Method for measuring thermal resistance of three-core cable packing layer

A three-core cable and filling layer technology is applied in the field of thermal resistance measurement of cable filling layer, which can solve the problem of difficulty in measuring the thermal resistance of the three-core cable filling layer, and achieve the effects of good reliability, convenient experimental operation and slight damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

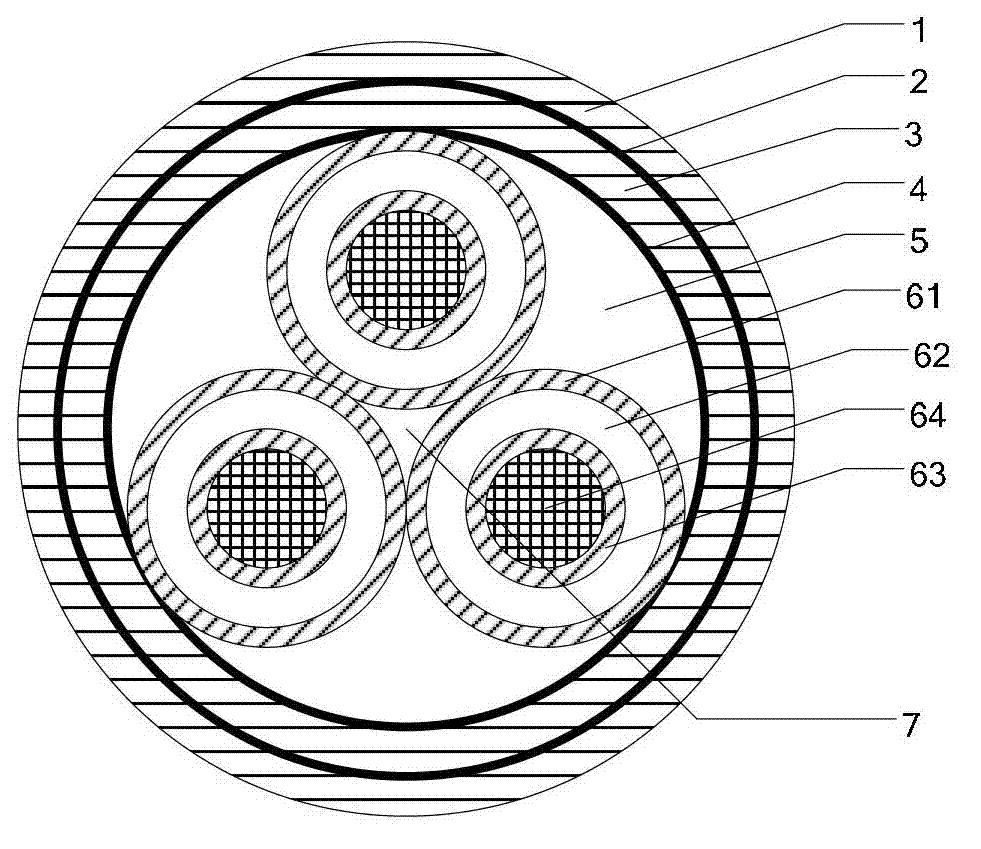

[0026] Such as figure 1 As shown, the structure of the three-core cable from outside to inside is outer sheath 1, armor tape 2, inner sheath 3, wrapping tape 4, filling layer 5, and three cores; each core is from outside to inside They are the metal shielding layer 61, the insulating layer 62, the conductor shielding layer 63, the conductor 64, and the central closed area 7 formed by connecting the metal shielding layers 61 of the three wire cores.

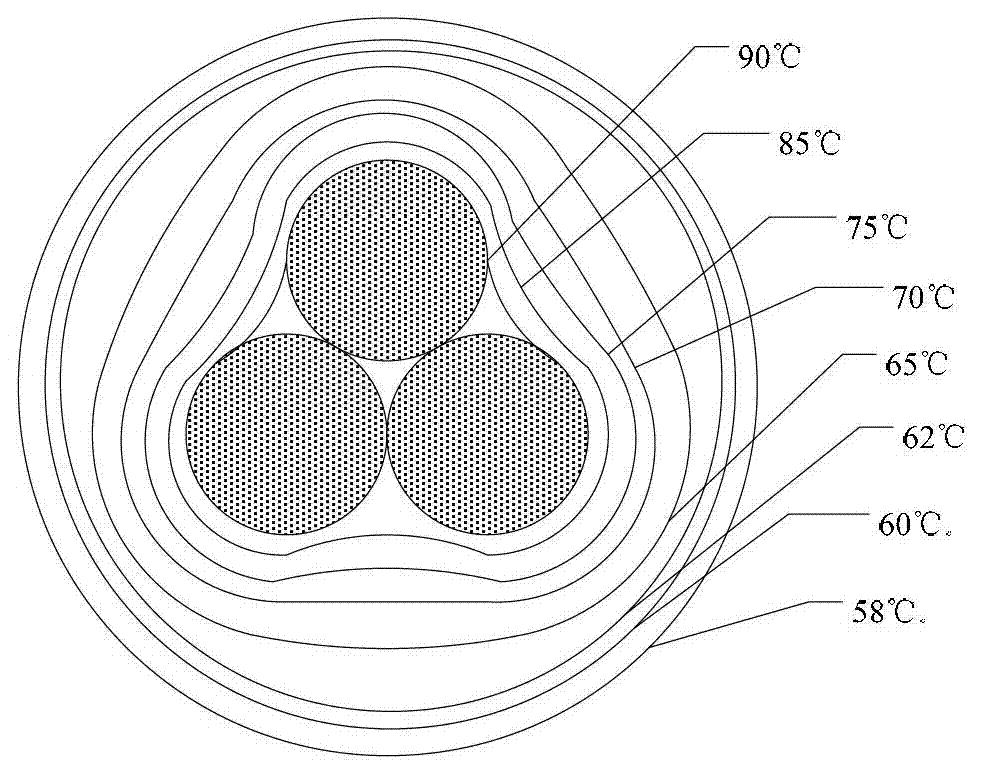

[0027] Such as figure 2 As shown, the temperature field distribution diagram of the three-core cable at 90°C obtained by using ANSYS simulation software, in which the conductor temperature is 90°C, the cable skin temperature is 58°C, and the thermal field distribution characteristics of the section of the three-core cable in a steady state are The same layer is isothermal outside the armored layer. This is due to the high thermal conductivity of the armored layer and good temperature uniformity. However, the inner conductor outs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com