Temperature compensation sensing method and device for cavity ring-down technology

A technology of temperature compensation and optical cavity ringdown, which is applied in the field of optical fiber sensing, can solve the problems that the influence of ambient temperature cannot be eliminated at the same time, and the physical quantity to be measured cannot be measured accurately, so as to achieve the effect of wide range of use and high sensitivity detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The invention is further described below in conjunction with the accompanying drawings.

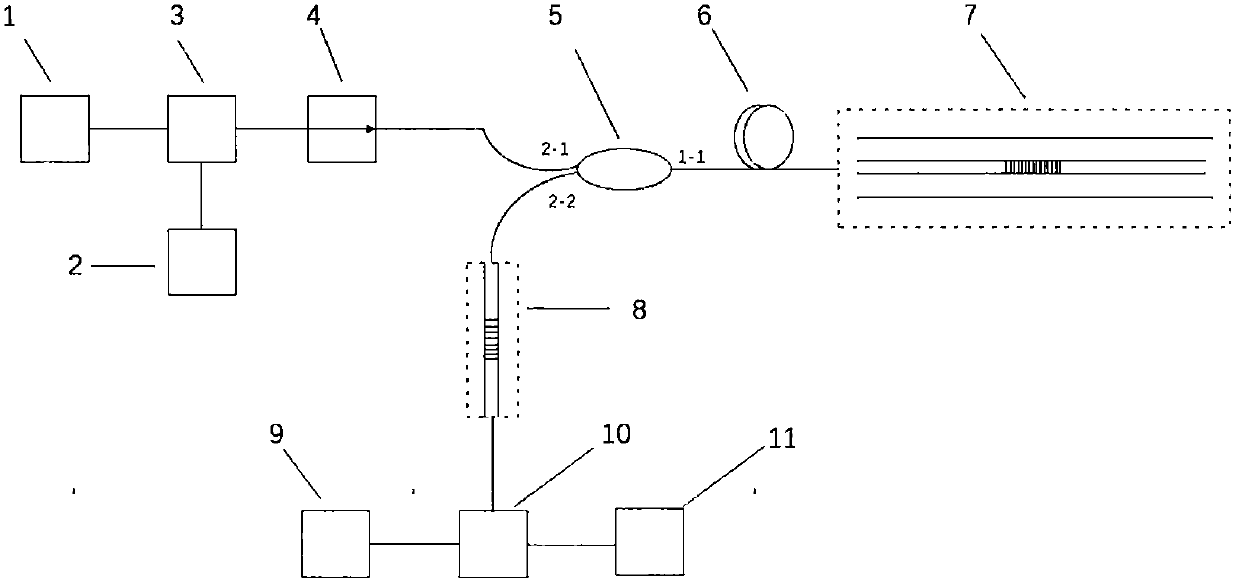

[0039] like figure 1 As shown, the temperature compensation sensing device of optical cavity ring down technology includes: broadband light source 1, signal generator 2, modulator 3, optical isolator 4, 2×1 fiber coupler 5, transmission fiber 6, temperature compensation fiber grating (FBG1) 8, sensor fiber grating (FBG2) 7, photoelectric converter 10, PC 9 and oscilloscope 11. The broadband light source 1 is connected to the optical input port of the modulator 3 through an optical fiber, the electrical signal input port of the modulator 3 is connected to the signal generator 2 with a cable, and the optical output port of the modulator 3 is connected to the optical isolator 4; 2×1 optical fiber 2_1, 2_2 ports in the coupler 5 are connected with the output end of the optical isolator 4 and the temperature compensation fiber grating (FBG1) 8 respectively, and the temperature compens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com