Steel slag centrifugal granulation device

A technology of centrifugal granulation and steel slag, which is applied in the field of iron and steel metallurgy, can solve problems such as difficulty in adapting to metallurgical production needs, large equipment footprint, and low production efficiency, and achieve the goals of improving recycling efficiency, uniform cooling effect, and increasing service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

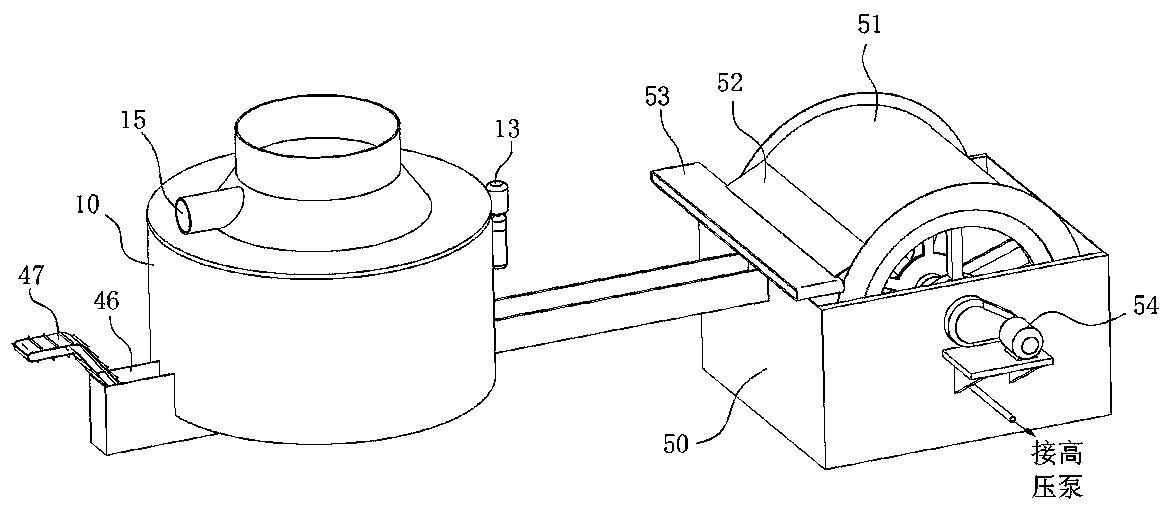

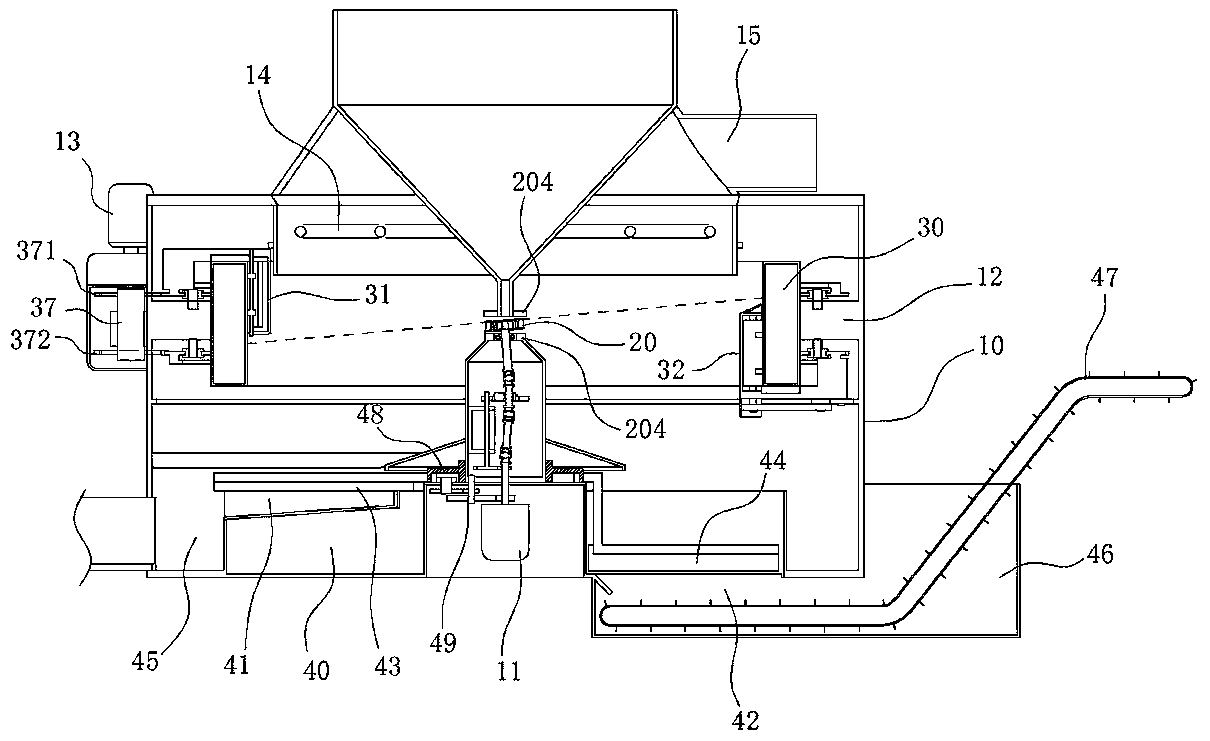

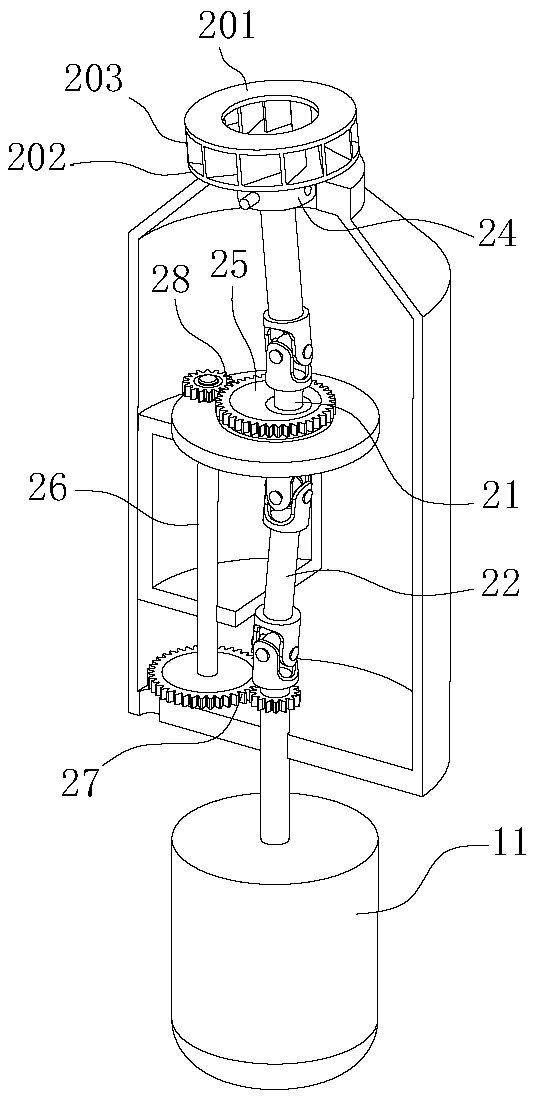

[0022] Such as figure 1 , 2 As shown, a steel slag recovery and processing system includes a centrifugal granulation device and a vacuum filtration device. The centrifugal granulation device includes a slag tank 10, and the center of the slag tank 10 is provided with a centrifugal disc 20, and the centrifugal disc 20 is The axis is rotated and the slag tank 10 is provided with a first drive motor 11 for driving the centrifugal disc 20 to rotate. A pouring port for molten steel slag is provided above the centrifugal disc 20. A cooling water jacket 30 is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com