Semi-trailer positioning and measuring system

A positioning measurement, semi-trailer technology, applied in the direction of measuring devices, measuring instruments, automobile tire testing, etc., can solve problems such as misalignment, beam deformation, and the inability to effectively ensure the accuracy of positioning measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

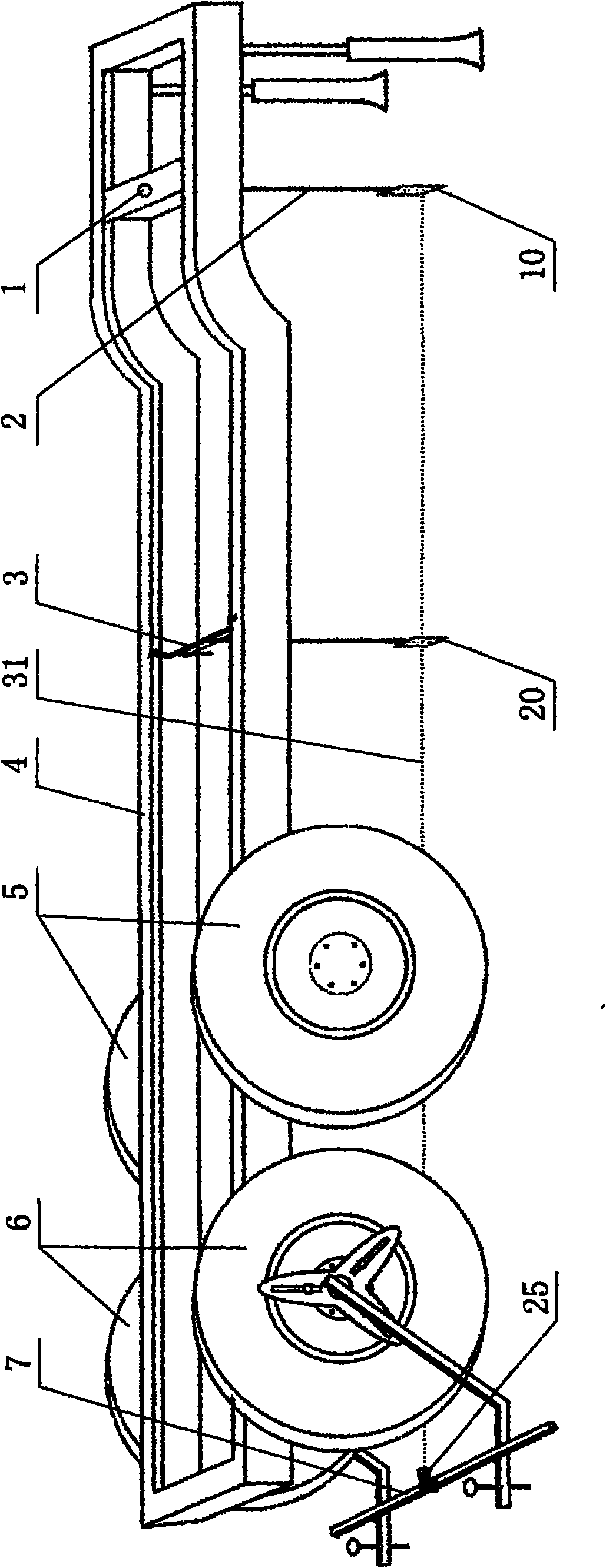

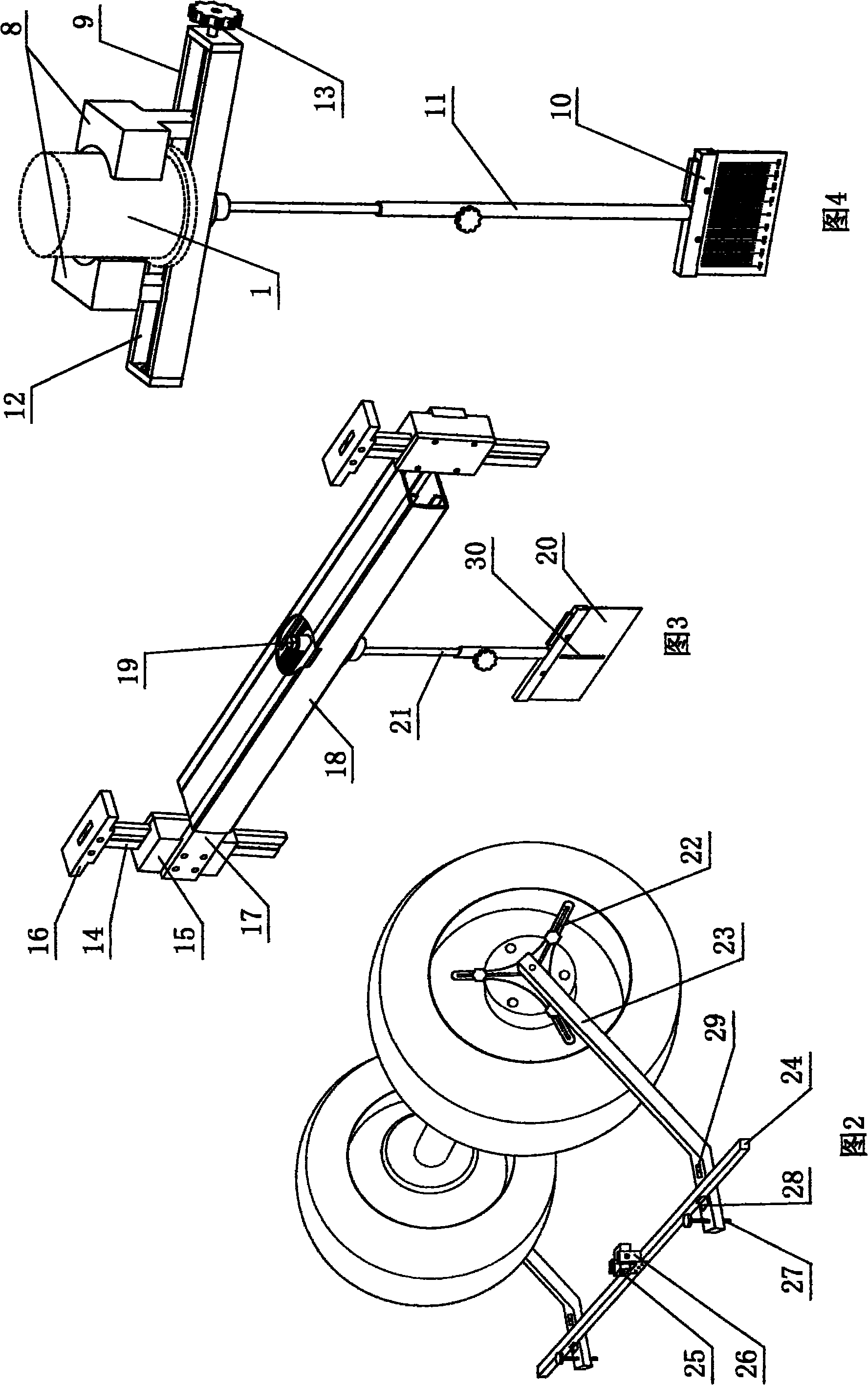

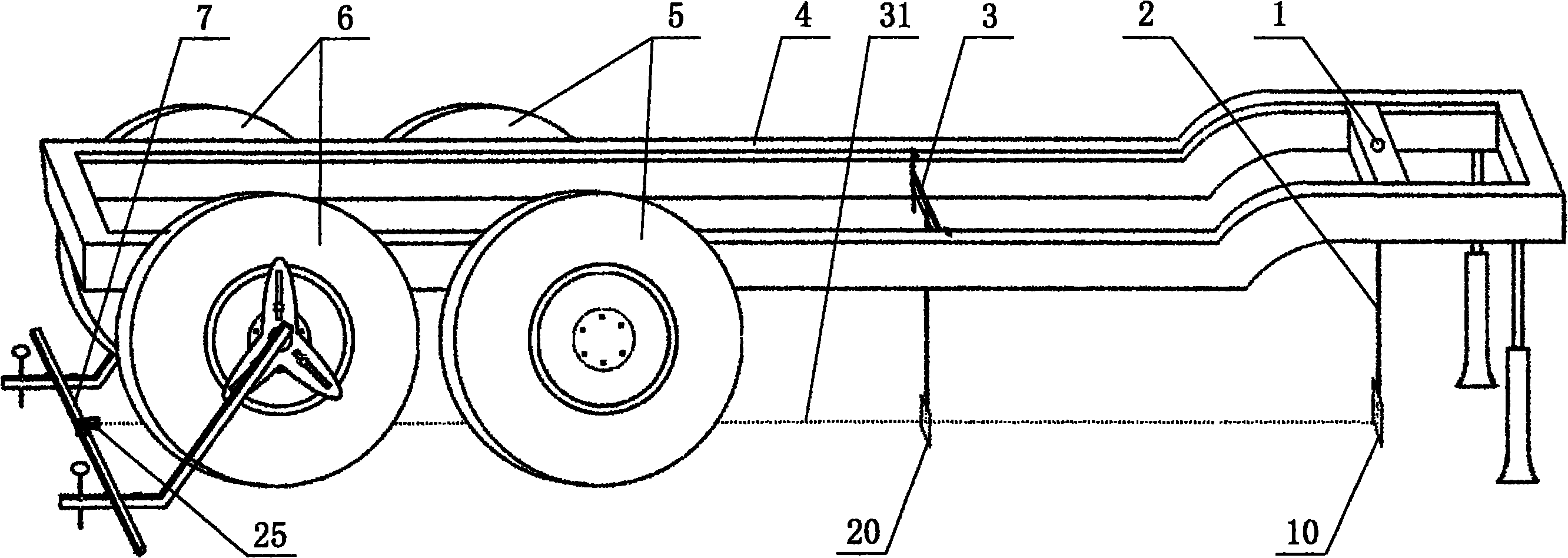

[0011] figure 1 In, a semi-trailer positioning measurement system, which includes a traction shaft centerline clamp 2, a beam center point clamp 3, and a tire center positioning device 7. As shown in Figure 4, the traction shaft centerline clamp 2 includes a pair of shaft holding chucks 8, a base 9, a scale plate 10, and a height adjustment mechanism 11. The base 9 is provided with a groove 12, and the groove 12 is equipped with threads. The threaded shaft is divided into two parts. The thread on one part is symmetrical with the thread on the other part. One end of the threaded shaft is set on the inner wall of one side of the groove 12 through a bearing, and the other end of the threaded shaft is set on the concave through another bearing. On the inner wall of the other side of the groove 12 and passing through the inner wall to connect with the outer handle 13, the lower part of the pair of shaft holding chucks 8 are respectively provided with threaded holes, and the two threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com