Device and method used for measuring deformation of diamond anvil under high temperature high pressure condition

A diamond anvil, high temperature and high pressure technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

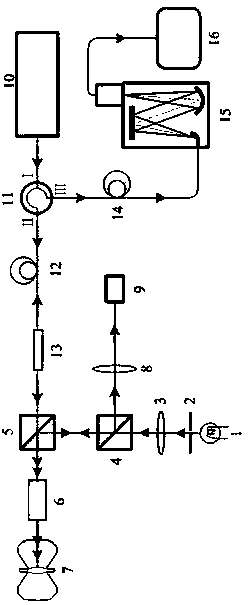

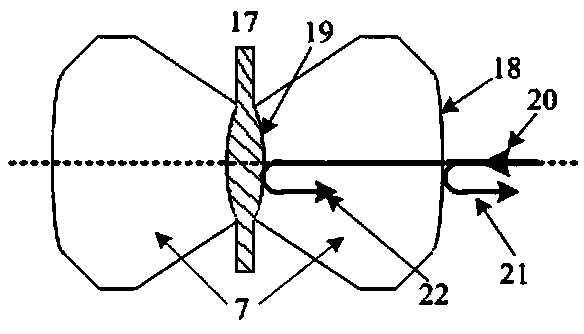

[0079] The implementation steps of the device for measuring the deformation of the diamond anvil under extreme high temperature and high pressure:

[0080] The first step is to turn on the lighting source 1, adjust the relative positions of the small hole 2, the first lens 3 and the lighting source 1, so that the emitted lighting light is parallel light;

[0081] The second step is to adjust the position and posture of the first broadband beam splitter 4 and the second broadband beam splitter 5, so that the emitted illumination light is parallel to the optical table, place an alternative plane reflector at the position of the diamond anvil 7, and make The reflective surface is perpendicular to the optical axis, and the light reflected back from the first broadband beam splitter 4 is used to adjust the second lens 8 and the charge-coupled detector 9;

[0082] In the third step, the microscopic objective lens 6 is added, and the attitude of the microscopic objective lens 6 is ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com