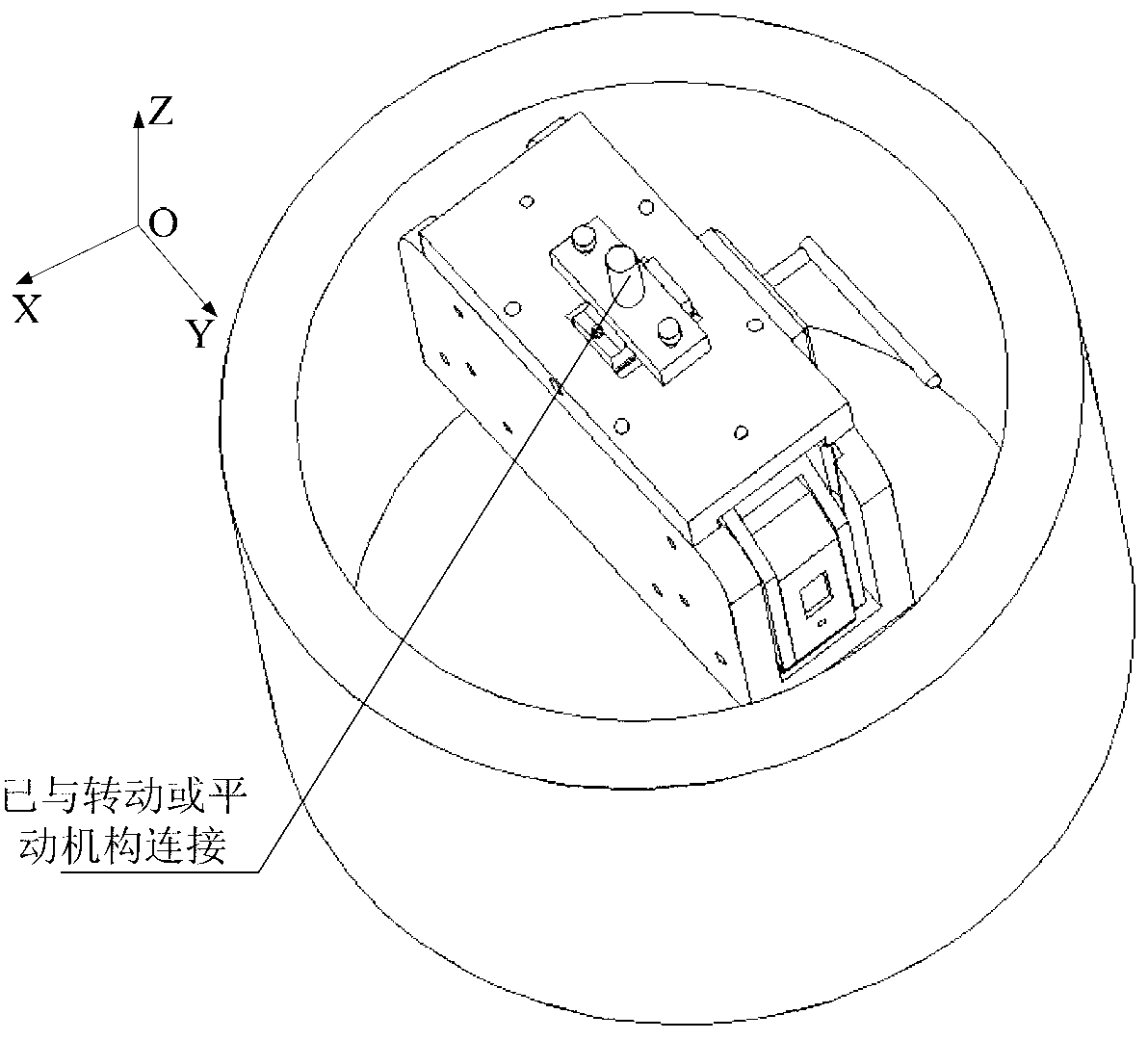

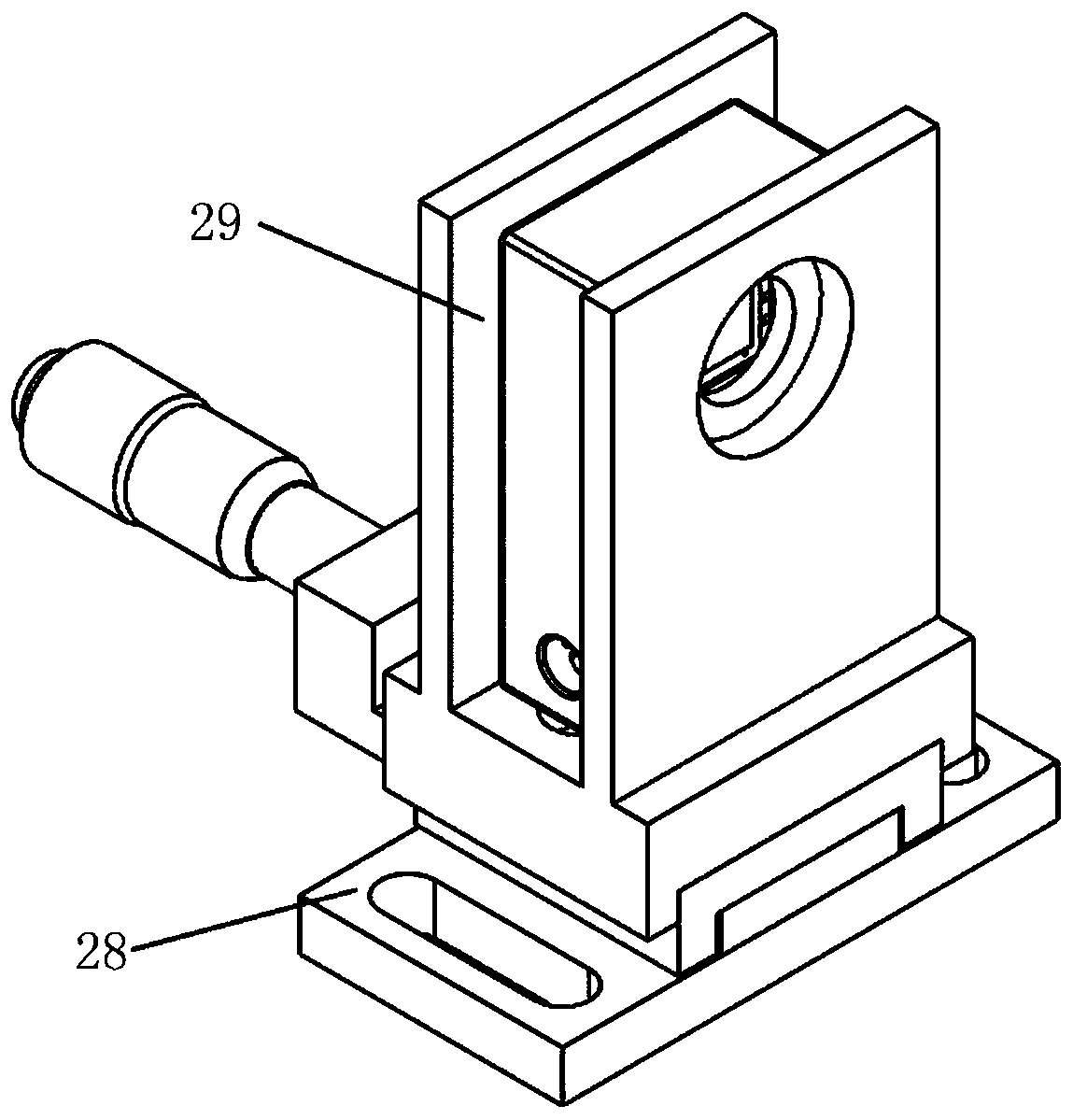

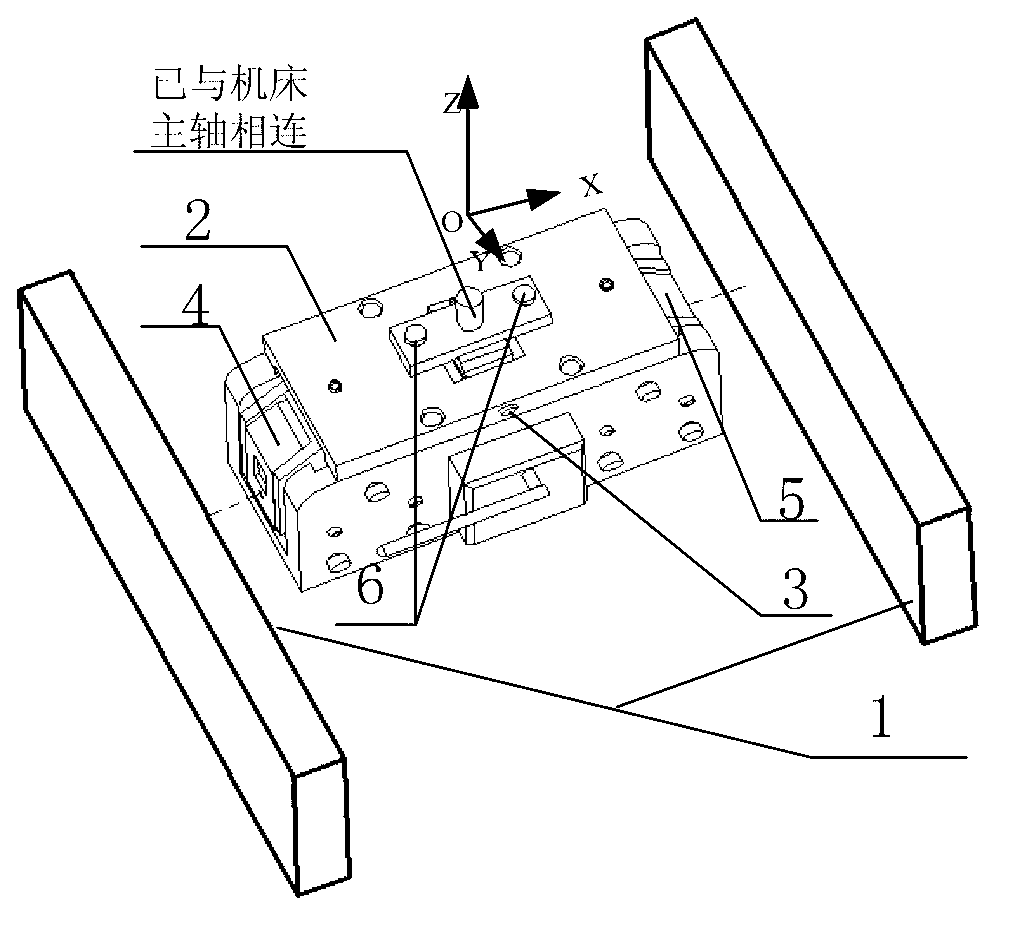

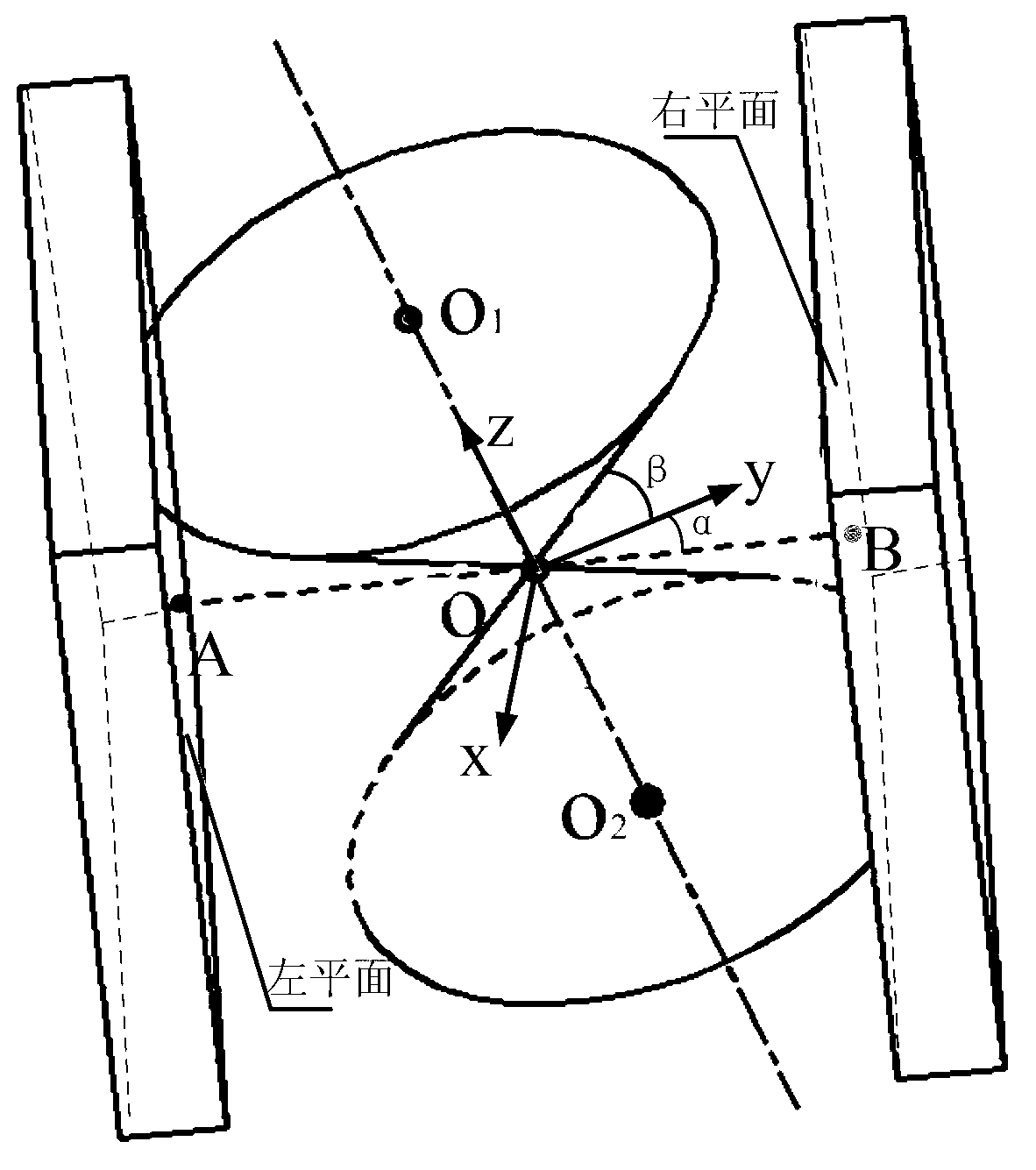

Aperture measuring method based on non-contacting type sensor combination

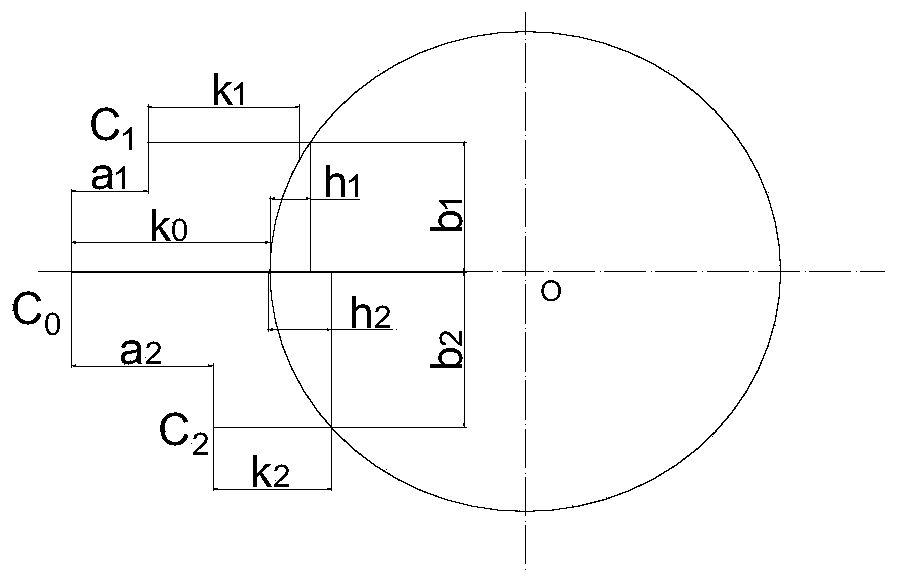

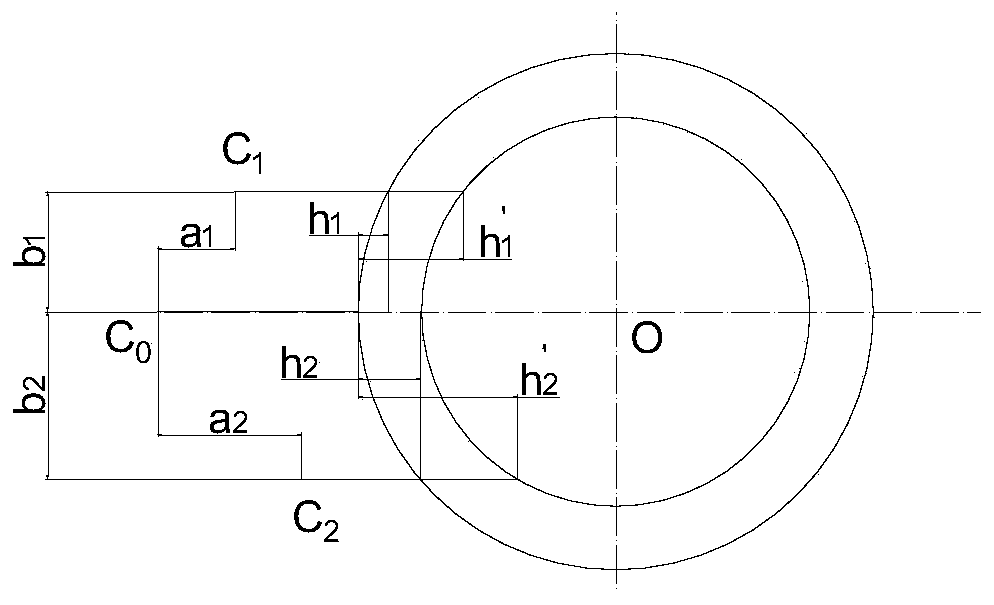

InactiveCN103278100AQuick and accurate measurementImprove detection accuracyUsing optical meansOptical axisDual sensor

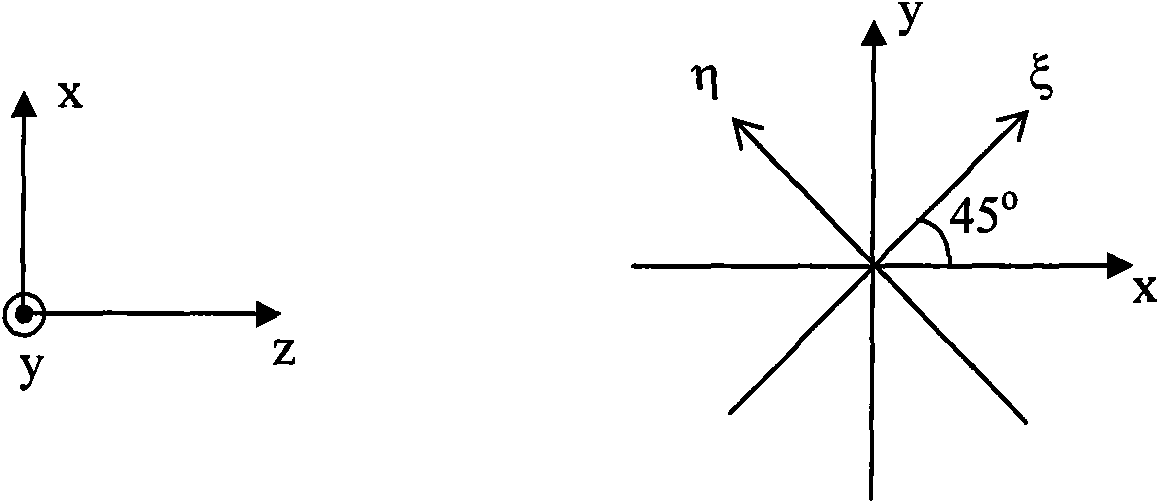

The invention discloses an aperture measuring method based on non-contacting type sensor combination, is suitable for measuring the size of the inner diameter of a workpiece, and relates to the geometric sense measuring field. The method comprises the following steps: first, installing a main shaft of a double-sensor measuring head on a mechanism with the horizontal moving function so as to form a complete set of measuring system which is arranged in a workpiece to be measured; at measuring time, measuring optical axes of two sensors on the double-sensor measuring head being enabled to be on the same straight line; the double-sensor measuring head first rotating on a ZOY face, and then horizontally moving on an XOY face, finally the diameter of an inner hole of the workpiece to be measured is obtained; or, the double-sensor measuring head sequentially rotates on the ZOY face and the XOY face to obtain the diameter of the inner hole of the workpiece to be measured. When the method is used for measuring the diameter of the inner hole of the workpiece to be measured, only two procedures need operating theoretically, so that measuring efficiency is greatly improved, and a large number of measuring labor hours are saved. Moreover, the non-contacting measuring head is arranged on a lathe, a motion execution mechanism of the lathe is used for enabling the measuring head to rotate or move horizontally, so that on-machine accurate measuring can be achieved.

Owner:TIANJIN UNIV

Two-phase fluid mesh capacitance tomography method

InactiveCN1595132AFlexible layoutHigh sensitivityResistance/reactance/impedenceMaterial capacitanceTomographyElectrical capacitance tomography

This invention discloses biphase current mesh capacitor tomography. The one pole of the insert mesh capacitor is a metal core in the insulation wire and the other pole is formed by the contact surface of conduct phase and mesh or wet surface in the biphase current and its surface insulation layer serves as dielectric between electrodes and identifies the capacitor value. The insert mesh capacitor sensor high-speed scan the biphase current in the pipe driven by electric or self rotation apparatus and gets the project information to different directions on the pipe section of biphase current and gets real time image of the biphase current. The insert capacitor sensor identifies local distribution information of the biphase current on whole pipe or container section and directly gets the real time image of the biphase current.

Owner:XI AN JIAOTONG UNIV

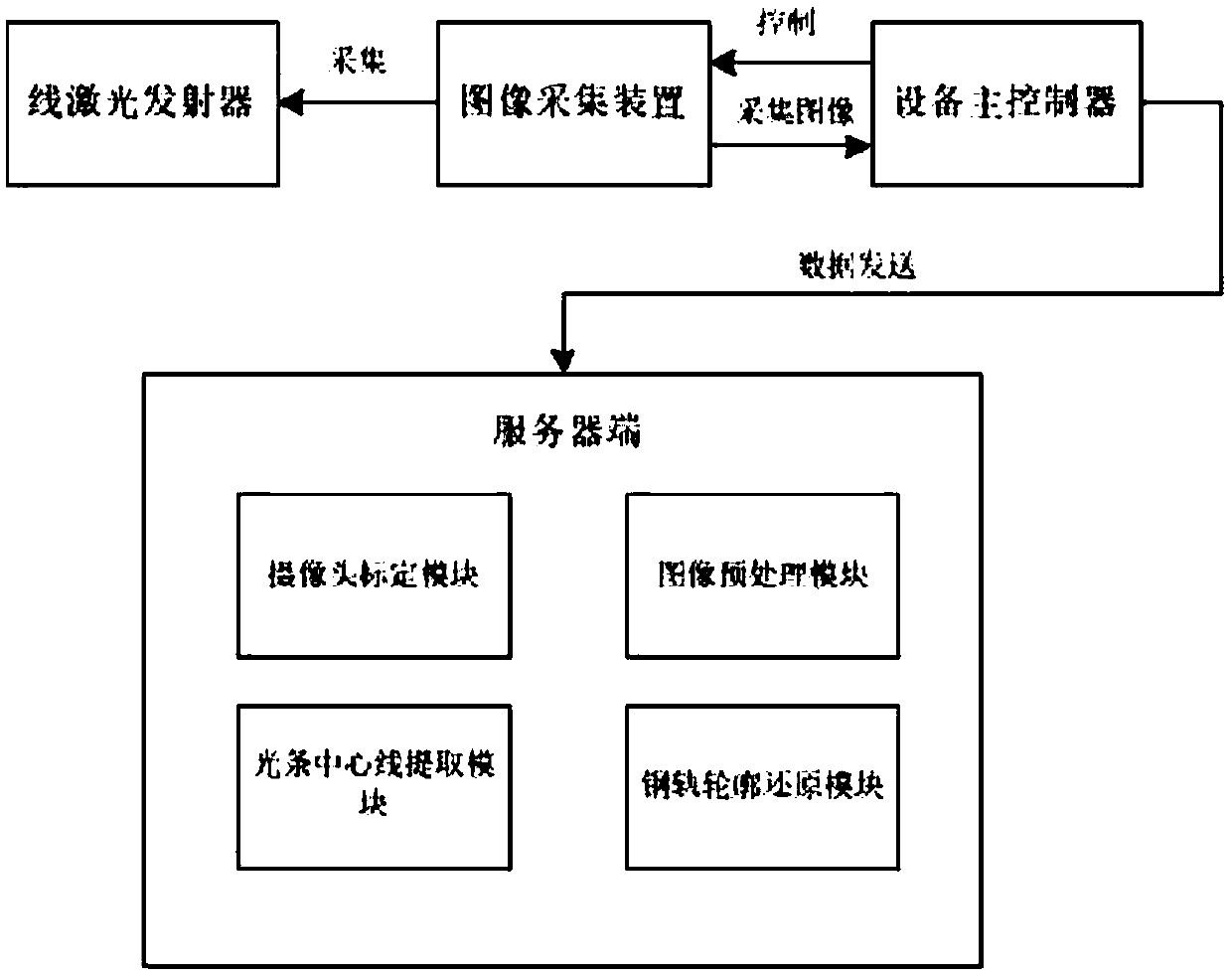

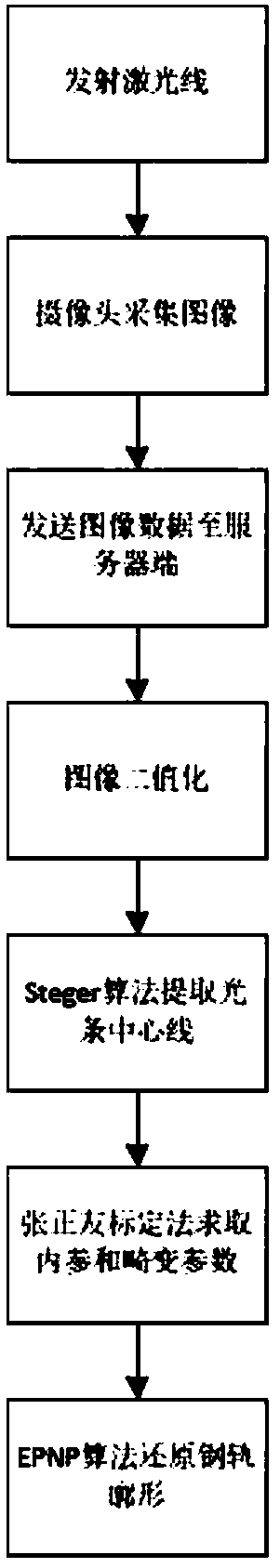

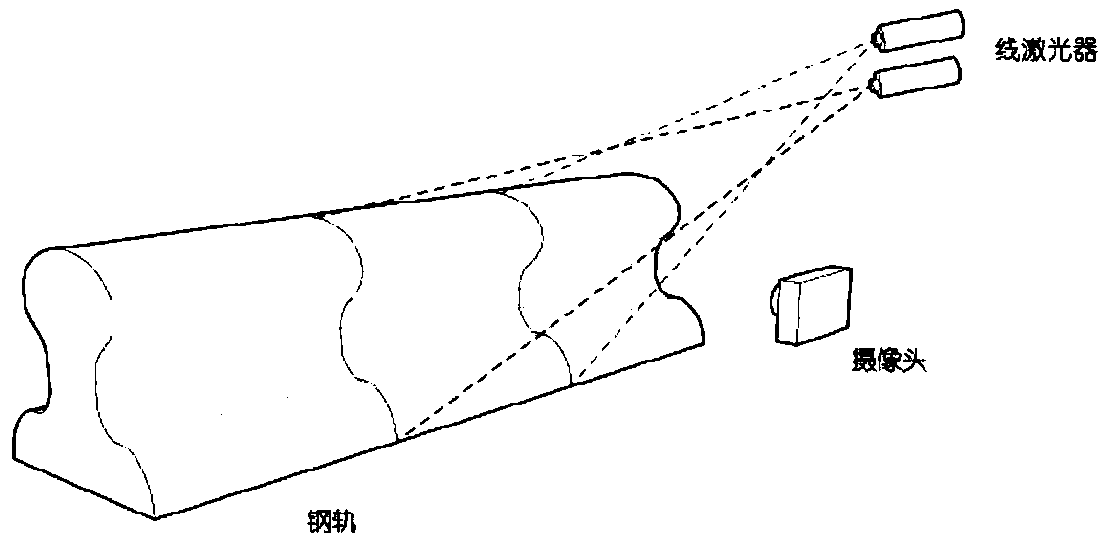

A rail profile detection method and system based on EPNP

PendingCN108986082ASolve the accuracy problemHigh precisionImage enhancementImage analysisLaser transmitterRail profile

The invention discloses a rail profile detection method and system based on EPNP. The system comprises: a line laser emitter, which is used for emitting laser lines to the rail to be detected to formlaser light strips, wherein the laser light strips correspond to the outer edge of the cross section of the rail; an image acquisition device for acquiring an image of a rail with a laser beam attached to a surface through a camera; a main controller of the equipment, which is used for sending the rail image data collected by the image collecting device to the server end.; and a server end, whichis used for receiving the image data sent by the main controller of the equipment, extracting the centerline of the light stripe in the image, obtaining the rail profile, and calculating the rail weardegree. The invention solves the problems of long time consumption and low precision of a conventional rail profile detection method, and has the advantages of low time complexity and high precision.

Owner:WUHAN UNIV OF TECH

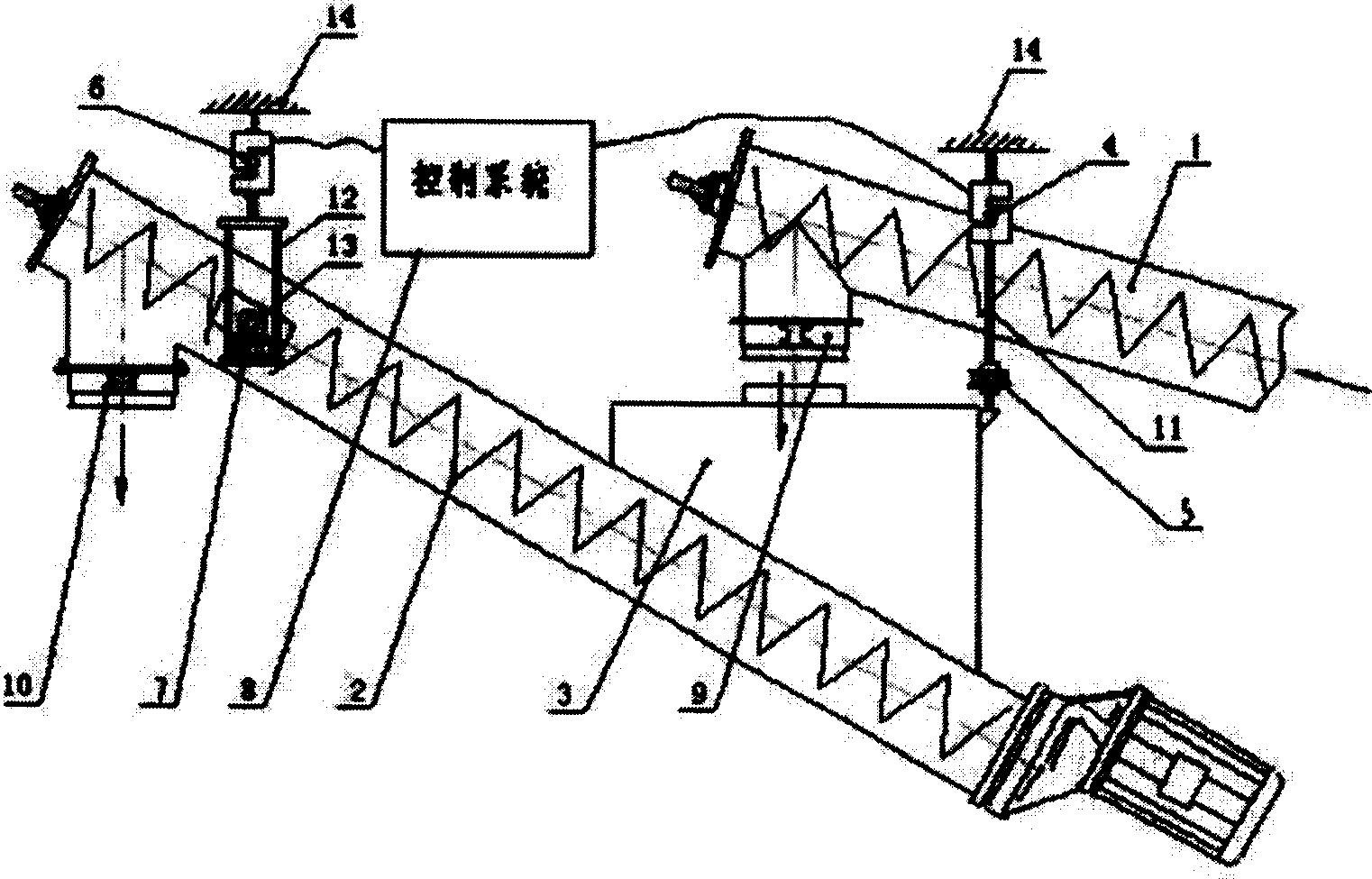

Weighing device for mortar car powder material and its method

InactiveCN100999109AFeed amount controlAccurate collectionSold ingredients supply apparatusControl systemVibration absorption

The present invention discloses a mortar carriage powder material weighing and metering equipment and method. Said equipment adopts two-stage obliquely-arranged first-stage spiral conveyor and second-stage spiral conveyor, on the feeding part of second-stage spiral conveyor a powder material hopper for receiving and temporarily storing dried powder is set, on the powder material hopper and discharging part are set front and rear hanger rod components which are respectively equipped with sensor, in the described front and rear hanger rod components the position connected with weighing sensor and the position connected with second-stage spiral conveyor are respectively equipped with vibration absorptive block for making vibration absorption, and said weighing sensor is electrically connected with upper-position machine. Said invention also provides its working principle and its concrete operation method.

Owner:SANY HEAVY IND CO LTD (CN)

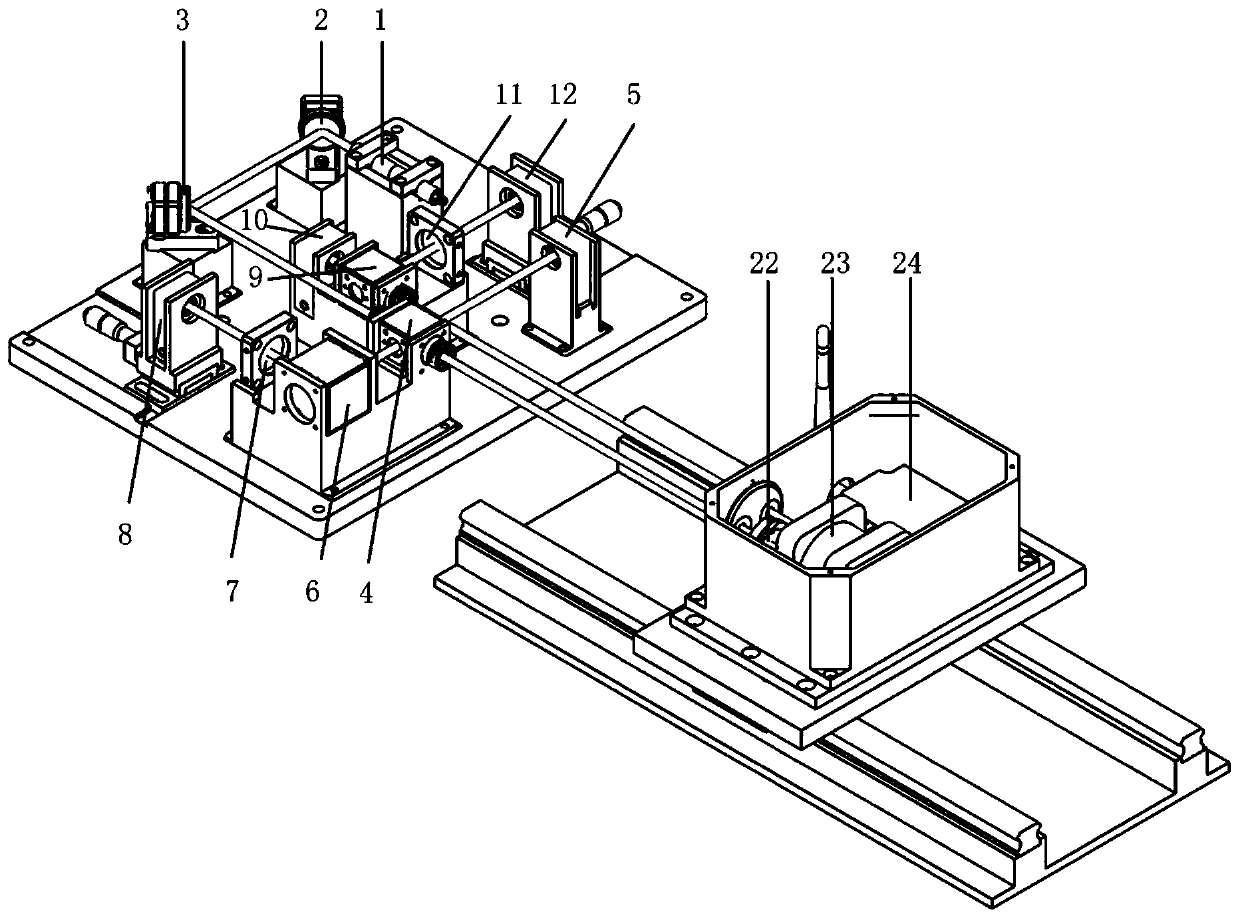

Five-degree-of-freedom error synchronous measurement device and method for linear motion system

The invention discloses a five-degree-of-freedom error synchronous measurement device and method for a linear motion system; the device comprises a fixed emission unit, a movement measurement unit anda signal processing unit; optical signals detected by four two-dimensional PSD position-sensitive sensors are connected with an upper computer through a USB after passing through a signal processingcircuit, an inclination angle sensor is in communication with the upper computer through the Bluetooth, and the straightness of the horizontal direction, the straightness of the vertical direction, the pitching angle, the deflection angle and the roll angle error of the linear motion system can be obtained by decoupling through processing of a measurement analysis module. According to a strict position relation design, the influence of optical element assembly errors on the measurement result can be ignored. All the measurement data are directly measured by the sensor instead of being obtainedthrough indirect calculation by establishing a complex mathematical model, so that the error caused by using complex mathematical calculation is reduced.

Owner:XI AN JIAOTONG UNIV

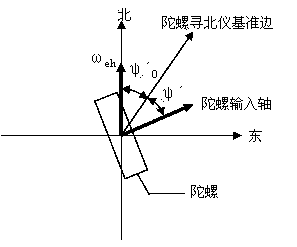

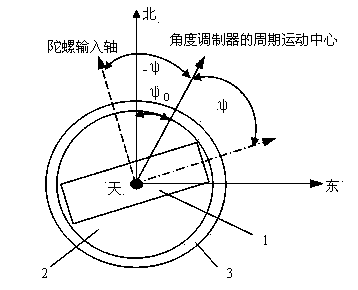

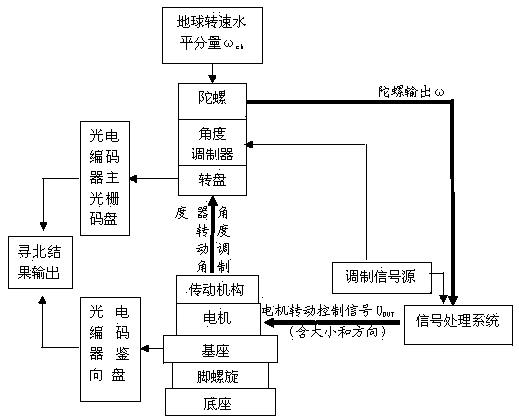

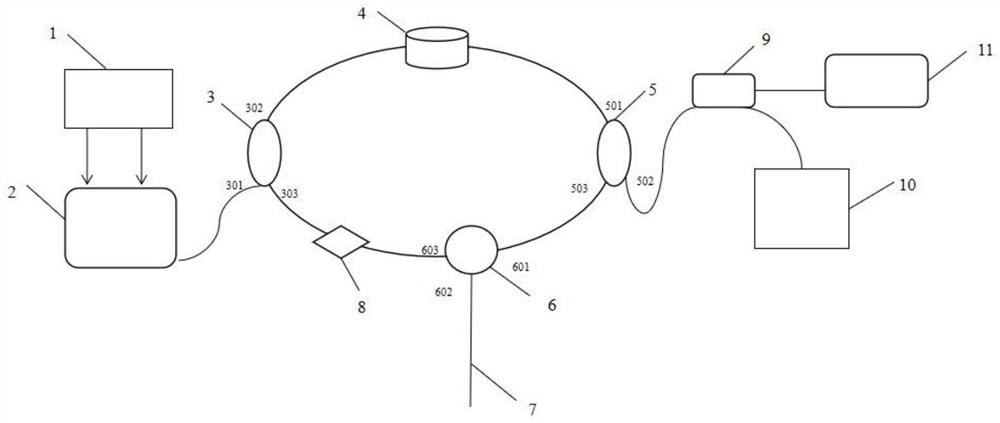

Novel gyro north seeker and north seeking method

InactiveCN103776434ARealize measurementRealize the north-seeking functionSpeed measurement using gyroscopic effectsRotary gyroscopesAngle modulationClosed loop

The invention relates to a novel gyro north seeker and a north seeking method. The novel gyro north seeker is composed of a gyro (1), an angle modulator (2), a rotary table (3), a photoelectric encoder main raster code disc (4), a photoelectric encoder direction identification disc (5), a base (6), foot screws (7), a leveler (8), a pedestal (9), a motor (10), a transmission mechanism (11), a modulation signal source (12), and a signal processing system (13). The invention provides the north seeking method consisting of: applying a periodic angular motion modulation signal to the gyro (1) by the angle modulator (2), changing direct measurement of a gyro (1) output intensity signal to measurement of a gyro (1) output frequency signal, and at the same time employing a synchronous tracking mode, and using the motor (10) to keep the periodic motion center of the angle modulator (2) coinciding with the north direction, i.e. psi0=0, and taking psi0=0 as a closed loop control condition to construct the north seeking method of a gyro north seeker closed loop system. Due to the employment of angle modulation and synchronous tracking technologies, the gyro north seeker based on the north seeking method greatly reduces the requirements for gyro technical indicators, improves the north seeking precision and anti-interference ability, and can realize rapid and high precision north seeking.

Owner:于中权

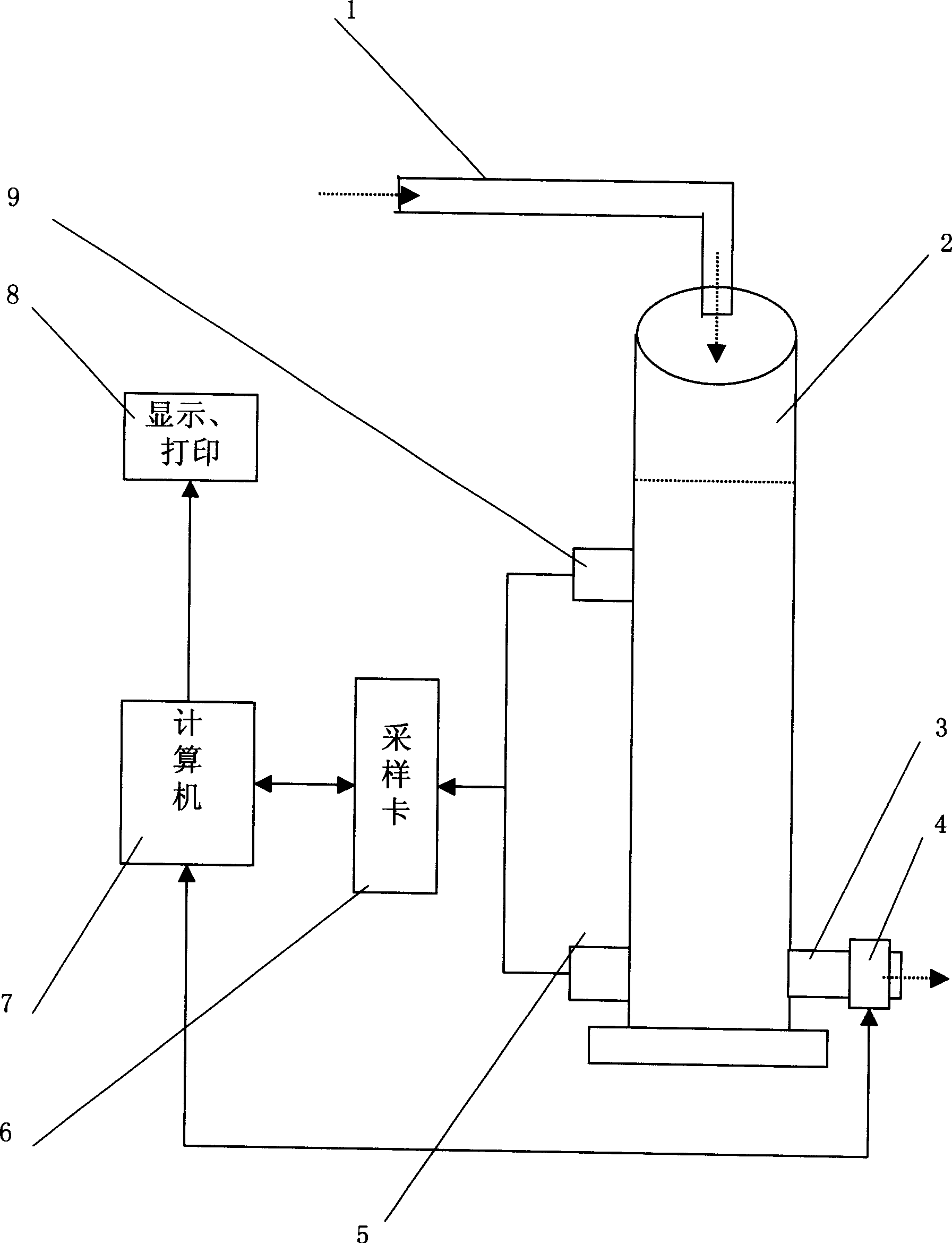

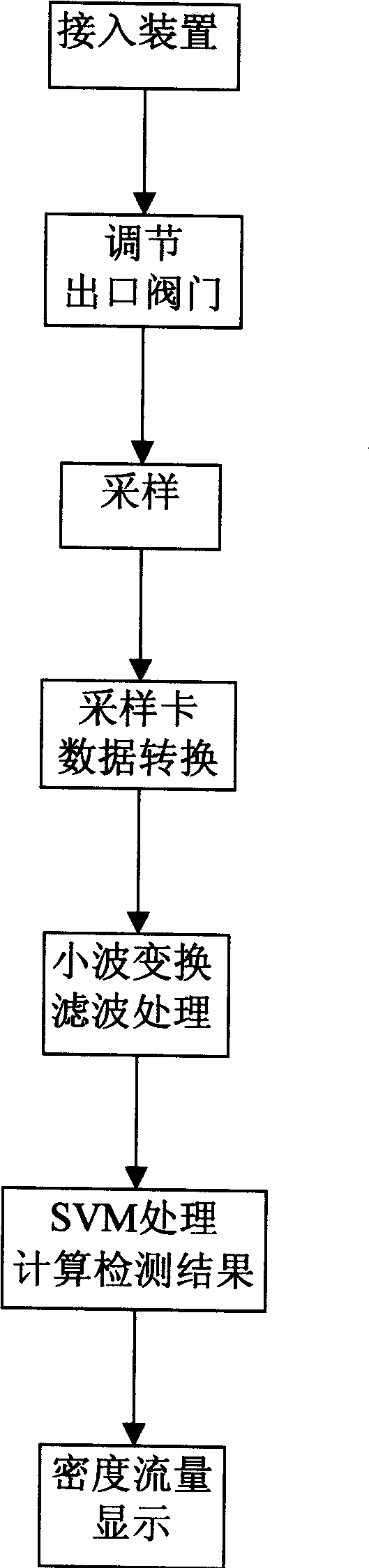

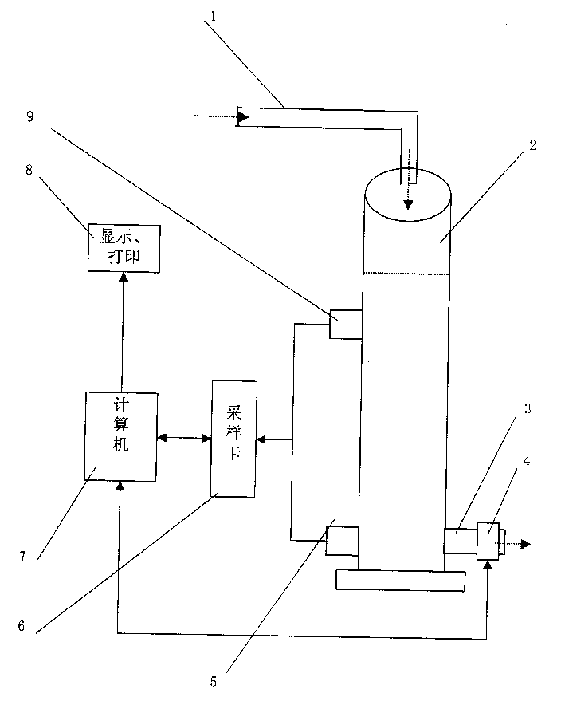

Multiple parameter measurement device and method for small caliber and small flow fluid

InactiveCN1527030AHigh measurement accuracyQuick responseSpecific gravity by measuring pressure differencesVolume/mass flow by differential pressureMeasurement deviceEngineering

The multiple parameter measurement device has vertical measuring tube, two, one upper and one lower, pressure sensors installed onto the wall of the vertical measuring tube and outlet tube with valve connected to the lower part of the measuring tube. The two pressure sensors are connected to sampling card and computer. The measured fluid is made to flow through the measuring tube from top to bottom. During measurement, the measured fluid is made first to fill the measuring tube with liquid level over the upper pressure sensor; valve is regulated to proper opening to maintain the dynamic balance between the flow-in and flow-out fluid; and the two pressure sensors measure the real-time pressure values, which are converted into digital signal and fed to computer to obtain measurement result of mass flow rate, volume flow rate and density. The present invention is suitable for measurement of fluid in small tube and in small flow rate.

Owner:桂林电子工业学院

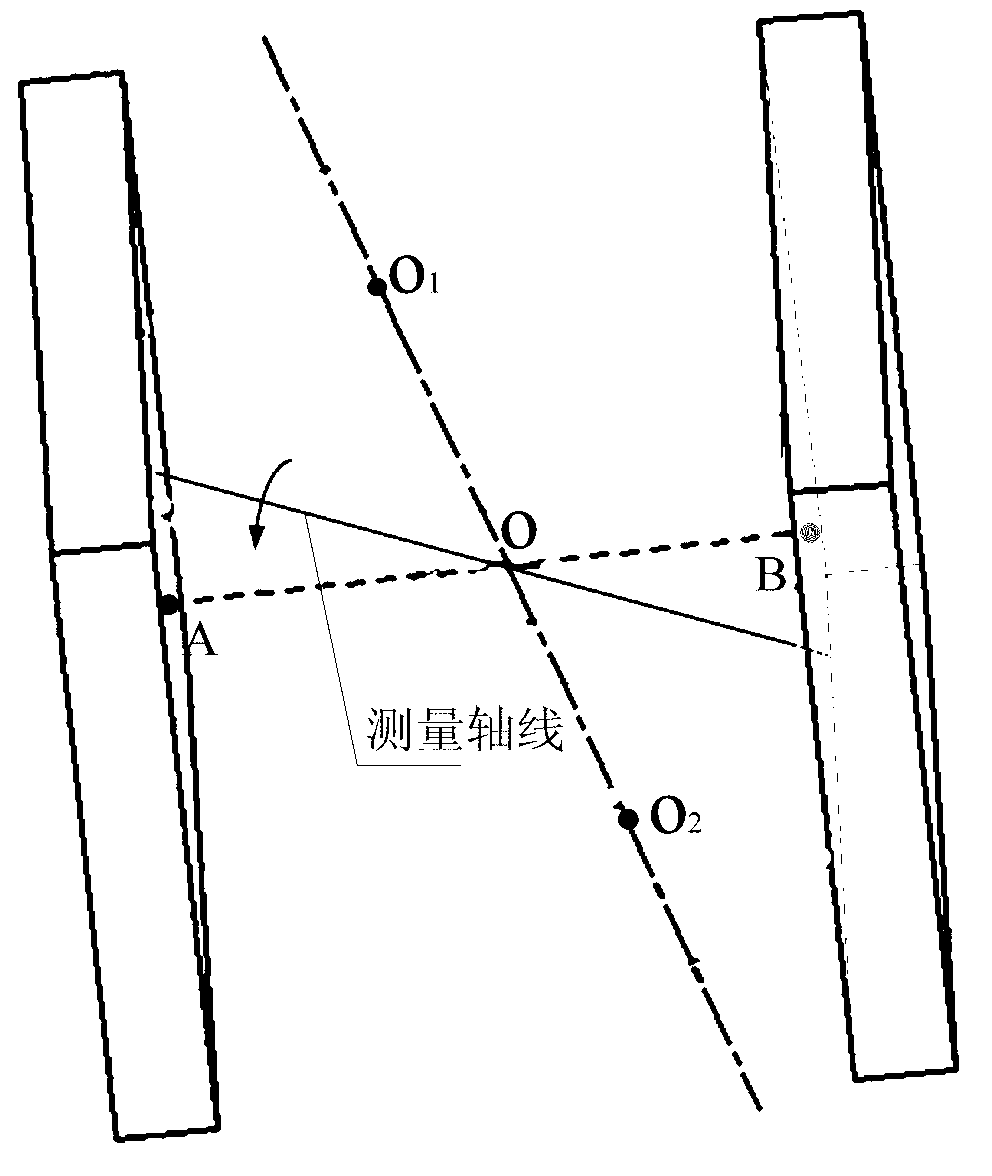

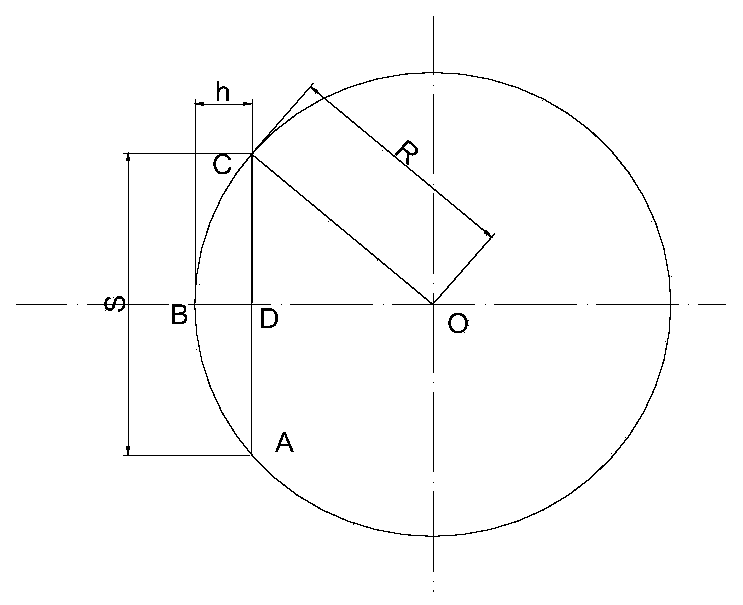

Non-contact inner parallel plane distance measuring method for large-sized workpiece

InactiveCN103009194AImprove securityPossibilities to limit automatic measurementsMeasurement/indication equipmentsClassical mechanicsParallel plane

The invention discloses a non-contact inner parallel plane distance measuring method for a large-sized workpiece. The method comprises the following steps: rotating a measuring head around a spindle rotation axis; respectively scanning two opposite planes of a measured workpiece by using a first laser displacement sensor and a second laser displacement sensor so as to obtain a distance between a measuring axis and an intersecting point of the two opposite planes; determining the distance as a measuring line; figuring out all measuring lines in real time; obtaining a first minimum value of the measuring lines; stopping the rotation of the measuring head around the spindle rotation axis in the position where the first minimum value is obtained; rotating the measuring head, so that the measuring axis rotates around a rotating shaft; and respectively scanning the two opposite planes of the measured workpiece by using the first laser displacement sensor and the second laser displacement sensor so as to obtain a second minimum value of the measuring lines, wherein the second minimum value is the distance between the two inner parallel planes. Through the adoption of the non-contact inner parallel plane distance measuring method for the large-sized workpiece disclosed by the invention, the internal size of the large-sized workpiece is measured, the measuring precision is improved, the measuring cost is reduced and the measuring time is reduced.

Owner:TIANJIN UNIV

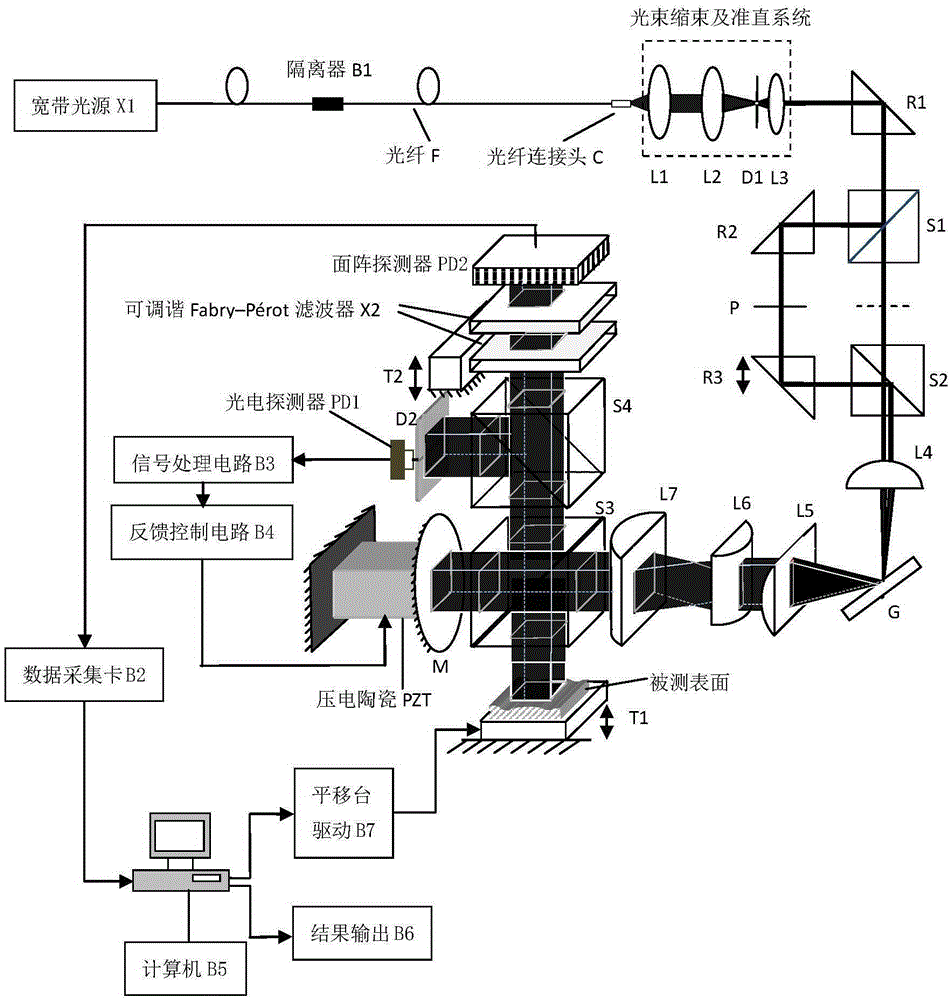

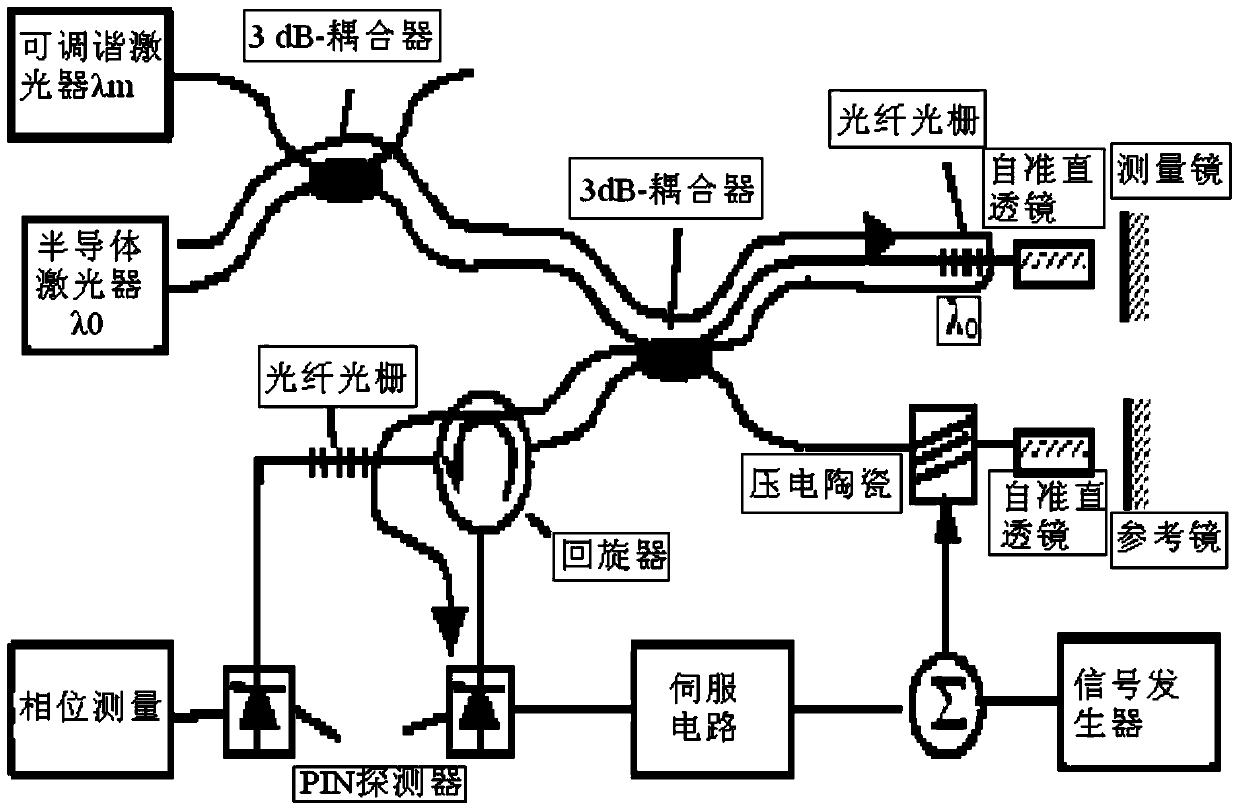

Super lateral resolution surface three-dimensional online interference measuring system based on spectral dispersion full field

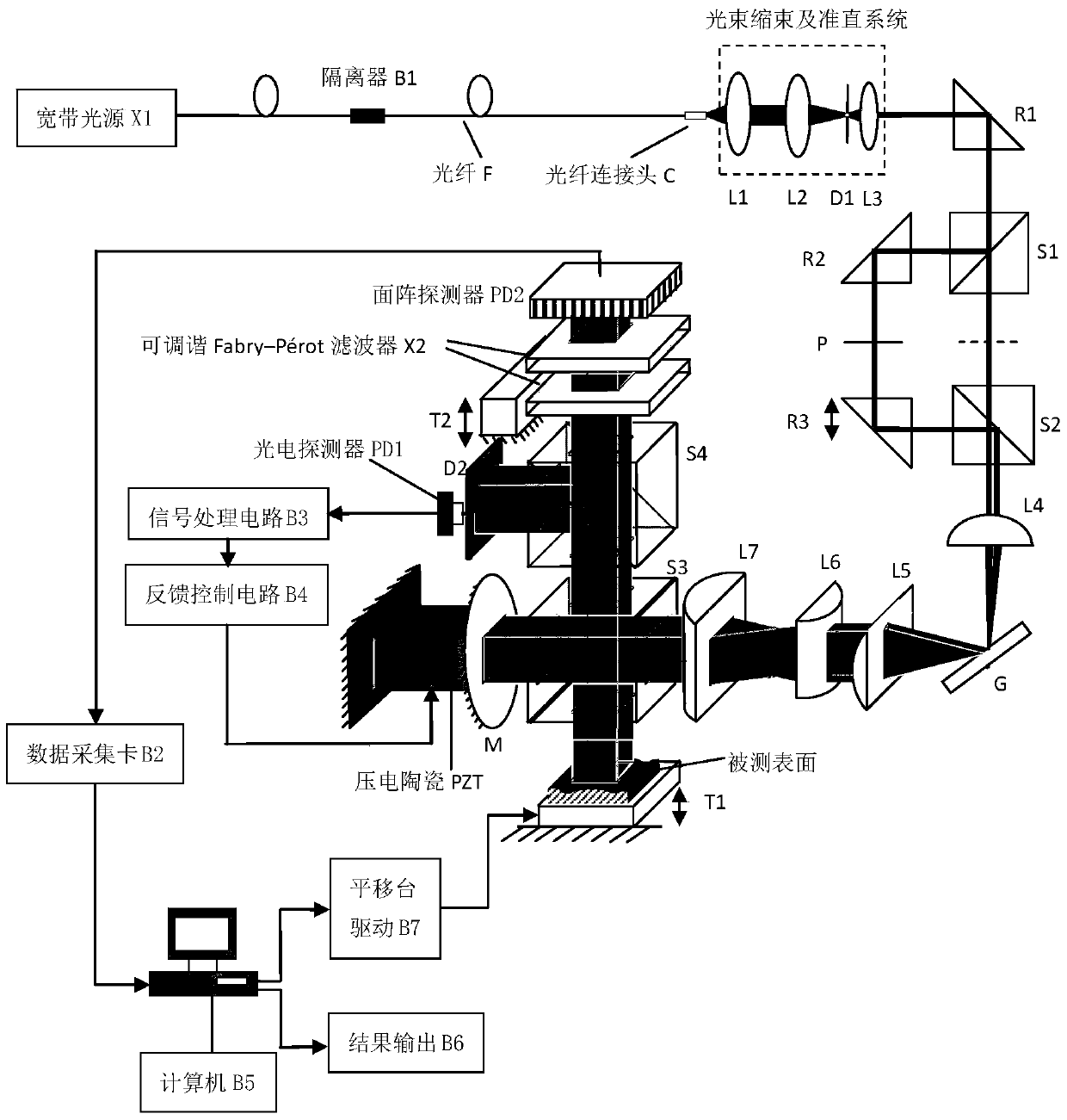

ActiveCN105333816AImprove anti-interference abilityAccurate traceabilityUsing optical meansGratingSignal processing circuits

The invention discloses a super lateral resolution surface three-dimensional online interference measuring system based on a spectral dispersion full field, and belongs to the field of optical measurement. The system is composed of a broadband light source, an isolator, a fiber, a fiber joint, a spherical-surface and cylindrical-surface spectroscopes, spectroscopes, right-angle prisms, diaphragms, a raster, a reflector, a surface array detector, a photoelectric detector, a Fabry-Perot filter, piezoelectric ceramics, a signal processing circuit, a feedback control circuit, a data acquisition card, a computer, translation benches, a translation bench driving part, a result output part and the like. The raster disperses a broadband spectrum to form a mating plate whose wavelength is continuously distributed in a transverse direction, and the mating plat is incident vertically to a measured surface through beam expansion for full-field measurement; a surface provided with a step whose height difference is greater than a half-wavelength and a large-depth-to-width-ratio groove is measured by use of two wavelengths; super lateral resolution measurement is realized by use of the Fabry-Perot filter; and ambient interference is compensated through feedback control, the system is enabled to be suitable for online measurement, the measuring result can be accurately traced to a wavelength reference, and the influence of the drift of a light source spectrum is eliminated.

Owner:BEIJING JIAOTONG UNIV

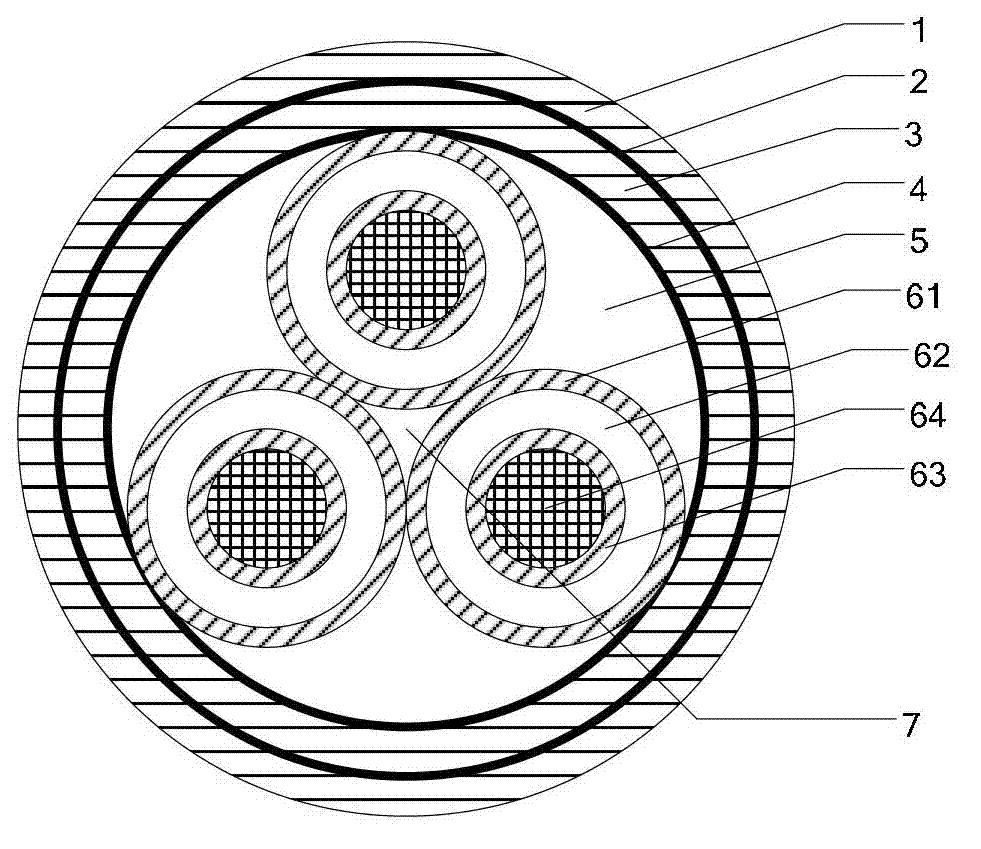

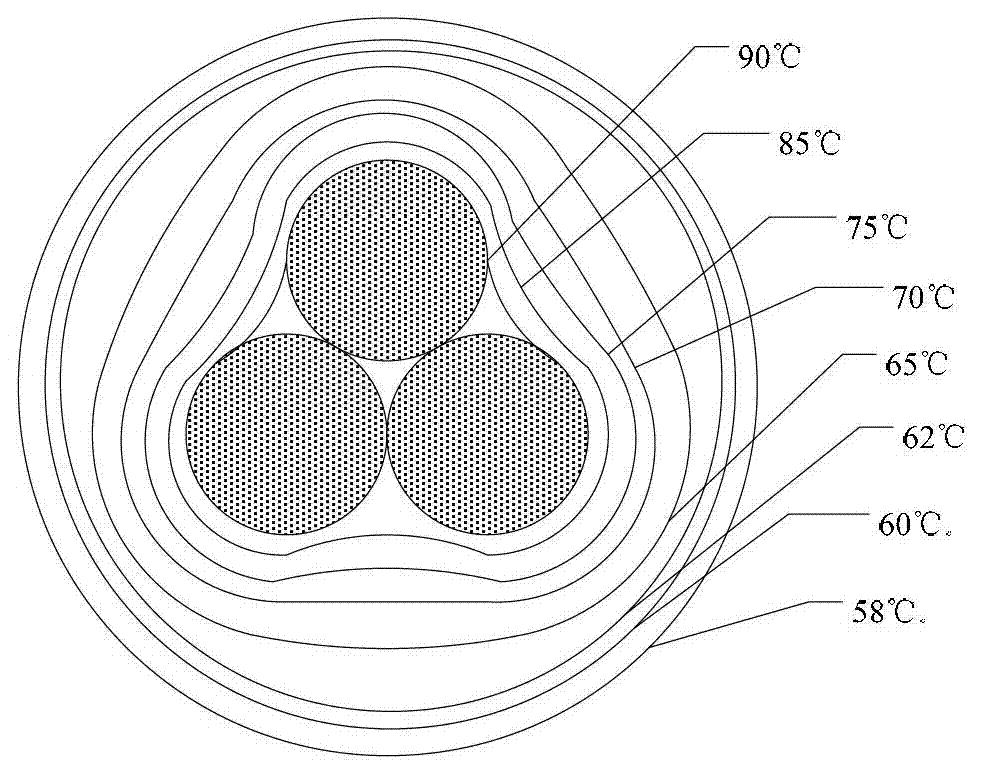

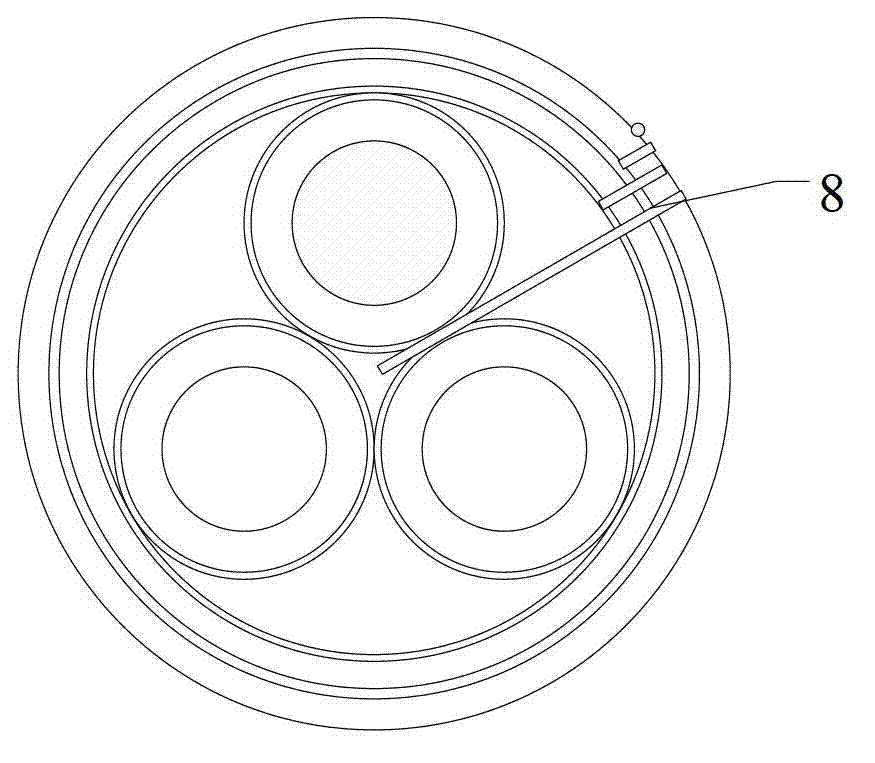

Method for measuring thermal resistance of three-core cable packing layer

ActiveCN103245691AMeasurement results have no effectSimple processing capacityMaterial heat developmentHeat flowEngineering

The invention discloses a method for measuring a thermal resistance of a three-core cable packing layer. The method comprises the following steps of: selecting any cross section of a three-core cable, acquiring the thickest radial direction of a packing layer in the cross section according to the appearance fluctuated characteristic of the three-core cable, drilling three holes along the radial direction, and respectively measuring the temperature of an armoring layer, an inner jacket and a central point in a closed area of the three-core cable by adopting a thermocouple respectively in the three holes; and on the basis of the steady thermal field distribution of the three-core cable and the principle that the heat conduction heat flow rate of each layer in the radial direction is identical at the steady state, calculating the thermal resistance of the packing layer in the thickest radial direction by utilizing the measured data. Due to the adoption of the method, the difficulty for sampling parameters of the packing layer of the three-core cable in the process for calculating the temperature of a steady conductor can be overcome, the measuring process is more direct, and the measuring result is more accurate.

Owner:广州骏拓电力科技有限公司 +1

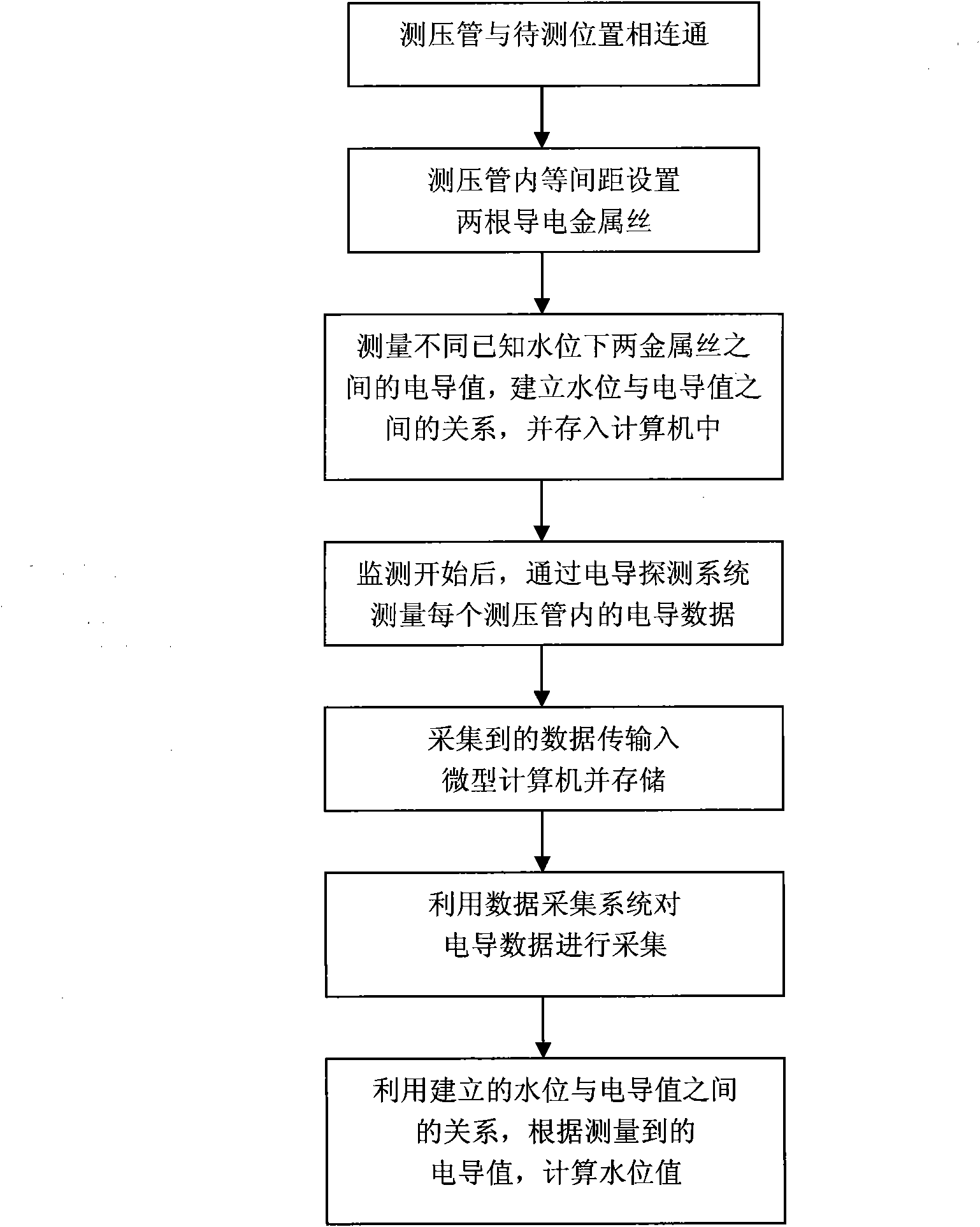

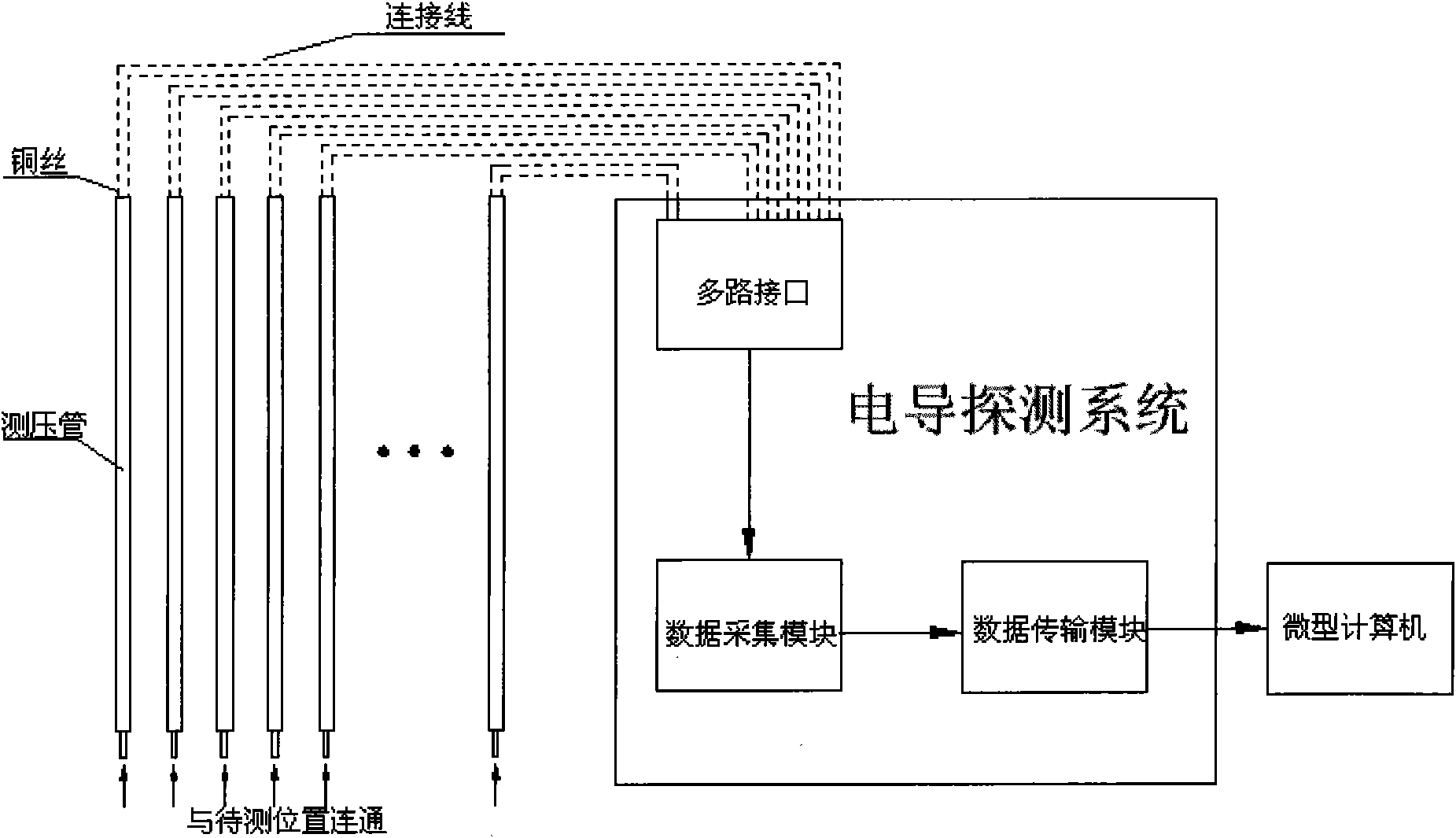

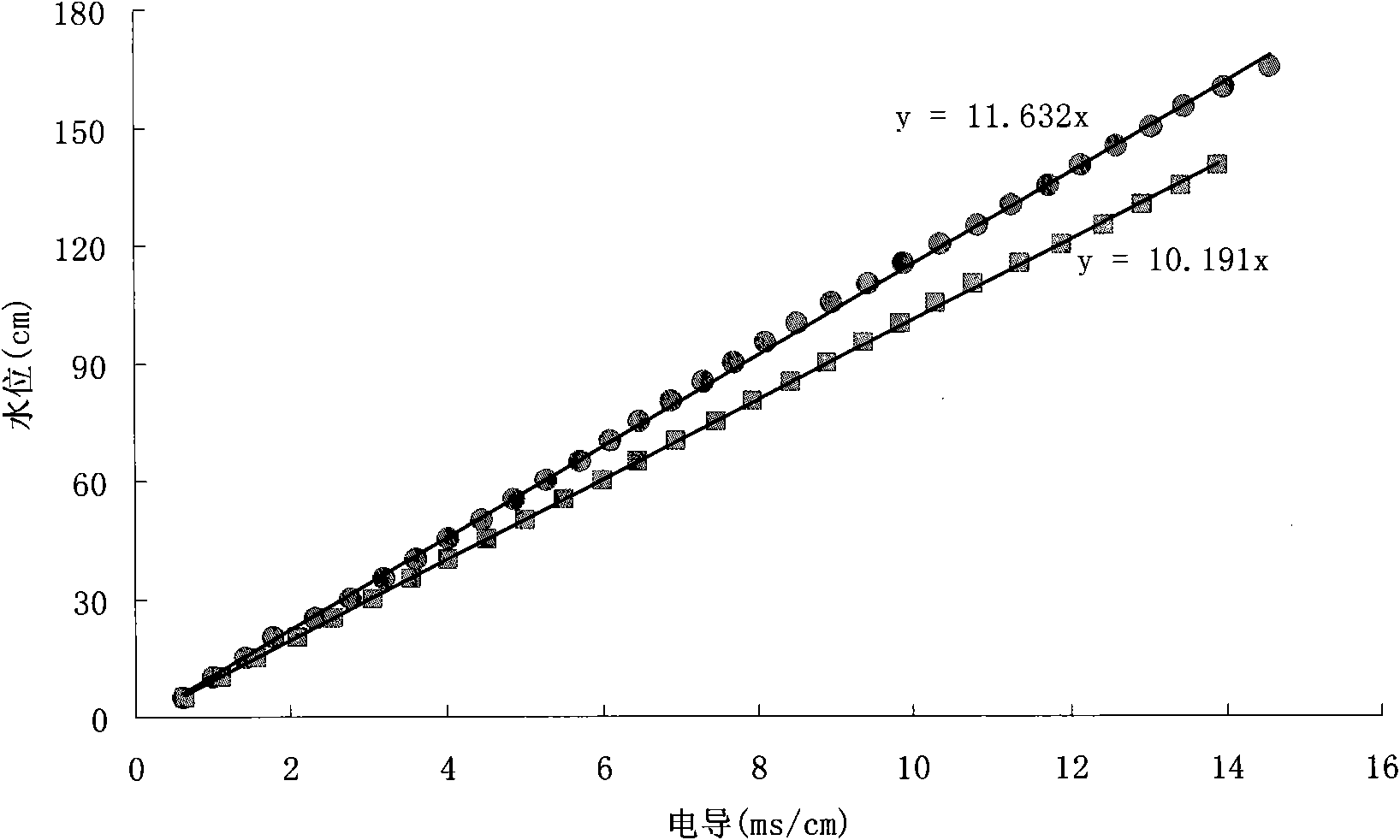

Method and device for automatically measuring water-level variation

InactiveCN101782417AIncrease or decrease quantityEasy to useLevel indicators by physical variable measurementMicrocomputerElectricity

The invention relates to a method and a measuring device for automatically measuring water-level variation, which utilize the principles of communicating vessels and use the water level in a piezometer tube to substitute for the water level of a position to be measured; two metal wires are arranged in the piezometer tube at equal interval, according to the physical conductive properties of medium, a relation curve of the water level and the conductive value can be obtained; and by measuring the conductive value of the piezometer tube and combining the obtained relation of the water level and the conductive value, the height of the water level can be figured out. The data of the conductive value is measured by a high-precision conductive detection system, the conductive data is automatically acquired via a data acquisition system and is transferred to a microcomputer, by measuring the conductive value changing with time to monitor the variation of the water level data and according to the method and the device provided by the invention, the water level data can be conveniently and accurately obtained, and the variation condition of the water level can be real-timely monitored.

Owner:HOHAI UNIV

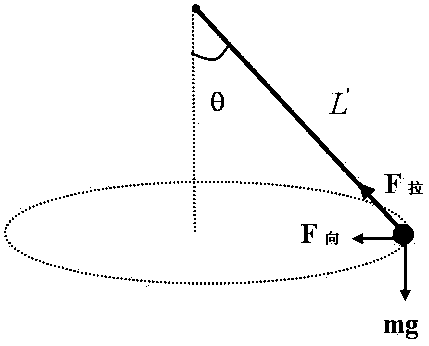

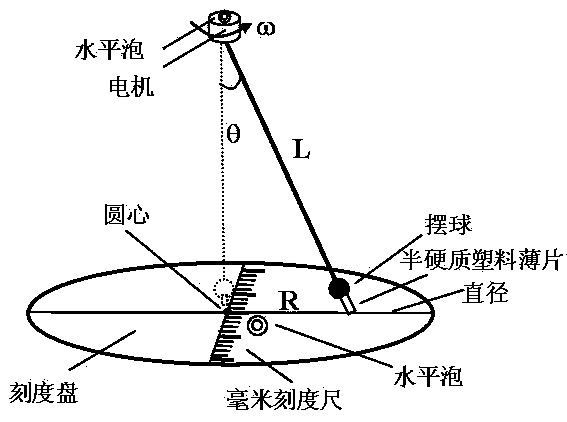

Method for measuring gravitational acceleration by using conical pendulum

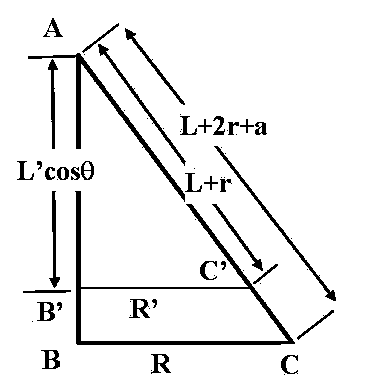

InactiveCN104020504AGuaranteed uptimeMeasurement results have no effectEducational modelsGravitational wave measurementAerodynamic dragEngineering

The invention provides a method for measuring gravitational acceleration by using a conical pendulum and relates to the field of physical parameter measurement. The method is novel for measuring the gravitational acceleration. According to the technical scheme, the length of a cycloid of a simple pendulum is L, the radius of a pendulum ball is r, and a semi-hard plastic sheet with the length a is fixed to the other side opposite to the cycloid in the diameter direction, where the cycloid is located, of the pendulum ball. The pendulum ball of the simple pendulum is driven by a rotating shaft to do the circular motion, the included angle theta of the cycloid and the vertical direction and a swing cycle T of the pendulum ball are measured, and thus the gravitational acceleration g=(2pi / T)2*L'cos theta, wherein pi=3.1415926. The method for measuring the gravitational acceleration by using the conical pendulum has the advantages that the novel method for measuring the gravitational acceleration is proposed, students are guided to correctly understand errors; compared with the mode that the inclination angle amplitude of the simple pendulum is gradually reduced due to air resistance, driving of a motor is adopted in the method, and stable operation at the constant speed can be ensured; the cyclic formula of the simple pendulum is an approximation, the inclination angle is required to be within five degrees, and the requirement is avoided in the method.

Owner:SICHUAN UNIV

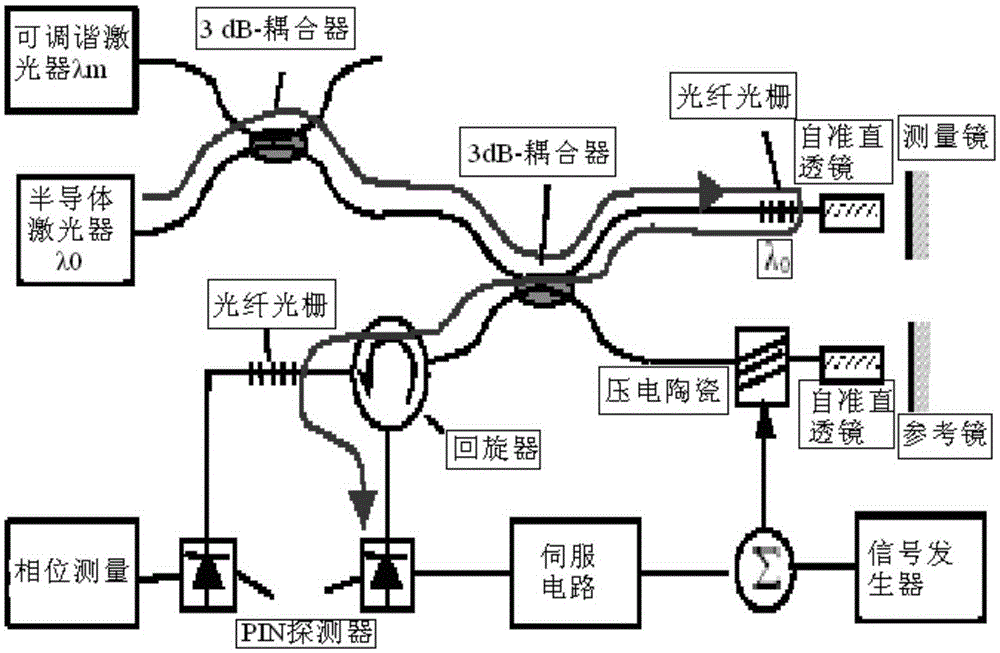

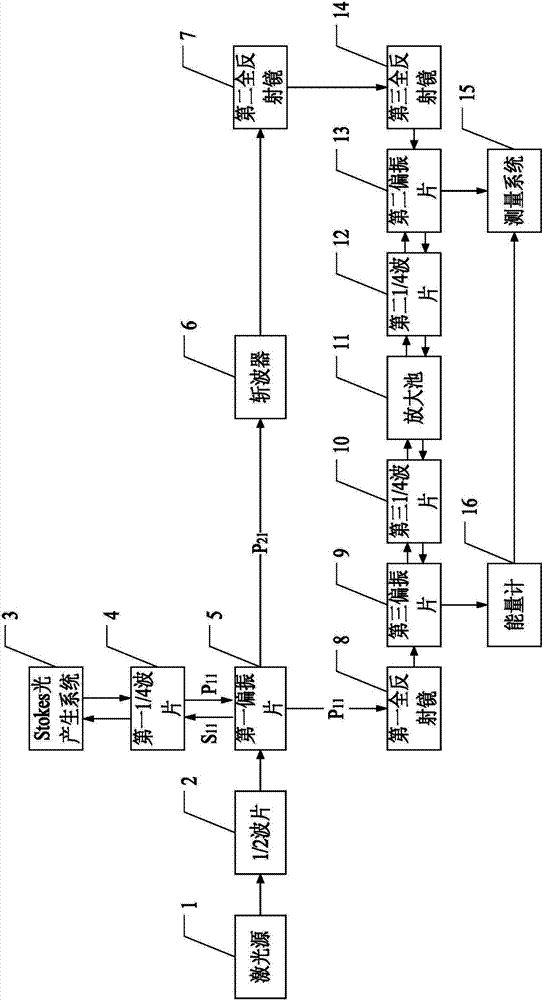

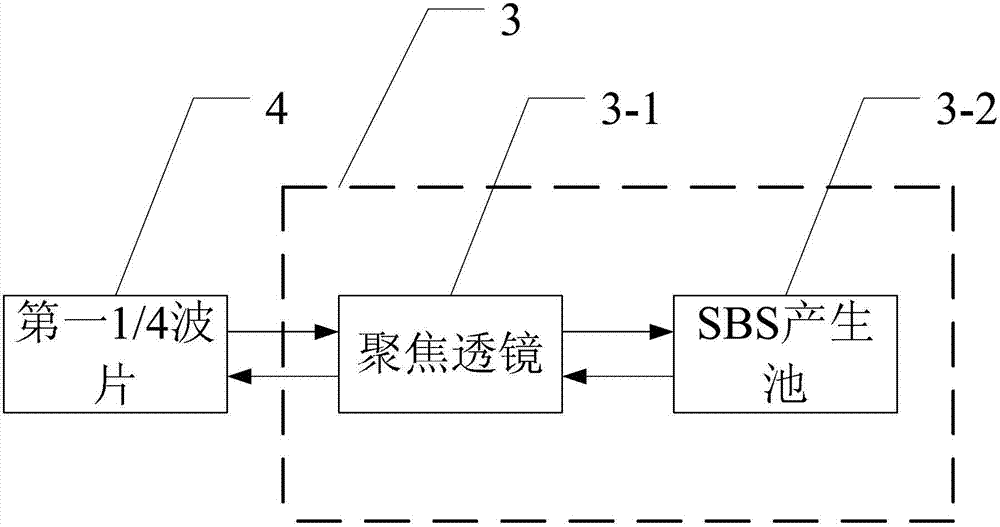

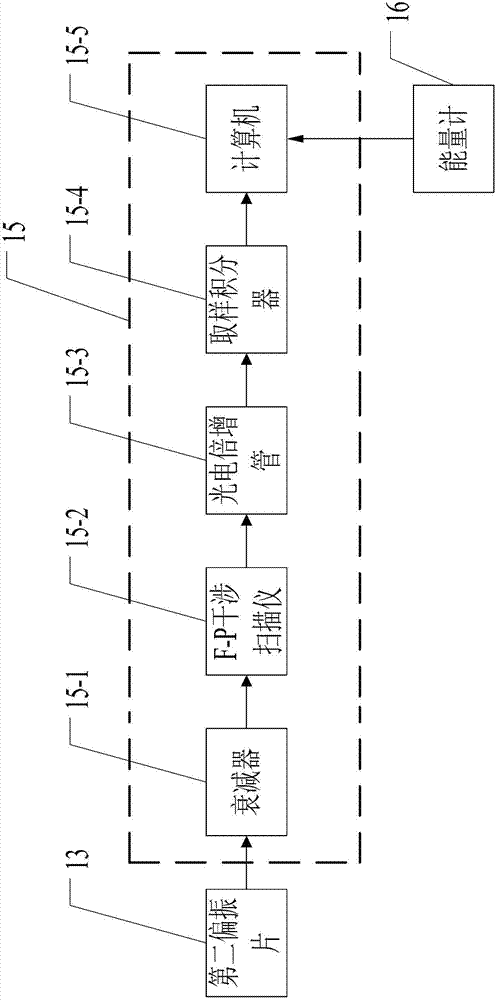

Device for measuring medium brillouin gain linetype and line width and a method for measuring medium brillouin gain linetype and line width based on device

ActiveCN102809437AMeasurement results have no effectEasy to measureAnalysis by material excitationFrequency spectrumLine width

The invention relates to a device for measuring a medium brillouin gain linetype and a line width and a method for measuring the medium brillouin gain linetype and the line width based on the device and aims to solve the problems existed in the measurement of the brillouin gain linetype and the line width that the measuring result credibility is low, and the own line width of a Stokes signal affects the measuring results of the brillouin gain linetype and the line width. The invention comprises the following steps: transmitting a laser pulse through a laser source, generating Stokes signal light through a Stokes light generation system, carrying out frequency spectrum measurement on Stokes light by a measuring system, controlling the passing and not passing of pump light in a light path by utilizing a chopper, further controlling the amplified incident Stokes light or the Stokes light before amplification, and measuring the medium brillouin gain linetype and the line width according to the information before and after the amplification of Stokes light frequency spectrum. The device and the method are applicable to the laser nonlinear field.

Owner:HARBIN INST OF TECH

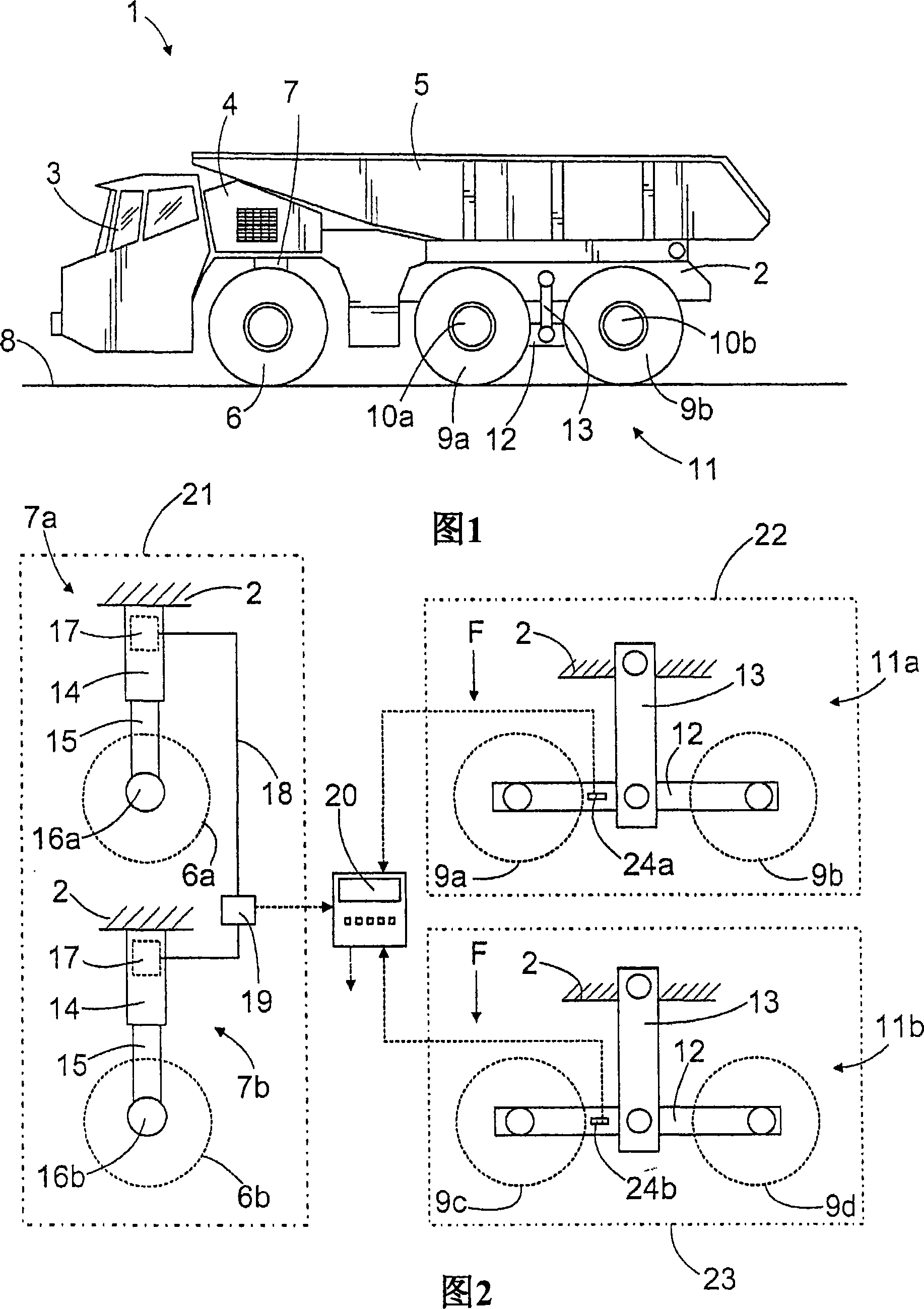

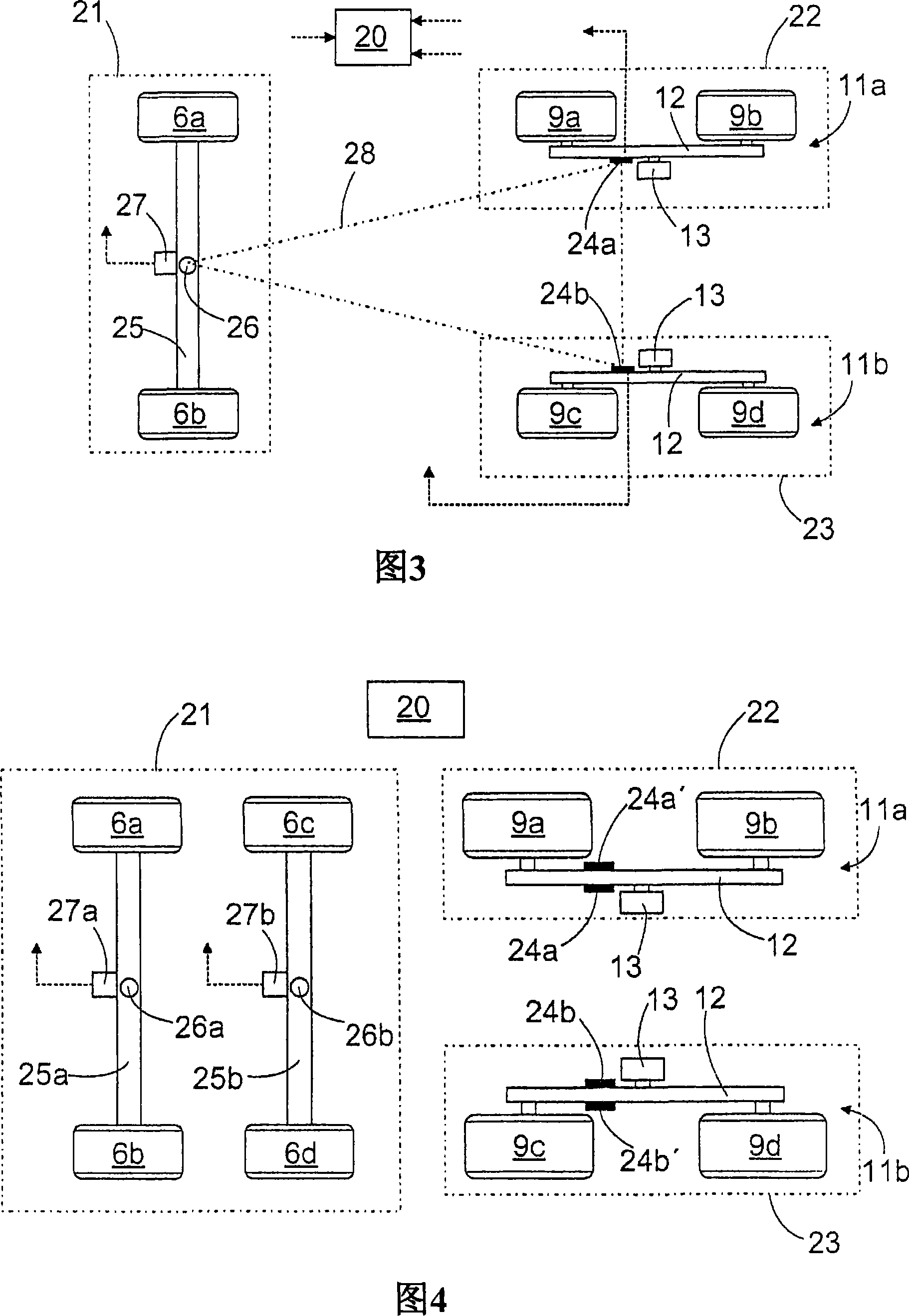

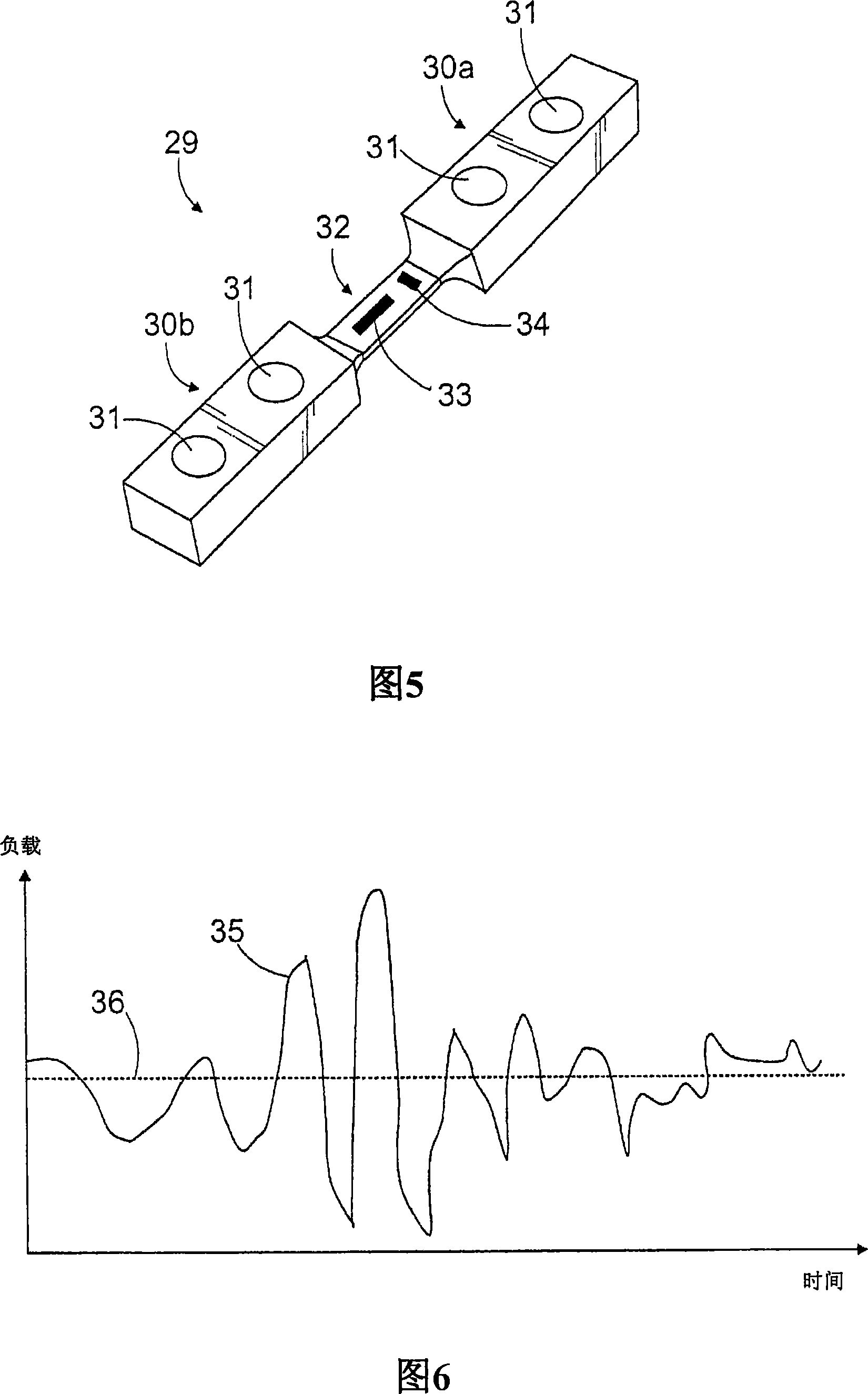

Arrangement for weighing transport vehicle load

InactiveCN101133305AWill not materially affect the measurement resultsQuick changeVehiclesSpecial purpose weighing apparatusBogieVertical load

The invention relates to a method for weighing a payload of a transport vehicle, a transport vehicle and a bogie structure. Vertical loads exerted on wheel suspension of the transport vehicle (1) are measured with sensors (19, 24, 27) and the measurement data is conveyed to a calculating unit (20) of weighing. Further, on a side surface of a horizontal arm (12) belonging to the bogie structure (11) there is arranged a sensor (24) for measuring the vertical load exerted on the horizontal arm (12).

Owner:SANDVIK MINING & CONSTR OY

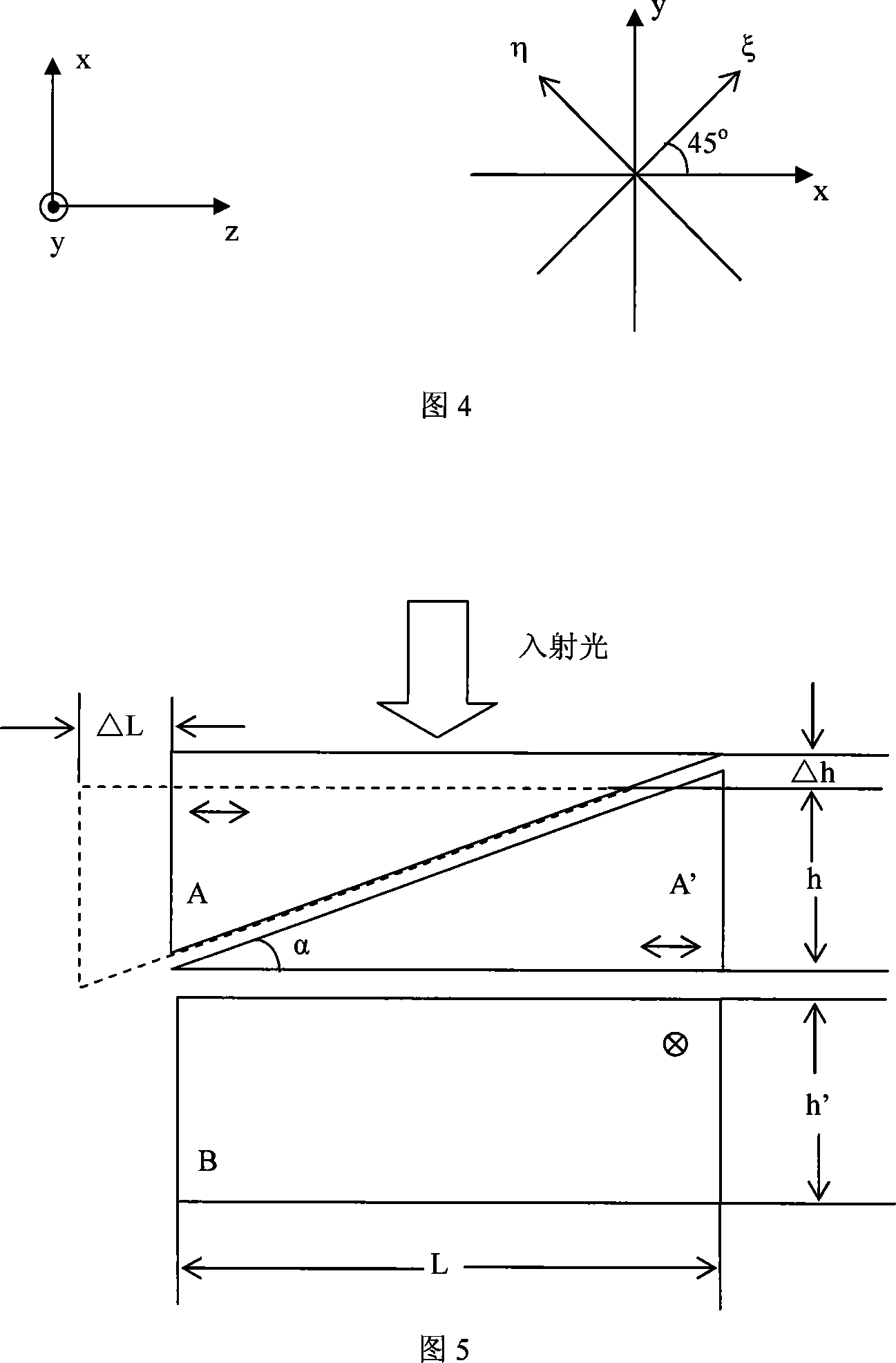

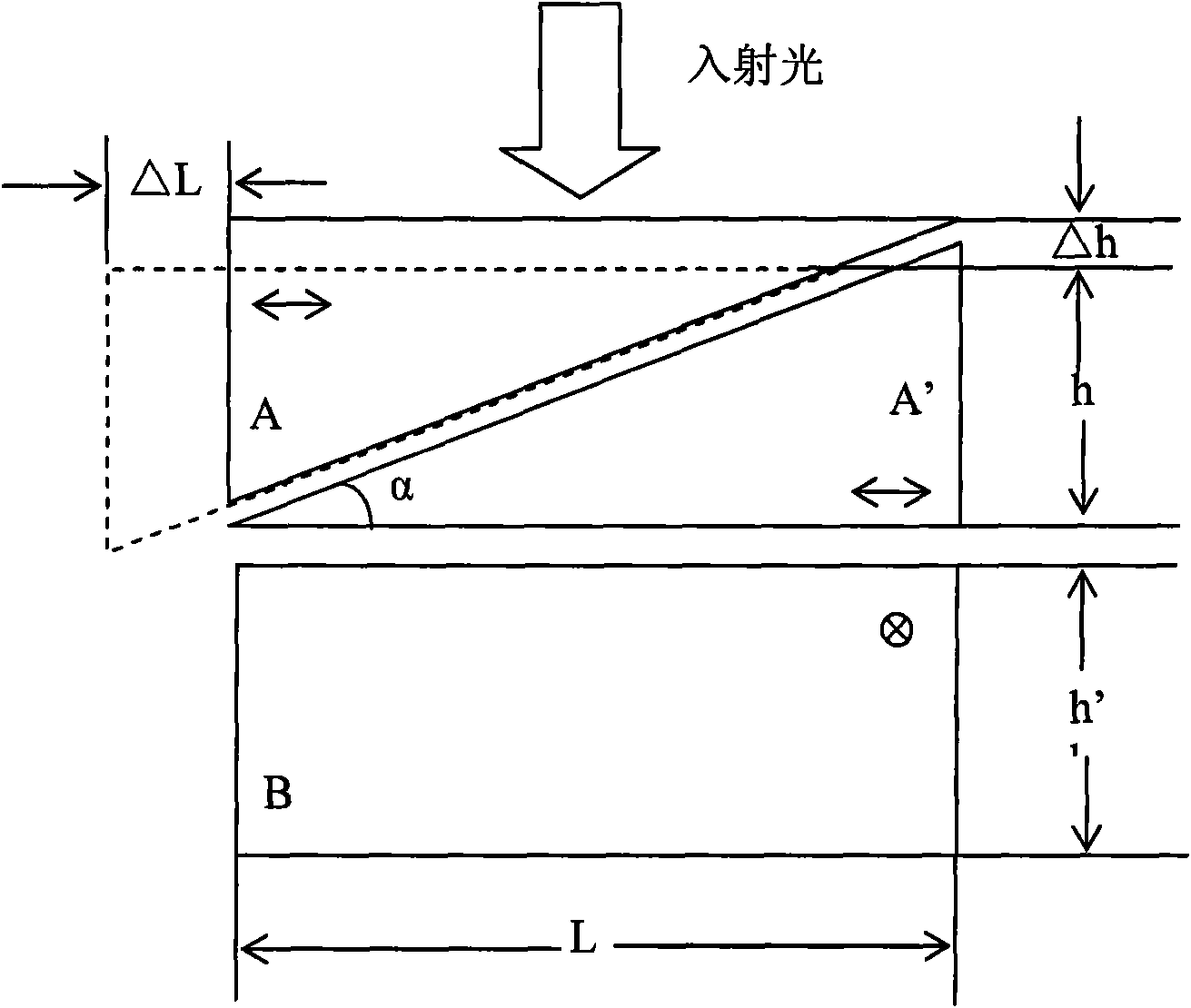

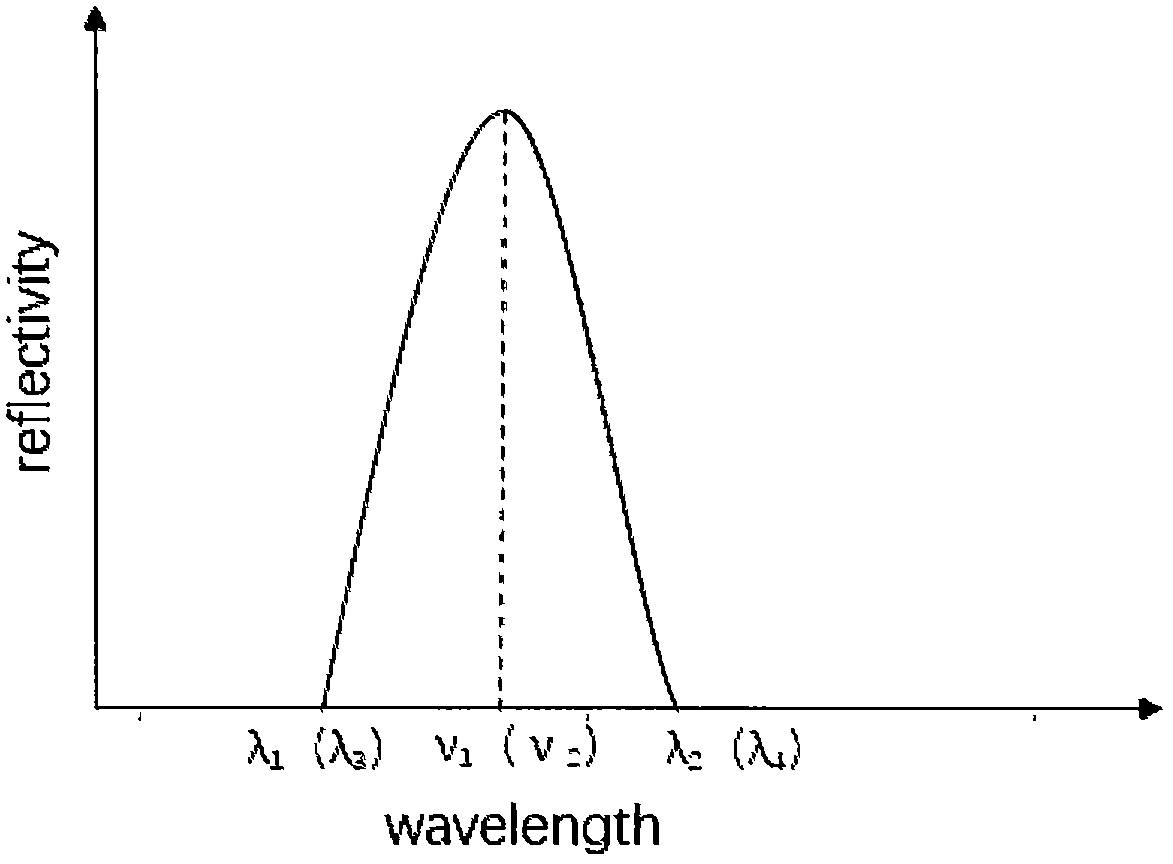

Method for measuring phase delay devices with different wavelengths by single wavelength light source and system thereof

InactiveCN101592525AAdvantages of measurement accuracyEliminate unstable measurement resultsOptical measurementsPhase retardationPhotodetector

The invention discloses a method for measuring phase delay devices with different wavelengths by a single wavelength light source and a system thereof, which belong to the technical field of optical measurement. A laser light source of the system is spilt into two beams, one beam orderly passes through a polarizer, an optical modulator, a phase retarder to be tested, a phase compensator, an analyzer, and a photodetector, and then a result display unit is used for displaying an output result; and the other beam is output to a laser monochromator. The method comprises the steps of: measuring displacements of the phase compensator corresponding to a group of light sources with different wavelengths respectively first after the establishment of the system; then establishing a fitting curve according to measured data; adding the phase retarder to be tested into a light path, then selecting a laser light source with any wavelength, adjusting the phase compensator, and recording a compensated distance delta L; and finally calculating the phase retardation quantity delta S of the phase retarder to be tested according to the fitting curve and the compensated distance delta L. The method and the system thereof can perform direct measurement on a phase retarder with any central wavelength to be tested, has high measurement accuracy and simple operation, and is easy to commercialize.

Owner:大恒新纪元科技股份有限公司北京光电技术研究所

A 3D online surface interferometry system with super lateral resolution based on spectral dispersion full field

ActiveCN105333816BFast measurementAccurate traceabilityUsing optical meansInterference fitData acquisition

The invention discloses a three-dimensional on-line interferometric measurement system for a surface with super lateral resolution based on spectral dispersion full field, belonging to the field of optical measurement. The system consists of broadband light source, isolator, optical fiber and optical fiber connector, spherical and cylindrical lens, beam splitter, rectangular prism, aperture, grating, reflector, area detector, photodetector, Fabry-Perot Filter, piezoelectric ceramics, signal processing, feedback control, data acquisition card, computer, translation stage and translation stage drive, result output, etc. The grating disperses the broadband spectrum into a light sheet with continuous distribution of wavelengths in the transverse direction, and the expanded beam is vertically incident on the surface to be measured for full-field measurement; two wavelengths are used to measure steps with a height difference greater than half the wavelength and grooves with a large aspect ratio Surface; Fabry-Perot filter is used to achieve super lateral resolution measurement; feedback control compensates environmental interference to make the system suitable for online measurement, and the measurement results are accurately traceable to the wavelength reference, and are not affected by the spectral drift of the light source.

Owner:BEIJING JIAOTONG UNIV

Positive sequence capacitance measuring method for parallel circuits

InactiveCN103399212AMeasurement has no effectMeasurement results have no effectResistance/reactance/impedencePower flowThree-phase

The invention relates to a positive sequence capacitance measuring method for parallel circuits, wherein positive sequence capacitance is measured by utilizing a three-phase experiment power supply and a mutual inductance measuring device. The three-phase experiment power supply is connected with a three-phase conducting wire through three connecting circuits respectively, and the mutual inductance measuring device is connected with the connecting circuits respectively through connecting branches; during measurement, a grounding knife switch at the tail end of the three-phase conducting wire is firstly opened, so that the three-phase conducting wire is insulated from the ground; grounding knife switches at the top end of the three-phase conducting wire are respectively opened, a three-phase high-pressure experiment power supply is applied, a central point of the power supply is grounded, the current of each phase, three-phase circuit voltage and three-phase active power are measured through a current transformer and a voltage transformer, and positive sequence capacitance parameters are obtained through calculation. Compared with the prior art, the method is convenient to use and simple for measurement, and the measuring results of positive sequence capacitance are coincident through detection under the condition that adjacent parallel circuits are at different grounding conditions.

Owner:STATE GRID CORP OF CHINA +2

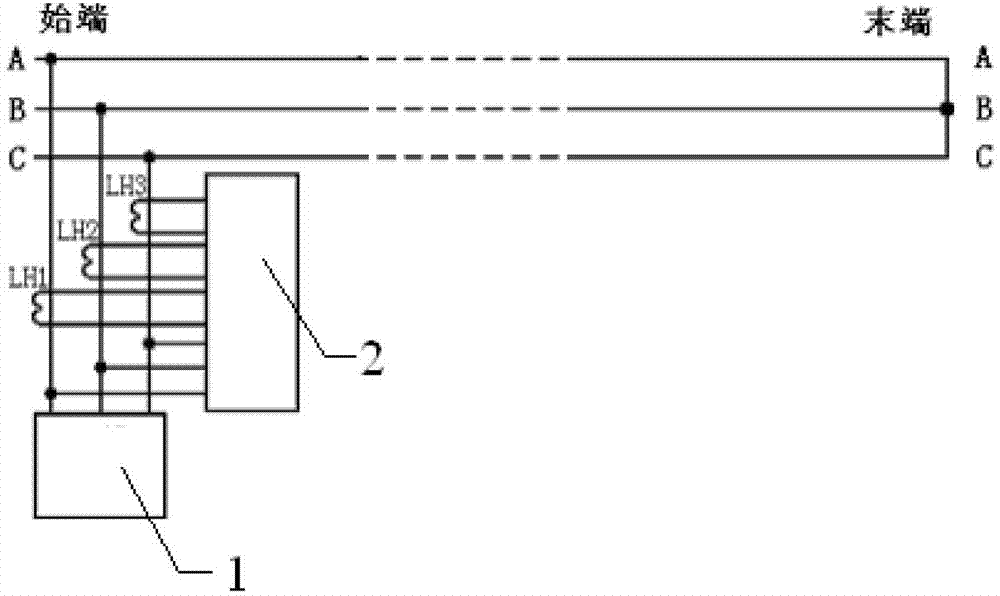

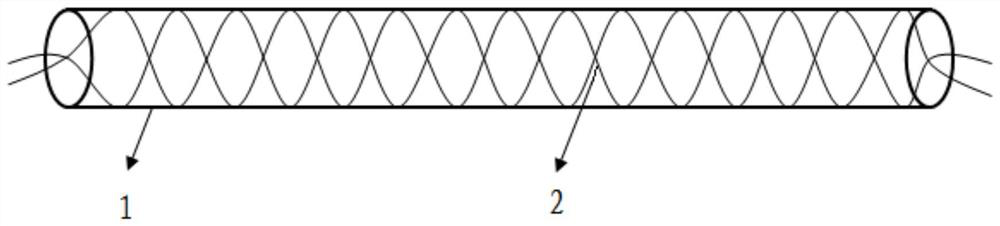

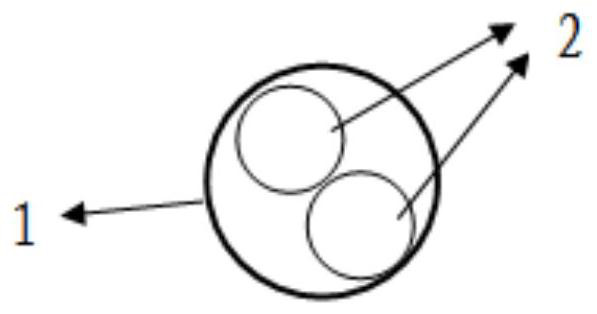

Novel twisted pair and micro alternating-current quantum voltage cross-temperature-zone transmission method

PendingCN112635122AMeasurement results have no effectAccurate measurementVoltage measurements onlyCables with twisted pairs/quadsMechanical engineeringTwisted pair

The invention discloses a novel twisted pair and a micro alternating-current quantum voltage cross-temperature-zone transmission method, and belongs to the technical field of cables. The two metal enameled wires with the same length are uniformly wound with each other and then are wrapped by an insulating sleeve to form the twisted pair, and the novel twisted pair can be used for transmitting micro alternating-current quantum voltage across a temperature zone; the twisted pair is applied to cross-temperature-zone signal transmission between a low temperature and a normal temperature, the influence of a direct-current component generated during lead transmission is suppressed, and the accurate measurement of a micro alternating-current quantum voltage is facilitated.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

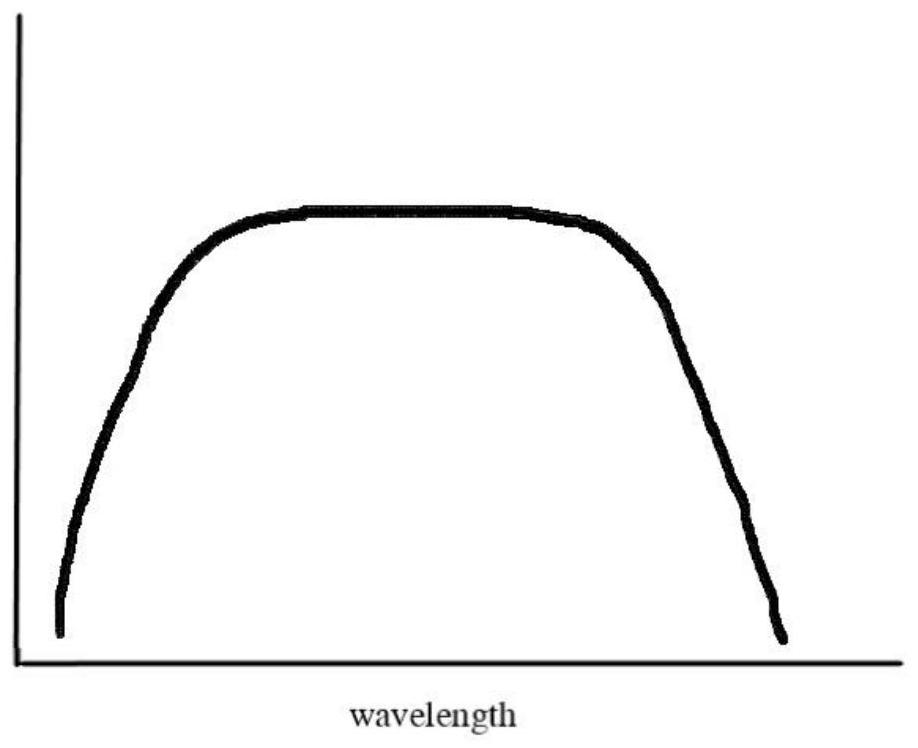

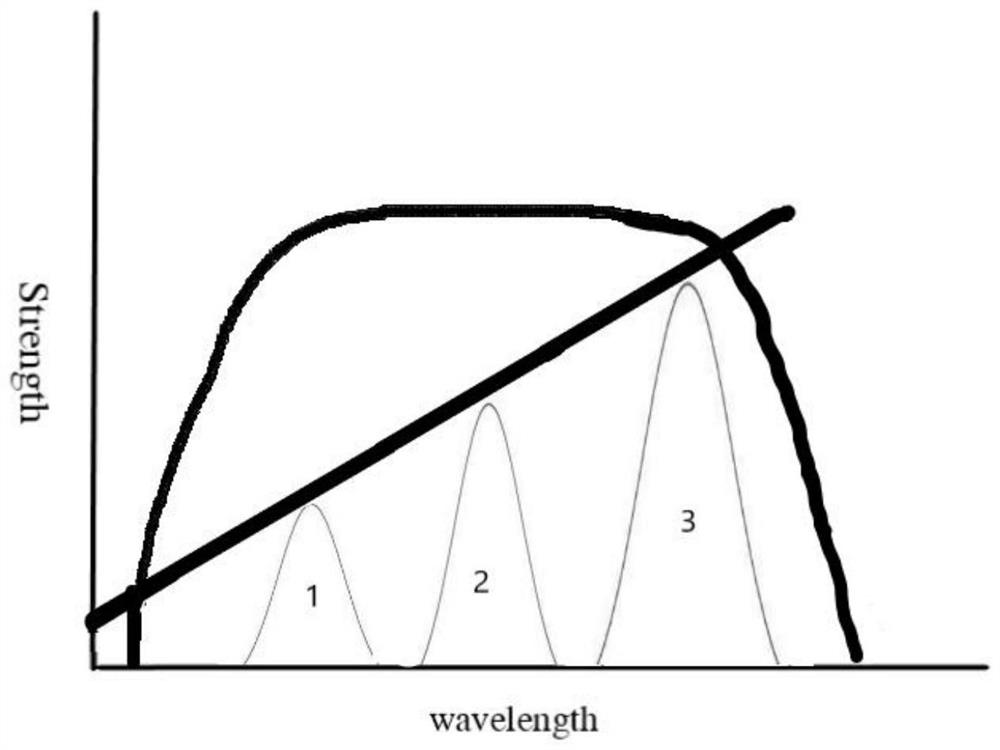

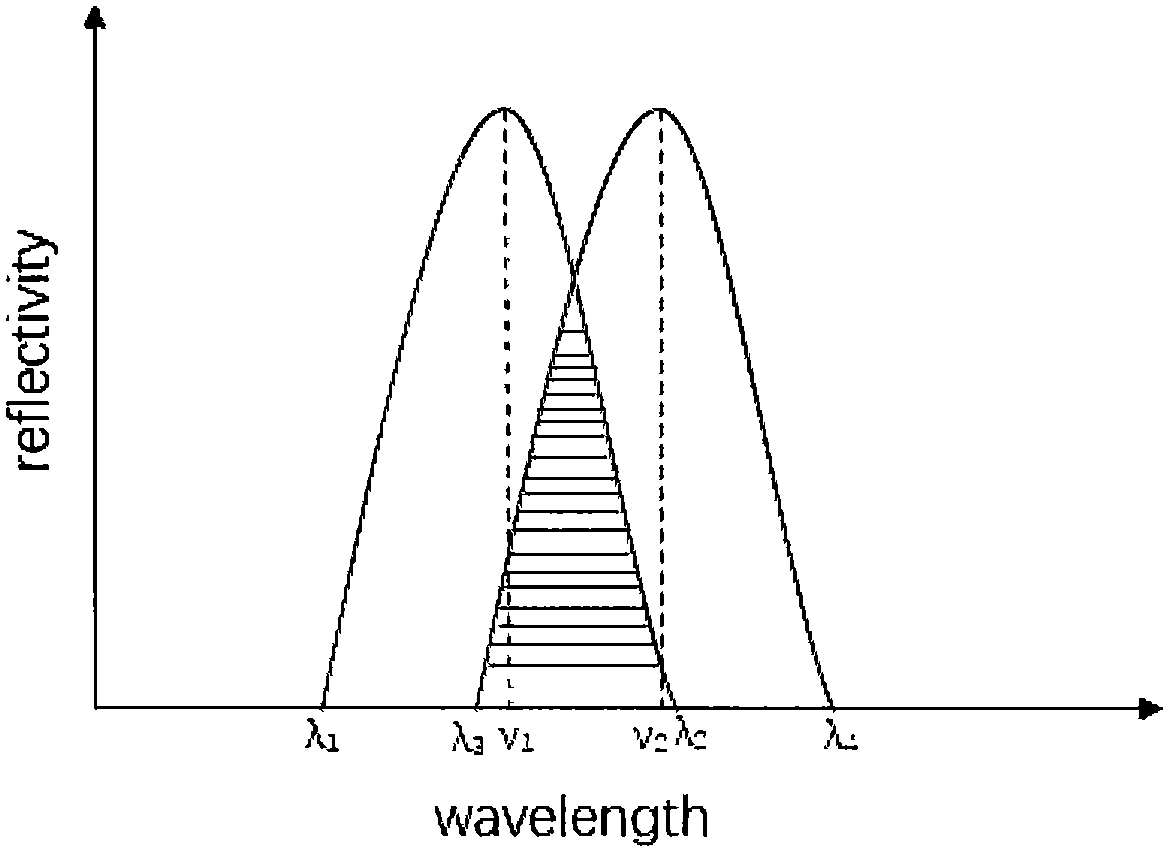

Large-range high-precision fiber bragg grating sensing method and device based on optical cavity ring-down

PendingCN111811554ALarge measuring rangeAccurate measurement accuracyConverting sensor output opticallyGratingEdge filter

The invention relates to a large-range high-precision fiber bragg grating sensing method and device based on optical cavity ring-down. The device comprises an LED broadband light source, a signal generator, a 2*1 optical fiber coupler, a transmission optical fiber, an optical fiber delay line, a circulator, a fiber bragg grating FBG, an edge filter, a photoelectric detector, a fiber bragg grating,a PC and an oscilloscope. Fiber optic ring cavity ring-down (FLRD) techniques are used. A spectrum of the broadband light source has a certain range, and when the fiber bragg grating is influenced byexternal parameters and wavelength conversion occurs, effective reflected light can be generated. The edge filter can enable the light intensity passing through the edge filter to be in linear one-to-one correspondence with the wavelength of the fiber bragg grating so that an output loss in the cavity is in linear relation with the wavelength of the fiber bragg grating. Because the ring-down timeis determined by the loss in the cavity, the parameters acting on the fiber bragg grating can be effectively measured by measuring the ring-down time so that large-range and high-precision measurement is realized.

Owner:CHINA JILIANG UNIV

Method device for detecting diameter of rope groove of hoister

InactiveCN110243298AGuaranteed installation accuracyMeasurement results have no effectUsing optical meansMeasurement deviceEngineering

The invention provides a method device for detecting diameter of a rope groove of a hoister. The method device comprises a bracket, a pedestal, a battery, a sensor main body, a sensor holder, a laser displacement sensor and the hoister. Through an arch height and chord length method, a position of a measurement device is adjusted, a projection point of the laser sensor at the rope groove is enabled to be at the lowest point of the rope groove, an initial measurement value of each rope groove is collected orderly, then, dynamic data is collected at different positions, shape errors of the rope grooves can be detected through monitoring on the data, the data is processed through matlab, and the processed data is substituted into a computational formula to solve the diameter of the rope groove.

Owner:ANHUI UNIV OF SCI & TECH

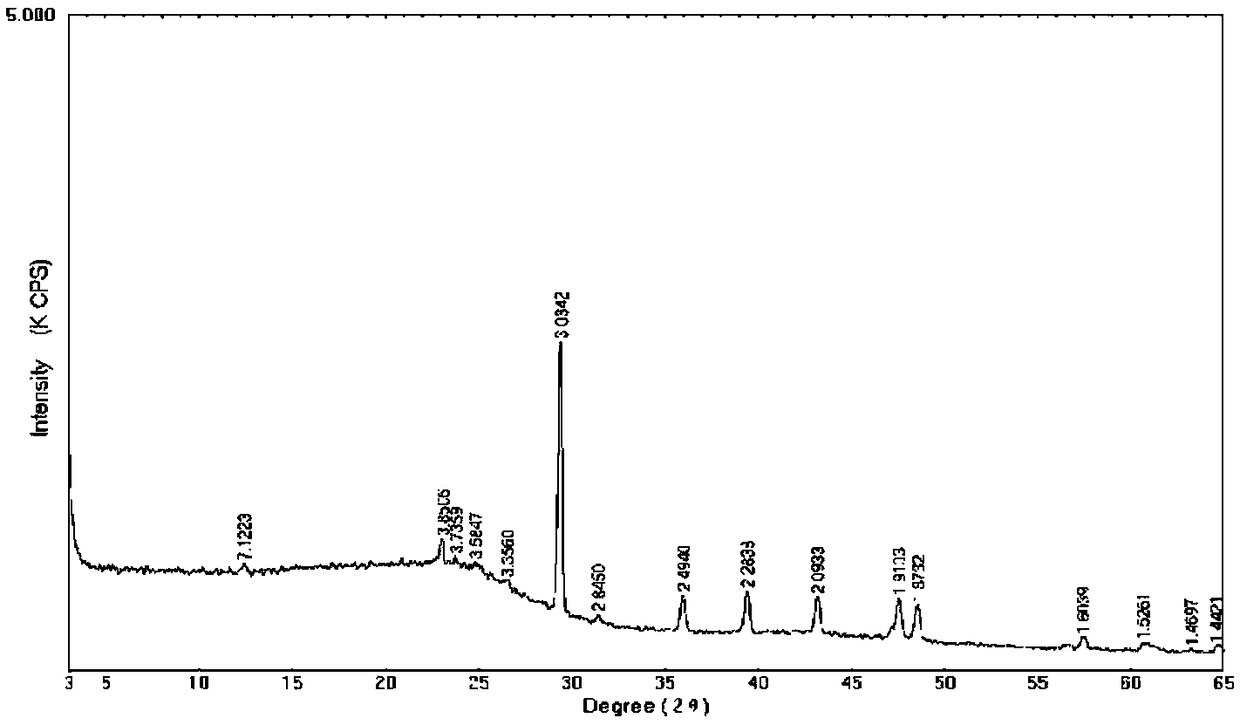

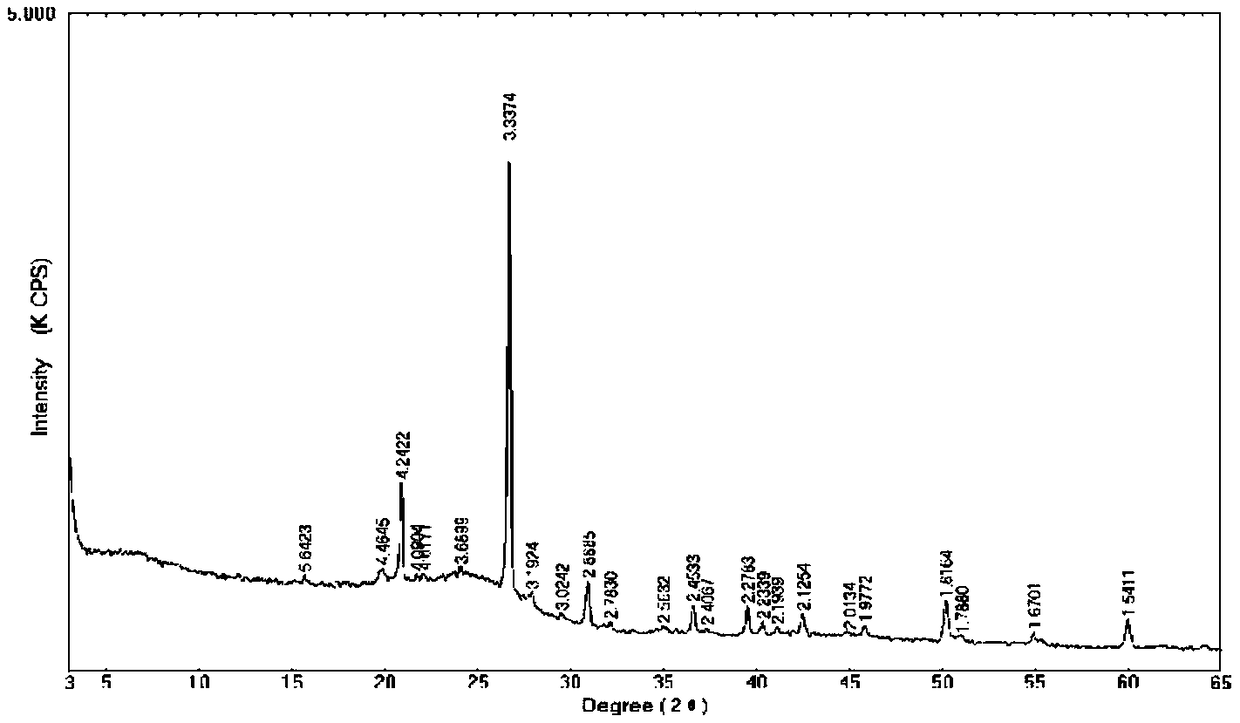

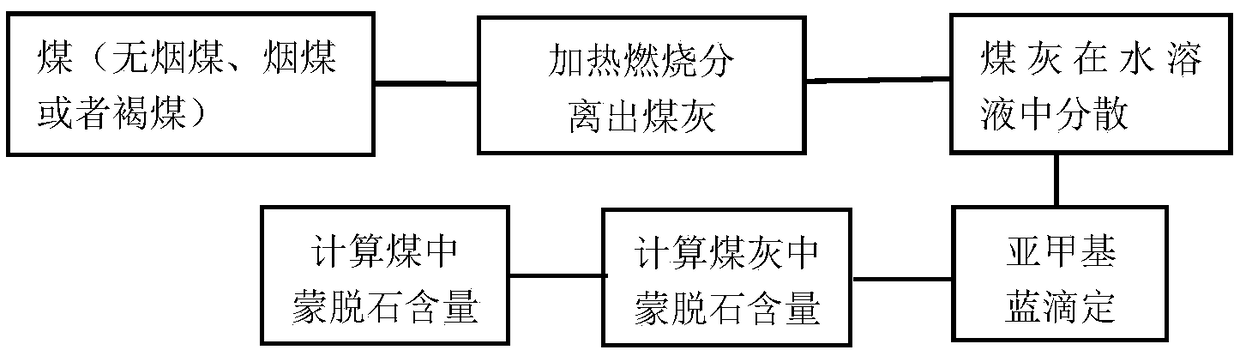

Semiquantitative indirect method for testing content of montmorillonite in coal minerals

ActiveCN108732295AImprove test accuracyEasy to operateChemical analysis using combustionChemical analysis using titrationMontmorillonitePulverized fuel ash

The invention discloses a semiquantitative indirect method for testing content of montmorillonite in coal minerals. The preparation method comprises the following steps: firstly, the coal minerals aresmashed, inorganic minerals in the coal minerals are separated by firing, content of coal ash relative to coal is calculated, then content of montmorillonite in the coal ash is measured with a methylene blue adsorption method, and content of montmorillonite in the coal is calculated finally according to content of the coal ash and content of montmorillonite in the coal ash. The inorganic mineralsin the coal are separated by firing, content of montmorillonite in the coal ash is measured, the measuring precision is higher than that of the conventional method (such as XRD) for measuring contentof montmorillonite in the coal directly, the operation method is simple, a result is shown quickly, and one novel idea can be provided for judging coal sensibility in coalbed methane development.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

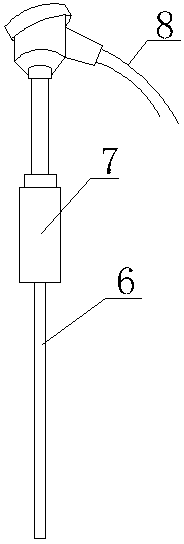

Method for improving main transformer remote-reading thermometer accuracy and remote-reading thermometer

InactiveCN103196572AReduce mistakesHigh measurement accuracyThermometer detailsElectric signal transmission systemsTemperature measurementMeasurement precision

The invention relates to a method for improving main transformer remote-reading thermometer accuracy and a remote-reading thermometer, and belongs to the technical field of power supply devices. The remote-reading thermometer comprises a temperature-sensing probe (1), a temperature transmitter (2), a temperature displayer (3) and a centralized control station (4). The temperature-sensing probe is installed on an upper cover of a main transformer (5), an output end of the temperature-sensing probe is connected with the temperature transmitter, and an output end of the temperature transmitter is respectively connected with the temperature displayer and the centralized control station. According to the method for improving the main transformer remote-reading thermometer accuracy and the remote-reading thermometer, the insertion depth of the temperature-sensing probe can reach more than 120mm, and therefore the remote-reading thermometer can reflect the real temperature of the transformer correctly and reduce errors caused by insufficient insertion depth of the temperature-sensing probe; and in the process of four-wire system wiring, according to the double-bridge measuring circuit principle, conductor resistance has no effect on measuring results, measurement accuracy is high (contact resistance is ignored), the main transformer remote-reading temperature measurement accuracy is improved, display errors of the remote-reading thermometer and a computer terminal can be controlled within a required range, and problems existing in production in a long term are solved.

Owner:STATE GRID CORP OF CHINA +1

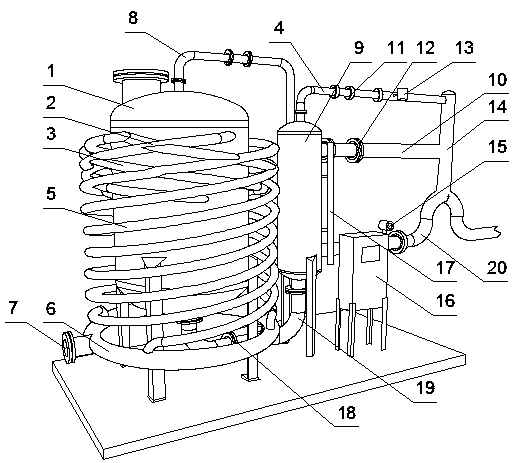

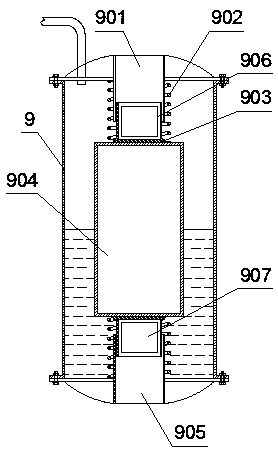

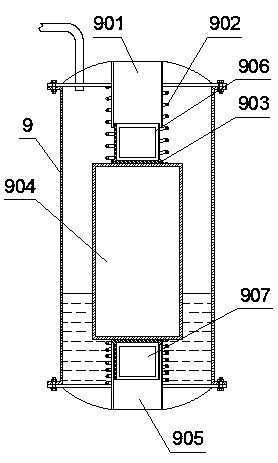

Rapid separation and metering device for multiphase flows

The invention discloses a rapid separation and metering device for multiphase flows, and relates to the technical field of oil field equipment. The rapid separation and metering device comprises a separation tank, a liquid level control tank and a control box; a device frame is arranged at the bottom end of the separation tank; the device frame is circularly provided with a ring-shaped pipe; one side of the ring-shaped pipe is communicated with a feeding port; a separation mechanism is arranged on the ring-shaped pipe; the separation mechanism is coiled outside the separation tank and is communicated with the inner parts of the ring-shaped pipe and the separation tank; the top end of the separation tank is connected with the top end of the liquid level control tank through a pipeline I; the bottom end of the separation tank is connected with the bottom end of the liquid level control tank through a pipeline IV; the top end of the liquid level control tank is communicated with a pipeline VI through a pipeline II; the upper part of the liquid level control tank is communicated with the pipeline VI through a pipeline III; the lower part of the liquid level control tank is communicatedwith the pipeline VI through a pipeline V; and a liquid level meter is arranged on the tank body of the liquid level control tank. The rapid separation and metering device for the multiphase flows iscapable of achieving the aim of rapid separation and continuous metering of the multiphase flows.

Owner:大庆市欣正科技发展有限公司

Temperature compensation sensing method and device for cavity ring-down technology

ActiveCN109060165AImprove accuracyEliminate effects to be measuredThermometers using physical/chemical changesFiber couplerConverters

The invention relates to a temperature compensation sensing method and device for a cavity ring-down technology. The device comprises a broadband light source, a signal generator, a modulator, an optical isolator, a 2*1 fiber coupler, a transmission fiber, a temperature compensation fiber bragg grating (FBG1), a sensing fiber bragg grating (FBG2), a photoelectric converter, a PC machine and an oscilloscope, wherein a ring-down cavity is composed of the temperature compensation fiber bragg grating (FBG1) and the sensing fiber bragg grating (FBG2), and the sensing fiber bragg grating (FBG2) is asensing area; and the broadband light source has a certain spectral width, when the ambient temperature changes, the overlapping spectra of the two fiber bragg gratings move synchronously, and the broadband light source can ensure that the loss in the ring-down cavity before and after the drift is equal and can further ensure that the ring-down time is the same. Therefore, the change of the ring-down time is only caused by the to-be-performed measurement, the purpose of temperature compensation can be achieved, and the accurate measurement of the to-be-performed measurement can be achieved. The invention provides the temperature compensation sensing method and device for the cavity ring-down technology with the advantages of low cost, good stability and temperature effect elimination.

Owner:鞍山峰澜科技有限公司

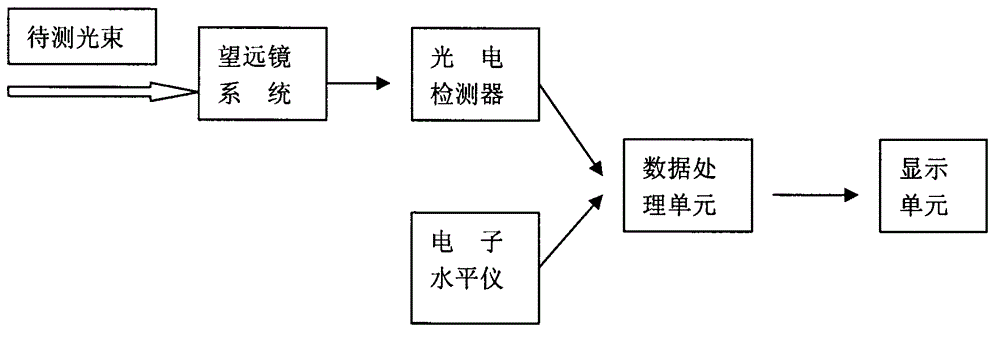

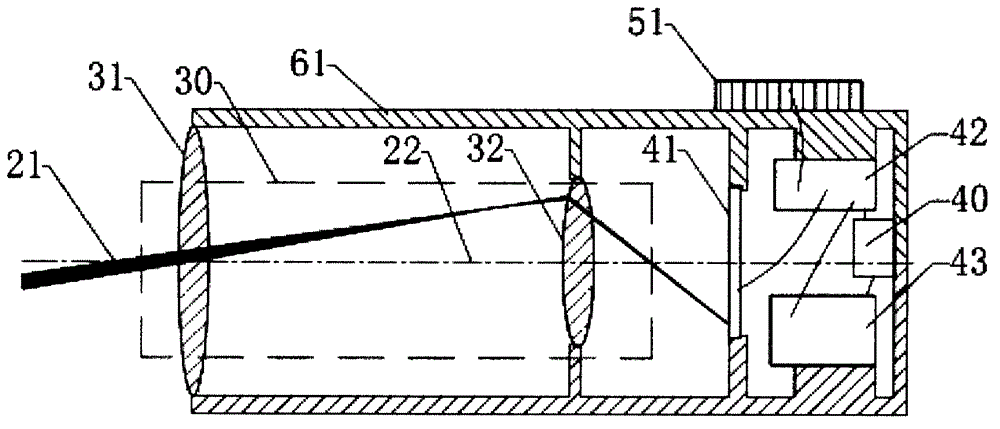

Method and device for measuring light beam angle

InactiveCN102914283AEasy to useAccurate angle measurementAngle measurementPresent methodMeasurement device

The invention aims to overcome the defects of the present method, provides a method for measuring a light beam angle and also provides a device for measuring the light beam angle. The method comprises the following steps: amplifying a flare angle of parallel light beam passing by a telescope system relative to a horizontal line; causing the light beam to enter into a photoelectric detector, detecting the position information of the center of the light beam on a sensor by the photoelectric detector, and simply converting the position information, thereby obtaining angle information; simultaneously receiving the information of an electronic level meter and the photoelectric detector by a data processing unit; giving an inclined angle between the axis and the horizontal line in the whole light beam angle measuring device system by the electronic level meter; indirectly giving the inclined angle between a to-be-measured light beam and the axis of the whole light beam angle measuring device system by the photoelectric detector; calculating, thereby obtaining the inclined angle between the to-be-measured light beam and the horizontal line; and performing by using a peripheral circuit, thereby sending a numerical value of the inclined angle between the to-be-measured light beam and the horizontal line to a display unit.

Owner:蓝景恒

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com