Semiquantitative indirect method for testing content of montmorillonite in coal minerals

A montmorillonite, semi-quantitative technology, applied in the direction of chemical analysis by titration, chemical analysis by combustion, etc., can solve the constraints of timeliness and universality of analysis and determination, small content, and inability to measure the mineral content of montmorillonite and other problems, to achieve the effect of simple and easy separation means, simple operation, and no influence on the measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

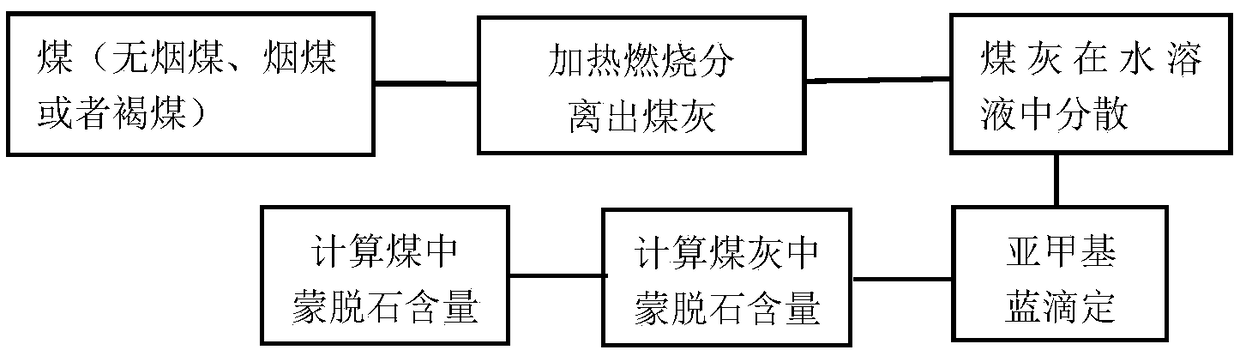

[0041] A method for semi-quantitative indirect testing of montmorillonite content in coal, the process flow chart is shown in image 3 ;Specific steps are as follows:

[0042] 1) Separation of inorganic minerals in coal by burning: crush the coal minerals (Xinjiang bituminous coal) to a particle size of less than 74 μm, and evenly spread them in an ash dish so that the mass of each square centimeter of the tiles does not exceed 0.20 g, and then heat them at a temperature of 610 ° C. Burning under the same conditions for 1-1.5 hours (and carry out inspection burning, the burning temperature is 610 ℃, each time is 15-20min, until the mass change after two consecutive burnings does not exceed 0.1% of the mass of coal ash) , take out, cool and dry to obtain coal ash, then weigh and calculate the coal ash content; wherein the calculation method of the coal ash content is shown in formula 1:

[0043]

[0044] In the formula, A is the coal ash content, the unit is percentage (%);...

Embodiment 2

[0056] A semi-quantitative indirect method for testing the content of montmorillonite in coal, the test steps are roughly the same as in Example 1, the difference is that: the coal is Shanxi anthracite, and the burning temperature is 730°C; 0.5347g of the obtained coal ash is weighed and dispersed In 50 ml of water, add dilute sulfuric acid solution 1mL (2.5mol / L); sodium pyrophosphate solution 10mL (1wt%).

[0057] The parameter test results obtained in different steps of this embodiment are shown in Table 1, and the calculated montmorillonite content in the coal is 0.09%.

[0058] The Shanxi anthracite described in this example was measured by the blue suction method described in step 2), and the test results showed that there was no montmorillonite component.

Embodiment 3

[0060] A semi-quantitative indirect method for testing the content of montmorillonite in coal, the test steps are roughly the same as in Example 1, the difference is that the coal is Shanxi anthracite (floor mudstone), and the burning temperature is 700°C; weigh 0.8546g The obtained coal ash was dispersed in 50 ml of water, and then 1 mL (2.5 mol / L) of dilute sulfuric acid solution and 15 mL (1 wt%) of sodium pyrophosphate solution were added.

[0061] The parameter test results obtained in different steps of this embodiment are shown in Table 1, and the calculated montmorillonite content in the coal is 2.29%.

[0062] The Shanxi anthracite described in this example was measured by the blue suction method described in step 2), and the result showed that the content of montmorillonite in the coal mineral was below 1 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com