Multiple parameter measurement device and method for small caliber and small flow fluid

A measurement method and measurement device technology, which is applied in the direction of detecting fluid flow by measuring pressure difference, determining specific gravity by measuring pressure difference, volume/mass flow generated by mechanical effects, etc., and can solve the problem of fluid measurement accuracy of small pipe diameter and small flow rate Problems such as failure to meet the requirements, single measurement parameters, and increased costs have achieved the effect of simple structure, high measurement accuracy, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

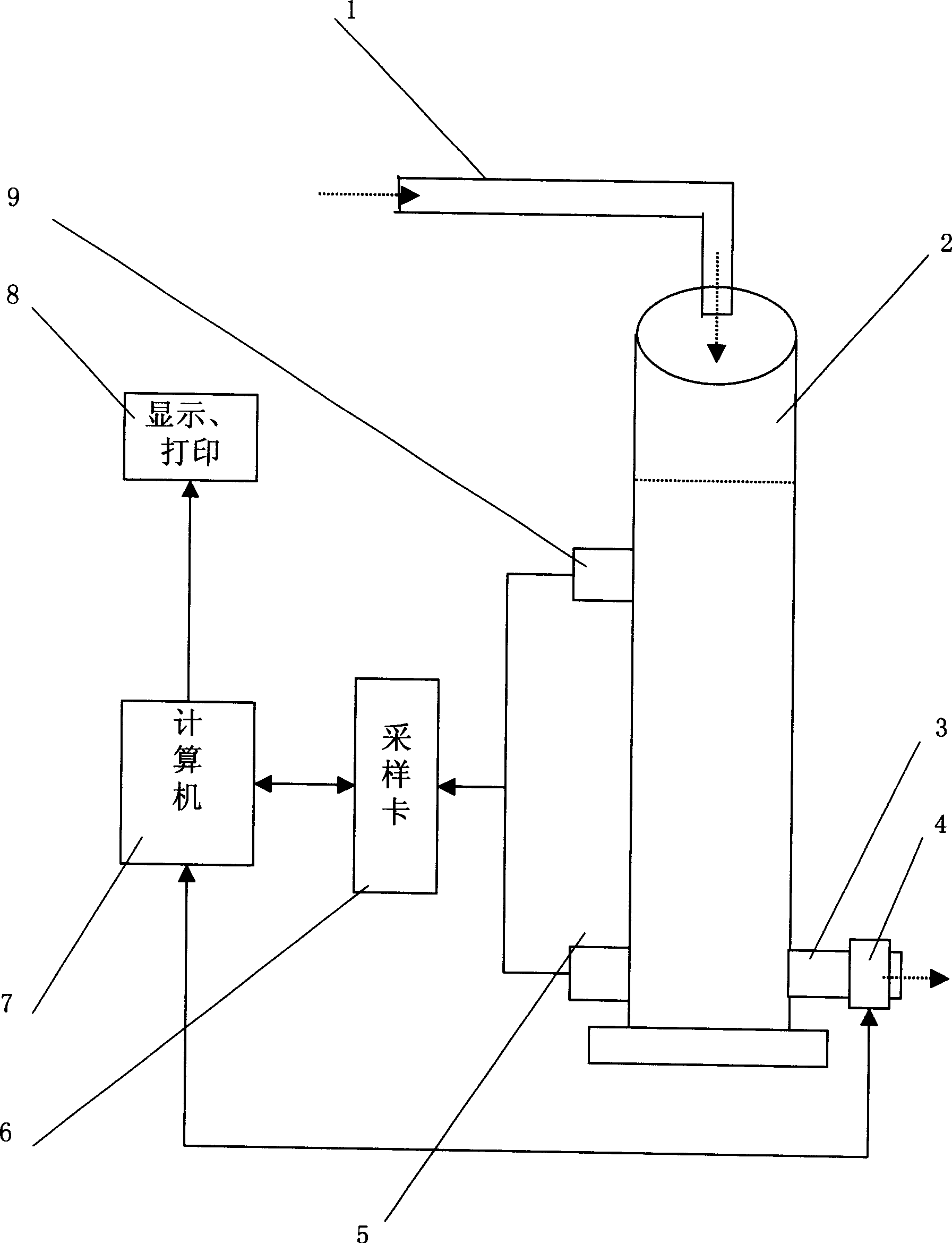

[0021] Such as figure 1 As shown, the multi-parameter measurement device for fluid with small diameter and small flow rate designed by the present invention includes a measuring tube 2 , pressure sensors 5 and 8 , a sampling card 6 and a computer data processing system 7 . An upper pressure sensor A9 and a lower pressure sensor B5 are installed on the wall of the vertical measuring tube 2 , the lower part of the measuring tube 2 has an outlet pipe 3 , and a valve 4 is installed on the outlet pipe 3 . The height of the outlet pipe 3 is equal to the height of the downforce sensor B5, that is, the centerlines of the two are on the same horizontal plane. The upper pressure sensor A9 and the lower pressure sensor B5 are connected with the sampling card 6, and the sampling card 6 is connected with the computer 7. The fluid pipe 1 to be measured is connected from the top of the measuring pipe 2 and connected out from the outlet pipe 3 below.

[0022] The upper pressure sensor A9 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com