Weighing device for mortar car powder material and its method

A technology of metering device and mortar truck, which is applied in the direction of selling raw material supply devices, can solve the problems of inaccurate metering, inaccurate dry powder material conveying and metering, and difficulty in meeting quality requirements, so as to reduce the influence of inertial discharge and eliminate drop. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

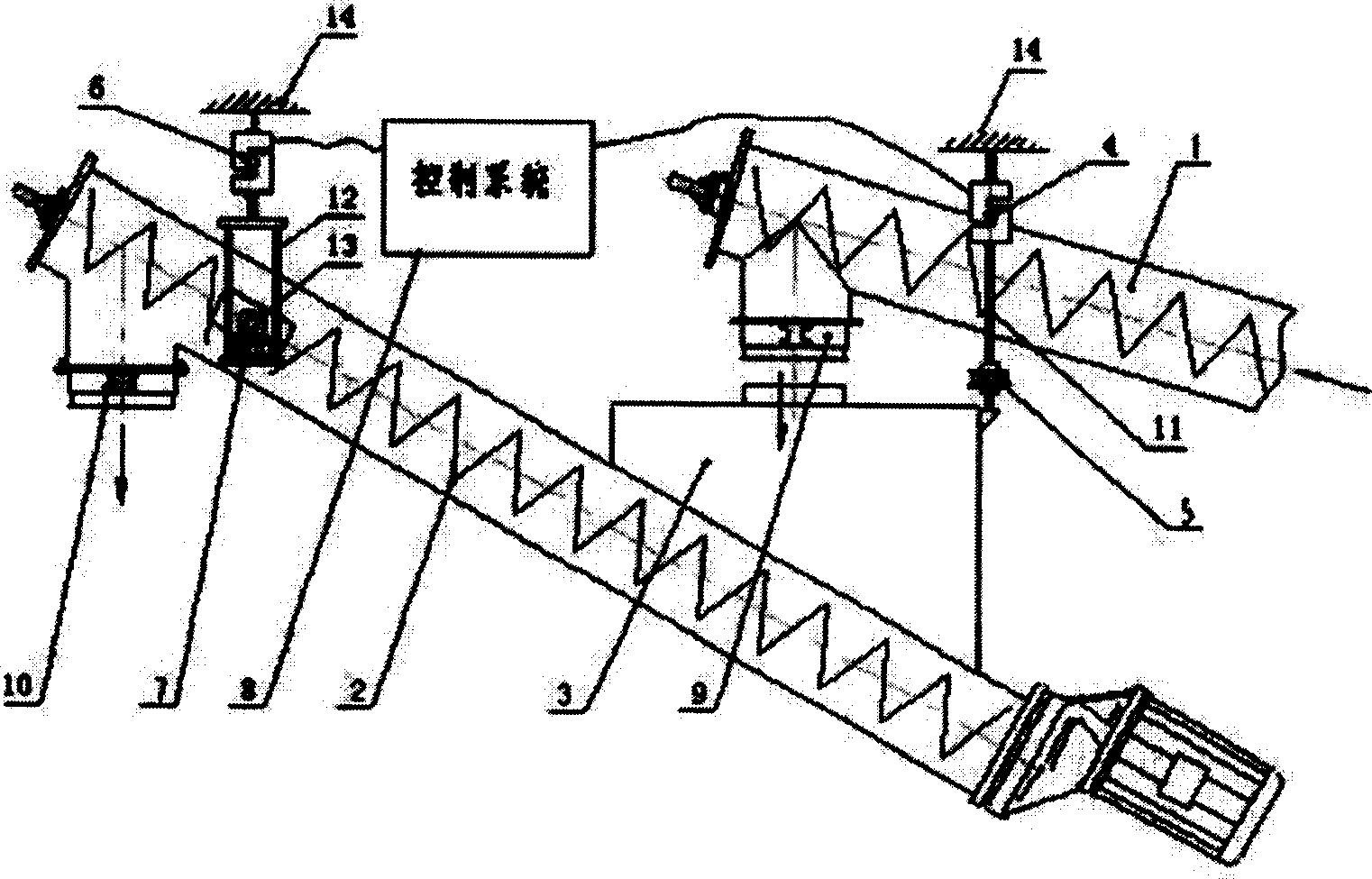

[0015] See accompanying drawing, the device of the present invention is made up of the screw conveyer that two sections are inclined to arrange; Powder hopper 3; a front boom part 11 with a load cell 4 is arranged on the powder hopper 3; a damping block 5 is arranged between the front boom part 11 and the powder hopper 3; the discharge section of the second stage screw machine 2 The two sides of the two sides are provided with connecting lugs 13 for supporting the rear boom part 12, and are connected with the rear boom part 12 with the load cell 6 through the connecting lugs 13, and the rear boom part 12 is connected with the second stage screw machine 2 is also provided with damping blocks 7 between the connecting lugs 13;

[0016] The weighing and measuring method of the device of the present invention: the first-stage screw machine 1 feeds the powder hopper 3 fixed on the second-stage screw machine 2 according to a given amount according to the instruction of the host compu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com