Method and device for measuring light beam angle

An angle measurement and beam technology, applied in the field of optical detection and optics, can solve the problems of constant absolute height, troublesome adjustment, difficult methods, etc., and achieve the effects of accurate monitoring angle, cost reduction, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

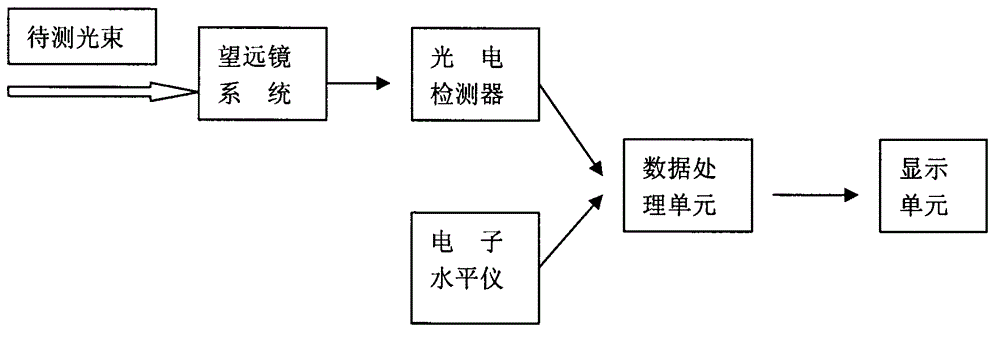

[0020] figure 1 It is a schematic diagram of the beam angle measurement method. The parallel beam passes through the telescope system, and its opening angle relative to the horizontal line is enlarged; the beam then passes through the photoelectric detection device, which can detect the position information of the center of the beam on the sensor, and the position information is obtained through simple conversion. The angle information can be obtained; the data processing unit receives the information of the electronic level and the photoelectric detection device at the same time. The angle between the central axis of the entire beam angle measuring device system can be calculated to obtain the angle between the beam to be measured and the horizontal line; after the peripheral circuit is processed, the value of the angle between the beam to be measured and the horizontal line can be sent to the display unit.

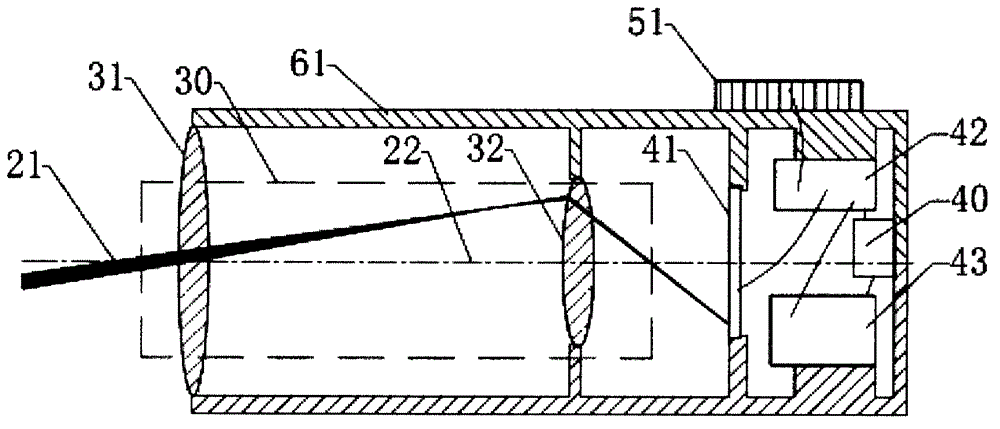

[0021] figure 2 It is a schematic diagram of the beam angle measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com