Patents

Literature

264results about How to "Avoid measurement effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

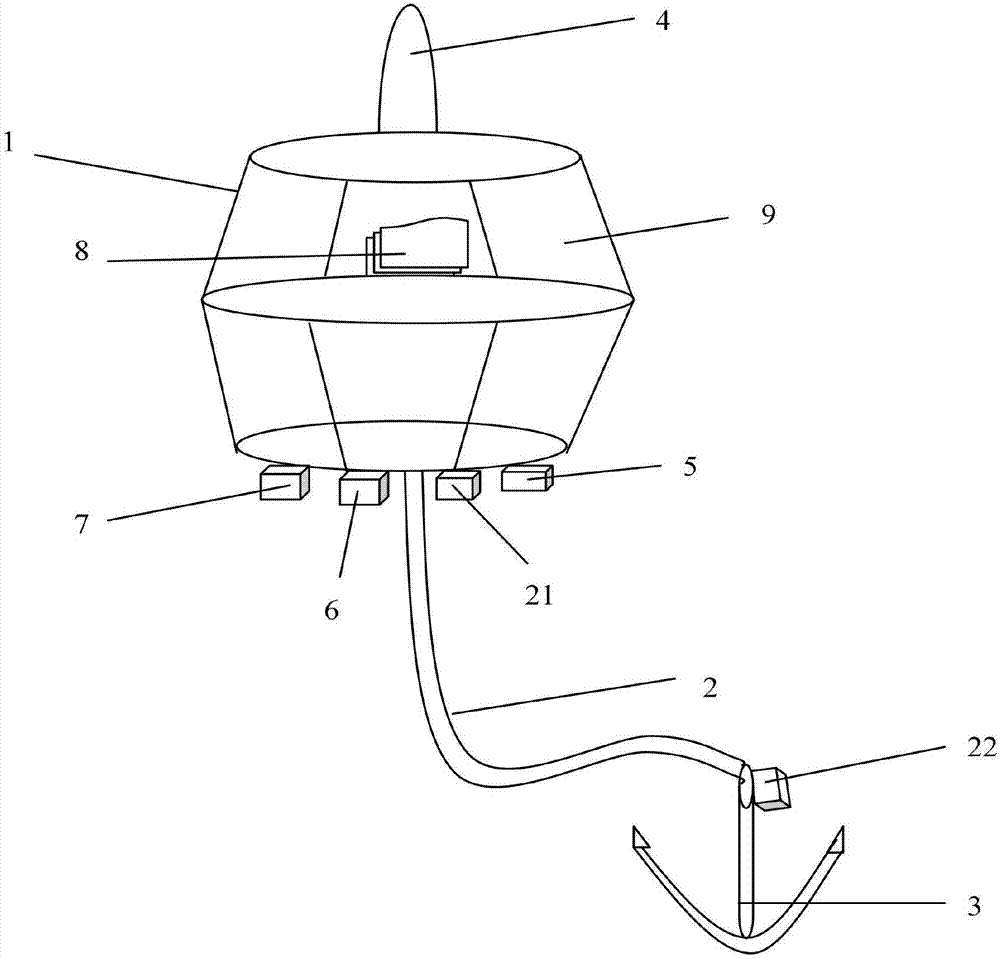

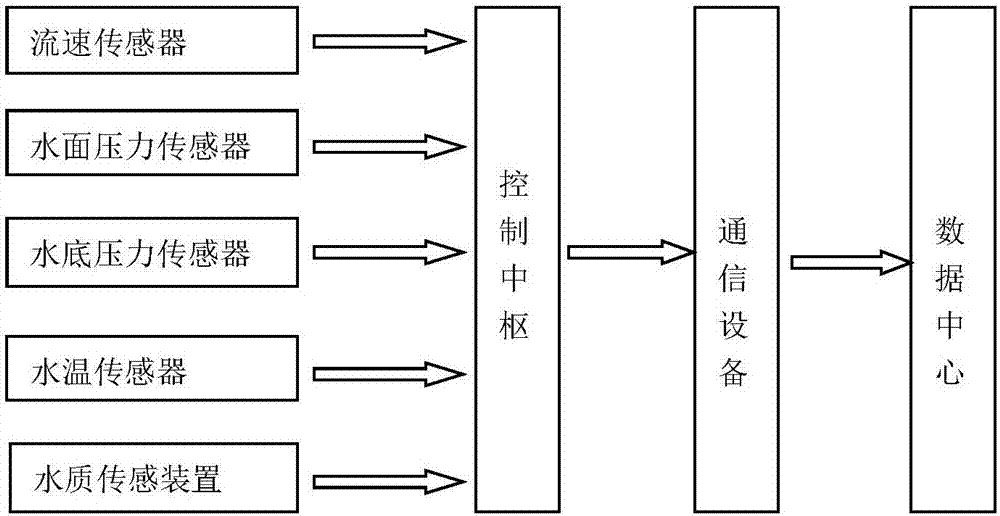

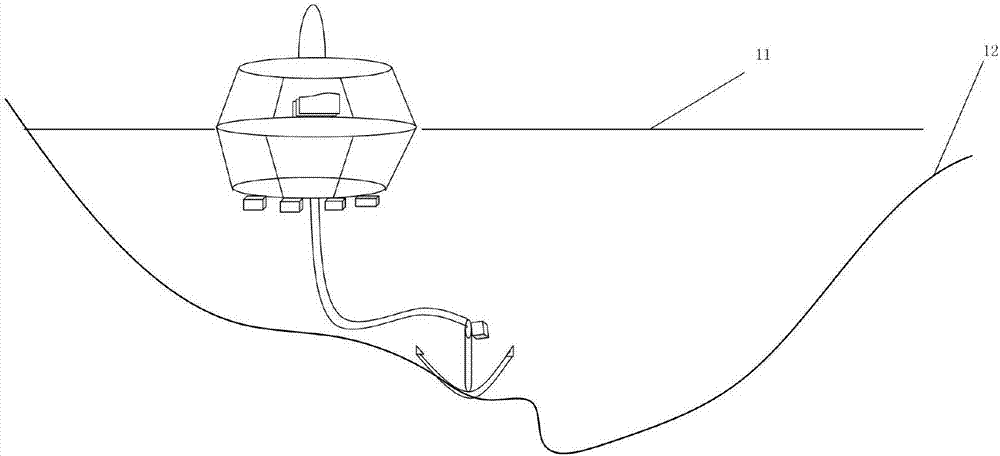

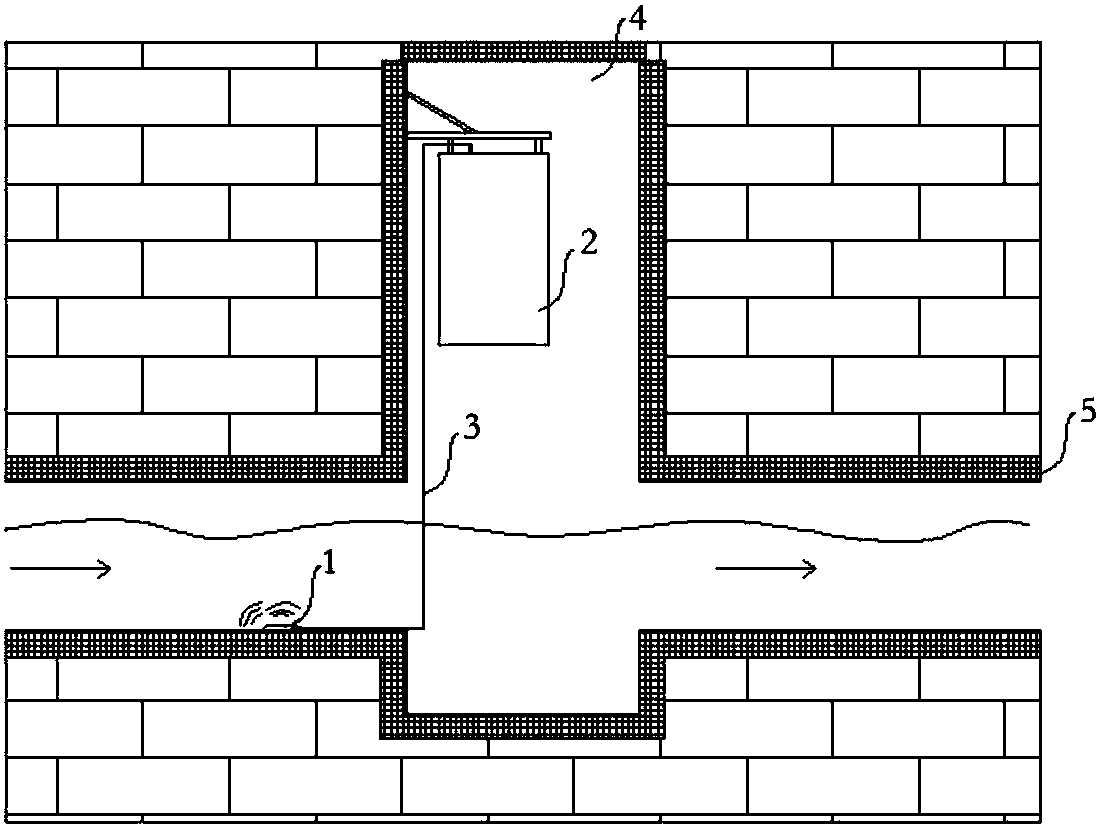

Float type automatic monitoring system of rivers and lakes of depopulated zone

PendingCN107576314AValid deliveryRealize online monitoringVolume/mass flow measurementTesting waterWater qualityEngineering

The invention relates to float type automatic monitoring equipment of rivers and lakes of a depopulated zone. The equipment comprises a floating ball, a multifunctional mooring cable and an underwaterdevice, wherein the floating ball, the multifunctional mooring cable and the underwater device are connected in sequence; communication equipment is arranged at the top of the floating ball, and a flow speed sensor, a water temperature sensor and a water quality sensing device are arranged at the bottom of the floating ball, so that signals can be effectively transmitted and online monitoring ofwater quality, water flow speeds and water temperature of water bodies of the lakes; the outer part of the floating ball is composed of a solar cell panel and self-powered and low-power-consumption operation can be realized; a water surface pressure sensor and a water bottom pressure sensor are arranged so that relative water levels of the lakes are measured through pressure difference and the influences, caused by environment factors including atmospheric pressure changes and the like, on the measurement of the water levels are overcome.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION +1

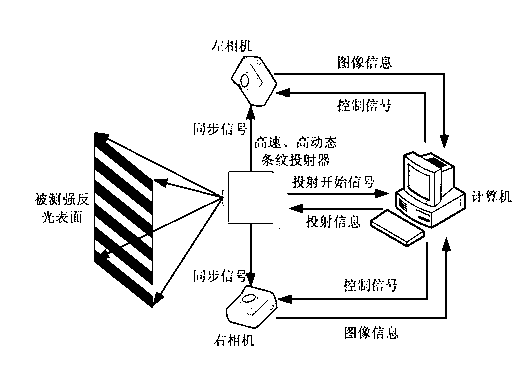

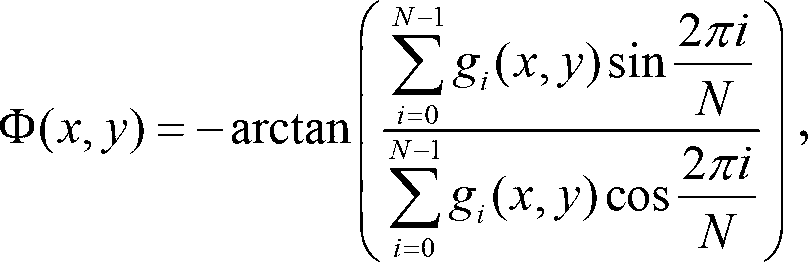

Measuring system of three-dimensional shape of strong reflecting surface based on high dynamic strip projector

ActiveCN102937425AAdaptableOvercome the influence of background light on measurementUsing optical meansThree dimensional shapeOptical measurements

The invention relates to a measuring system of a three-dimensional shape of a strong reflecting surface based on a high dynamic strip projector. The measuring system comprises a computer, the high dynamic strip projector and an image acquisition unit. Projection control information is sent to the high dynamic strip projector by the system through the computer, strip images in different light intensities and gray levels are controlled to be projected, meanwhile, control information is sent to the image acquisition unit by the computer, and the image acquisition unit is controlled to carry out photographing in different time periods of exposure; collected image information is transmitted to the computer by the image acquisition unit, the image is processed by the computer, and three-dimensional information of a to-be-detected object is acquired by image fusion, dephasing, phase unwrapping and stereo matching. According to the measuring system of the three-dimensional shape of the strong reflecting surface based on the high dynamic strip projector, saturation and / or excessive darkness of a collected strip image caused by the strong reflecting surface can be overcome, high-precision non-contact optical measurement of the three-dimensional shapes of the strong reflecting surfaces of metals and the like can be realized, and the measuring system of the three-dimensional shape of the strong reflecting surface based on the high dynamic strip projector can be applied to high-precision non-contact optical measurement of the three-dimensional shapes of the strong reflecting surfaces and mirror-similar surfaces of various metals.

Owner:BEIHANG UNIV

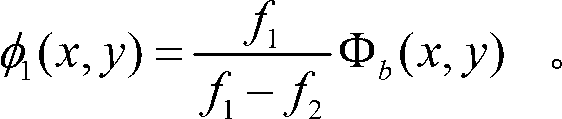

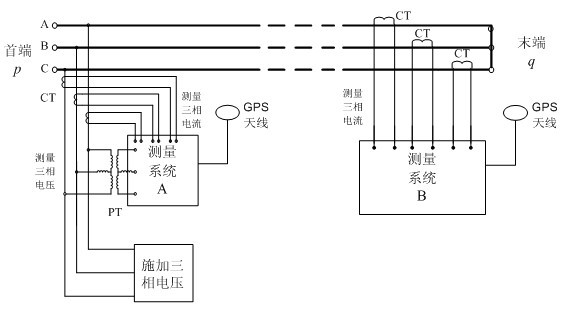

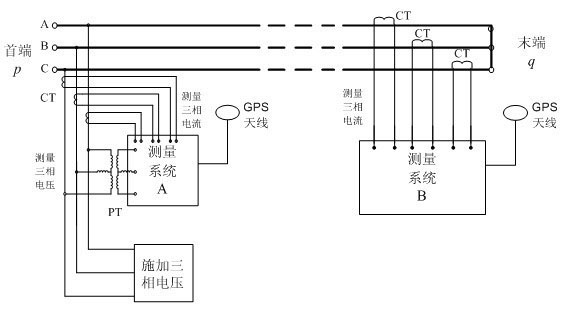

Method for measuring positive sequence parameters of ultra-high voltage transmission line based on double end measuring information

InactiveCN102129009ASuitable for measurementSolving the Simultaneity Problem of MeasurementFault locationCapacitanceUltra high voltage

The invention relates to the technical field of measuring parameters of a transmission line of a power system, in particular to a method for measuring positive sequence parameters of an ultra-high voltage transmission line based on double end measuring information. The method comprises: measuring positive sequence impedance and positive sequence capacitance of the transmission line; when measuring the positive sequence impedance of the transmission line, cutting off the to-be-measured transmission line, performing three-phase short connection to the tail end of the transmission line, adding athree-phase voltage on the front end of the transmission line; when measuring the positive sequence capacitance of the transmission line, cutting off the to-be-measured transmission line, performing three-phase opening to the tail end of the transmission line, adding the three-phase voltage on the front end of the transmission line; using a global satellite positioning system technology to simultaneously measure the three-phase voltage on two ends of the transmission line and the three-phase current on two ends of the transmission line, and synchronously sampling the three-phase voltage and three-phase current. The method in the invention solves the influence of the distributed capacitance on the transmission line to the positive sequence parameters measurement so as to greatly increase the precision of the positive sequence parameters measuring result of the transmission line.

Owner:WUHAN UNIV

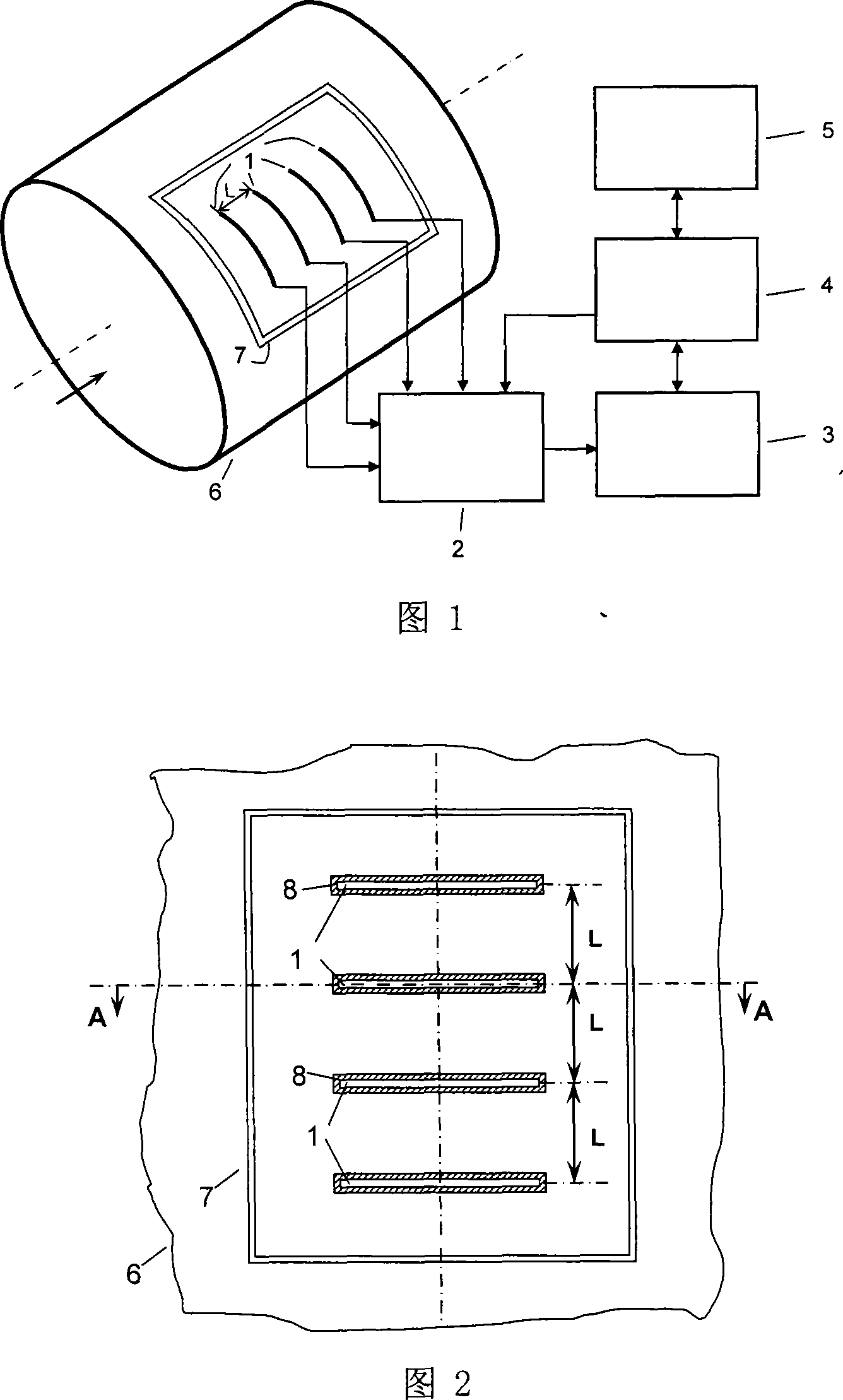

Intelligentize device used for fine material pipeline pneumatic conveying monitoring

InactiveCN101183250ANo wearSmall amount of operation and maintenanceProgramme controlComputer controlObservational errorElectricity

The present invention provides an intelligent device used for monitoring a powder pipe pneumatic conveying. The present invention comprises an electrostatic sensor electrode array, an electronic circuit board and a casing. The electrostatic sensor electrode array and the electronic circuit board which are electrically connected are fixed on the casing which is shielded. The electronic circuit board consists of a signal processing unit, a data processing unit, a system control unit and a user interface unit. The device uses the electrostatic sensor electrode array which is embedded on the inner wall of a transmission pipeline in non-invading way to pick up the electrostatic signal sensed by the powder in the transmission pipeline and give the velocity and flow state of the powder in the transmission pipeline. The beneficial effects are that the device carries out online real time monitoring to the velocity and flow state of the powder; the flow of the powder is not interfered by the electrode; the present invention is of no abrasion problem and little operational maintenance. The present invention overcomes the measurement error caused by improper selection of electrode center distance and enlarges the measurement ranged of the velocity. The present invention is of accurate measurement result and stable and reliable device and can be used for the powder pneumatic conveying monitoring in power, cement, food and other industries.

Owner:TIANJIN UNIV

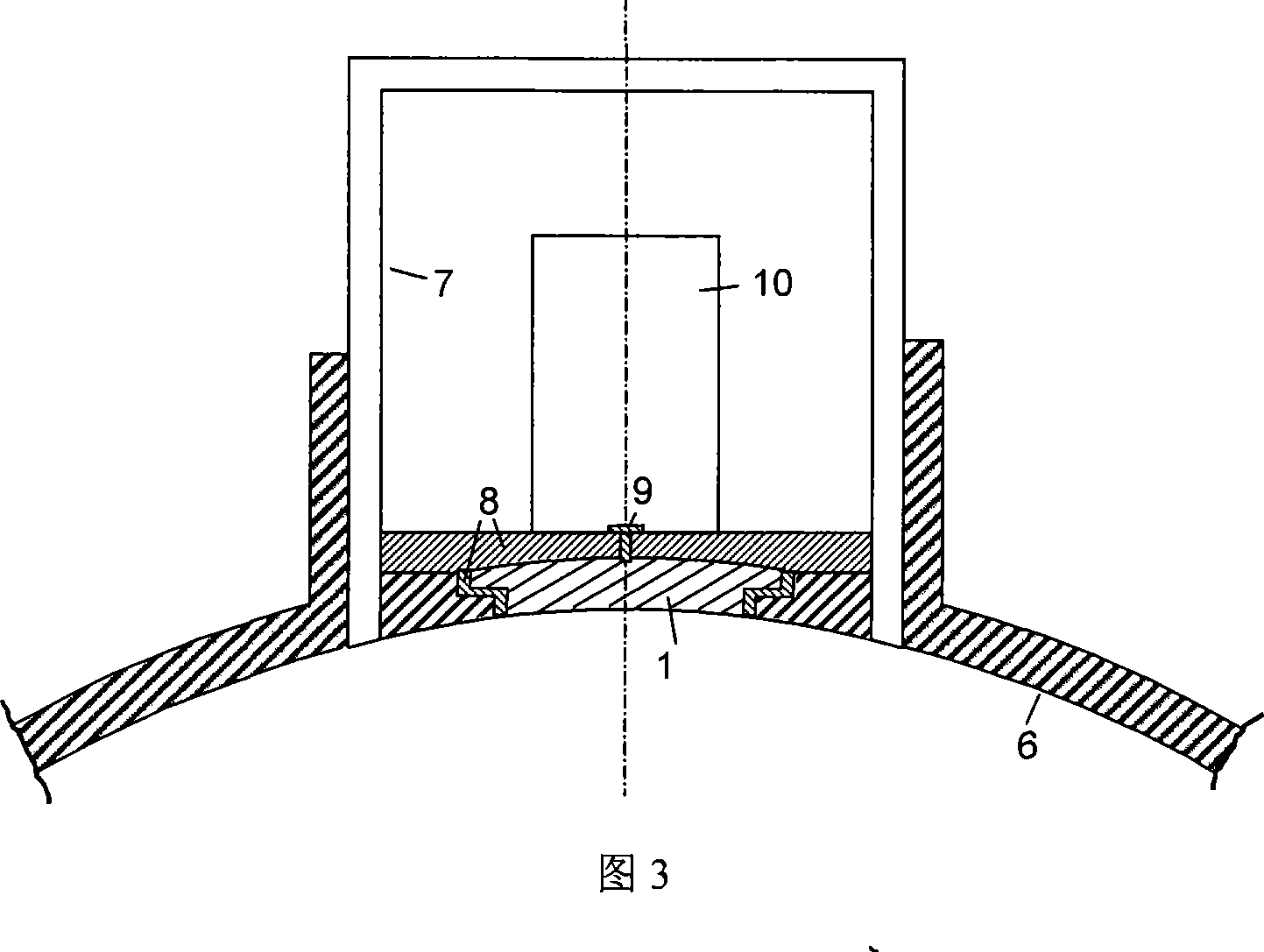

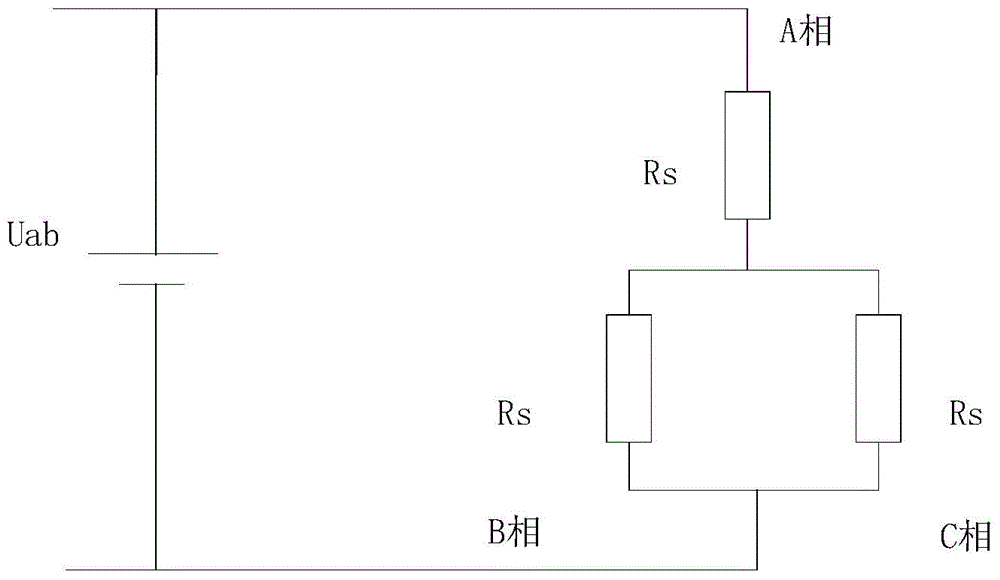

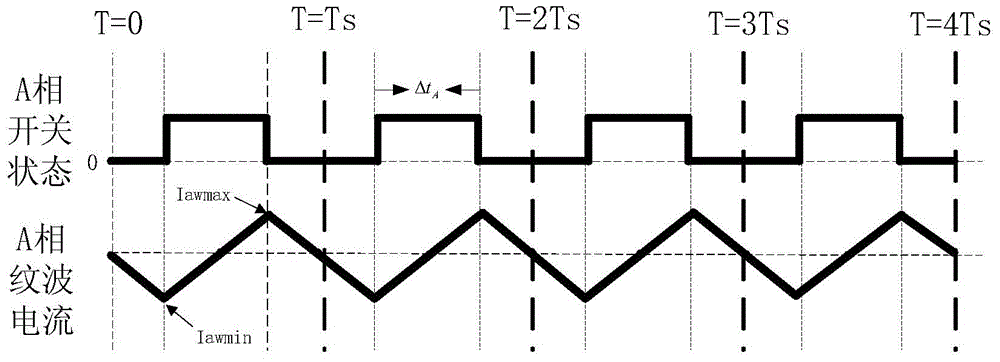

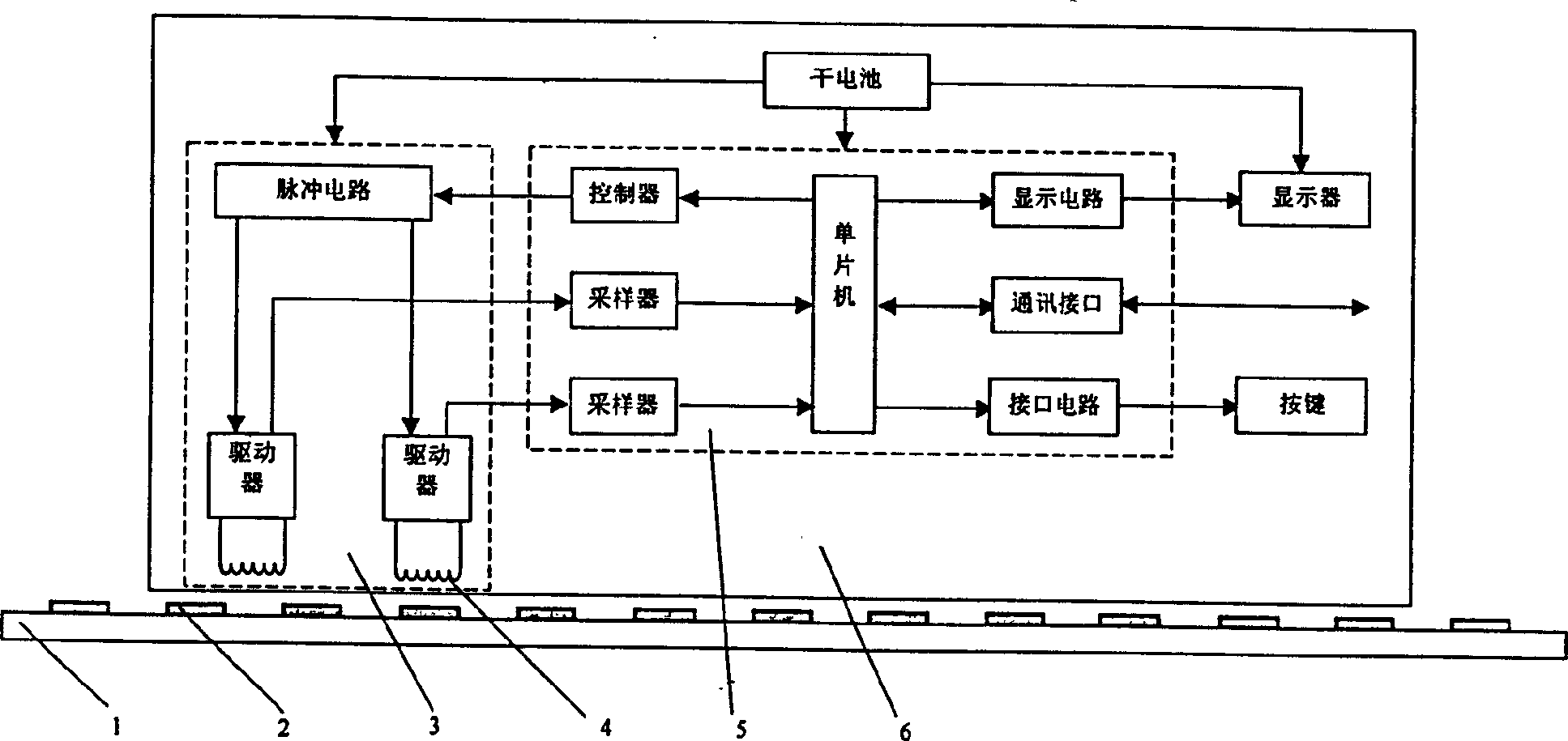

Permanent magnet synchronous motor parameter identification method, device and control system

ActiveCN104967386APrecise positioningAvoid measurement effectsElectronic commutation motor controlVector control systemsVoltage pulseSynchronous motor

The invention discloses a permanent magnet synchronous motor parameter identification method, which belongs to the technical field of synchronous motor parameter testing. A current or voltage pulse vector whose direction is the same as that of A-phase axis of a motor stator is inputted to the permanent magnet synchronous motor, a voltage excitation signal with a zero average voltage and containing a non-zero voltage pulse is inputted between the B phase and the C phase of the permanent magnet synchronous motor, and current of each phase of the permanent magnet synchronous motor during the process is sampled; according to three-phase current obtained through sampling in the case of steady three-phase current of the motor, the inputted current or voltage pulse vector and parameters of the excitation voltage signal are combined, and stator resistance, d-axis inductance and q-axis inductance of the permanent magnet synchronous motor are calculated and obtained. The invention also discloses a permanent magnet synchronous motor parameter identification device and a control system. Influences on d-axis and q-axis inductance measurement by d-axis positioning errors can be avoided, quickness of current sampling is not required, and measurement accuracy is better.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

Water proof electronic digital display callipers

InactiveCN1439861ASmall duty cycleReduce power consumptionSlide gaugesUsing electrical meansElectricityElectrical conductor

A water-proof electronic caliber rule with digital indication is composed of displacement measuring device consisting of electric eddy sensors, metallic reflectors uniformly arranged on fixed rule by a certain wavelength, and several sensor coils installed on moving rule by a particular pitch. When an alternative current flows through said coils, an alternative magnetic field is generated in space to generate an electric eddy on said reflector. When fixed and moving rules move relatively, the magnetic field is modulated under the action of electric eddy, so measuring displacement value.

Owner:SHANGHAI JIAO TONG UNIV +1

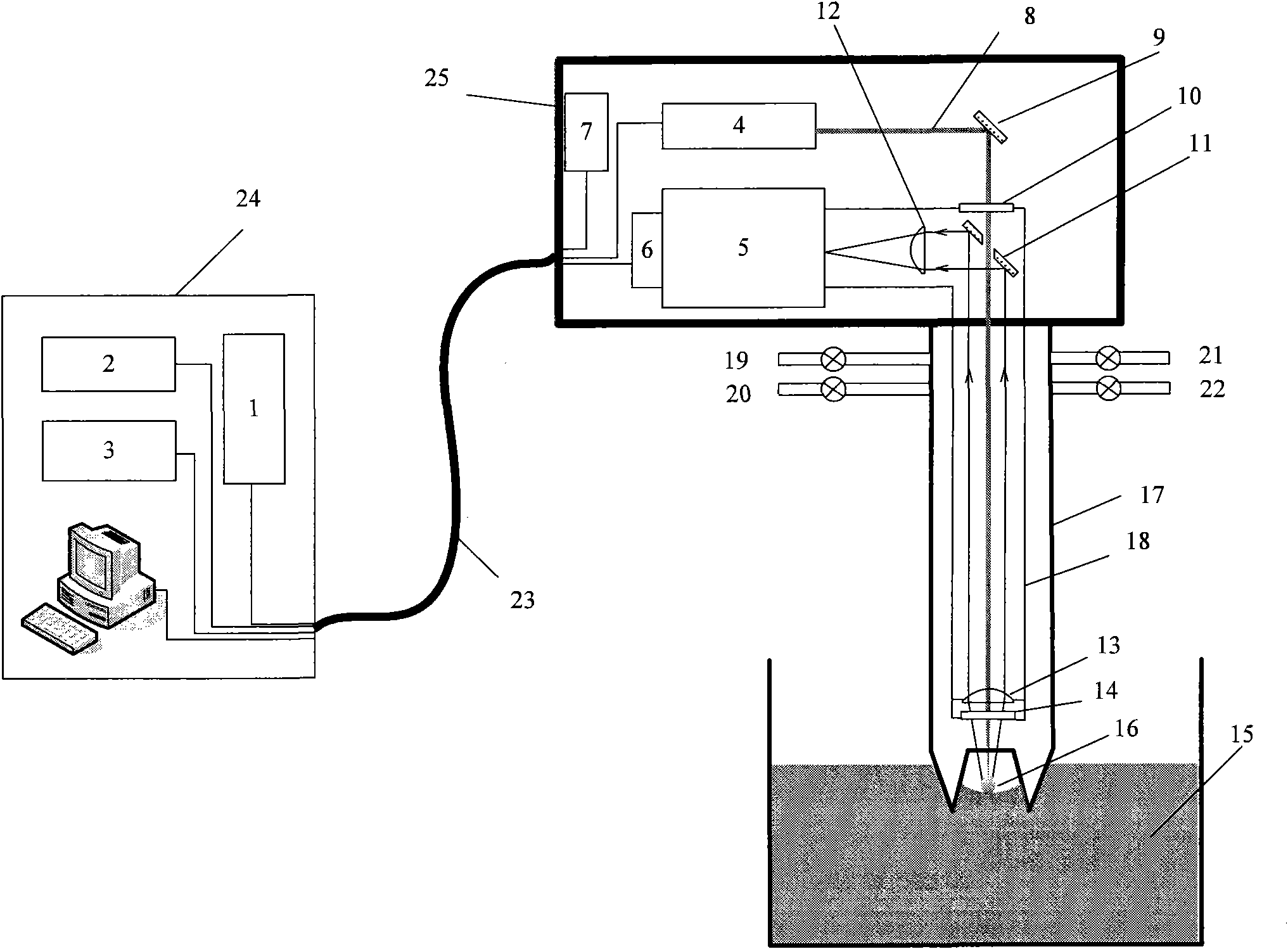

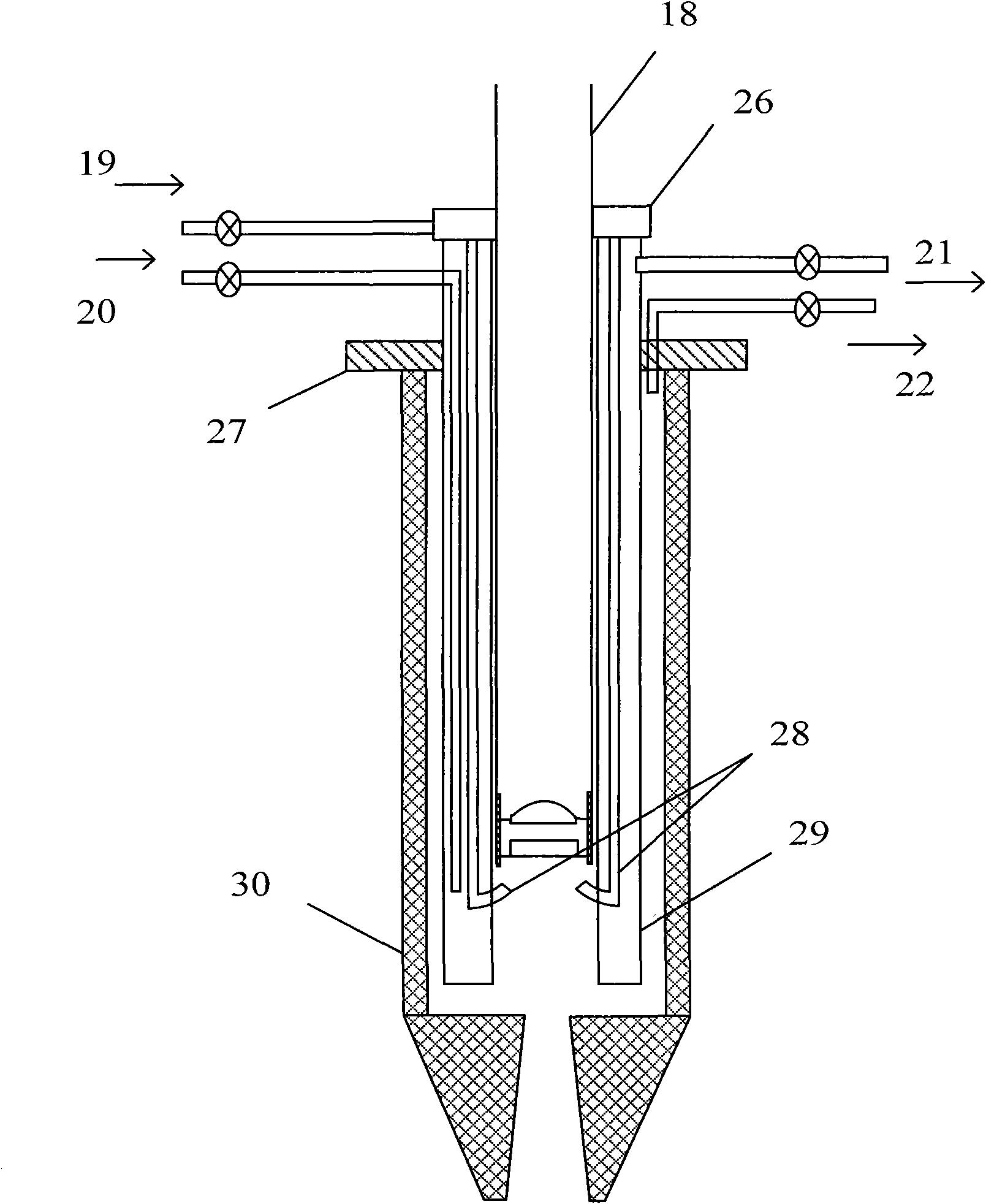

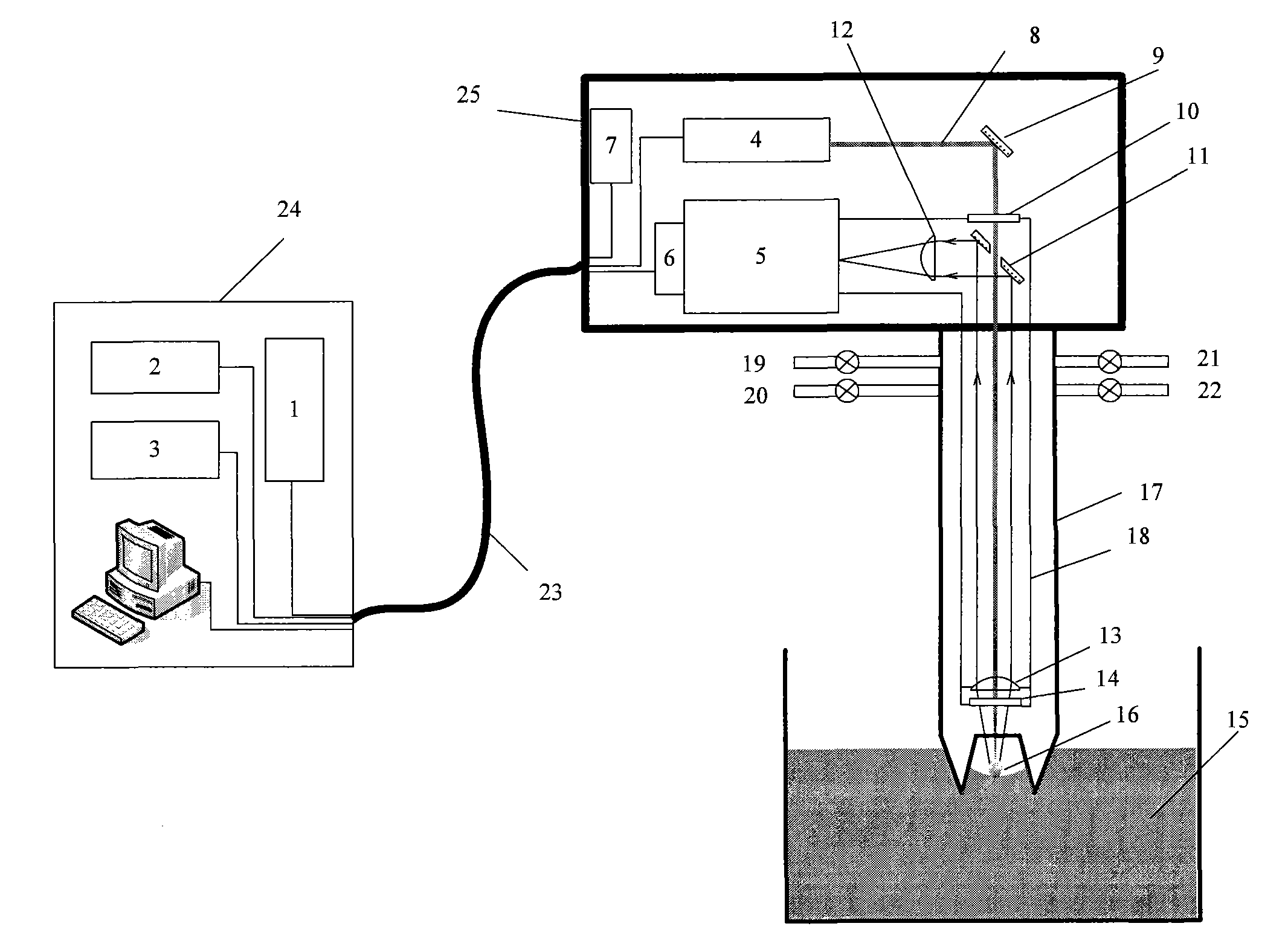

In-situ on-line detection device for metallurgy liquid metal component

ActiveCN102313721AShorten detection timeImprove product qualityAnalysis by material excitationPhysicsElectricity

The invention relates to an in-situ on-line detection device for a metallurgy liquid metal component. The device comprises a front-end high-temperature-resisting optical probe, a middle-end signal generating and acquiring part and a rear-end control platform, wherein the front end of the front-end high-temperature-resisting optical probe is arranged in metallurgy liquid metal to generate an optical signal and is used for transmitting the optical signal to the middle-end signal generating and acquiring part; the middle-end signal generating and acquiring part is used for converting the received optical signal of the front-end high-temperature-resisting optical probe into an electrical signal and outputting the electrical signal to the rear-end control platform; and the rear-end control platform is used as a manual operation and display platform and is used for receiving the electrical signal transmitted by the middle-end signal generating and acquiring part, processing the received electrical signal, controlling a laser signal of the middle-end signal generating and acquiring part and controlling the flow of water and gas in the front-end high-temperature-resisting optical probe. By the device, detection time is greatly shortened, the quality of a product is substantially improved, production cost is reduced, and energy consumption is reduced; and the device has an accurate measurement result and can be used for measuring difficultly-measured components such as C, S, P and the like.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

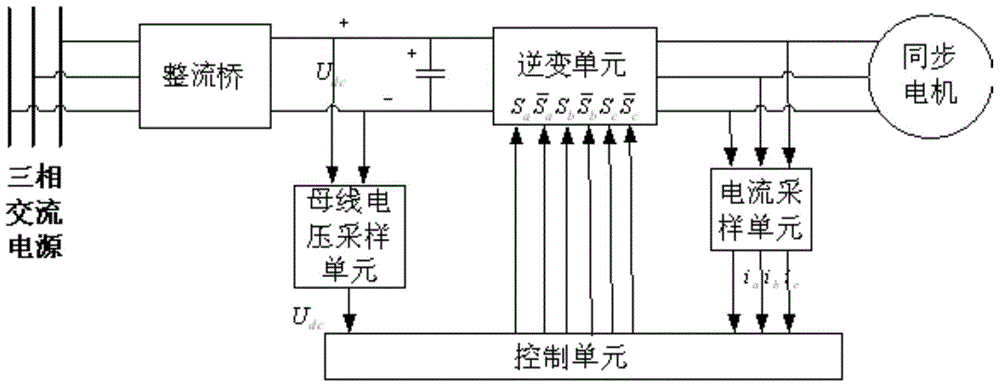

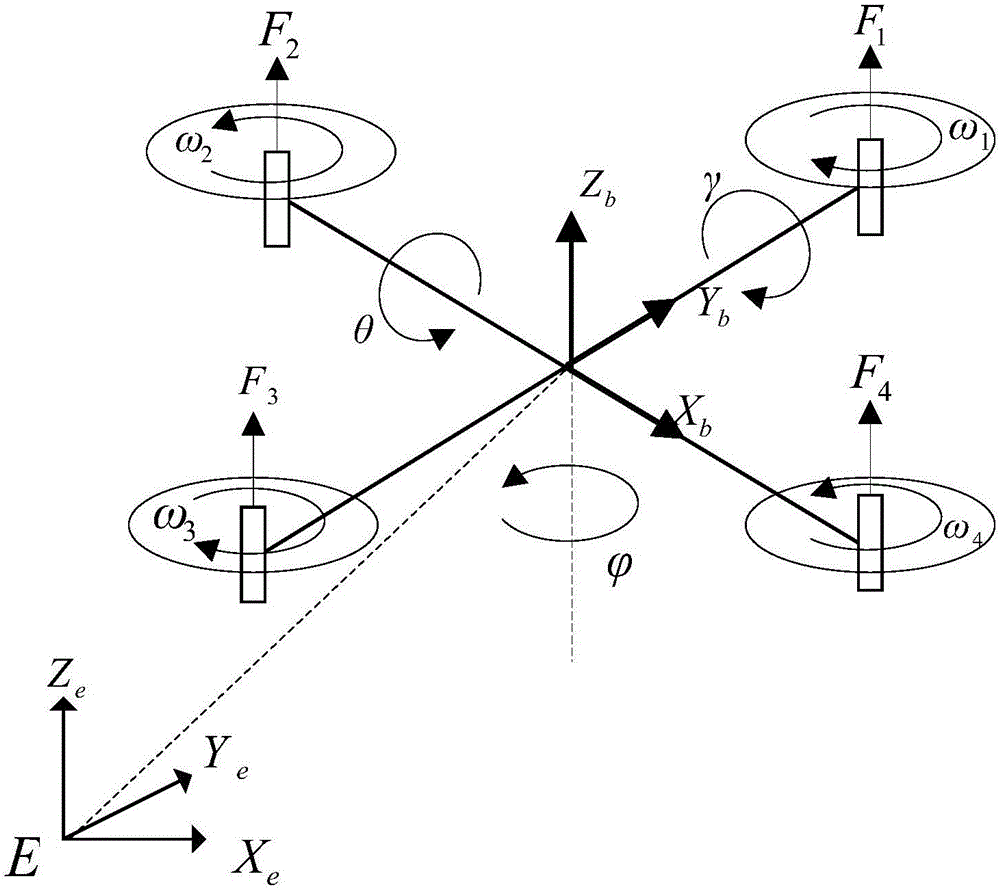

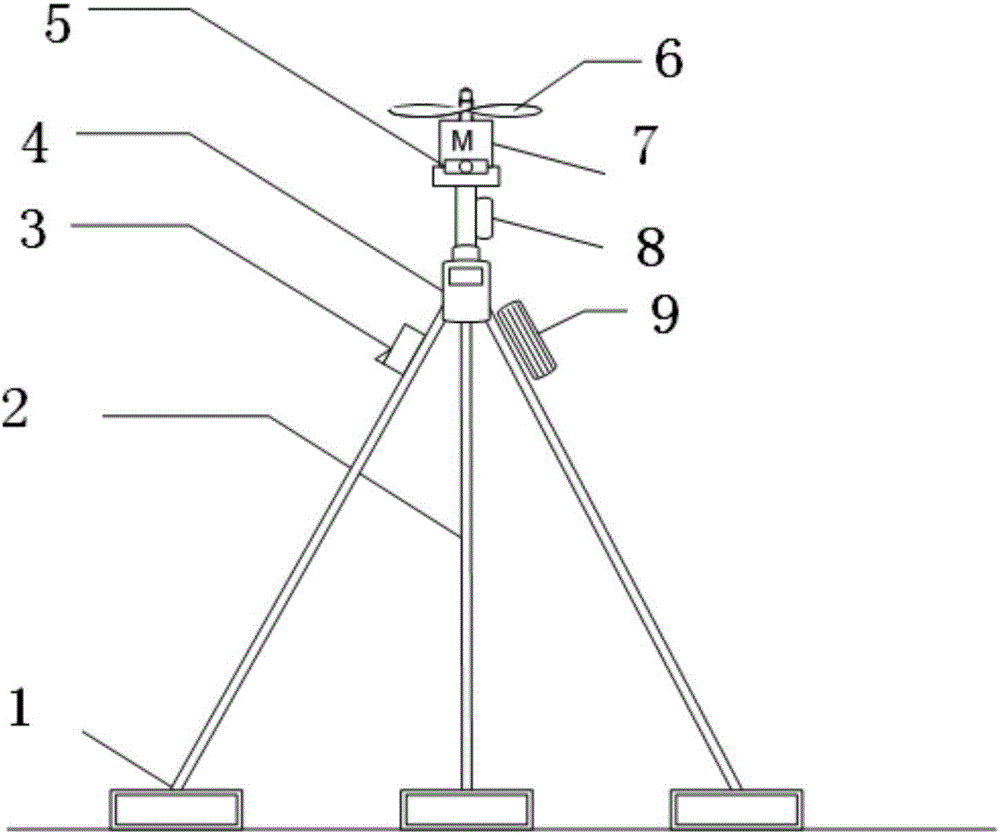

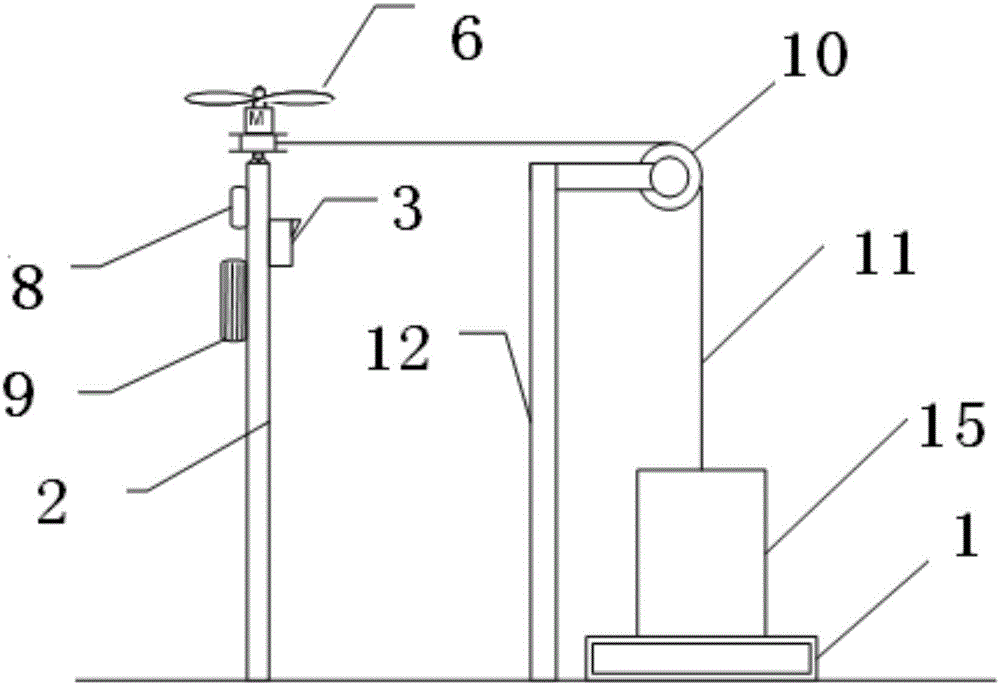

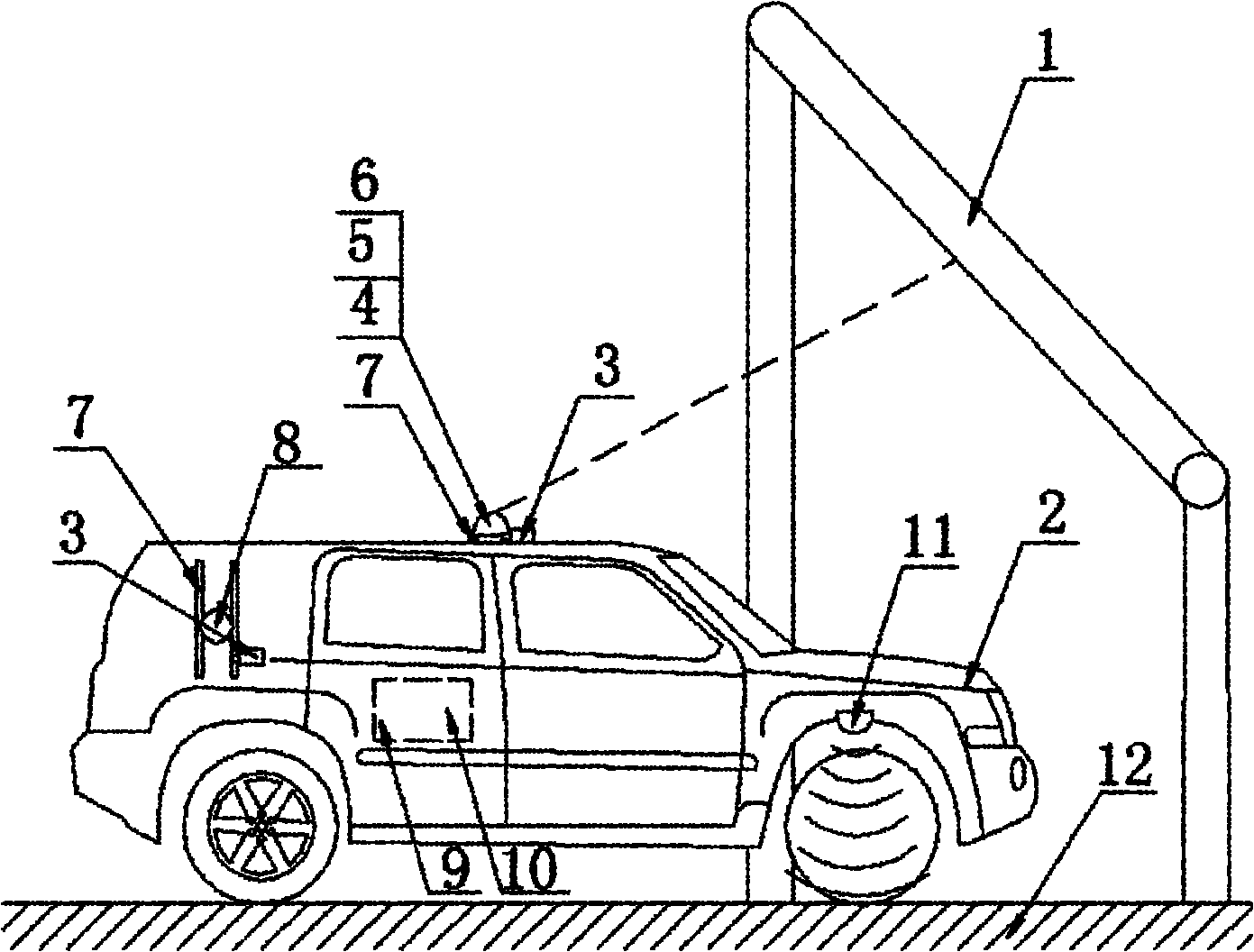

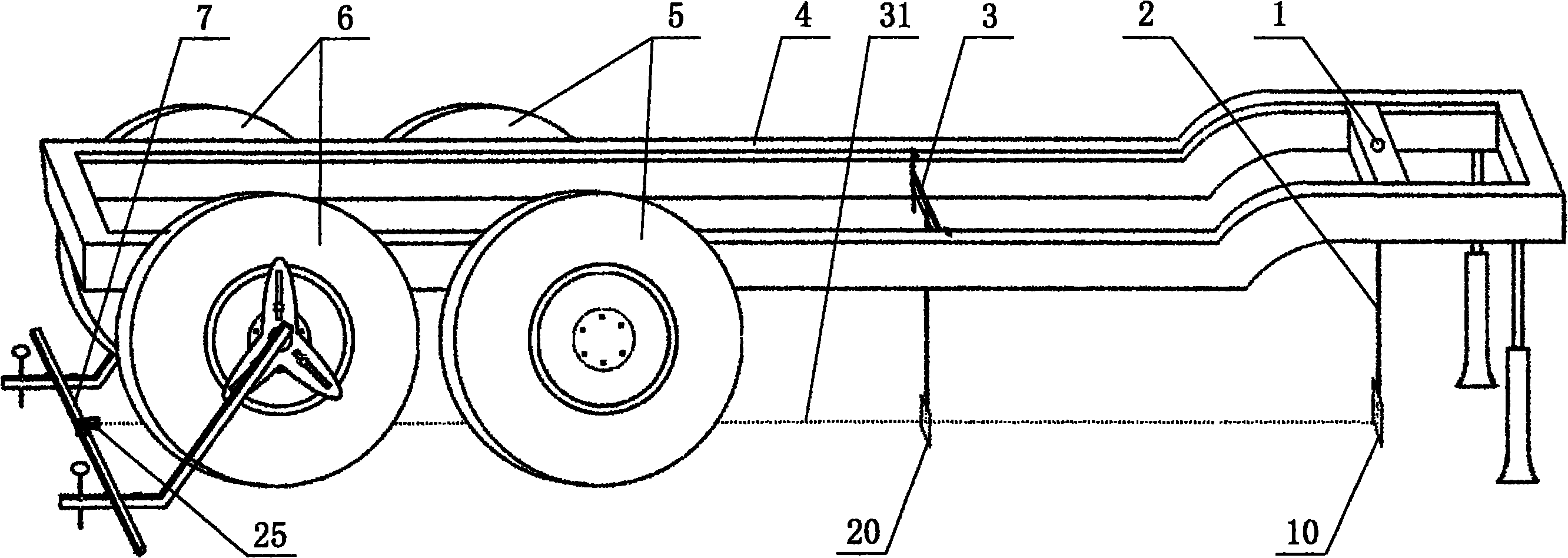

Four-rotor aircraft parameter measuring and modeling method

ActiveCN106043740AAvoid measurement effectsHigh measurement accuracyGround installationsFlight vehicleWorkload

The invention relates to a four-rotor aircraft parameter measuring and modeling method. The method includes: for paddle rotors and a body portion of a four-rotor aircraft, adopting a method combining experimental measuring and mathematical calculating to build a dynamic model; setting up a special experimental platform, and measuring rotor lift coefficient and rotor torque cofficient in the dynamic model; performing equivalent substitution on an aircraft body, abstracting complex aircraft body structure into several main portions, and directly performing rotational inertia calculation according to a physical definition. By using the method, the problem that wind tunnel experiment is expensive or high cost in purchasing a professional mechanical measuring instrument is solved; in the aspect of detail dealing, a tripod experiment platform structure is adopted, so that influence on electronic scale measuring caused by ground effect and airflow generated by the rotors is avoided; reflective strips are pasted on the back of each rotor, so that measuring accuracy of an infrared rotational speed meter is improved. Through model simplifying, calculation workload is reduced greatly.

Owner:WUHAN UNIV OF SCI & TECH

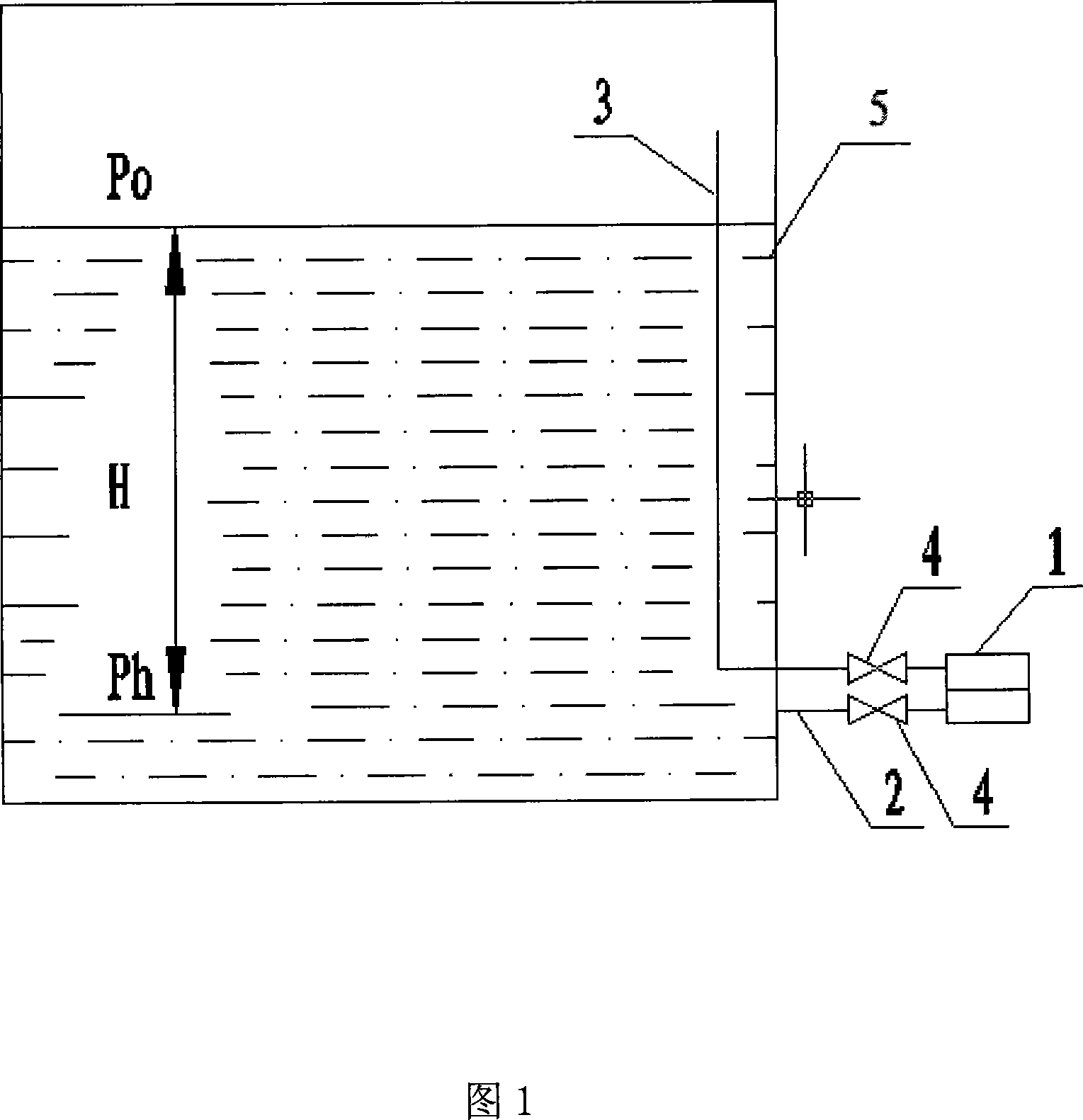

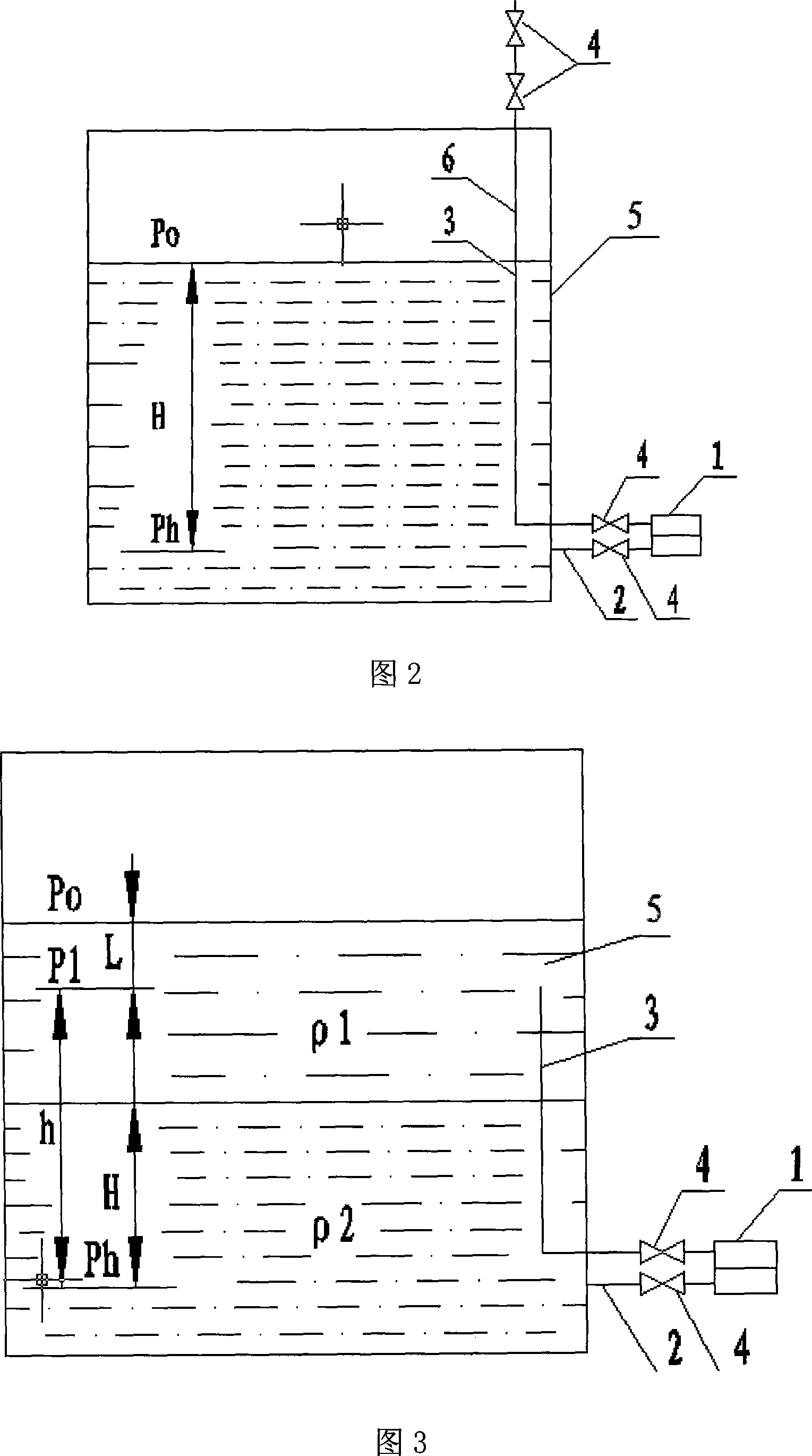

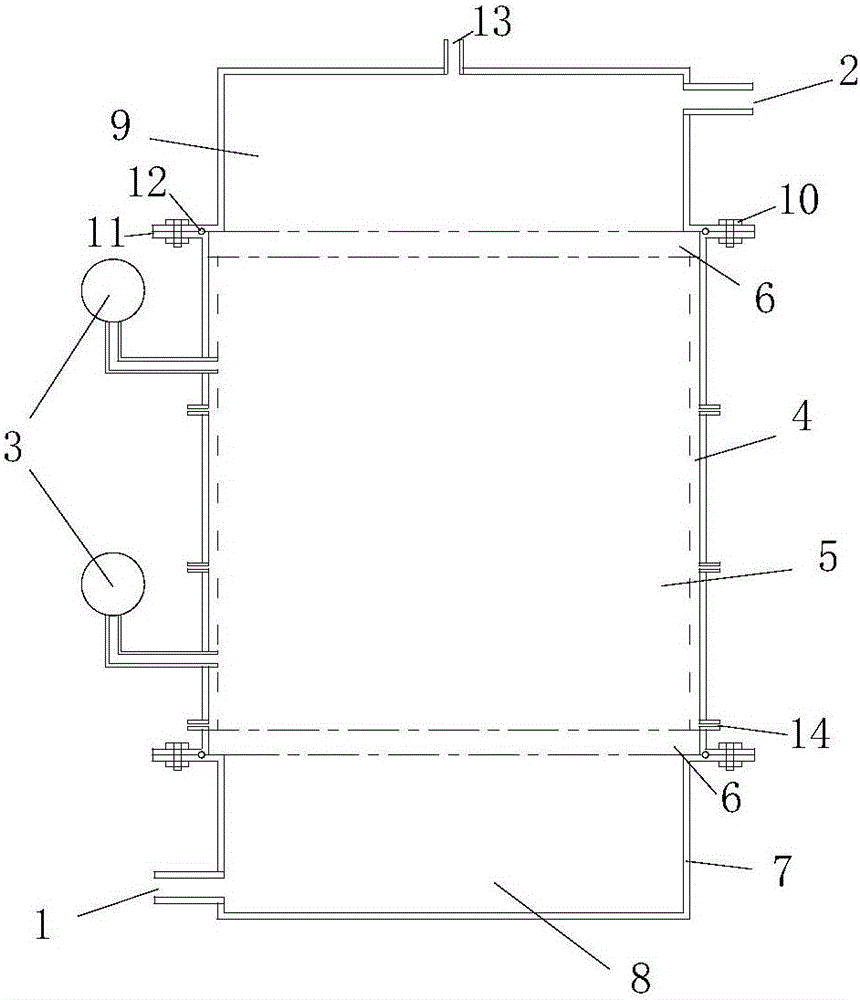

Built-in pressure sampling method for differential pressure levelmeter

InactiveCN101206133ACounteracts level measurement errorsNot affected by medium temperature changeLevel indicators by pressure measurementDifferential pressureNegative phase

The invention belongs to the liquid level instrument, in particular to a built-in pressure tapping method of a differential pressure type level gauge, which at least comprises a liquid storage tank (5), a differential pressure type level gauge (1), a positive phase pressure guiding pipe (2) and a negative phase pressure guiding pipe (3); the positive phase pressure guiding pipe (2) and the negative phase pressure guiding pipe (3) are respectively connected with a positive end and a negative end of the differential pressure type level gauge (1). The invention is characterized in that: a vertical section of the negative phase pressure guiding pipe (3) is arranged inside a vessel, liquid contained by the vessel is prearranged into the negative phase pressure guiding pipe (3), the invention can remove the influence on measuring due to vapor or medium temperature variation in the vessel, meanwhile, the structure is simple, the operation is easy and the maintenance cost is low.

Owner:XIAN CHANGQING TECH ENG

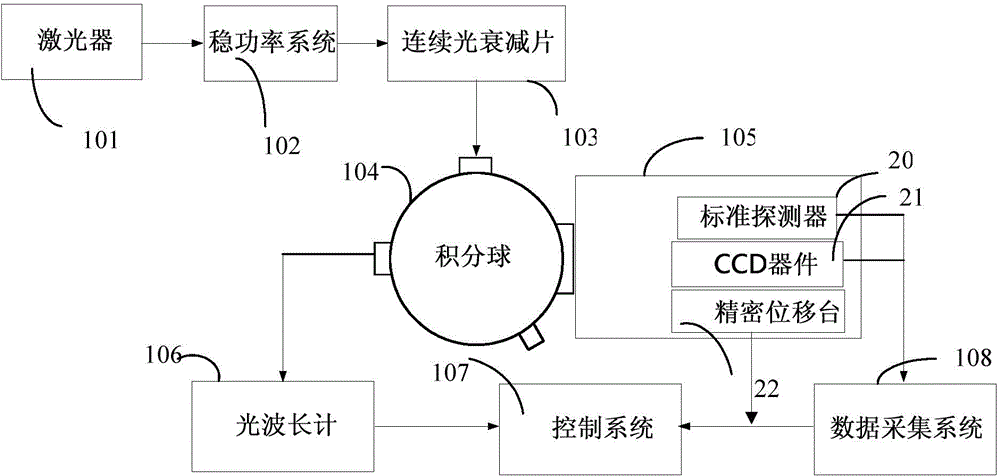

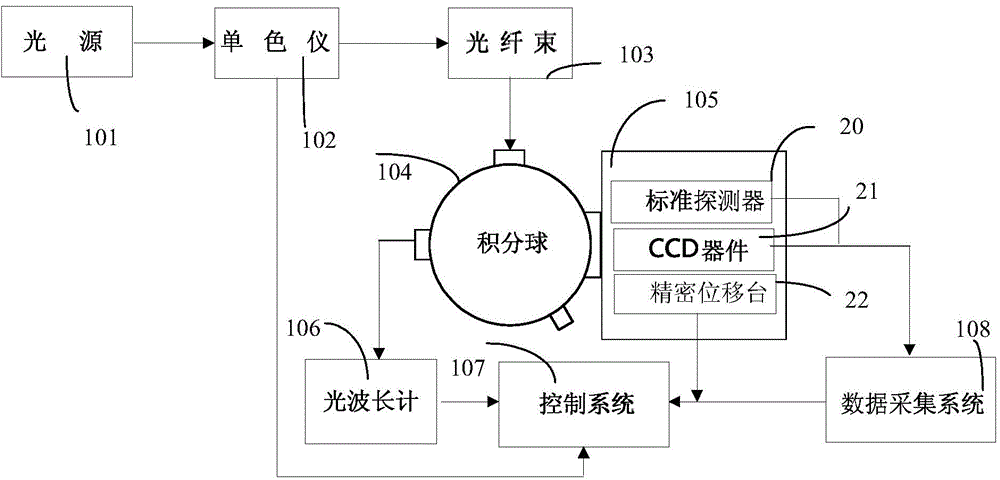

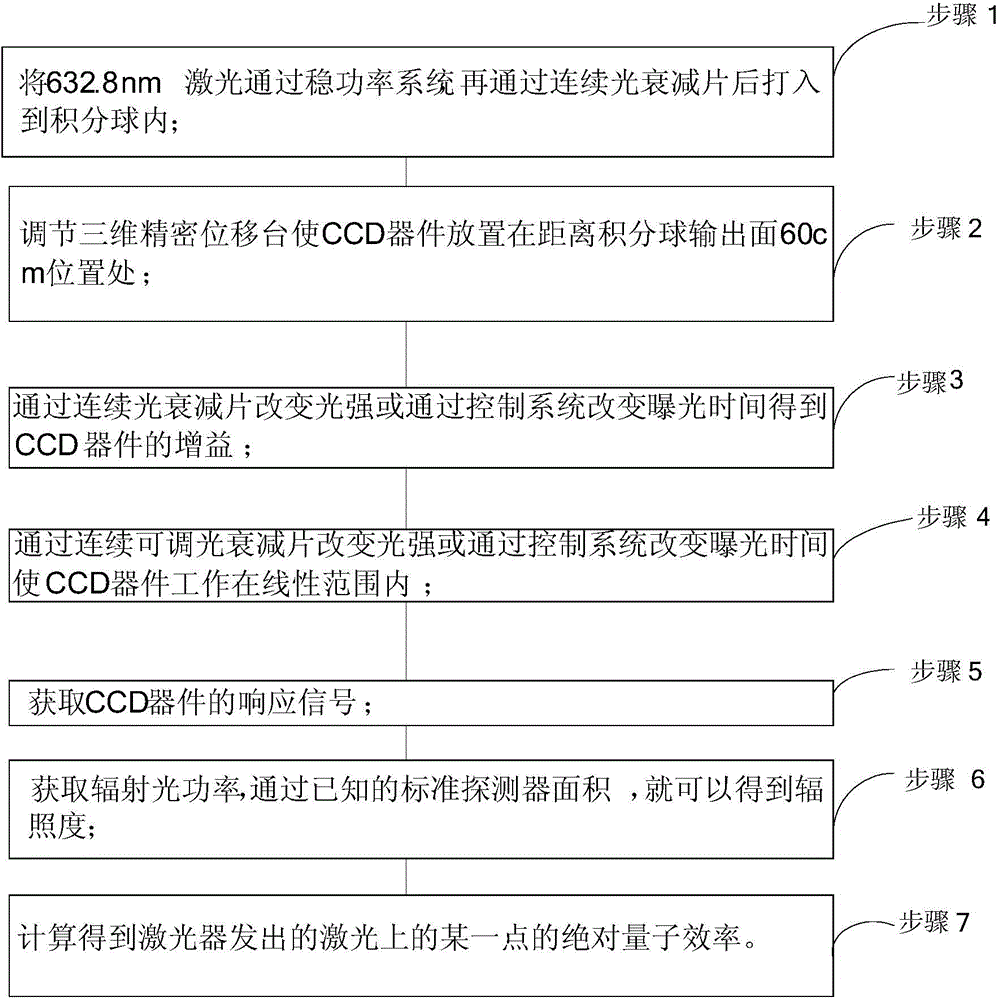

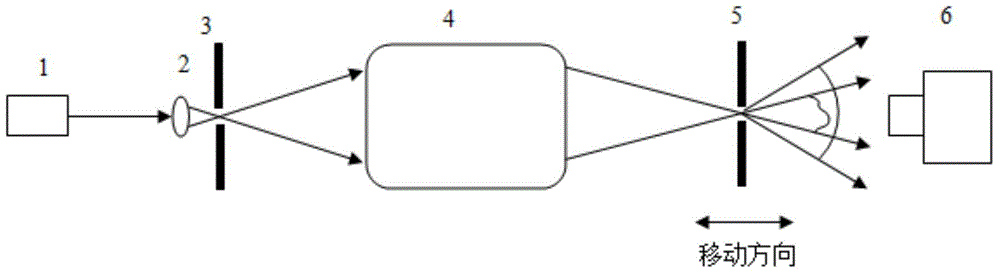

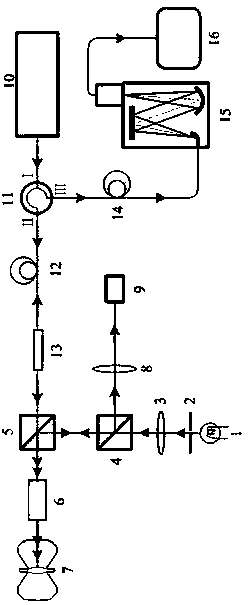

CCD device quantum efficiency measuring device and method

ActiveCN104142226AReduce line widthGood repeatabilityTesting optical propertiesQuantum efficiencyMeasurement device

The invention provides a CCD device quantum efficiency measuring device and method. The device comprises a CCD device absolute quantum efficiency measuring apparatus and a CCD device relative quantum efficiency measuring apparatus, the CCD device absolute quantum efficiency measuring apparatus is used for measuring the absolute quantum efficiency of a CCD device on a 632.8 nm wavelength point, and the CCD device relative quantum efficiency measuring apparatus is used for measuring the relative quantum efficiency of the CCD device within the wavelength range from 300 nm to 1100 nm. According to the CCD device quantum efficiency measuring device and method, a 632.8 nm laser is used for emitting light into an integrating sphere to carry out absolute calibration after the light passes through a power stabilizing system, lasers with different levels of output power can be selected according to different CCD devices, the problem that optical power is low is avoided, no light loss is caused, a standard detector directly traces the source to a low-temperature radiometer on the 632.8 nm wavelength point, and therefore the number of intermediate links is reduced, and uncertainty of measurement is improved.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

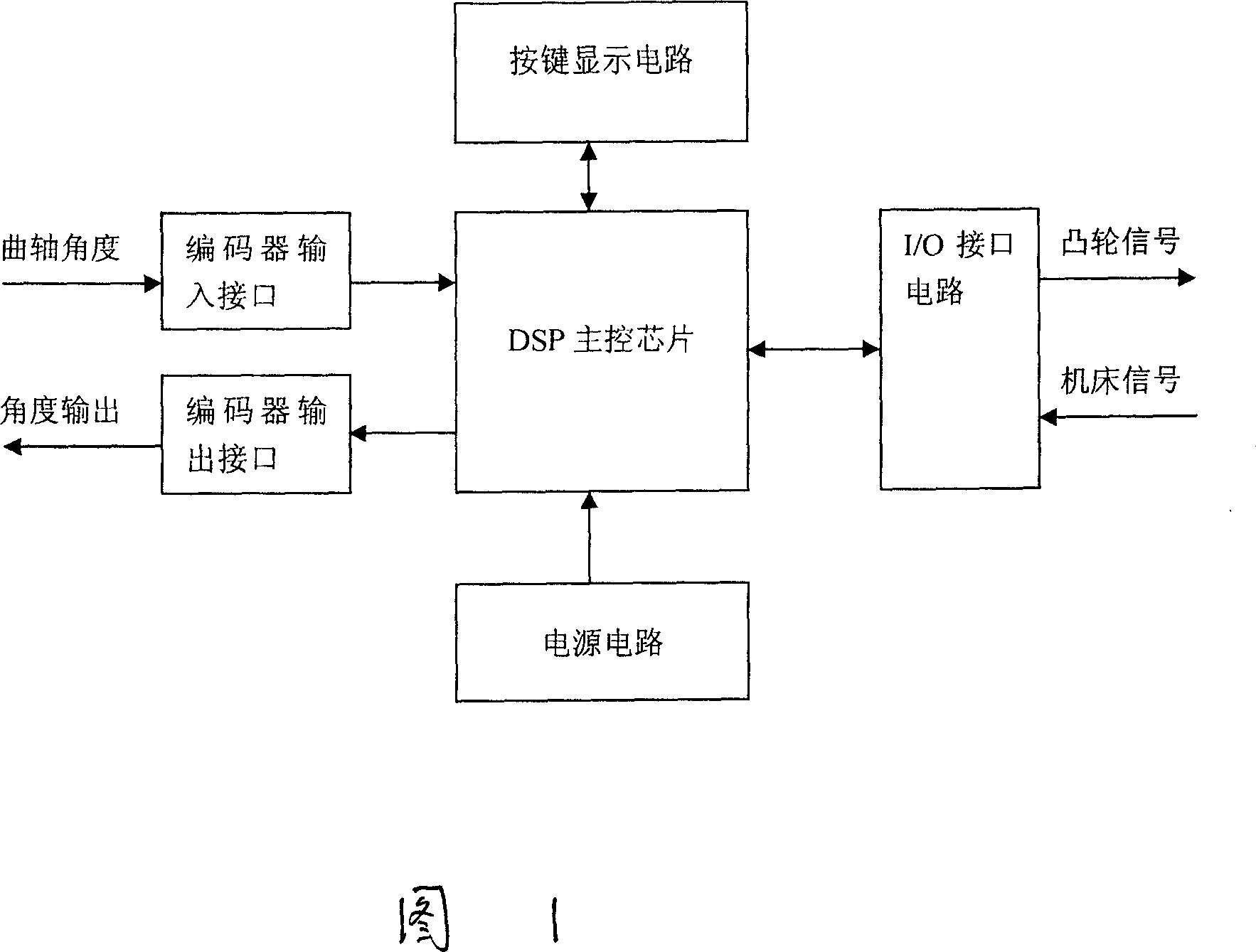

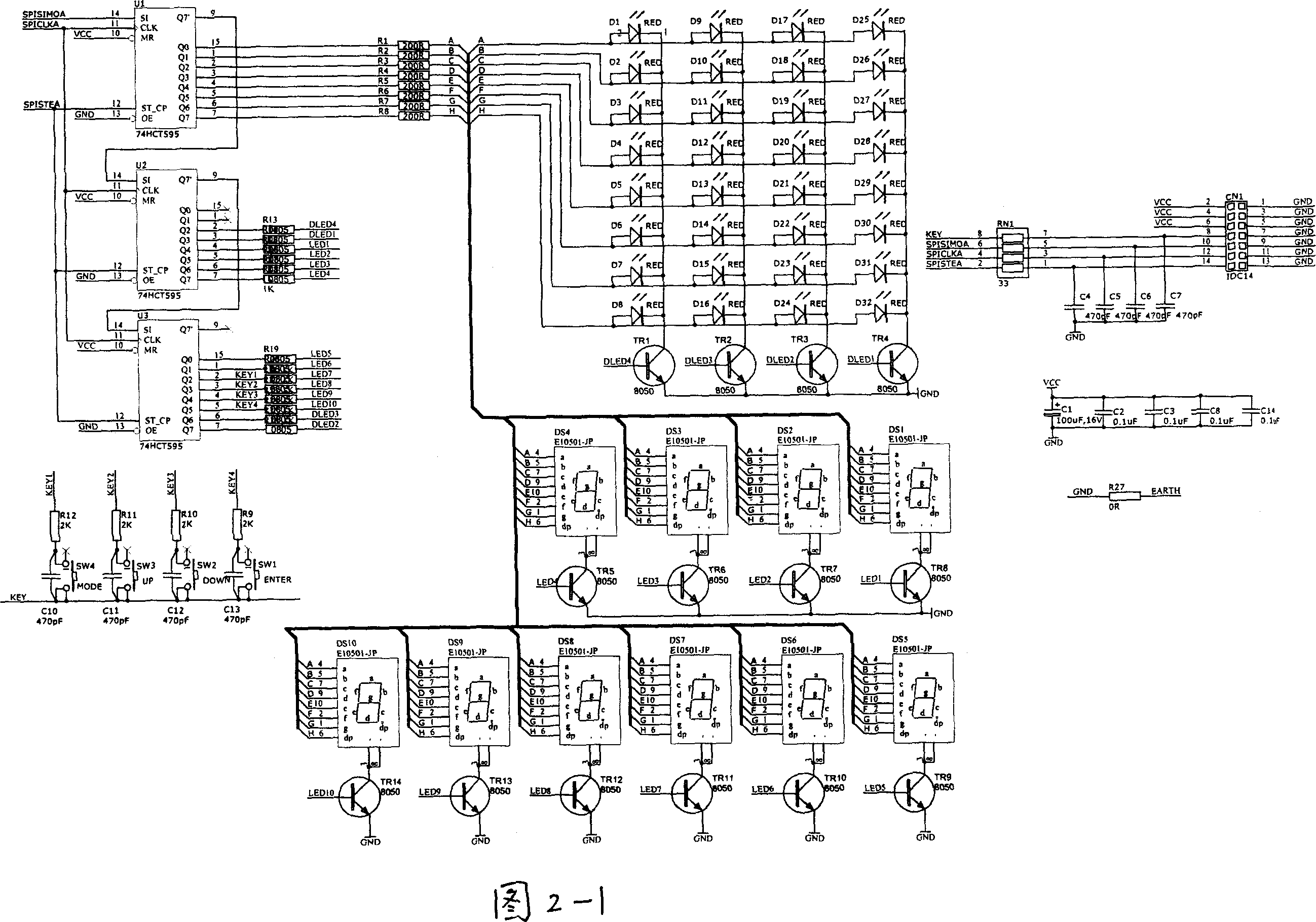

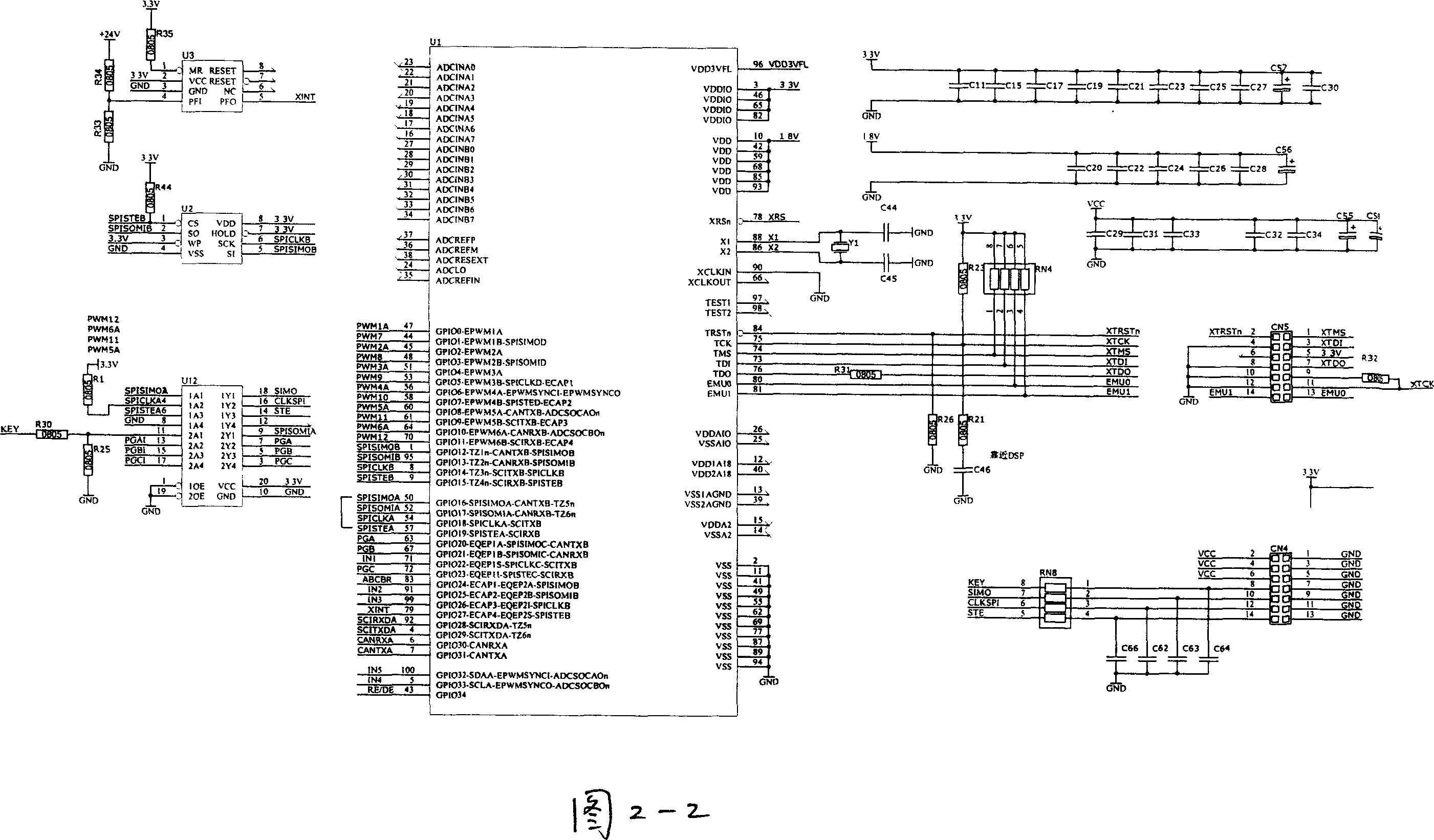

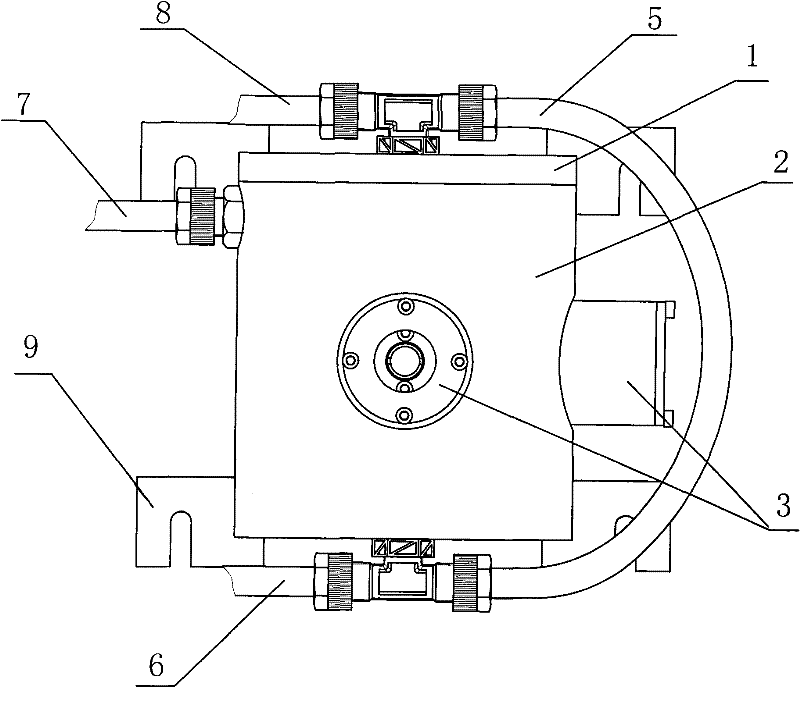

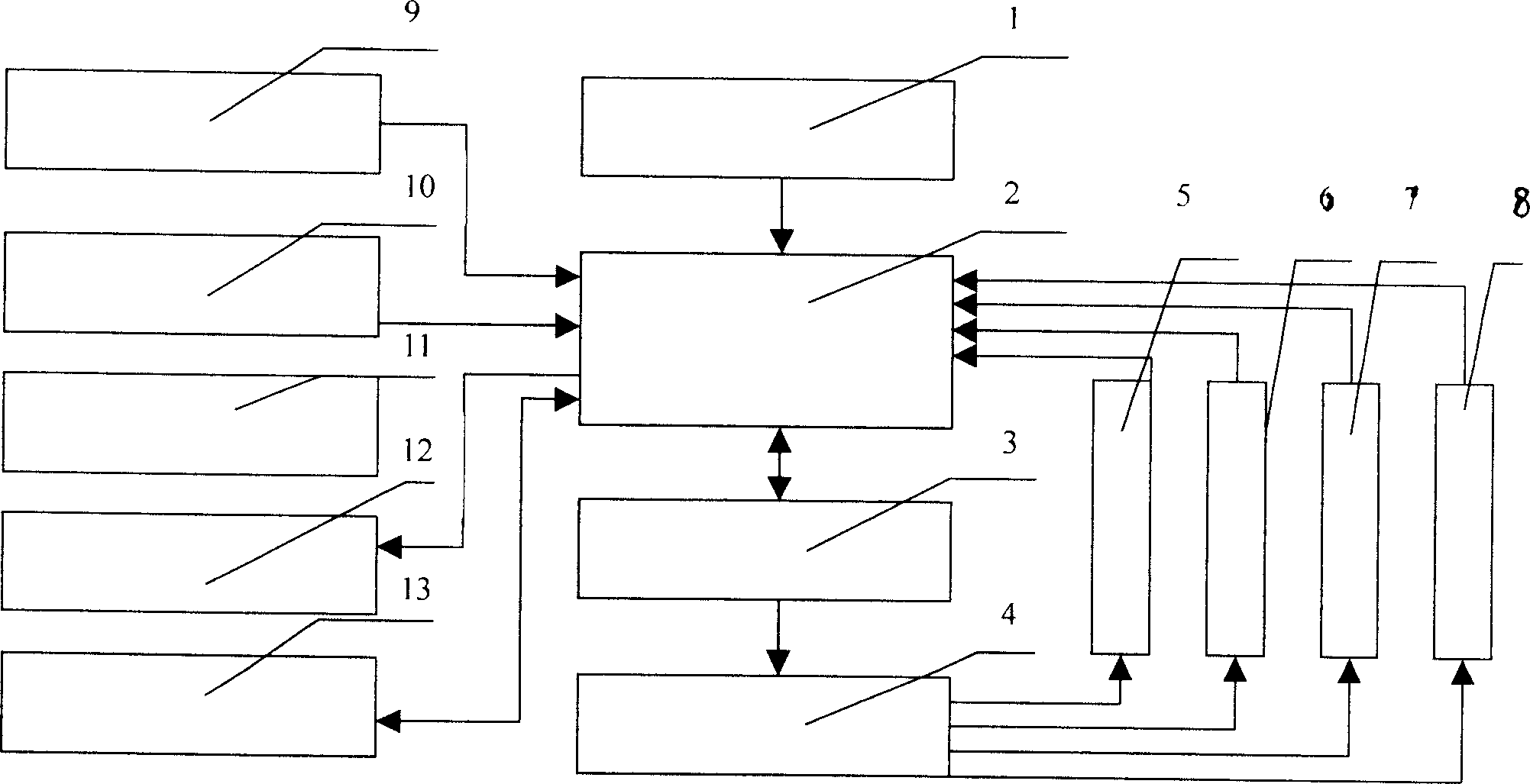

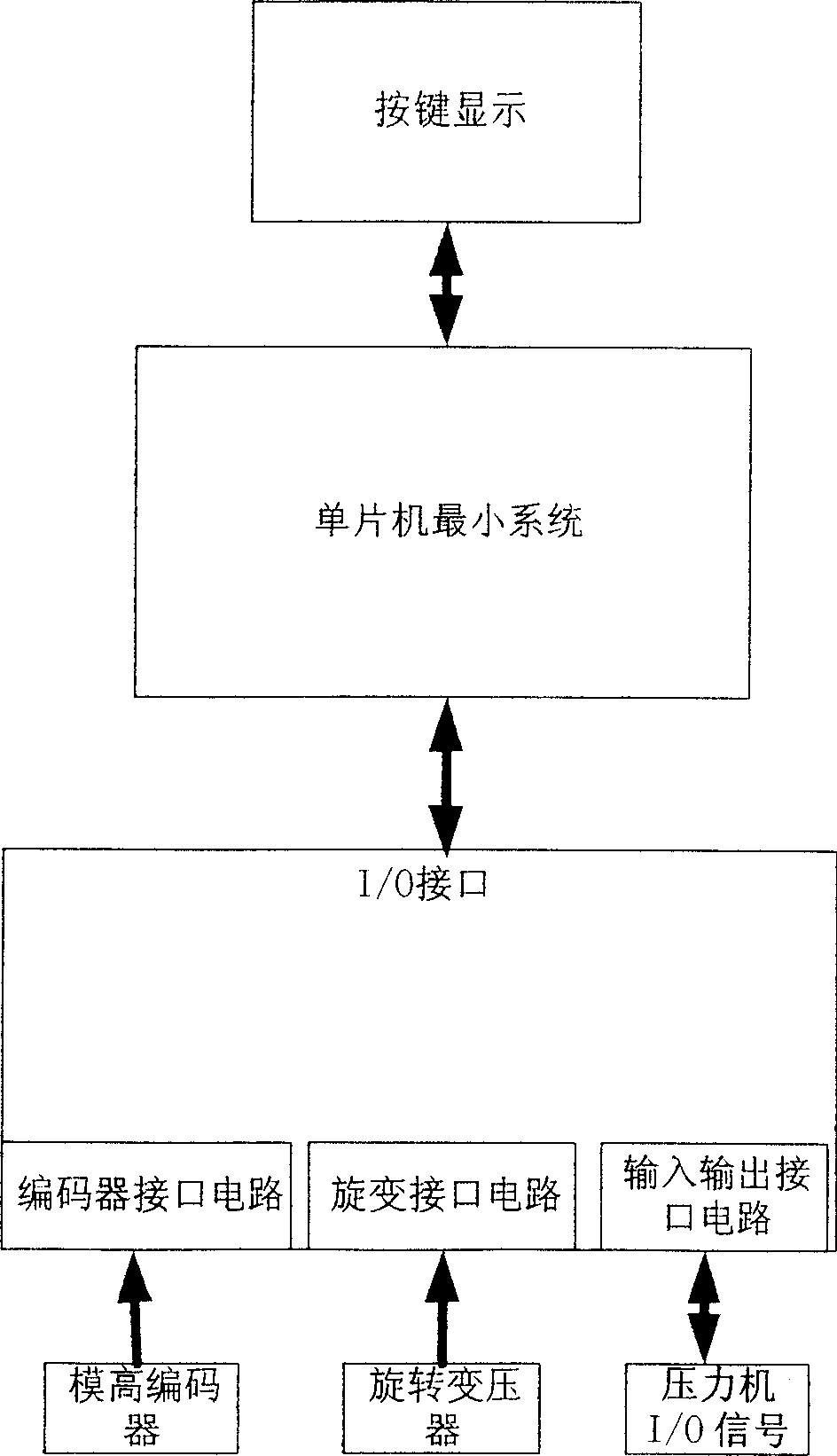

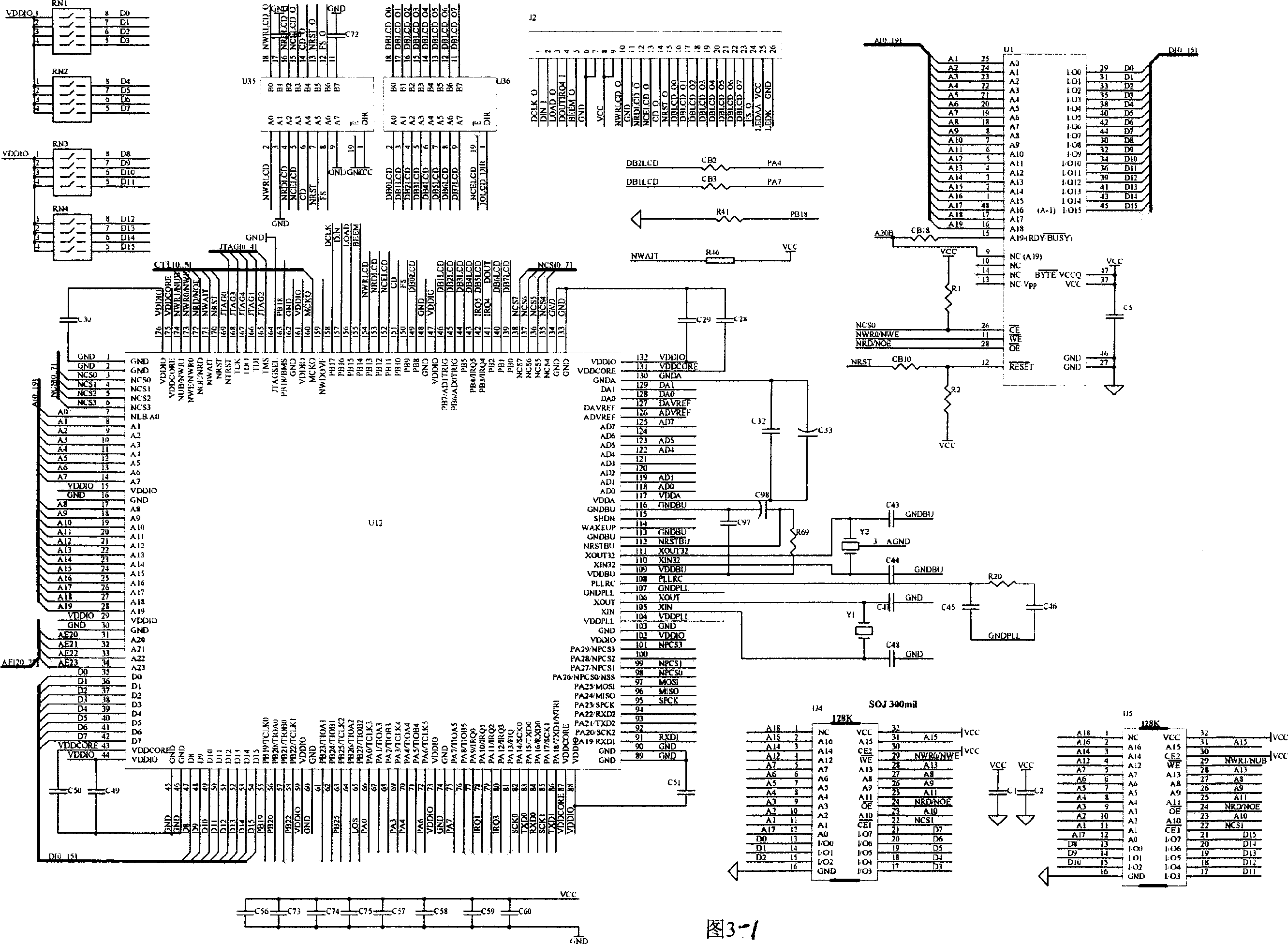

Mechanical pressure machine electronic control method and electronic cam control device

The invention relates to an electric control method of mechanical compressor and relative electric cam controller. Wherein, it uses rotation coder as the sensor of crank angle / block strike; uses embedded system as core controller, to control the clutch / brake of compressor to generate cam signal output, number the work piece, and detect the friction state of clutch friction plate. The invention replaces former mechanical cam, mechanical / electric accouter, and middle relay. And it uses coder and embedded system to avoid the time of mechanical cam adjustment, to improve the automatic level and safety level. The controller comprises button display circuit, DSP control chip, I / O interface circuit, coder input interface circuit, coder output interface circuit, and power circuit.

Owner:NANJING ESTUN AUTOMATION CO LTD

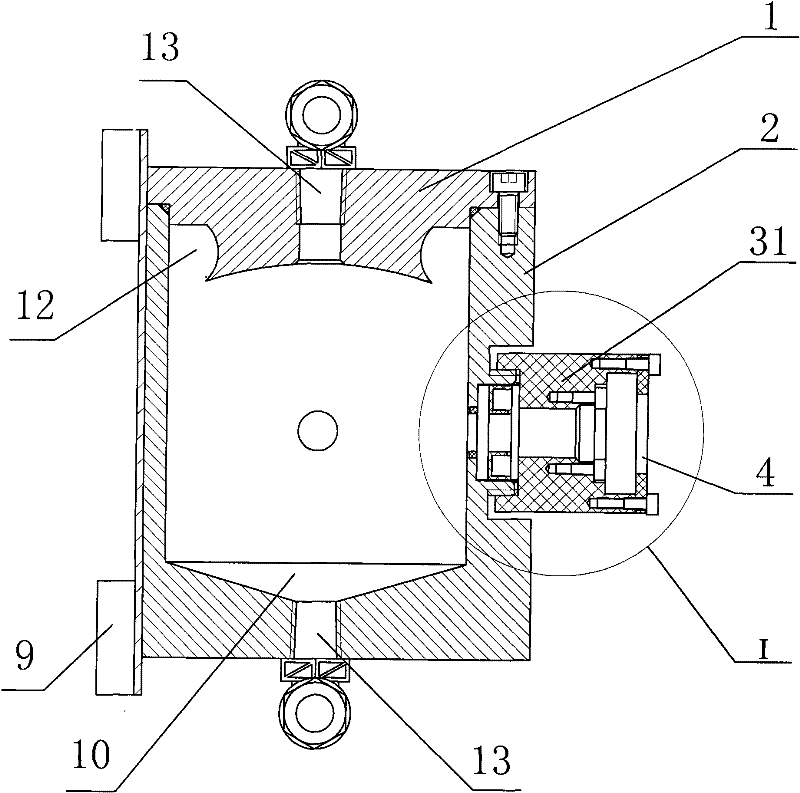

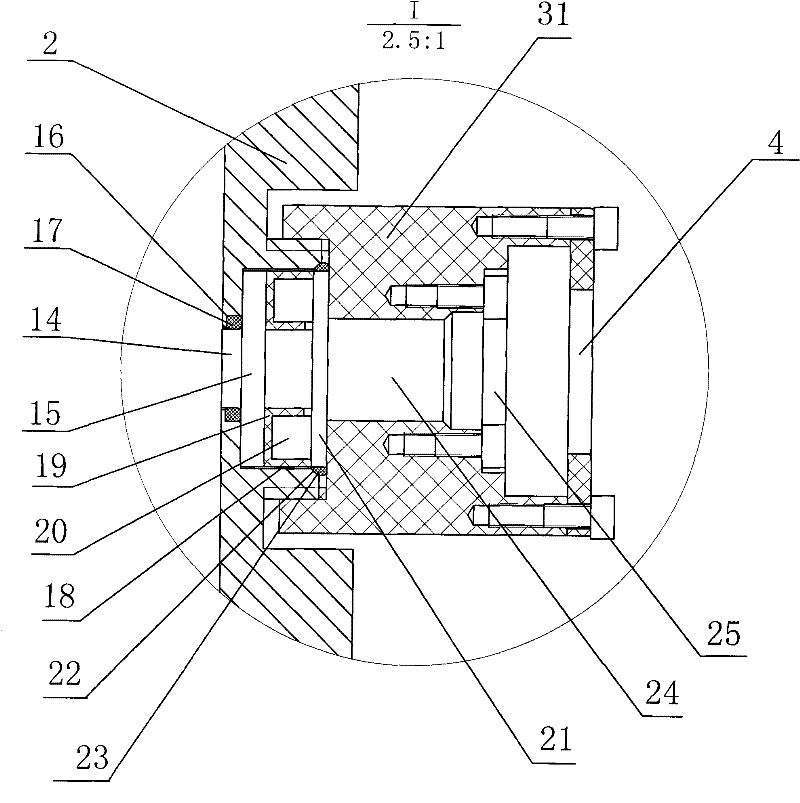

Turbidity Flow Cell

ActiveCN102288544AImprove sealingShorten the straight line distanceMaterial analysis by optical meansFlow cellTurbidity

The invention provides a turbidity flowing cell. Trough holes on the side wall of the main body of the flowing cell form two light source transmission holes through which light can penetrate, light emitted by a light-emitting device is directly transmitted into the inner cavity of the flowing cell by virtue of one light source transmission hole, and the light in the inner cavity of the flowing cell is received by a receiving device by virtue of the other light source transmission hole. The invention also provides another turbidity flowing cell which also comprises a transmitting / receiving device besides the main body the flowing cell, wherein one part of the transmitting / receiving device is embedded into the side wall of the main body of the flowing cell with certain thickness to form an integrated structure with the main body of the flowing cell. The flowing cell and a light source structure form a unified whole, thus linear distance between sample liquid in the flowing cell and a light source is greatly shortened and measuring accuracy is improved.

Owner:北京利达科信环境安全技术有限公司

Determination instrument and determination method for osmotic coefficients of drilling and coring test part

InactiveCN105973782AStop seepageAvoid measurement effectsPermeability/surface area analysisSoil scienceOsmotic coefficient

The invention discloses a determination instrument and determination method for osmotic coefficients of a drilling and coring test part, aiming at effectively avoiding influences of lateral wall seepage, determining the osmotic coefficients of common rock soil bodies and porous concrete and further determining the osmotic coefficients of a drilling and coring test part of the rock soil bodies before and after grouting. The technical scheme of the determination instrument is as follows: the determination instrument comprises a water outlet buffering region, a testing cavity and a water inlet buffering region which are arranged in sequence from top to bottom; the water outlet buffering region, the testing cavity and the water inlet buffering region are fixedly connected to form a sealed cavity; a water outlet is formed in the upper end of a lateral wall of the water outlet buffering region; an exhaust hole is formed in the top of the water outlet buffering region; a water inlet is formed in the lower end of the lateral wall of the water inlet buffering region; in a testing process, a testing part is arranged in the testing cavity; a seepage-proof layer is arranged between the test part and an inner lateral wall of the testing cavity; water permeable layers are arranged at the upper and lower ends in the testing cavity; in the testing process, the testing part is located between the water permeable layers at the two ends and is in contact with the water permeable layers.

Owner:CHANGAN UNIV

Flow measuring device for partially filled pipe drainage pipeline

ActiveCN108318092ASimplify installation and maintenance problemsHigh utility valueVolume/mass flow measurementUltrasonic dopplerComputer module

The invention discloses a flow measuring device for a partially filled pipe drainage pipeline. The measuring device is a separated type structure, the device comprises a streamline probe and a flowmeter host, and the streamline probe is connected with the flowmwter host through a waterproof cable; the streamline probe is a totally-enclosed waterproof structure, wherein the front end of the streamline probe is provided with a first underwater acoustic transducer and a second underwater acoustic transducer in parallel, the top end is provided with a third underwater acoustic transducer, the bottom of the probe is provided with a pressure transmitter, and the back end is provided with a temperature sensor; the flowmeter host comprises an ultrasonic Doppler flow rate measuring module, ultrasonic liquid level measuring module, a pressure transmitter measuring module, a temperature measuring module, an FPGA operational module, an MCU main control module, a battery and voltage-stabilized source module, a GPRS communication module and a debugging interface circuit. According to the device, through the separated type structure of integrating the streamline probe with five sensors and the host, the problems are simplified that the flowmeter installation and maintenance are difficult.

Owner:TAIHUA WISDOM IND GRP CO LTD

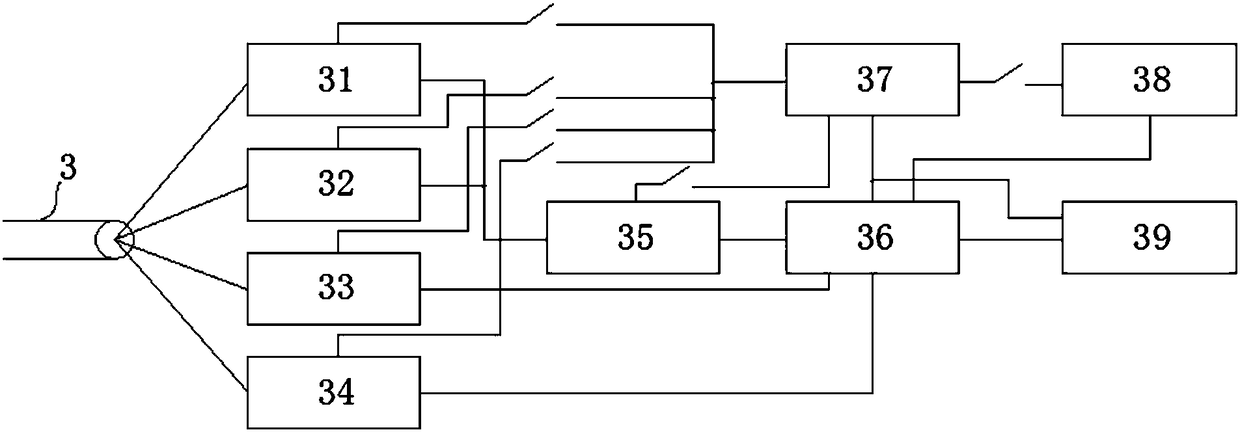

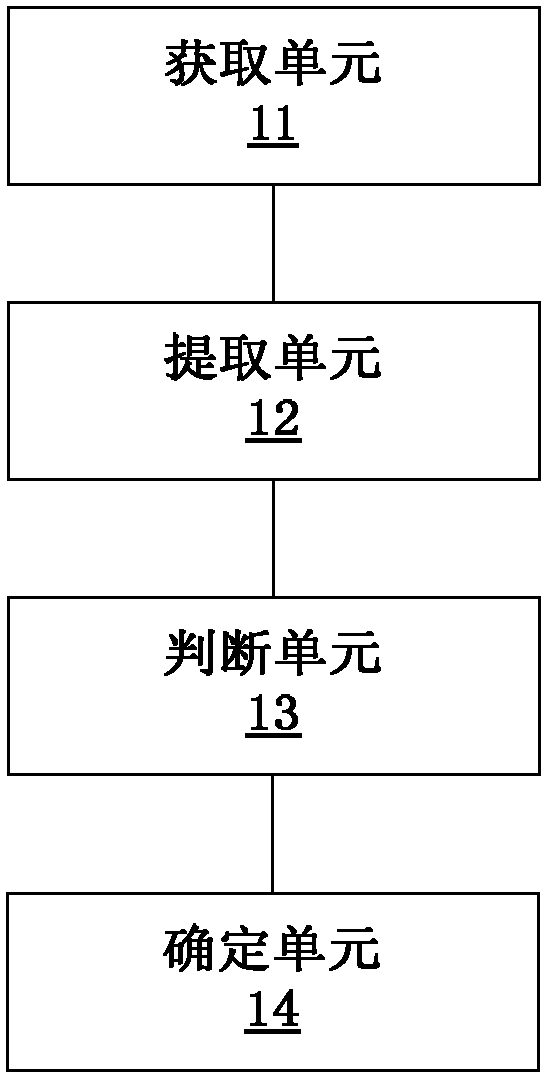

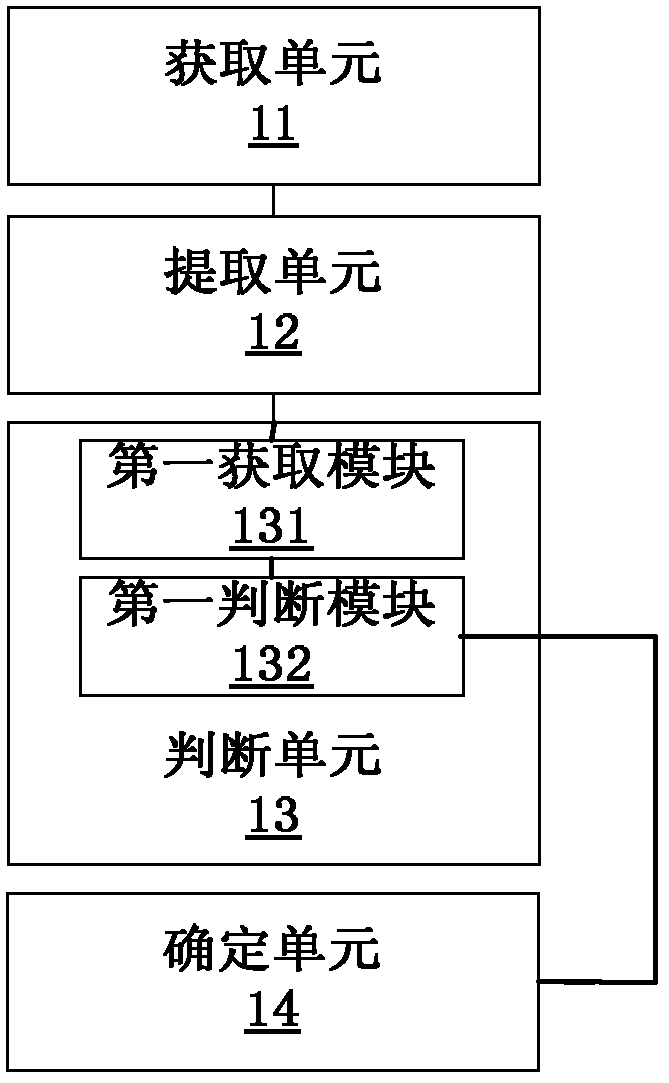

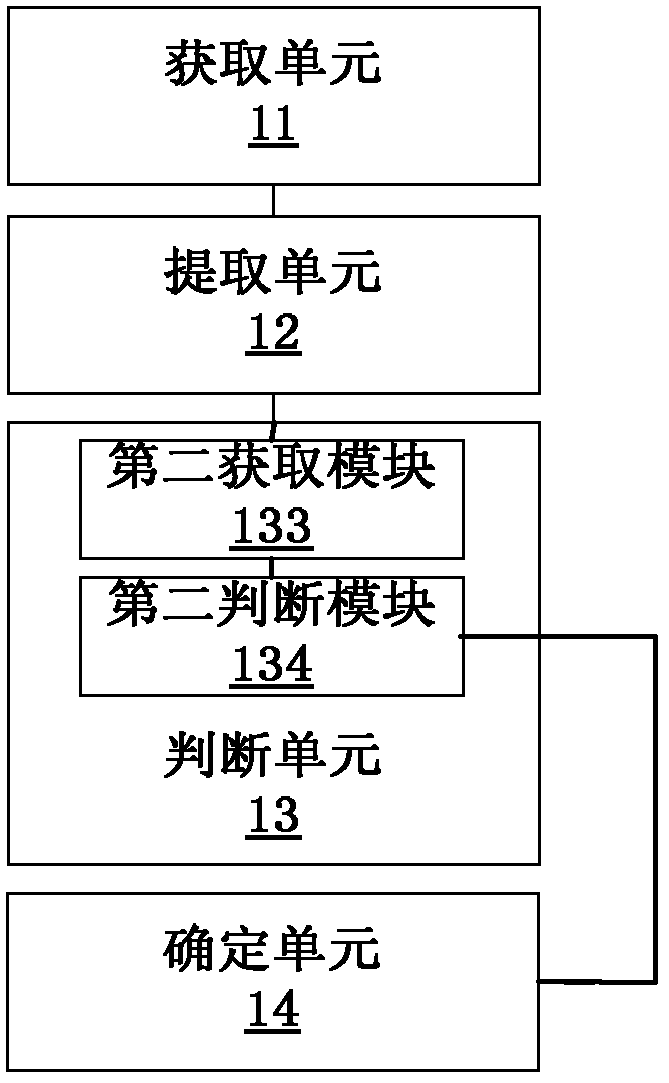

Method and device for detecting subsidence area of ground and data processing equipment

InactiveCN102706328AExpand the scope of detectionHigh precisionPhotogrammetry/videogrammetryHeight/levelling measurementSatellite remote sensingData processing

The invention discloses a method and a device for detecting a subsidence area of ground and data processing equipment. The method for detecting the subsidence area of ground comprises the following steps: acquiring satellite remote sensing image data in a target area; extracting plant spectral information data in the satellite remote sensing image data; judging whether an area matched with the plant spectral information data in a reference area exists in the target area or not, wherein the reference area refers to an area with the known subsidence condition of ground; and determining the subsidence condition of ground in a first area to be identical to that in the reference area when the first area in the target area is matched with the plant spectral information data in the reference area. According to the invention, the detection result is objective and accurate.

Owner:CHINA SHENHUA ENERGY CO LTD +1

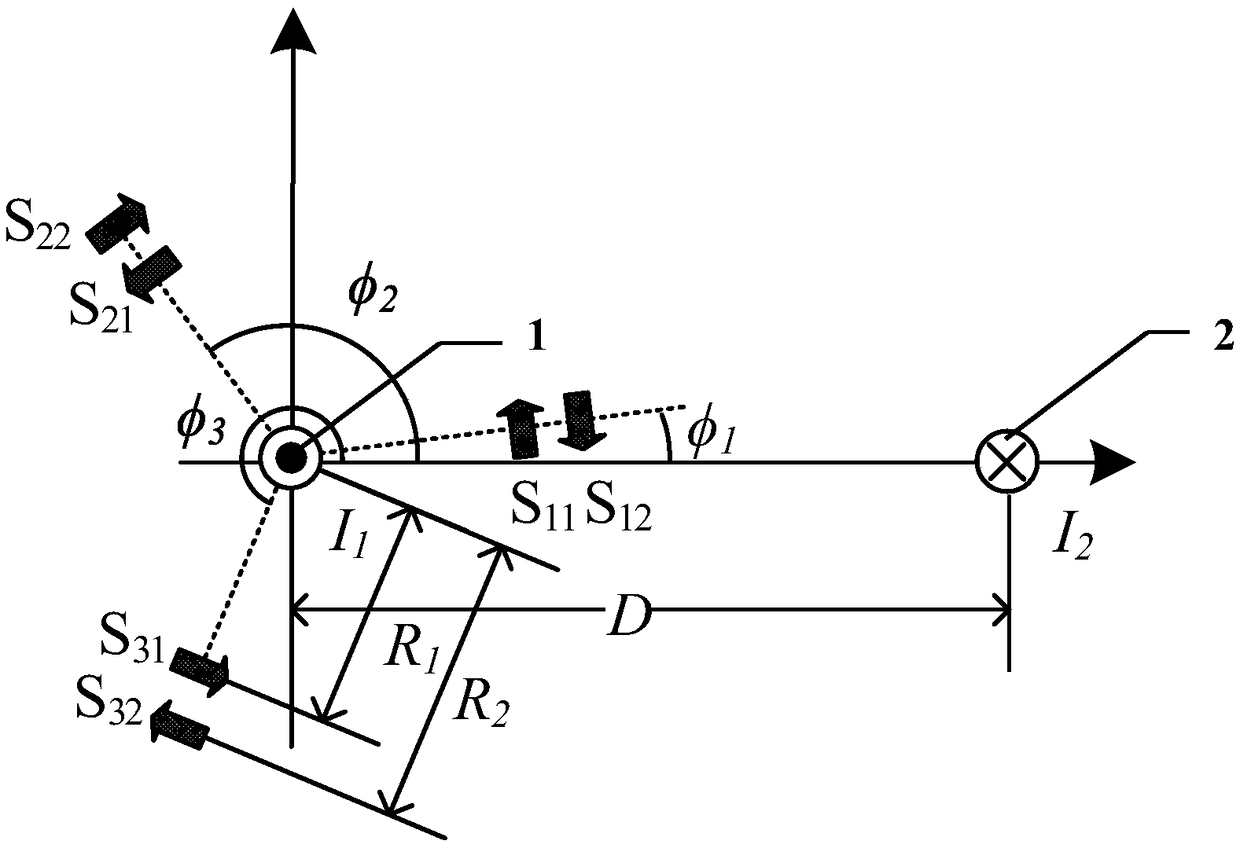

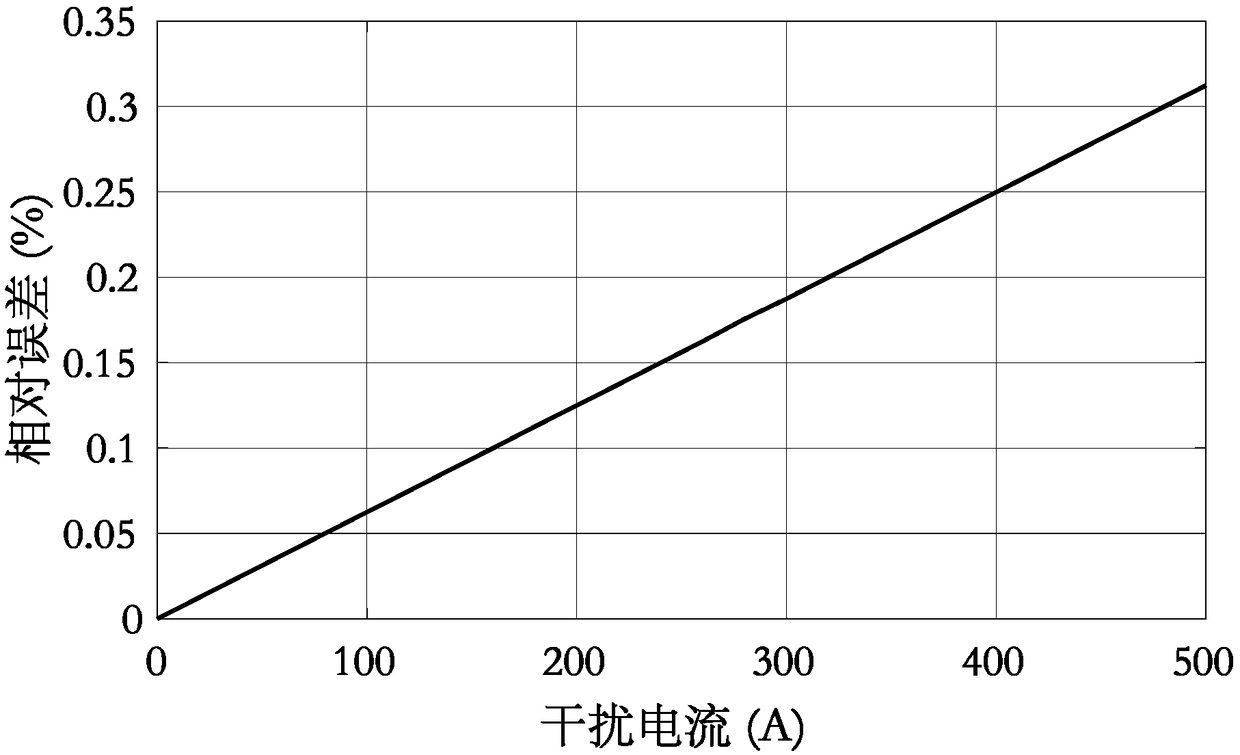

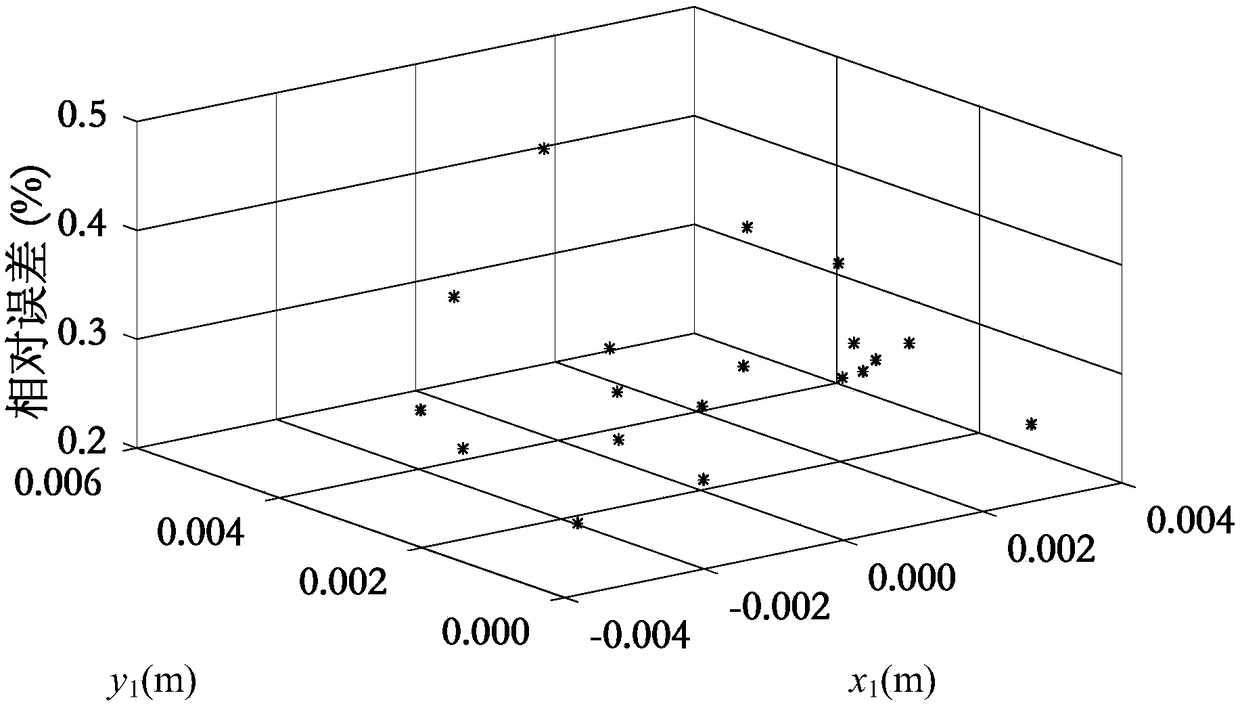

Noncontact current measuring device suitable for intelligent power grid protection system

ActiveCN109444510AAvoid measurement effectsCurrent measurements onlySensor arrayElectrical conductor

The invention discloses a noncontact current measuring device suitable for an intelligent power grid protection system. The noncontact current measuring device is constructed by three sets of tunneling magnetic resistance effect sensor (TMR sensor) arrays which are distributed in one circle. Each set of TMR sensor array is composed of two TMR sensors which have parallel magnetic sensitivity and opposite directions. The phase angle between the TMR sensor arrays is 120 DEG. The TMR sensor is parallel with the tangential line of the circle. The distances between the TMR sensors to the circle center are same. The measuring point positions which are separated from the circle centers for R1 and R2 in two TMR sensors of each set of TMR sensor array are used for measuring magnetic flux density ofa magnetic field that is generated by a current carrying conductor at the measuring point points. The current of the current carrying conductor can be obtained according to six magnetic flux densitiesthrough an equation set solving mode. Furthermore, the magnetic field which is generated by interference current of surrounding electrical equipment and the interference from a geomagnetic field areneutralized. The noncontact current measuring device is particularly suitable for current monitoring of a certain phase in a ground fault line selection in a DC or AC condition.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

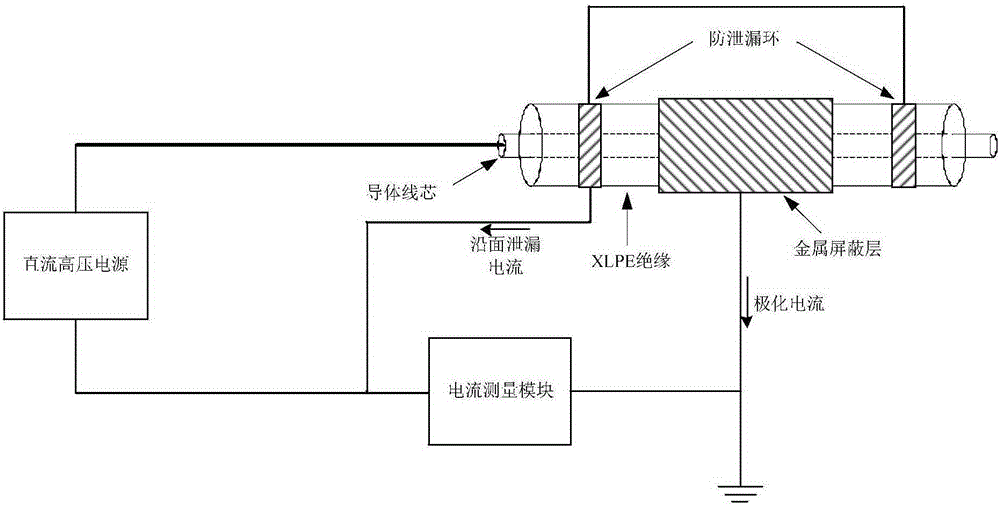

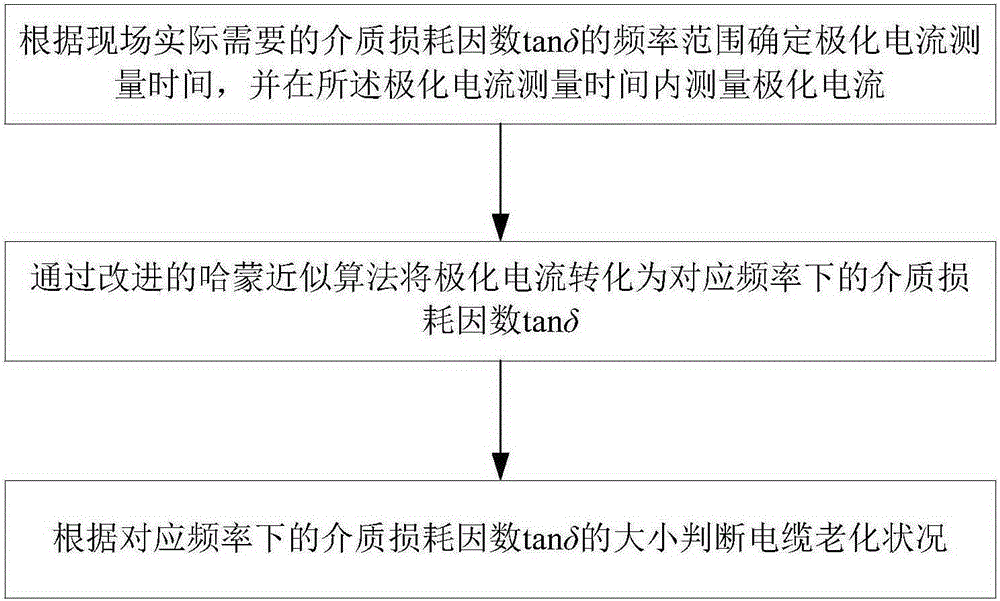

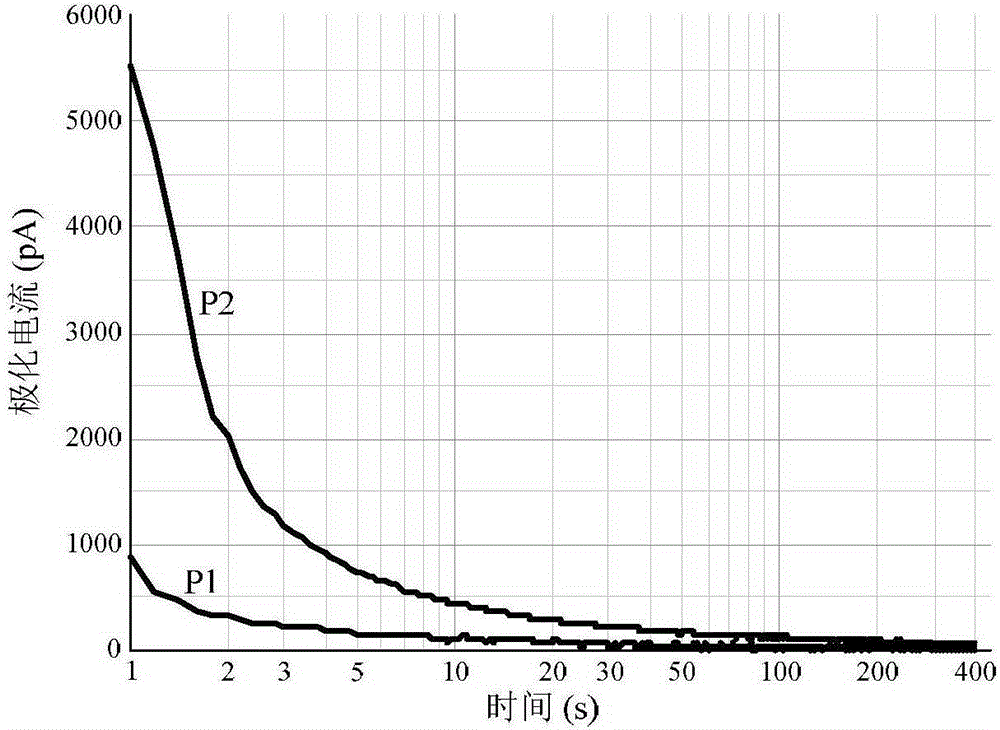

Aging site rapid diagnosis method for 10 kV XLPE cable based on polarization current measurement

ActiveCN105259486AConversion is fast and intuitiveReduced measurement timeTesting dielectric strengthDielectric loss factorTan delta

The invention discloses an aging site rapid diagnosis method for a 10 kV XLPE cable based on the polarization current measurement. According to the technical scheme of the invention, the Harmon approximation algorithm is improved when the fitting parameter n of the relaxation current is larger than or equal to 0 and smaller than or equal to 0.3, or is larger than or equal to 1.2 and smaller than or equal to 2. In this way, the application range of the Harmon approximation algorithm is expanded and the measurement time of the polarization current is greatly shortened according to the frequency range of a dielectric loss factor tan Delta determined based on the field actual need. Moreover, based on the improved Harmon approximation algorithm, the dielectric loss factor tan Delta at a corresponding frequency can be quickly and intuitively obtained, so that the cable aging condition can be judged based on the value of the dielectric loss factor tan Delta at the corresponding frequency. Therefore, by adopting the aging site rapid diagnosis method for the 10 kV XLPE cable based on the polarization current measurement, the aging condition of a field cable can be rapidly diagnosed. At the same time, the method is wider in application range and can reflect the cable aging condition more accurately. The requirement of the field time measurement can be met.

Owner:HUAZHONG UNIV OF SCI & TECH

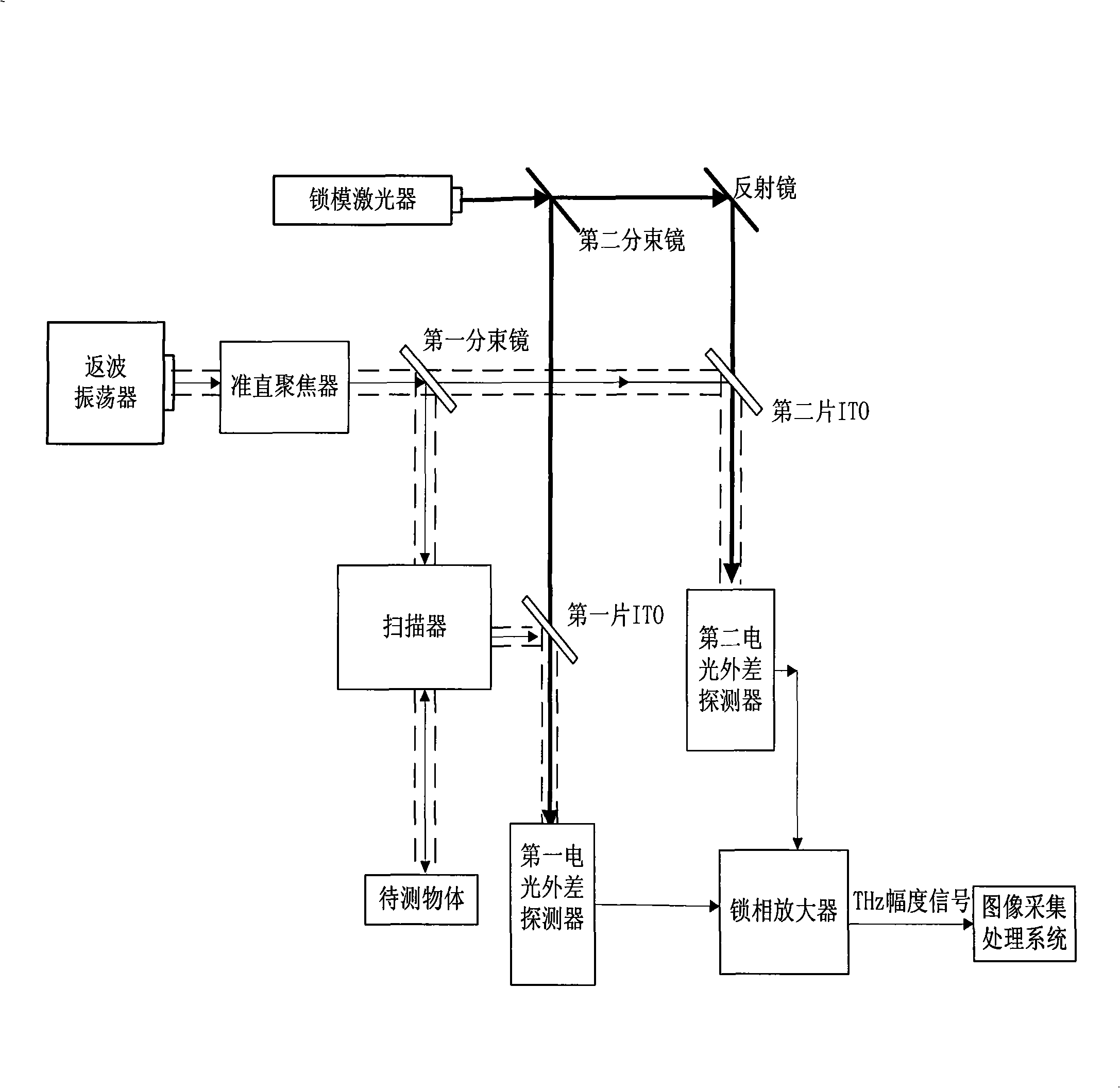

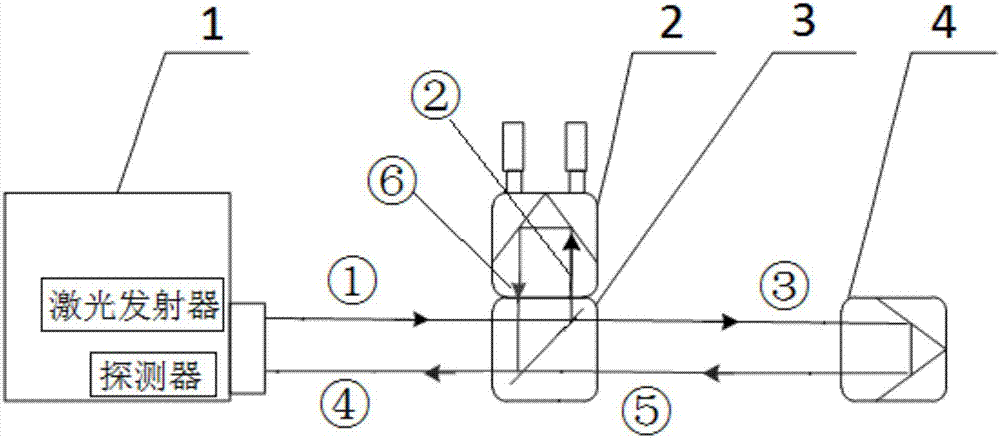

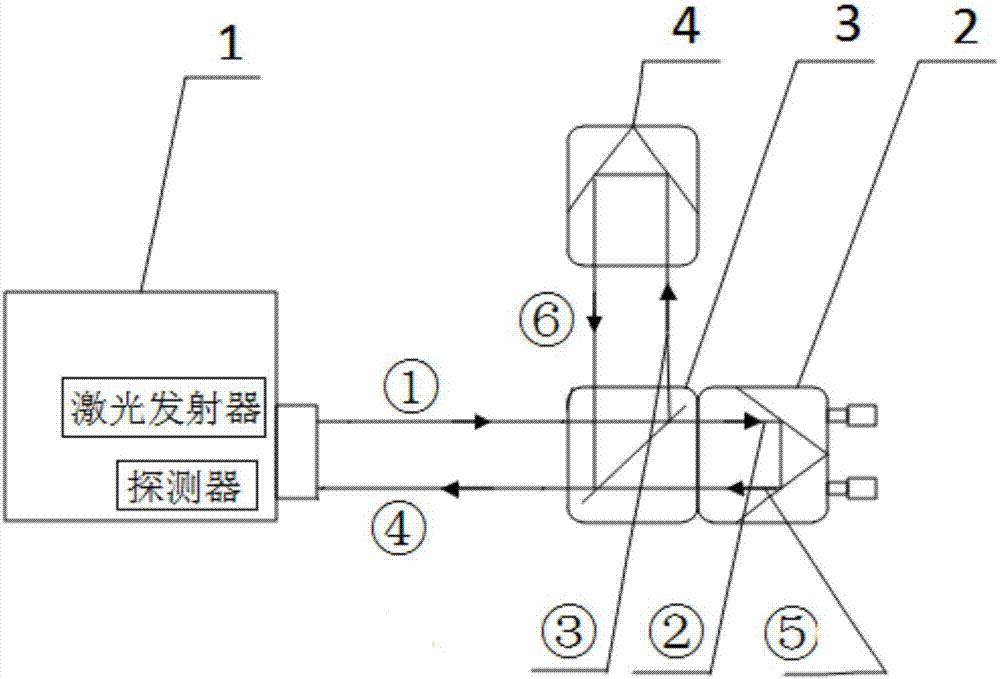

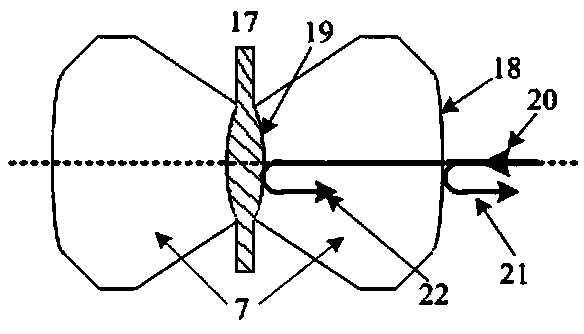

Electro-optical heterodyne detection type THz wave rapid two-dimension imaging apparatus

InactiveCN101354358AImprove job stabilityLarge dynamic rangeOptically investigating flaws/contaminationSignal-to-noise ratio (imaging)Phase locking

The invention discloses an electrooptic heterodyne detection typed quick two-dimensional terahertz wave imaging device. The whole imaging device mainly comprises a high-power backward-wave oscillator (BWO), a ZnTe electrooptic crystal, a mode-locked laser, a photosensitive diode array and a high-speed phase locking amplifier. The BWO with high output power is taken as a continuous terahertz radiation source and combined with the femtosecond mode-locked laser so as to realize the electrooptic heterodyne detection of THz intensity signals; a polyhedral tilting mirror is adopted for realizing line scanning and combined with pendulum mirror frame scanning so as to realize high-speed image scanning; a terahertz scanning system with separated optical shaft and receiving optical shaft is adopted and combined with a technique with synchronous scanning view field and receiving view field so as to realize image obtaining with the high speed of 1 frame in 2 seconds and the high signal-to-noise ratio of over 40 dB. The system has the advantages that the system can overcome the system measurement influence that is caused by unstable output of the terahertz radiation source, and has quick imaging speed, high working stability and large dynamic range.

Owner:CHINA JILIANG UNIV

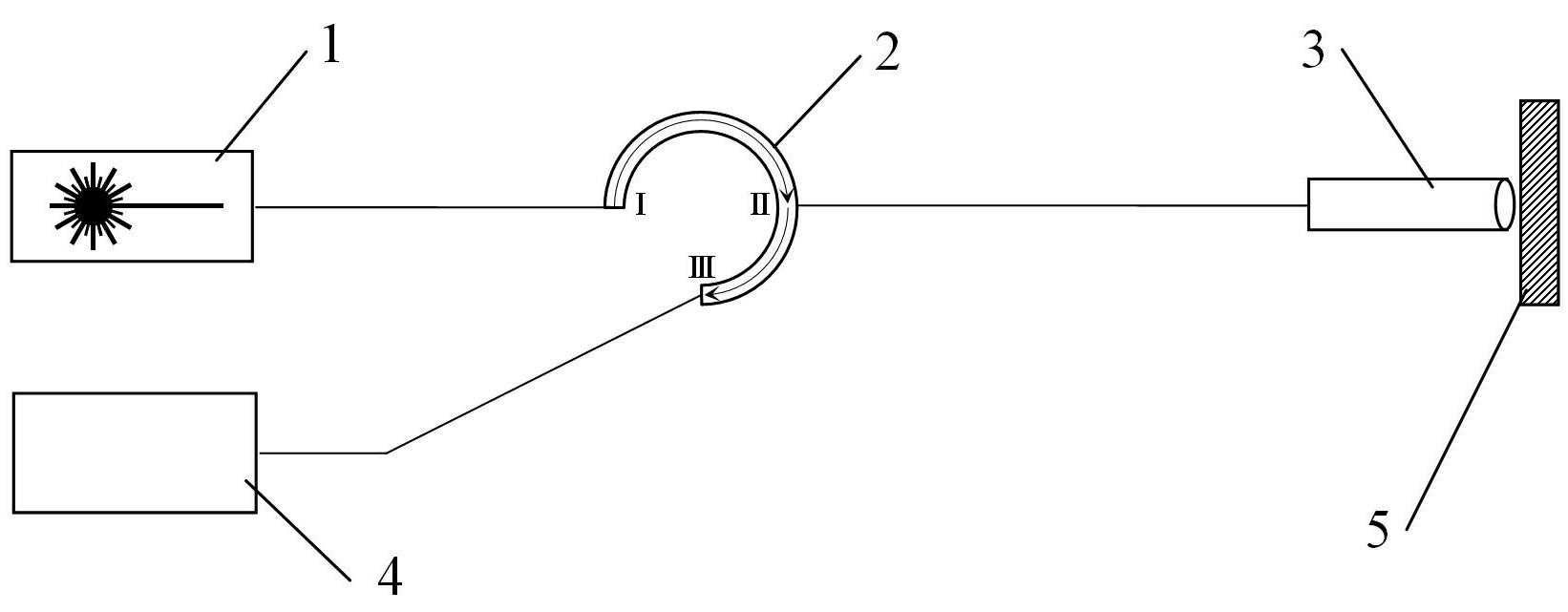

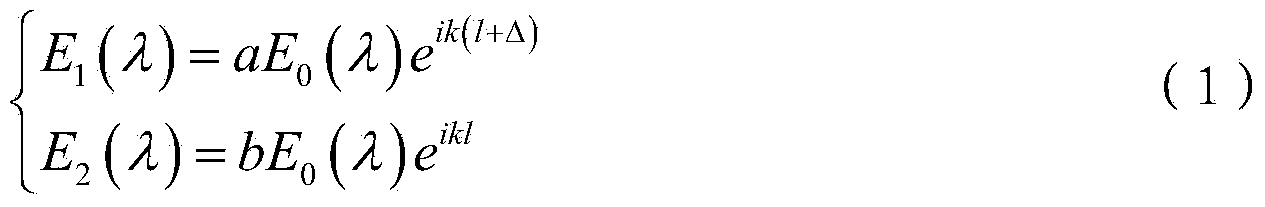

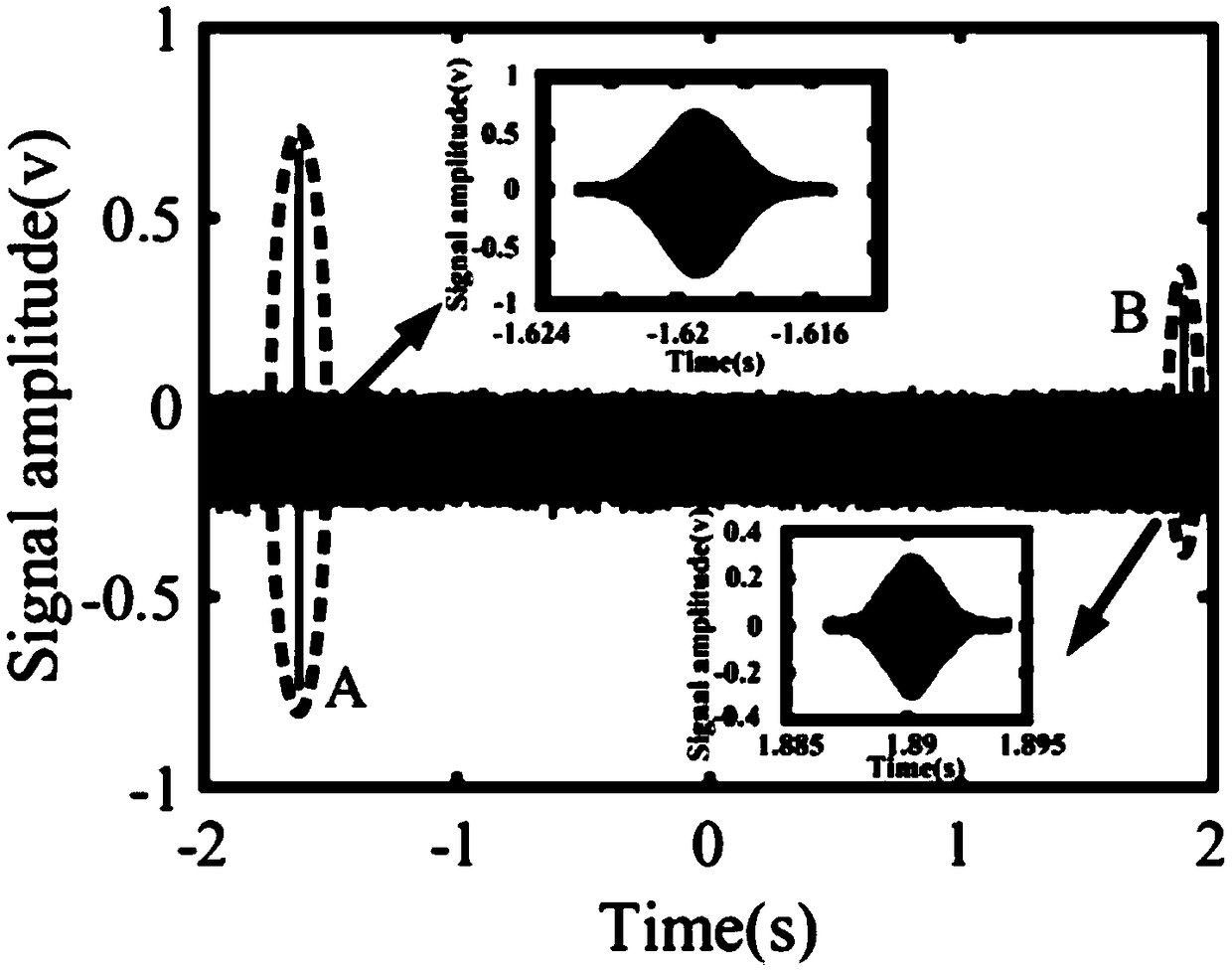

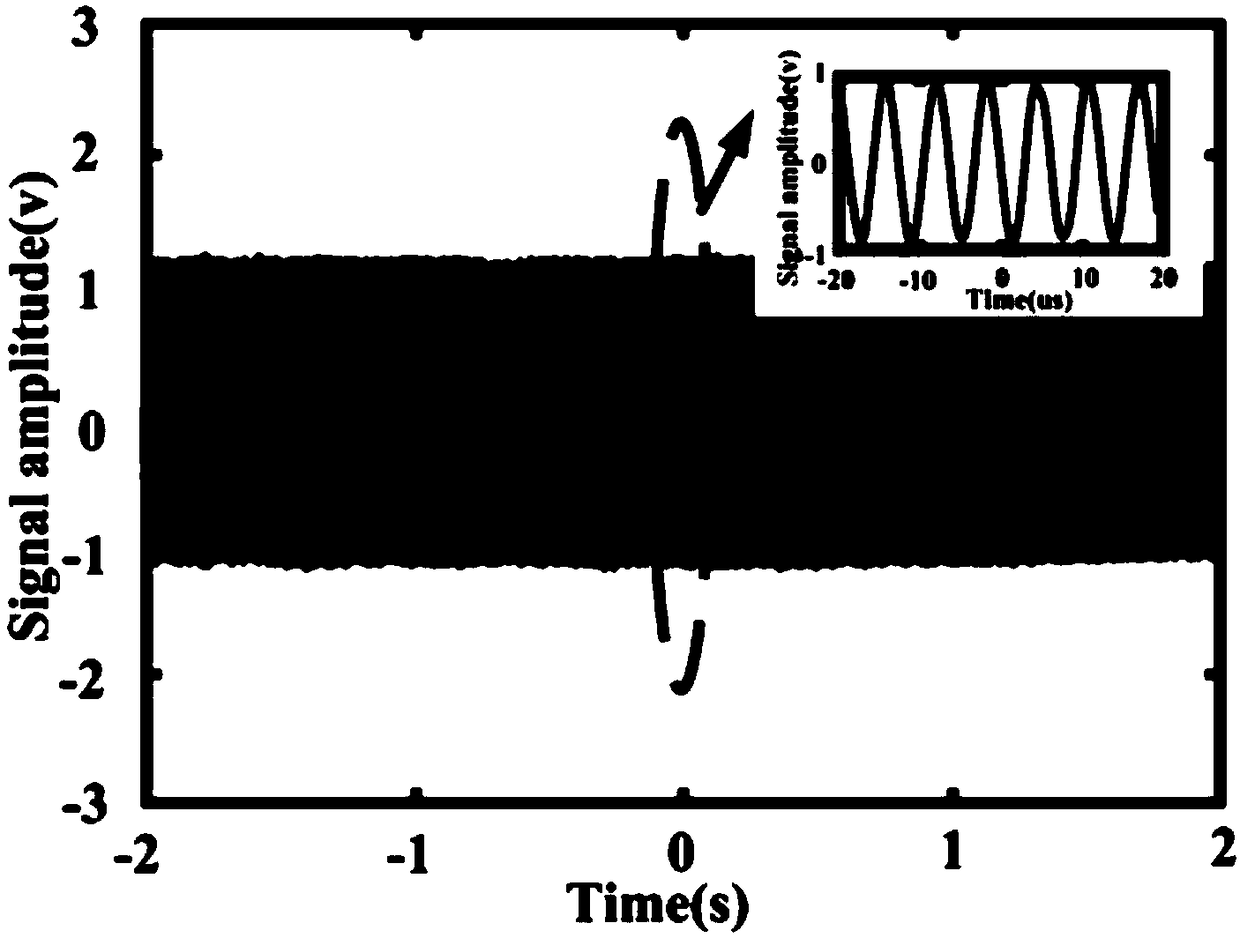

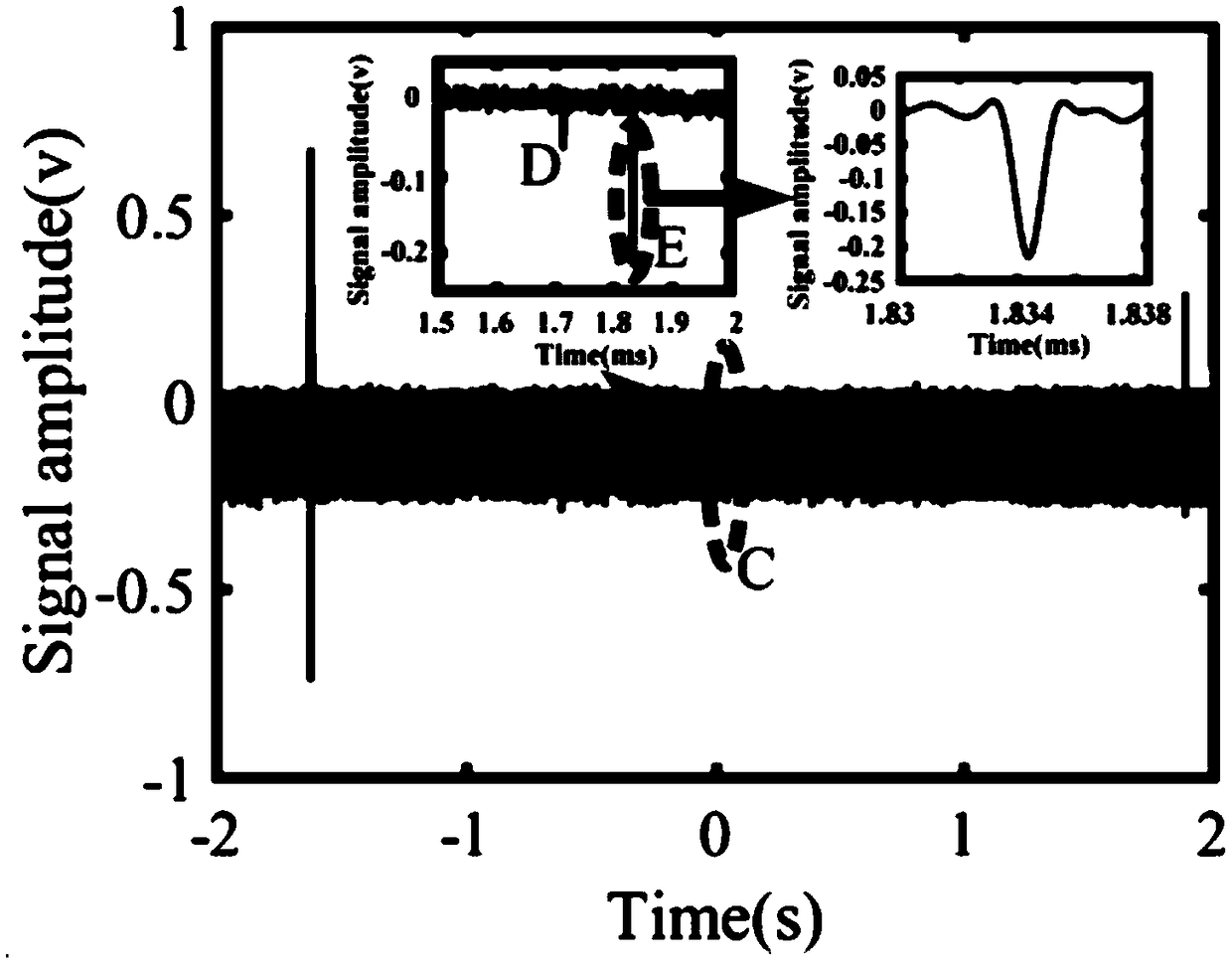

System for measuring nanometer micrometric displacement based on full-fiber frequency domain interference

InactiveCN102645168AReduce the difficulty of debuggingReduce the difficulty of operationUsing optical meansFiberMeasurement device

The invention discloses a system for measuring the nanometer micrometric displacement based on full-fiber frequency domain interference. A broadband light source of the system is connected with a port I of an optical fiber circulator through an optical fiber, a port II of the optical fiber circulator is connected with one end of a silica optical fiber probe through the optical fiber, a port III of the optical fiber circulator is connected with an optical spectrometer through the optical fiber, and tail fibers of components are connected through a flange plate or in a welding method. The system disclosed by the invention has the ability of measuring the nanometer micrometric displacement, is a non-contact type measuring device, can be used for statically and dynamically measuring the distance from the surface of an objected to be tested to the surface of the probe, and can be used for measuring metal or nonmetal. According to the system disclosed by the invention, by adopting a full-fiber-structured device, the operation difficulty is greatly reduced, the promotion and the use of the device are facilitated, and the anti-interference ability is strong.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

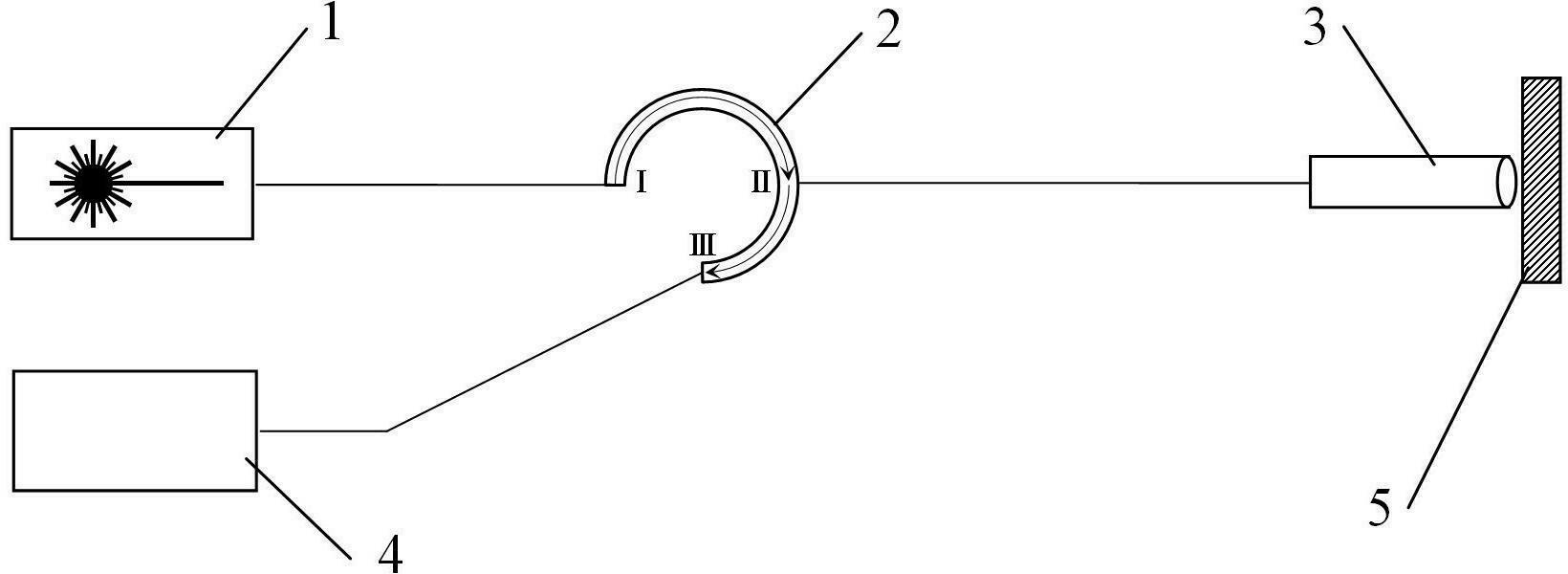

Optical system wavefront measurement device and method based on circular carrier frequency phase demodulation method

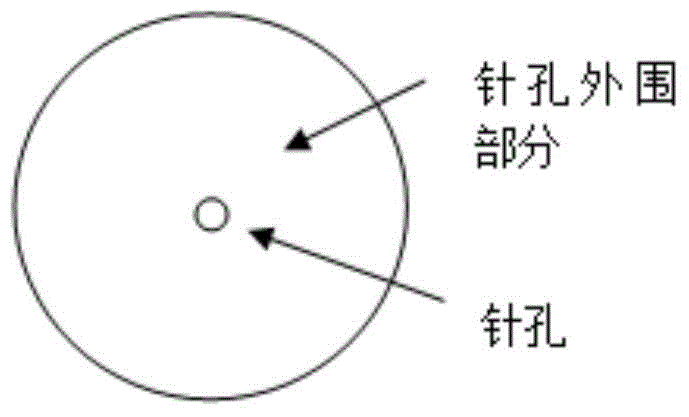

ActiveCN103557948ARealize measurementExperiment operation is simpleOptical measurementsDiffraction effectBeam expander

The invention discloses an optical system wavefront measurement device and method based on a circular carrier frequency phase demodulation method. The device comprises a laser, a beam expander, a spatial filter, an optical system to be measured, a point diffraction plate and a CCD camera, wherein the laser, the beam expander, the spatial filter, the optical system to be measured, the point diffraction plate and the CCD camera are sequentially coaxially arranged in the direction of an optical path; the spatial filter is arranged on the focus of the beam expander; the point diffraction plate is arranged on an emergent wave surface rendezvous point of the optical system to be measured; the point diffraction plate comprises a pin hole and a pin hole peripheral part, and the pin hole peripheral part is plated with a high-reflection film layer. The measurement method includes the steps that before an ideal wave surface generated by the point diffraction plate through the pin hole diffraction effect is used as a reference wave, the point diffraction plate moves in the direction of the optical axle to form a circular carrier frequency interferogram, and a four-phase splice method is utilized to directly solve original phases in the circular carrier frequency interferogram, namely the wavefront of the optical system to be measured. According to the method, the emergent wavefront of the optical system can be measured by few components, and the measurement device is easy to operate, high in accuracy and capable of meeting the requirement of transient measurement.

Owner:NANJING UNIV OF SCI & TECH

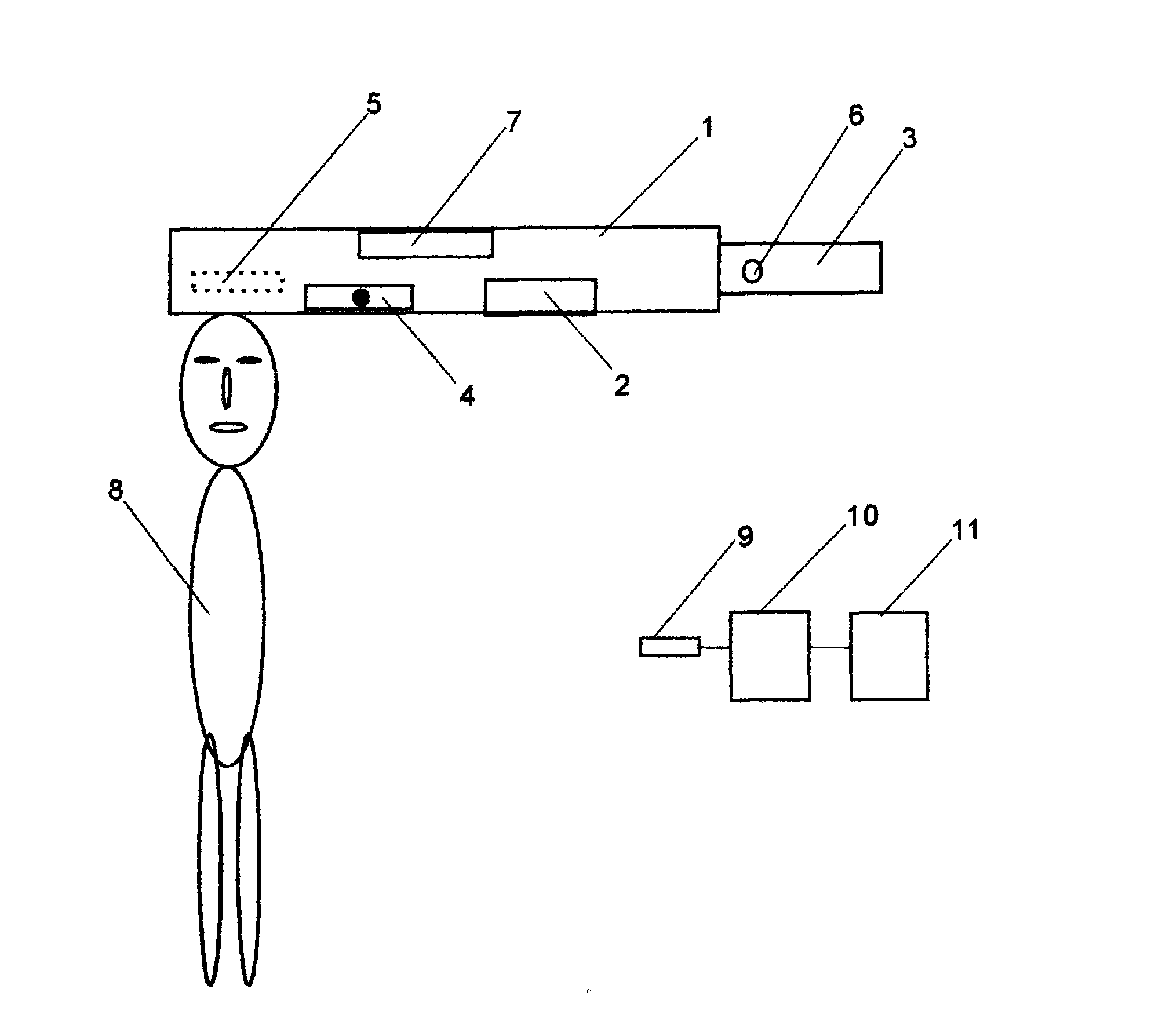

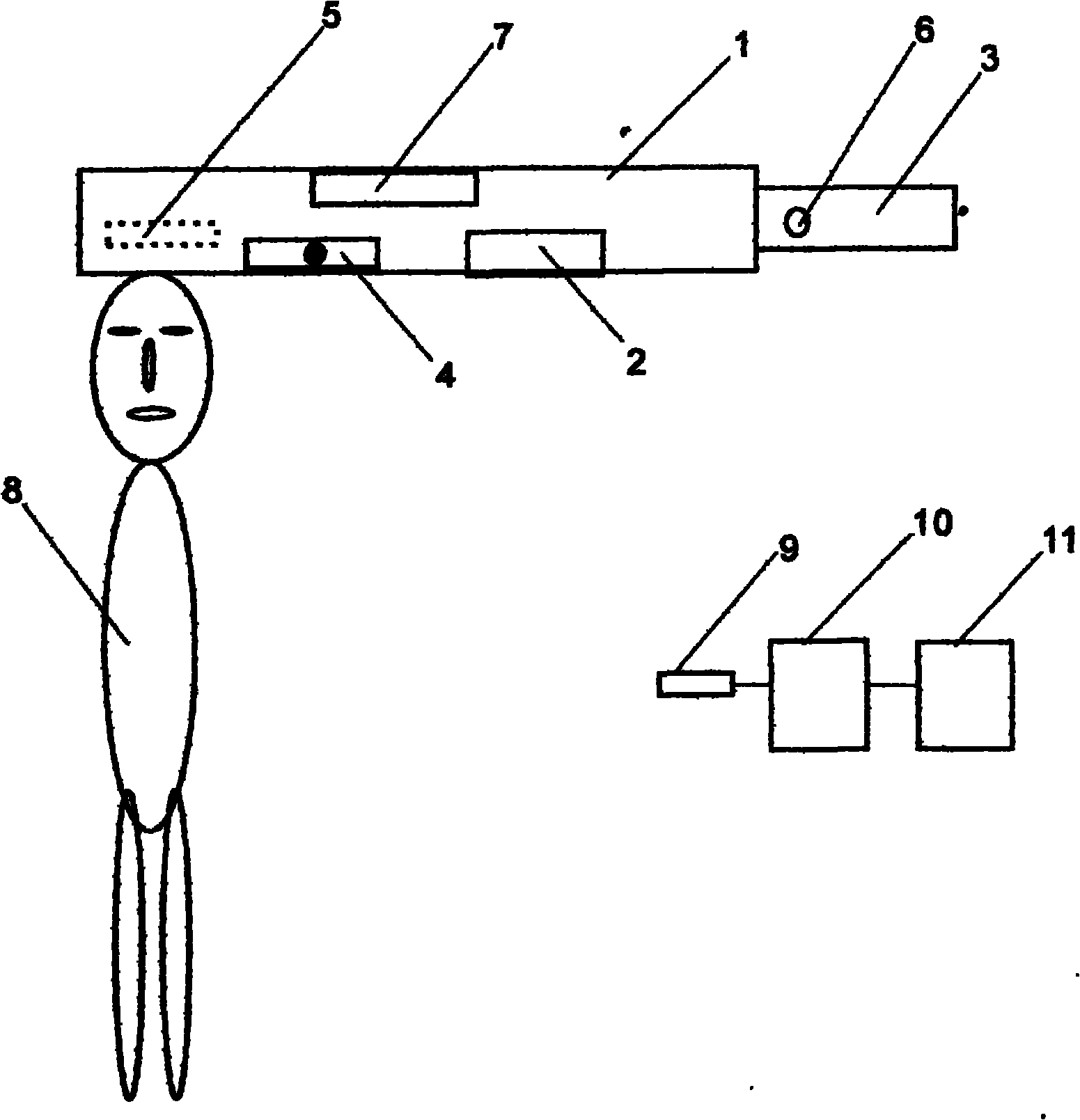

Head placement type height measurement method

InactiveCN102090894AAvoid measurement effectsReduce volumeDiagnostic recording/measuringSensorsMedicineEngineering

The invention discloses a head placement type height measurement method, which relates to the technical field of the measurement and aims to solve the technical problem of height measurement. The measurement method comprises the following steps of: 1) arranging a ranging probe on a measuring rod; 2) arranging a horizontal device on the measuring rod; 3) placing the measuring rod on the head top of a measured person; 4) observing the horizontal device, and adjusting the measuring rod to a horizontal state; 5) starting the measurement; and 6) displaying a measured value. In the head placement type height measurement method, the influence of hair shape of the measured person on the measurement is avoided because the measuring rod is directly placed on the top of the head of the measured person; moreover, the measured rod is small in volume, low in cost, and convenient to carry.

Owner:姜维林

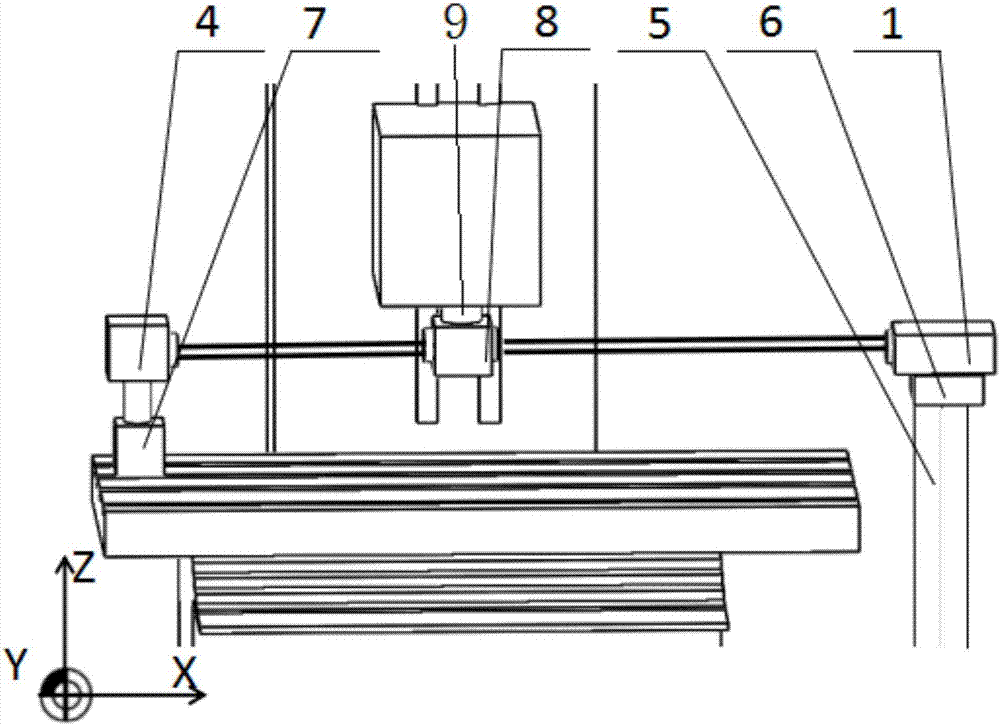

Testing method for heat locating errors of linear shaft of vertical machining center

InactiveCN106975983AImprove accuracyAvoid influenceMeasurement/indication equipmentsGeometric errorMeasurement point

The invention discloses a testing method for the thermal positioning error of a linear axis of a vertical machining center. This method first measures the positioning error of each measuring point of the linear axis of the vertical machining center at the initial moment, that is, the geometric error, and then measures the positioning error of each measuring point of the linear axis of the vertical machining center at any time, and the conditions remain unchanged during the two measurements , and finally make a difference between the two data to obtain the thermal positioning error of each measurement point of the linear axis of the vertical machining center at any time. In this way, the influence of the geometric errors of the various components of the machine tool on the thermal positioning error measurement is avoided, and the accuracy of the measurement results is improved. This method can quickly and efficiently complete the on-machine test requirements of the thermal positioning error of the linear axis, which not only avoids the influence of the geometric errors of the various components of the machine tool on the measurement of the thermal positioning error, but also avoids the use of displacement sensors or standard parts as well as clamping, finding The deviation problem caused by positive and fixed improves the accuracy of the measurement results.

Owner:HEBEI UNIV OF TECH

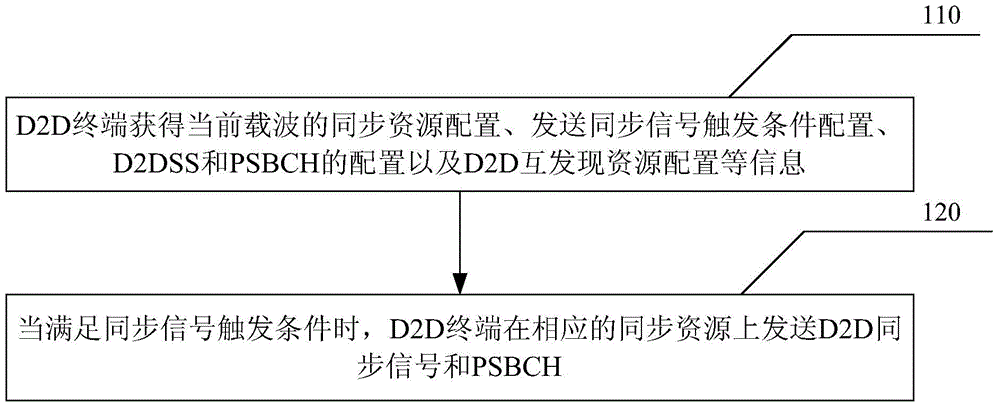

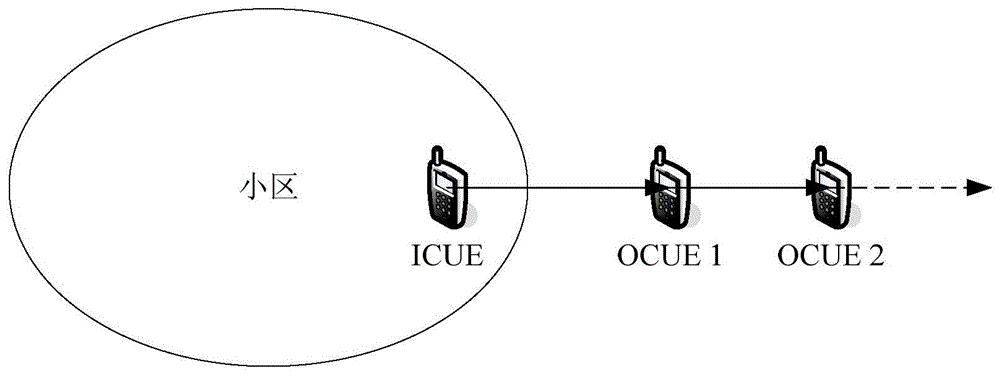

Method and equipment for realizing time and frequency synchronization between D2D (Device to Device) terminals

ActiveCN106211027AAvoid measurement effectsReduce complexitySynchronisation arrangementPilot signal allocationTelecommunicationsDevice to device

The invention provides a method for realizing synchronization between D2D (Device to Device) terminals. Under a PC (Personal Computer) scene, after ICUE (In Coverage User Equipment) meets trigger conditions of a D2DSS (Device to Device Synchronization Signal), the D2DSS and a PSBCH (Physical Sidelink Broadcast Channel) are sent on synchronization resources configured on a cell and multiplexing the same physical resources with a D2DSS and a PSBCH which are sent by Rel-12D2D UE through a code division way or occupy the physical resources different from the physical resources of the D2DSS and the PSBCH which are sent by the Rel-12 D2D UE in order to realize the mutual discovery between the ICUE and OCUE (Out of Coverage User equipment) which participate in the mutual discovery. Through the method, the influence on Rel-12 D2D UE measurement can be effectively avoided, and meanwhile, the system-frame-level synchronization between the ICUE and the OCUE which participate in the mutual discovery under the PC scene is realized at the smaller complexity.

Owner:BEIJING SAMSUNG TELECOM R&D CENT +1

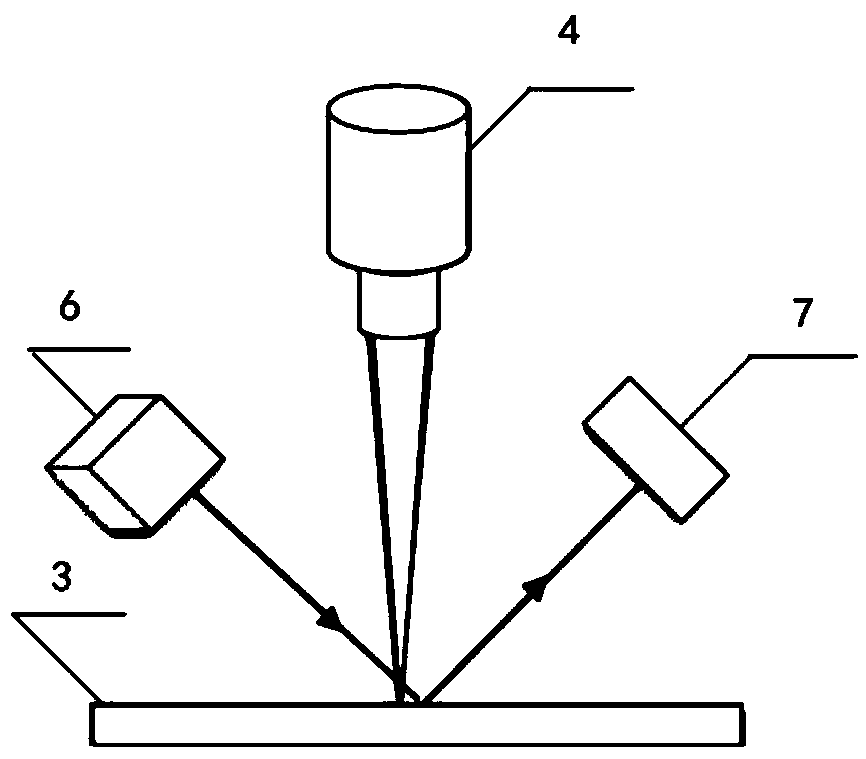

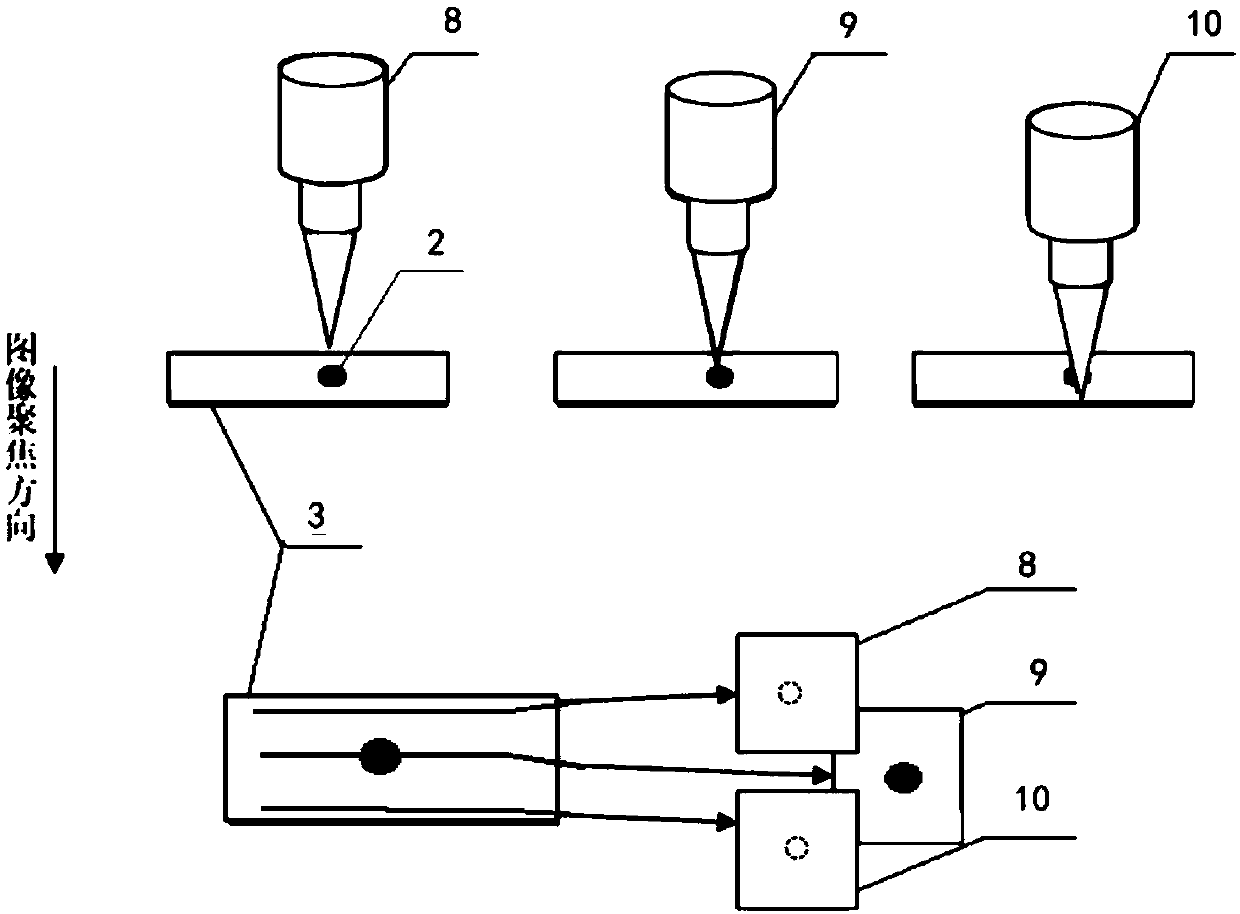

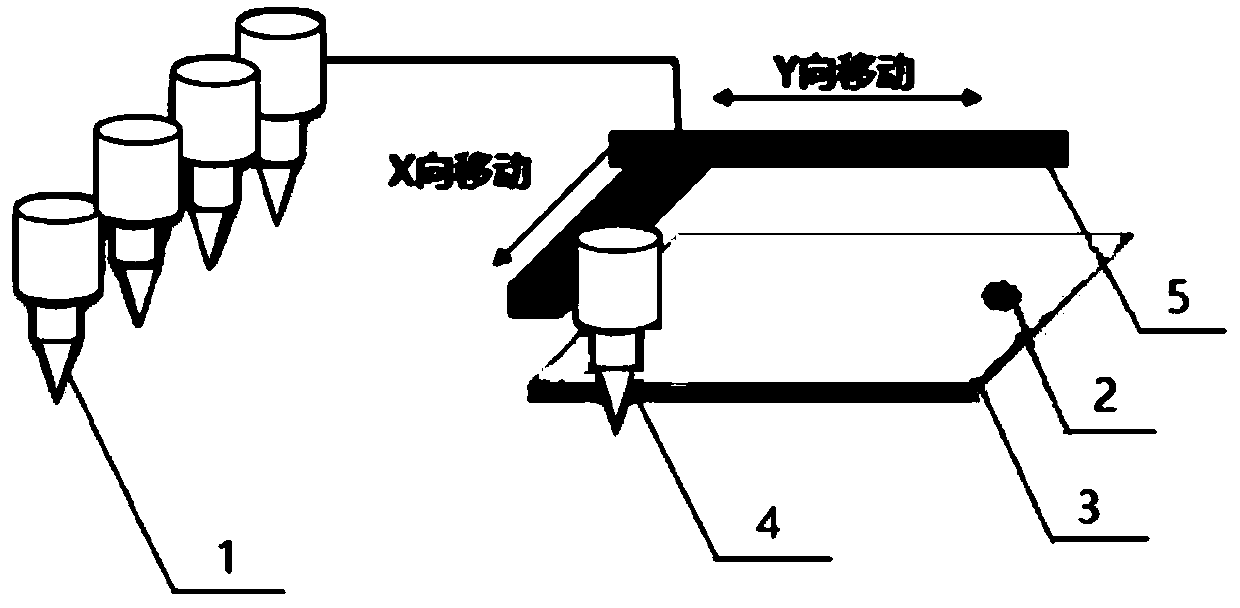

Plate glass defect rechecking system and rechecking method

ActiveCN109632828AAvoid warpingHigh precisionMaterial analysis by optical meansLaser transmitterEngineering

The invention discloses a plate glass defect rechecking system and rechecking method. The system comprises an X / Y directional transferring mechanism which can move along an X direction and a Y direction on a production line, wherein a CCD probe, a laser emitter and a photoelectric receiver are fixedly installed on the X / Y directional transferring mechanism, the laser emitter and the photoelectricreceiver are arranged on the two sides of the CCD probe correspondingly, and when a position of a defect is determined in the detection process, the laser emitter and the photoelectric receiver jointly confirm the focusing reference surface of the CCD probe, the CCD probe photographs N layers arranged of a plate glass, N photos are shot in total, the photo with the clearest defect is found out from the N photos, the defect position is determined, and then the follow-up process is carried out. According to the system, the defect position found through the system is high in precision, the shot photos can accurately reflect the size and other image characteristics of the defect, the defect can be accurately recognized conveniently, and manual intervention and re-judgment can be facilitated.

Owner:IRICO DISPLAY DEVICES

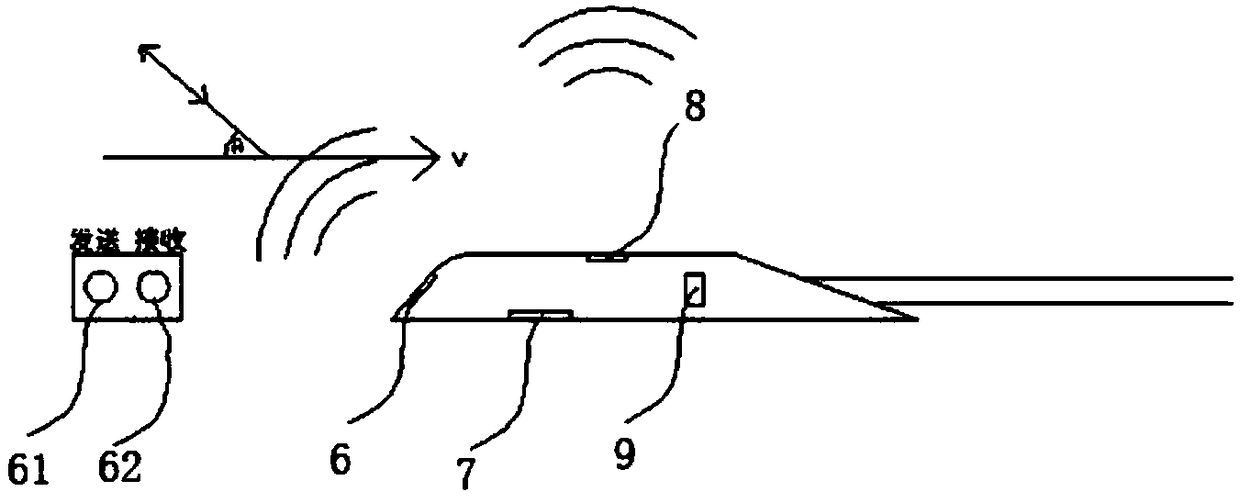

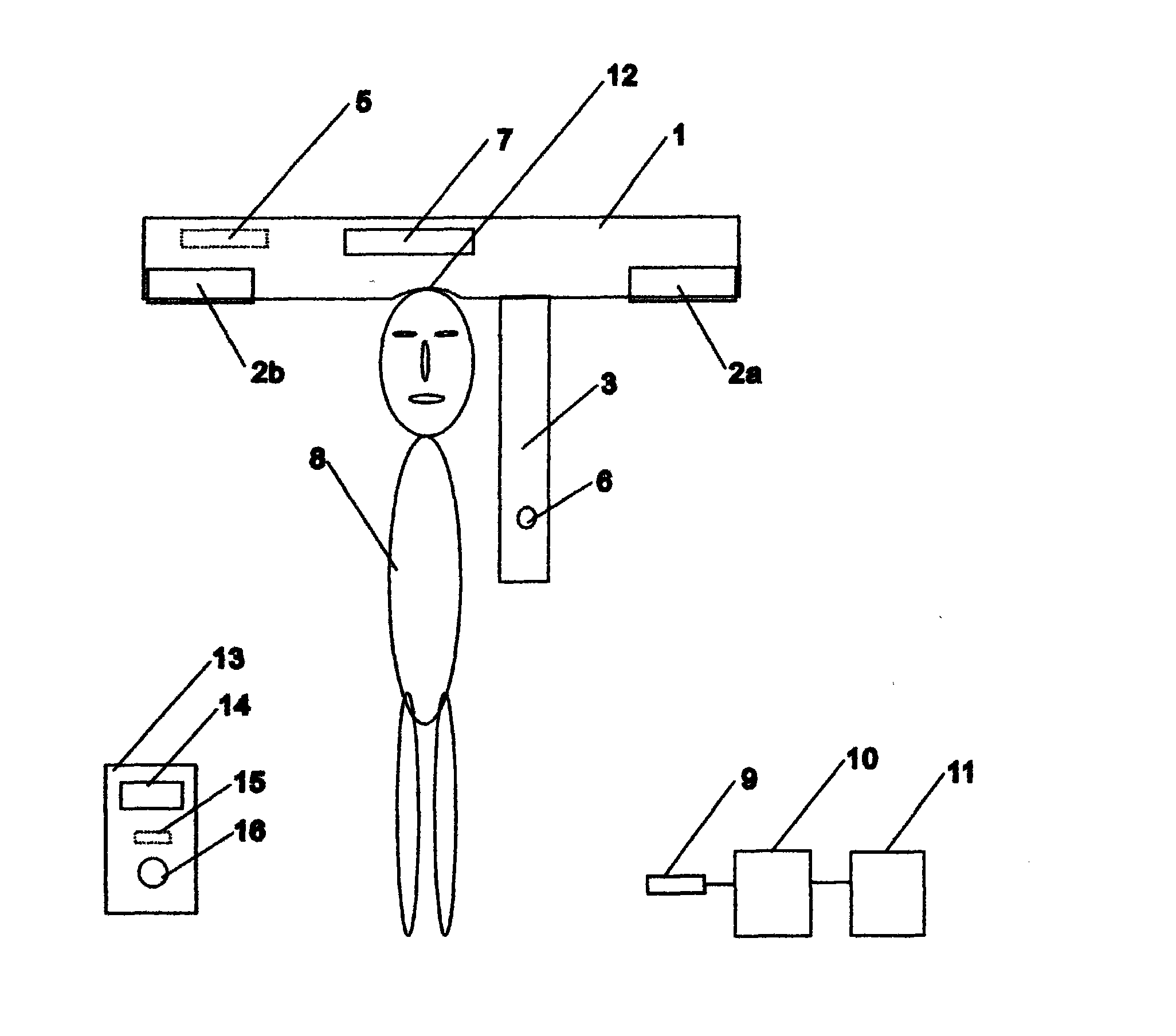

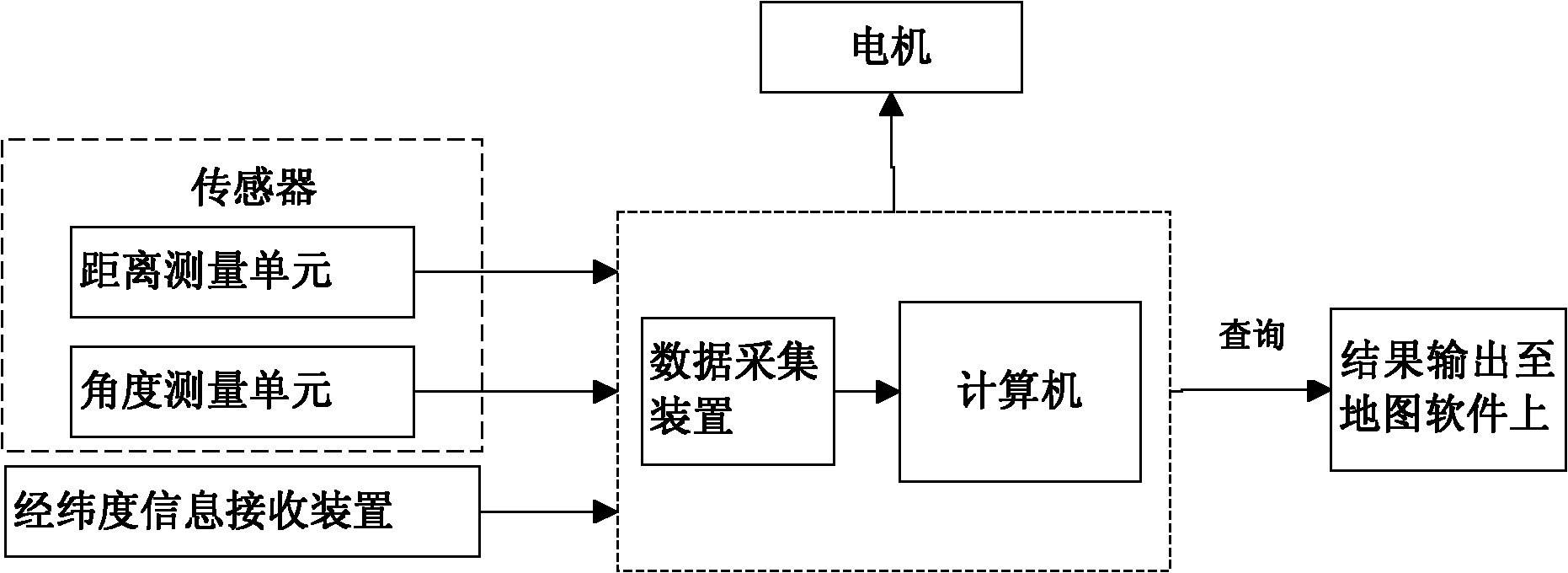

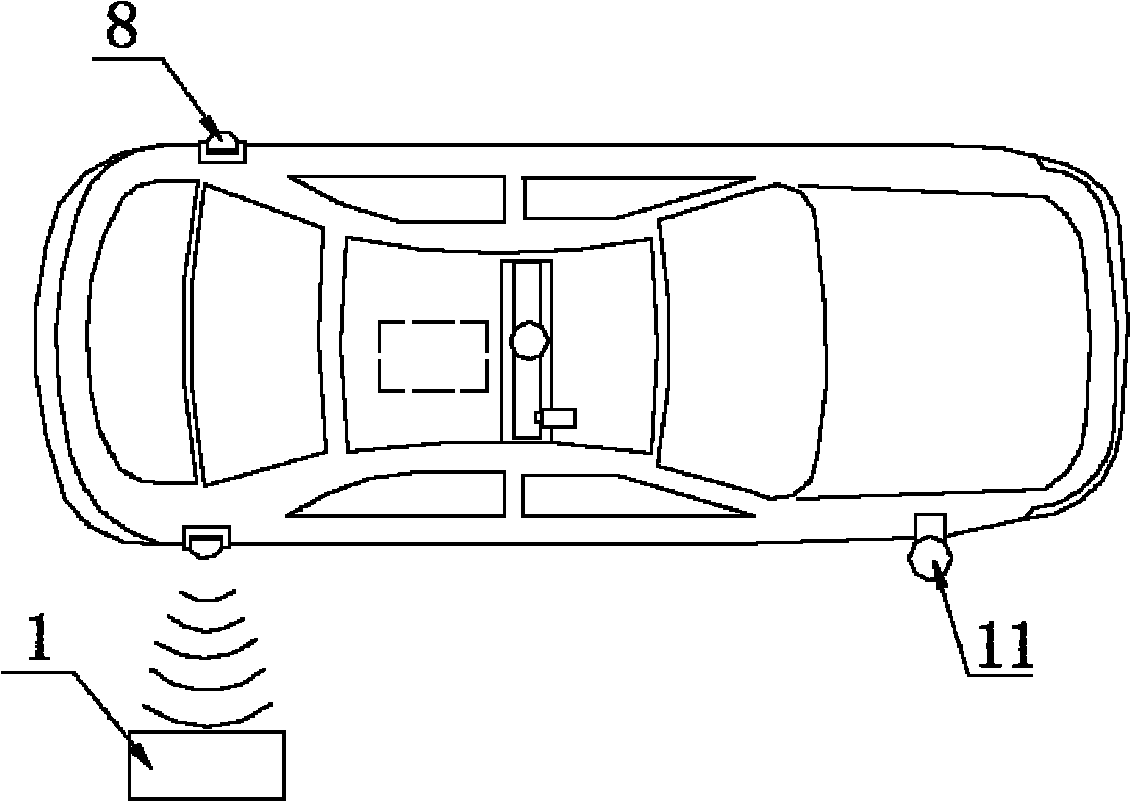

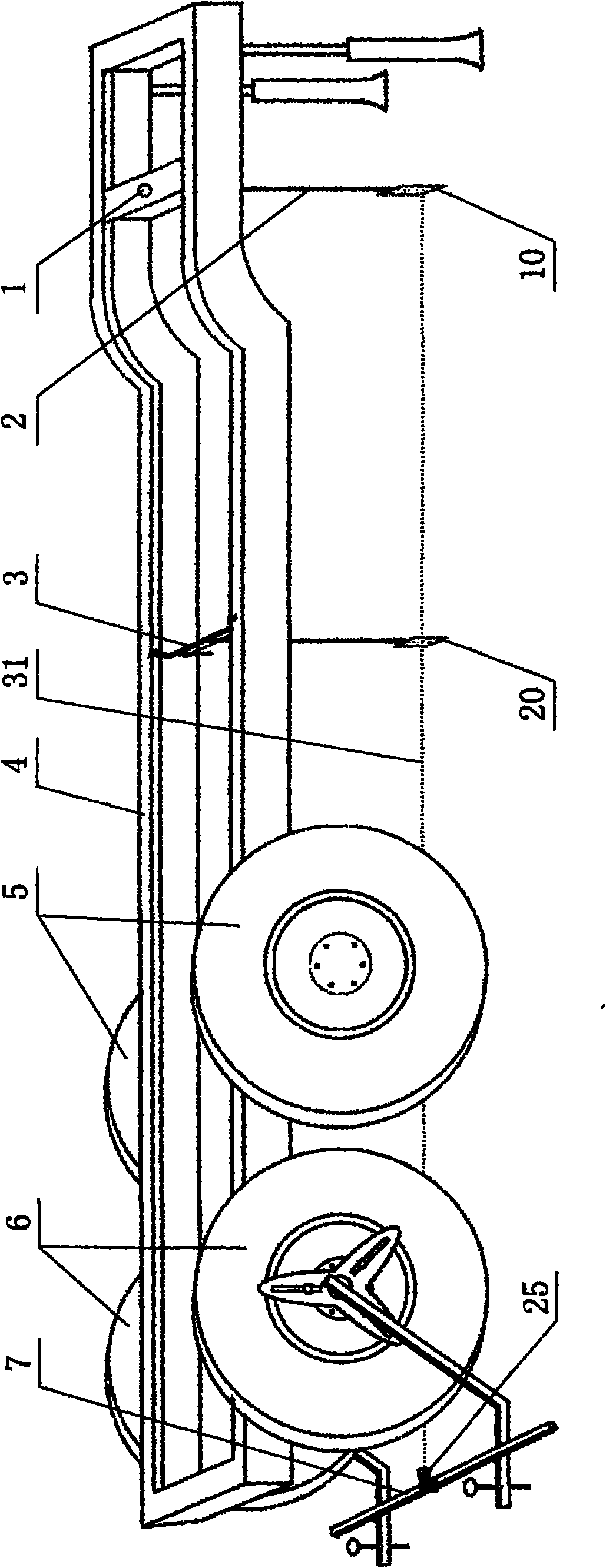

Trafficability characteristic detection system of vehicle in transit

InactiveCN101996493AAvoid measurement effectsImprove work efficiencyDetection of traffic movementLongitudeData acquisition

The invention relates to a trafficability characteristic detection system of a vehicle in transit, which comprises a vehicle (2), wherein sensors, a data collector (9), a computer (10) for data processing and storage and a latitude and longitude information receiving device (6) are arranged on the vehicle (2), wherein signals sent by the sensor and the latitude and longitude information receiving device (6) are input into the computer (10) through the data collector, the sensors at least comprise two lateral distance measuring sensors (8), a vehicle top distance measuring sensor (4) and an angle measuring sensor (5), the two lateral distance measuring sensors (8) are respectively arranged at both sides of the vehicle (2) and are pointed to the outside of the vehicle (2), the vehicle top measuring sensor (4) is arranged at the top of the vehicle (2), is pointed to the right ahead position of the vehicle and is in an inclined upwards direction, and the angle measuring sensor (5) is used for measuring the included angle between the pointing direction of the vehicle top distance measuring sensor (4) and the horizontal plane. The trafficability characteristic detection system can improve the efficiency of route selection and can avoid the influence on the obstacle measurement by manual factors to the maximum degree.

Owner:WUHAN UNIV OF TECH

Automatic control system of mechanical press

ActiveCN1727175AOvercoming fragileAvoid measurement effectsProgramme control in sequence/logic controllersPressesClutchAutomatic control

An automatic control system of mechanical press features that the rotary transformer is used as the sensor of crankshaft angle and slide blockí»s stroke, its encoder is the sensor of die height regulation, and the minimal single-chip computer system with the special control software is used for the logic control to overall units of mechanical press and their functions. Its advantages are simple structure and high reliability.

Owner:南京埃斯顿软件技术有限公司

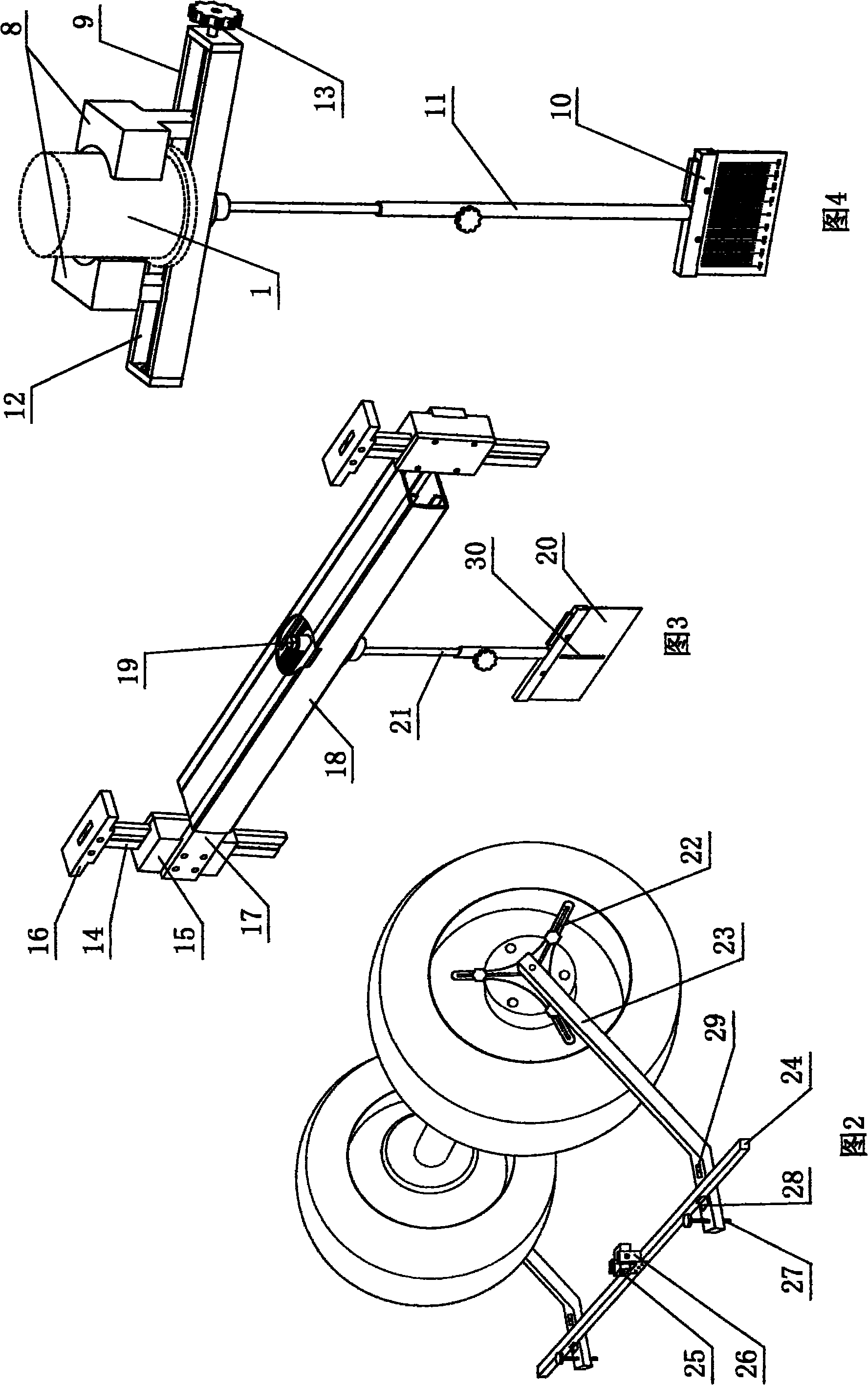

Semi-trailer positioning and measuring system

ActiveCN101968358AAvoid measurement effectsGuaranteed accuracySurveying instrumentsVehicle tyre testingLight spotEngineering

The invention discloses a semi-trailer positioning and measuring system which comprises a traction-shaft central-line clamping apparatus, a crossbeam central-point clamping apparatus and a tyre-center positioning device. When in measurement, the traction-shaft central-line clamping apparatus is arranged on a traction shaft of a crossbeam, a hanger of the crossbeam central-point clamping apparatus is hung on the measured crossbeam and positioned between the traction shaft and a closest bridge, the tyre-center positioning device is sequentially placed on a tyre at the outer side of each measured bridge, a rim central-clamping jaw of the tyre-center positioning device is clamped on a shaft sleeve positioned in the rim of the tyre at the outer side of each bridge and ensures that the center thereof is superposed with the center of the rim central-clamping jaw, and laser is irradiated onto a scale plate through a light passing hole by adjusting the position of a laser emitting pipe of the tyre-center positioning device; a light spot is beaten on a scale mark '0', which indicates that the bridge is vertical to a reference line and does not need to be adjusted; and if the light spot is not positioned at the '0' position of the scale mark, the bridge is adjusted according to the offset position of the light spot. The system can avoid the influence on measurement due to the geometric model changes, such as the deformation of the crossbeam or the dislocation of the bridge, and the like and ensure the accuracy of measurement.

Owner:YANCHENG GAOMA ELECTRONICS EQUIP

Device and method used for measuring deformation of diamond anvil under high temperature high pressure condition

ActiveCN103644859AImprove stabilityImprove strength measurementUsing optical meansOptical pathBroad band

The device relates to the non-contact measuring field and particularly relates to a device and a method used for measuring deformation of a diamond anvil under the high temperature high pressure condition. The method and the device are provided according to the technical problems existing in the prior art. Specifically, deformation of the diamond anvil under the high temperature high pressure condition is acquired through a probe light emission light path, a signal reception light path and a signal processing computer; broad band probe light is provided by the probe light emission light path, signal light returned back from a front table top of the diamond anvil and reference light returned from a back table top of the diamond anvil are collected by the signal reception light path, and frequency spectrum interference of the two light beams is generated in a fiber spectrometer of the signal reception light path; a frequency spectrum interference signal outputted by the fiber spectrometer is processed by the computer, and deformation of the diamond anvil under the high temperature high pressure condition is acquired.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

High-precision seawater sound velocity measuring method based on optical frequency comb interference

ActiveCN108844613ASolve the distance problemSolve the errorVelocity propogationUsing wave/particle radiation meansContinuous lightOptical frequencies

The invention discloses a high-precision seawater sound velocity measuring method based on optical frequency comb interference. The method comprises the following steps: a high-precision seawater sound velocity measuring optical path based on optical frequency comb interference is set up, so that a precise displacement platform continuously moves so as to change the optical distance of an interference optical path and a first reflection optical path; oscilloscope measurement data are collected; moment points t1 and t2 at which the optical distance of the interference optical path are equal tothe optical distance of the measuring optical distance and a reference optical path separately are obtained according to interference fringes at optical frequency combs A and B; the number of continuous light interference fringes between t1 and t2 is calculated, thereby determining the flight distance of sound waves; and the flight time of sound waves is calculated according to a sudden change oflight intensity caused by a pulse acousto-optic effect. The high-precision seawater sound velocity measuring method based on optical frequency comb interference takes the optical frequency comb interference and the pulse acousto-optic effect as fundamental principles to detect a seawater sound velocity profile, and aims at realizing sound velocity measurement with high accuracy and high stability.

Owner:TIANJIN UNIV

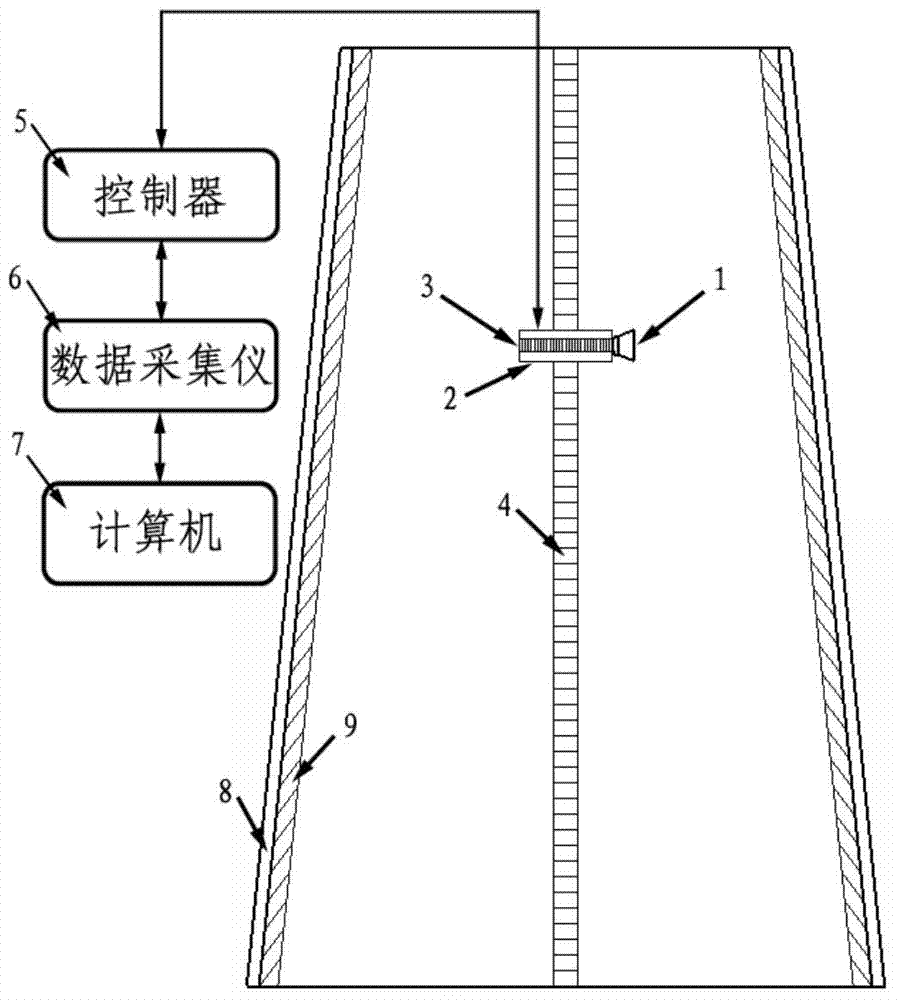

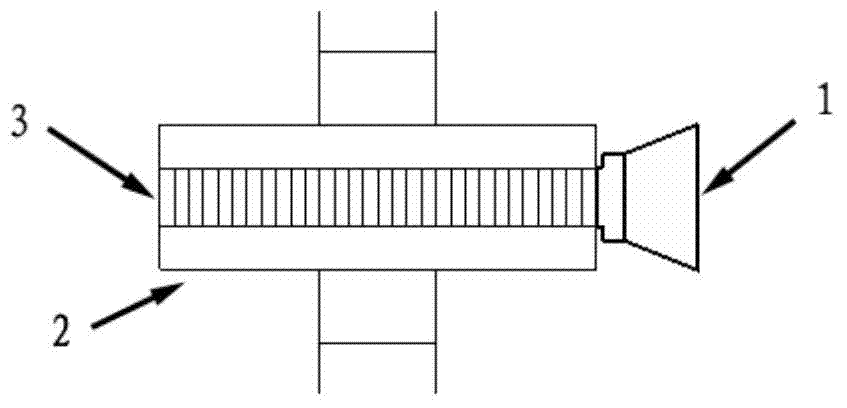

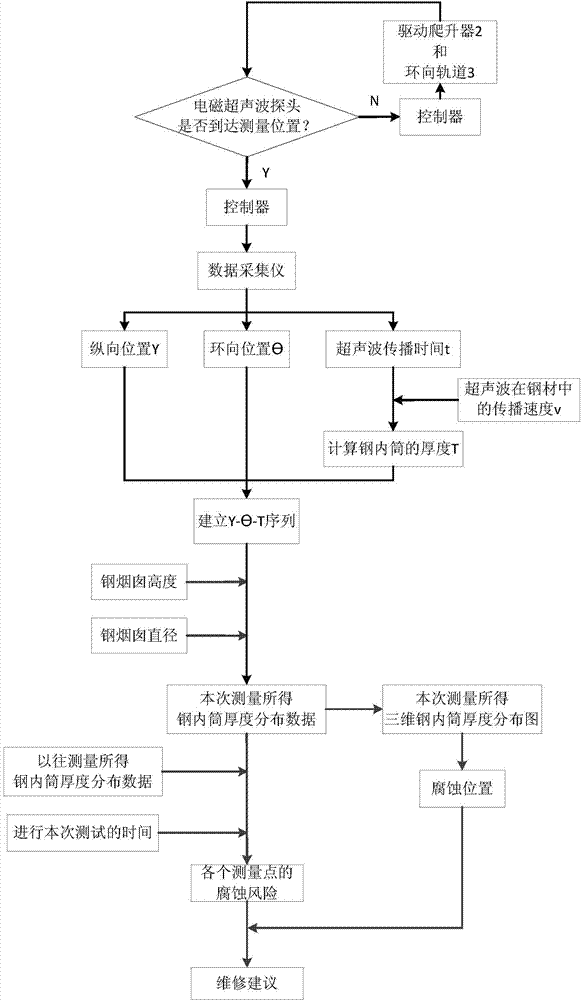

Steel chimney corrosion monitoring system and method based on non-contact ultrasonic technology

InactiveCN103940726ARealize non-contact measurementAvoid measurement effectsWeather/light/corrosion resistanceTime historyEngineering

The invention belongs to the industrial control field and in particular relates to a steel chimney corrosion monitoring system and method based on a non-contact ultrasonic technology. The system is composed of an electromagnetic ultrasonic probe, a climber, an annular guide rail, a longitudinal guide rail, a controller, a data acquisition instrument and a computer. The non-contact ultrasonic technology is utilized to measure the thickness of a steel chimney in a non-contact state, and the corrosion position and the corrosion risk of the chimney can be acquired through comparative analysis of thickness distribution of an inner steel barrel and thickness vibration tendency along with time history, so that an advice is given timely for maintenance. The system and the method can automatically, rapidly and precisely realize assessment and analysis of the steel chimney health condition, so as to reduce the corrosion risk and the corrosion degree of the steel chimney and improve the working efficiency of the steel chimney and even the whole production process.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com