Multifunctional supersonic vibration auxiliary machining machine tool and control method thereof

A technology of ultrasonic vibration and auxiliary processing, which is applied in the direction of automatic control devices, metal processing machinery parts, metal processing, etc., to achieve the effect of improving production efficiency, improving production efficiency, and reducing processing points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical scheme and working process of the present invention will be further described below in conjunction with the accompanying drawings.

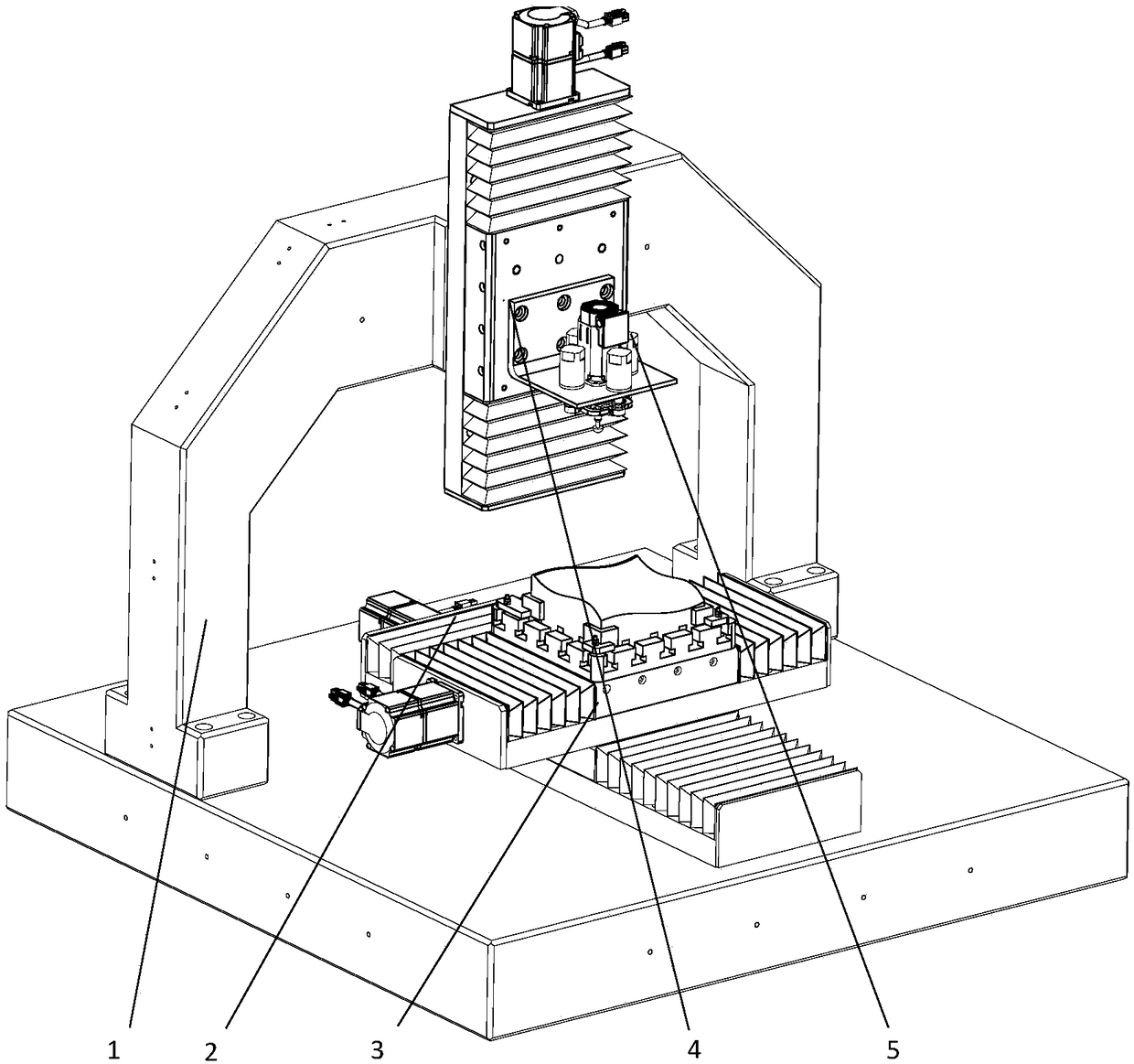

[0037] The overall layout of the machine tool is figure 1 shown.

[0038] Such as Figure 11 As shown, the rotational movement of the cross shaft 514 is transmitted to the tool 508 through the cross groove end of the tool shaft 510 so that it can rotate. The four ultrasonic vibrators 502 are respectively controlled to make the end of the tool have different vibration forms. The four piezoelectric The stack 512 is controlled using the same control law. When it elongates suddenly, the ratchet 513 is accelerated to rotate instantaneously through the impact of the pawl 5111, so that it can vibrate in the circumferential direction.

[0039] Processing path planning process 1:

[0040] Such as Figure 14 As shown, set the length d of the workpiece 1 , width d 2 , the minimum distance d between two adjacent trajectories, the max...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com