Rapid separation and metering device for multiphase flows

A metering device and fast technology, applied in the directions of measurement, production of fluid, wellbore/well components, etc., can solve the problems of poor metering accuracy of multiphase flow, and achieve the effects of high metering accuracy, compact structure and wide range ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

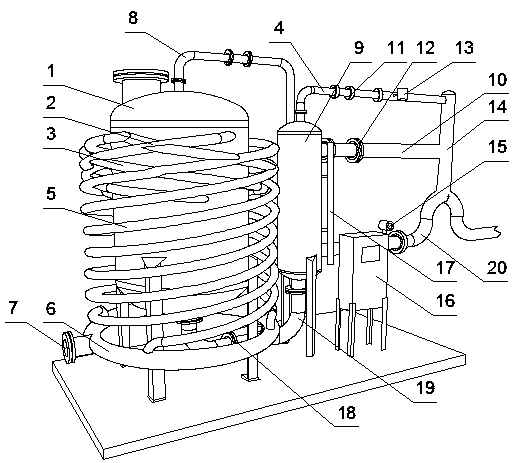

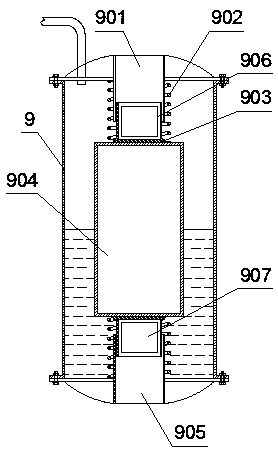

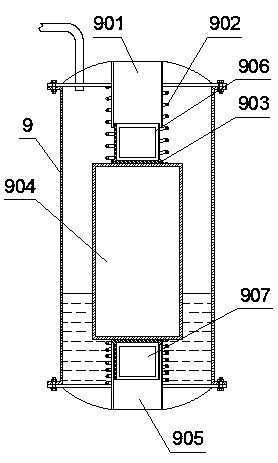

[0027] With reference to each figure, the present invention specifically adopts the following embodiments: comprising a separation tank 1, a liquid level control tank 9 and a control box 16, the bottom of the separation tank 1 is provided with a device frame, and the device frame is surrounded by an annular pipe 6, and the annular pipe 6- The side communicates with the feed port 7, the ring pipe 6 is provided with a separation mechanism, the separation mechanism is coiled outside the separation tank 1, the separation mechanism is connected with the ring pipe 6 and the inside of the separation tank 1, and the top of the separation tank 1 is connected to the liquid level through the pipe 8. The top of the control tank 9 is connected, the bottom of the separation tank 1 is connected to the bottom of the liquid level control tank 9 through the pipe 4 19, the top of the liquid level control tank 9 is connected to the pipe 6 14 through the pipe 2 4, and the upper part of the liquid le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com