Permanent magnet synchronous motor parameter identification method, device and control system

A permanent magnet synchronous motor, parameter identification technology, applied in the control system, vector control system, motor generator control, etc., can solve the problems of inaccurate d-axis positioning, affecting the accuracy of measuring inductance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

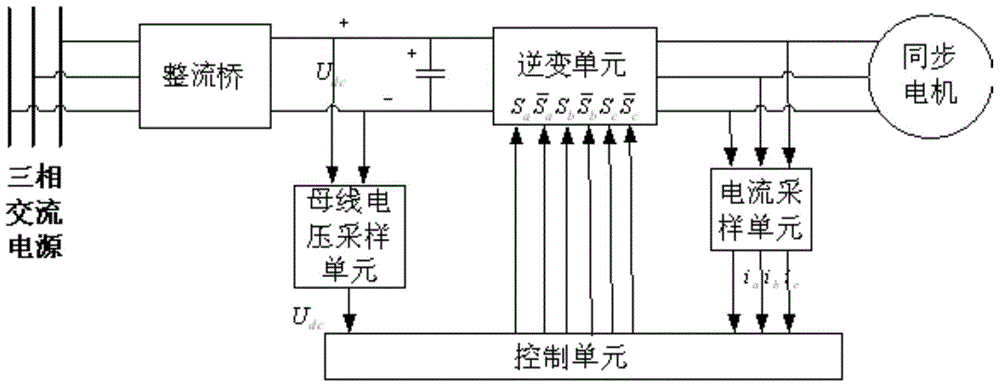

[0088] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

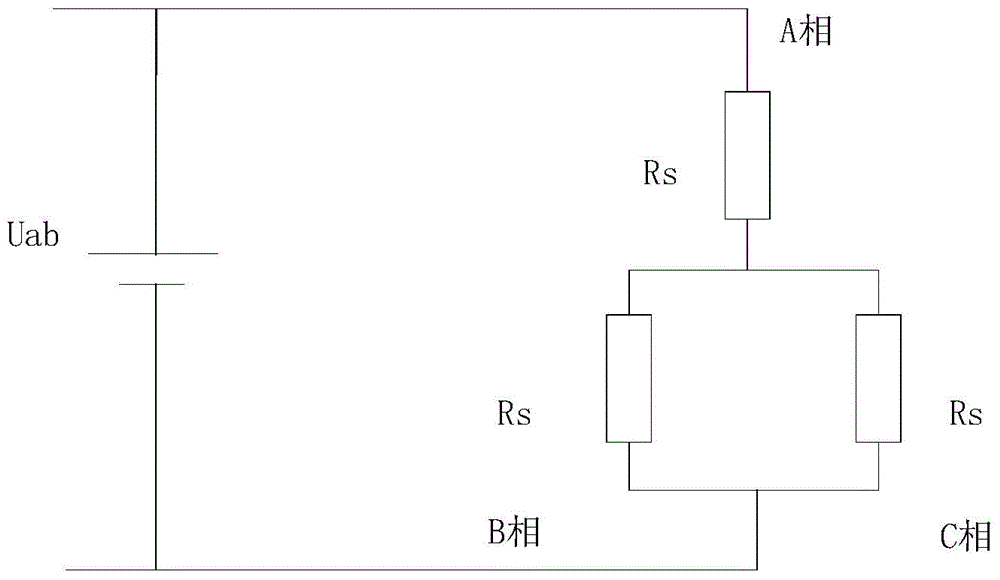

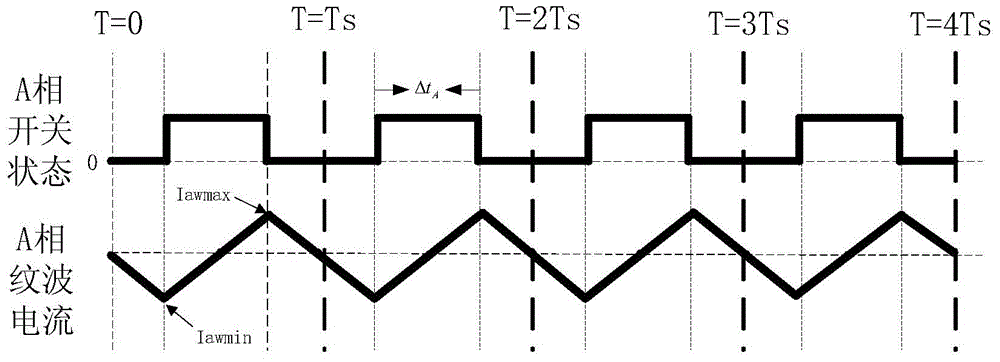

[0089] Aiming at the deficiencies in the prior art, the present invention proposes a parameter identification method for permanent magnet synchronous motors. The method first inputs a current or voltage pulse vector in the same direction as the motor stator A-phase axis to the permanent magnet synchronous motor, thereby controlling the positioning of the motor. On the d-axis, a voltage excitation signal with an average voltage of zero and non-zero voltage pulses is input between phase B and phase C of the permanent magnet synchronous motor at the same time; and then according to the rise of the ripple current generated by the three-phase current and the falling slope, calculate the direct axis and quadrature axis inductance, and calculate the stator resistance according to the d-axis d-axis dc component and d-axis dc current and voltage in steady state. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com