Non-contact inner parallel plane distance measuring method for large-sized workpiece

A parallel plane, non-contact technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of multi-working hours, complicated handling process, affecting processing efficiency and cost, etc., and achieves benefits for measurement Accuracy, reduction of measurement error sources, and operation time saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

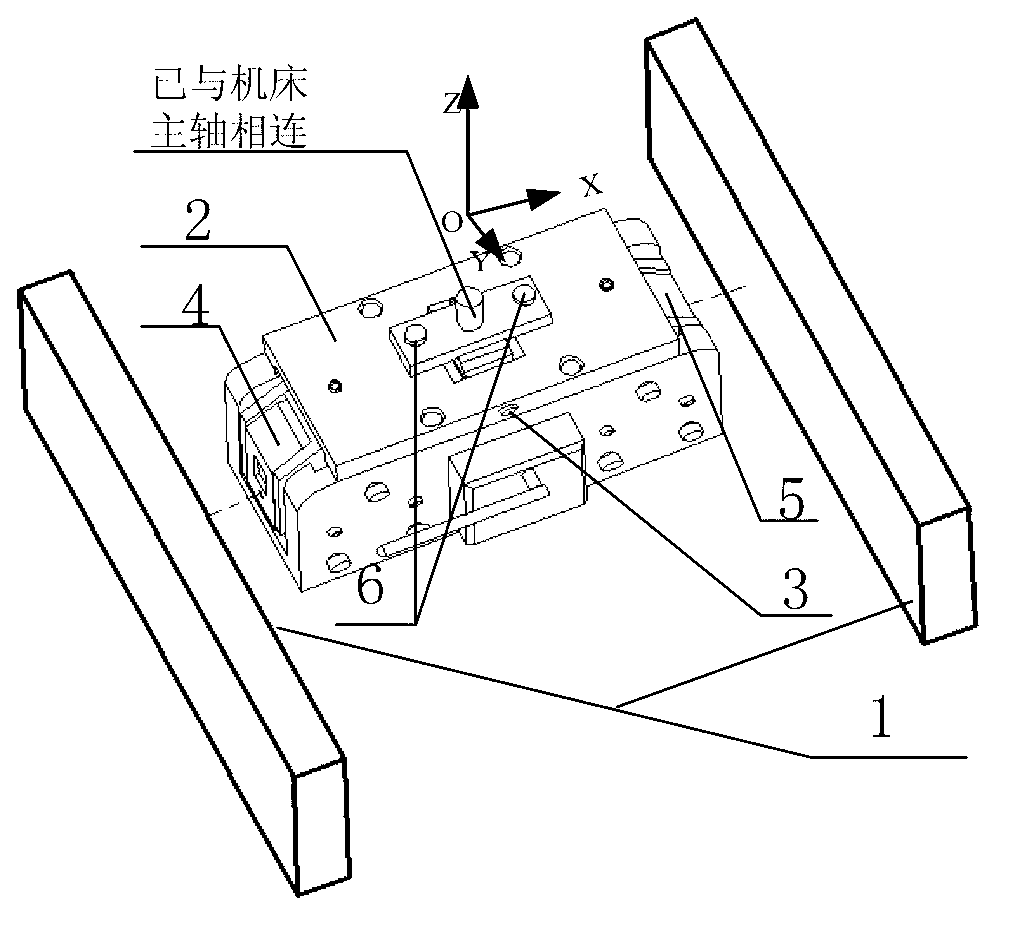

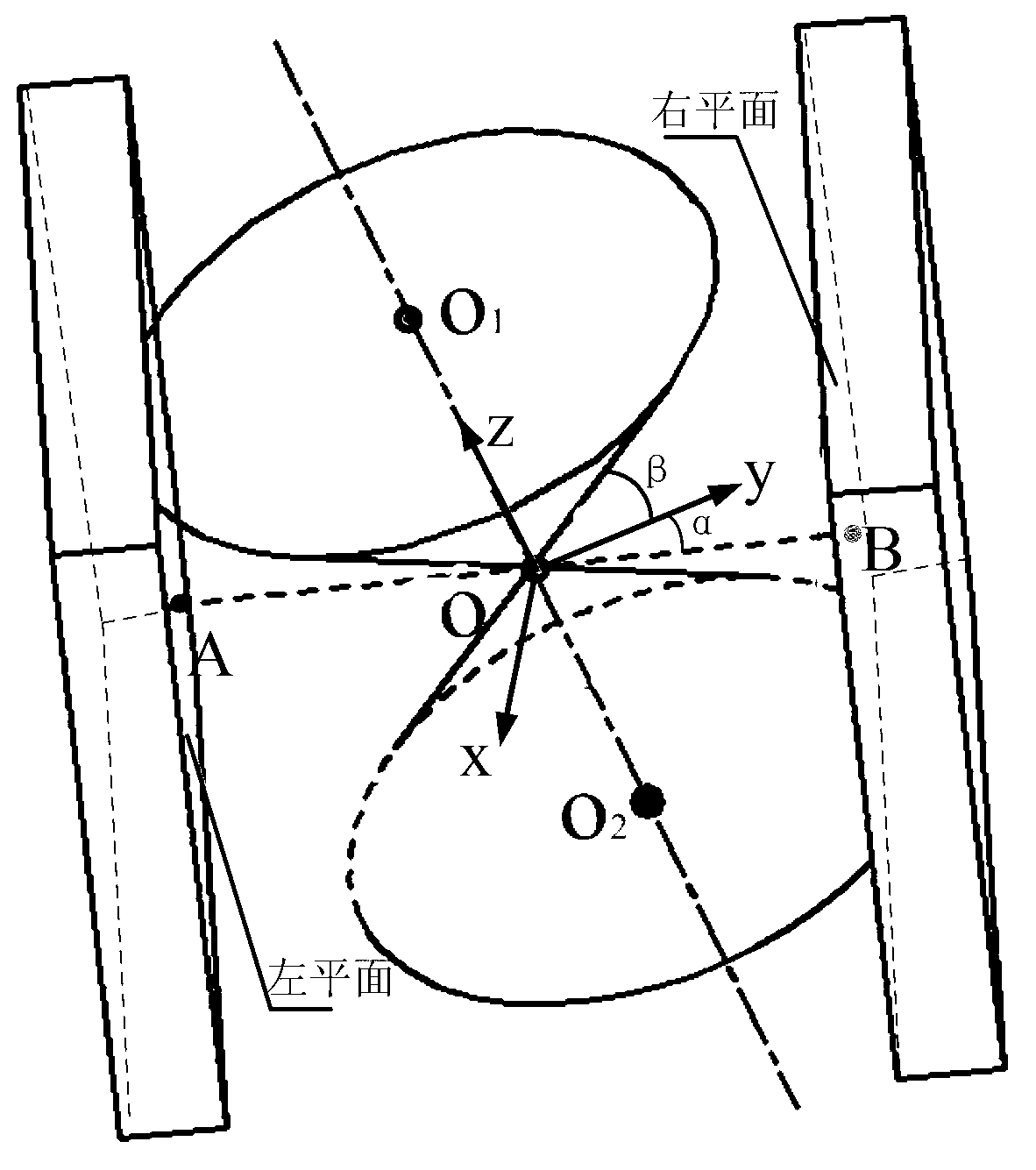

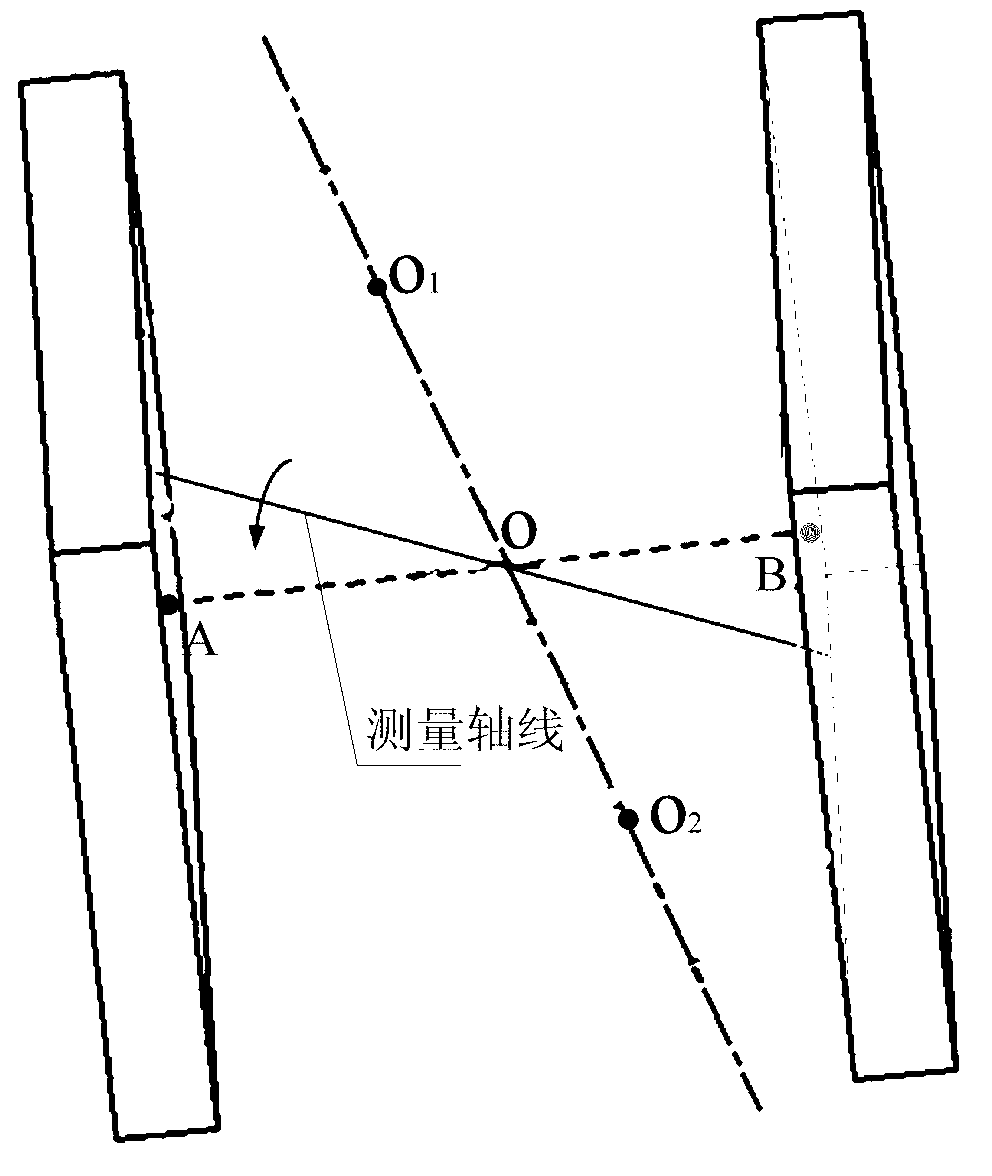

[0036] In order to realize the measurement of the internal dimensions of large workpieces, improve the measurement accuracy, reduce the measurement cost and shorten the measurement man-hours, the embodiment of the present invention provides a non-contact method for measuring the distance between parallel planes within large workpieces, see figure 1 , figure 2 , image 3 with Figure 4 , see the description below:

[0037] see figure 1 The probe 2 is provided with a first laser displacement sensor 4 and a second laser displacement sensor 5. Before the probe 2 is used, the optical axes of the laser beams emitted by the first laser displacement sensor 4 and the second laser displacement sensor 5 coincide, and the overlapping The straight line is defined as the measurement axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com