High-precision seawater sound velocity measuring method based on optical frequency comb interference

A technology of optical frequency comb and measurement method, which is applied in measurement devices, measurement of propagation speed, measurement of ultrasonic/sonic/infrasonic waves, etc., can solve the problems of transmission signal interference, error, and difficulty in ensuring that the ultrasonic travel distance is strictly consistent with the calibration distance, etc. Achieve the effect of high-precision data assurance, high stability, and fast sound velocity profile measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

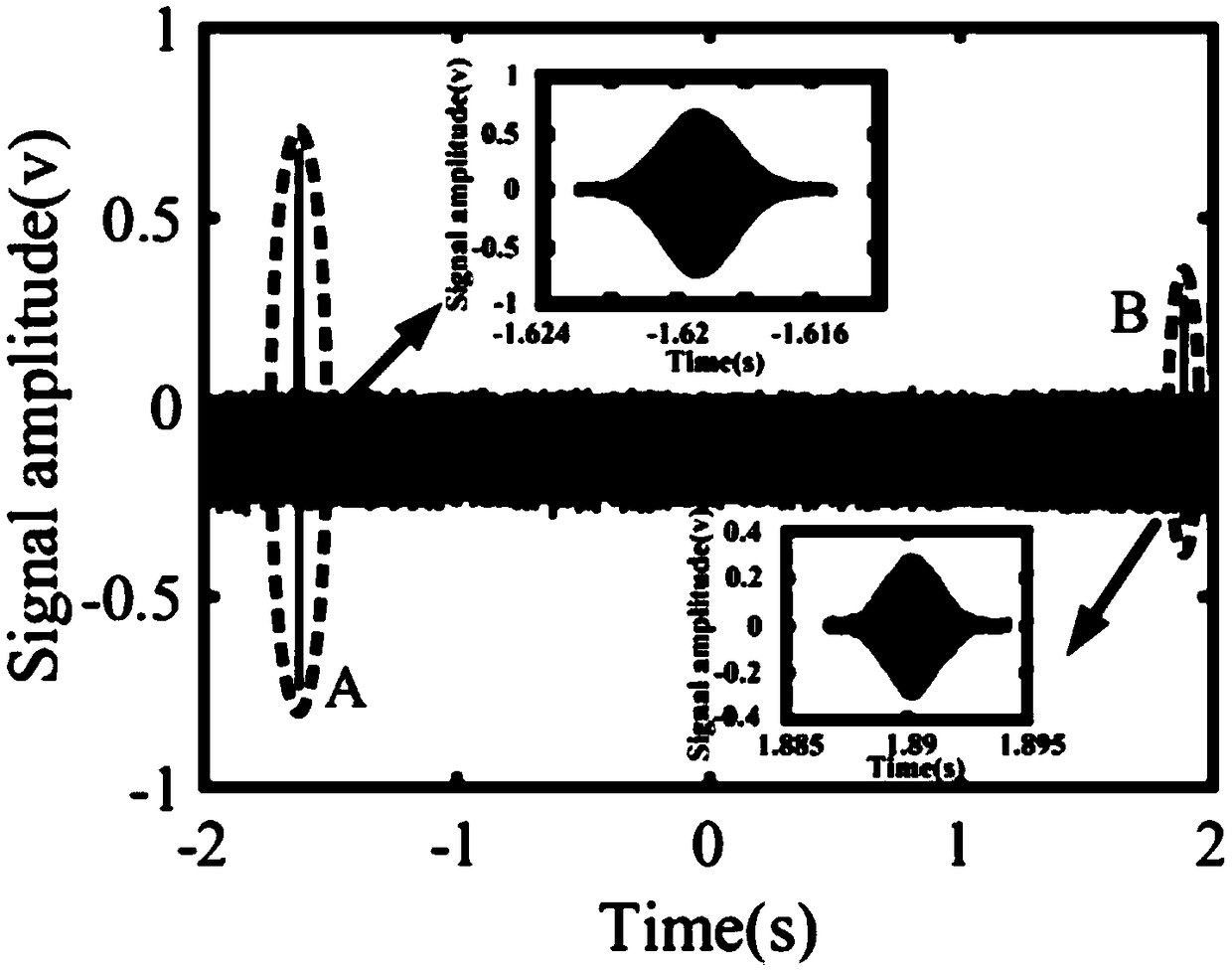

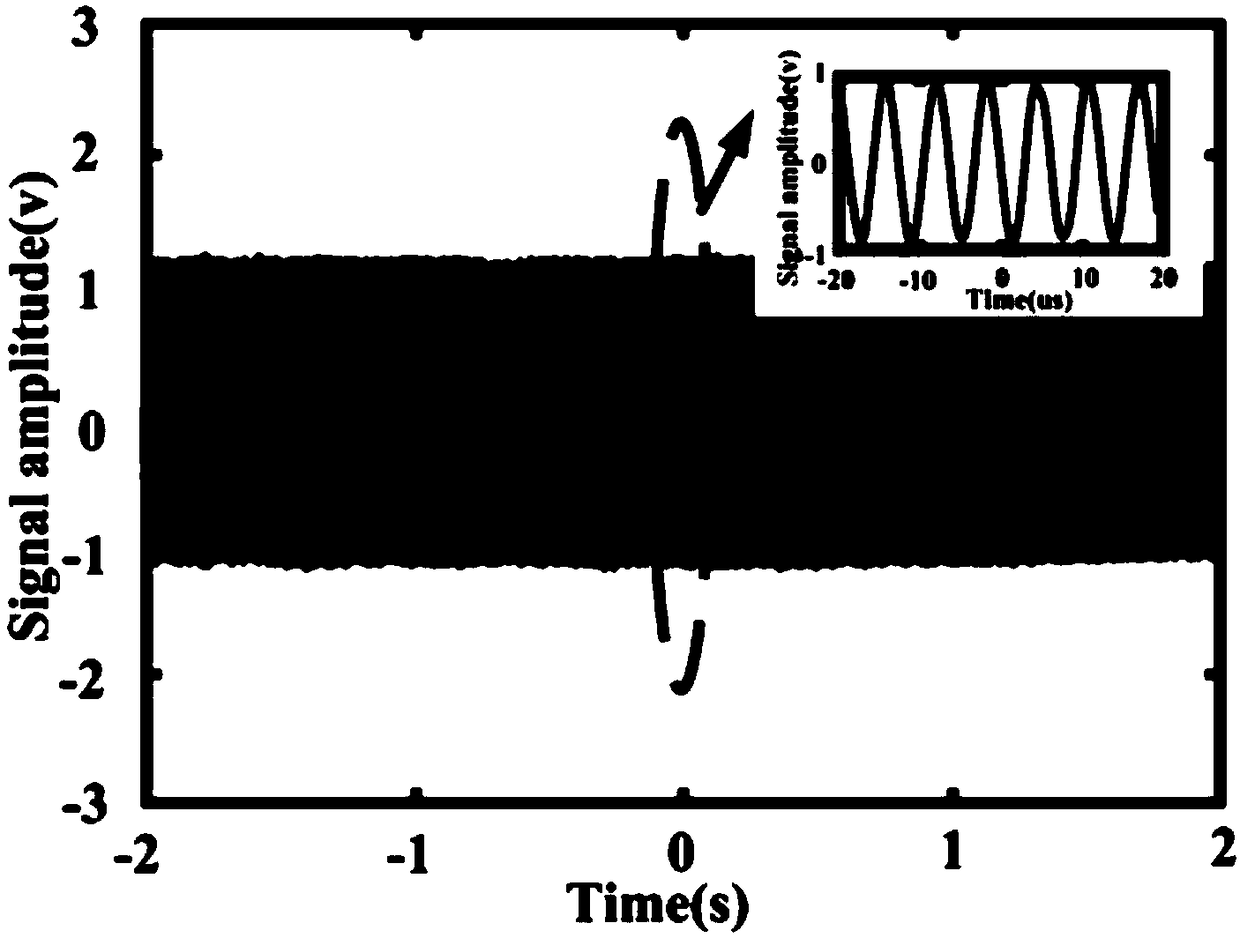

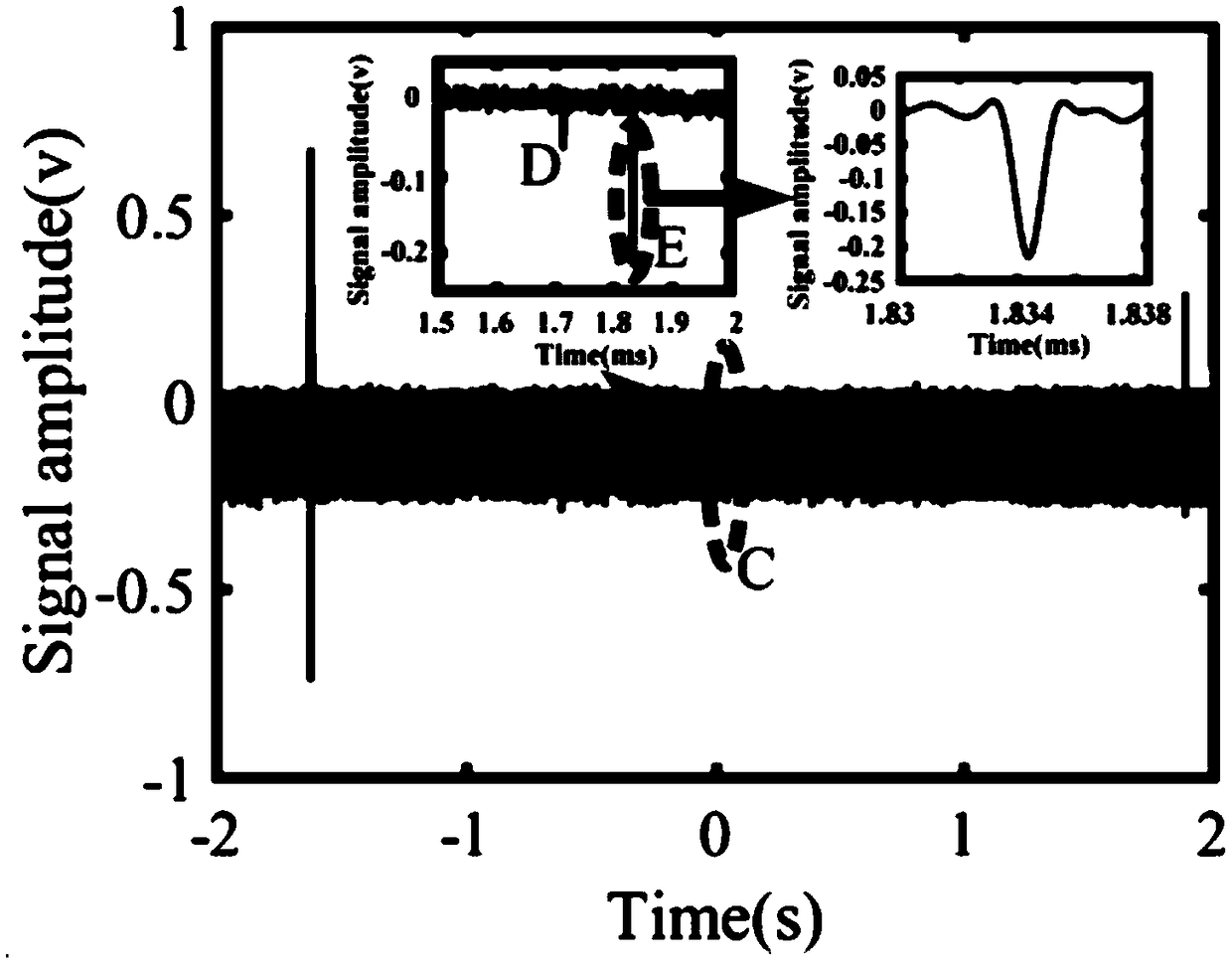

[0055] The embodiment of the present invention introduces a new method for detecting the seawater sound velocity profile based on the principle of acousto-optic effect and continuous light interferometry distance based on the good properties of optical frequency comb interference and obvious phenomena, the purpose is to achieve high precision , high stability, fast seawater sound velocity profile measurement, see image 3 , Figure 4 . The method includes the following steps:

[0056] 101: First, use the first beam splitter 2 to split the femtosecond laser emitted by the optical frequency comb 1 into two vertical beams, and then use the second beam splitter 3 to split the transmitted light passing through the first beam splitter 2 into vertical first beams. Beam of light 3-1, second beam of light 3-2. And the first light 3-1 becomes the first emitted light 3-3 after passing through the first reflector 4, and the first reflected light 3-3 becomes the second emitted light 3 p...

Embodiment 2

[0068] Combine below image 3 , Figure 4 The specific implementation method of seawater sound velocity profile measurement provided by the embodiment of the present invention is described in detail.

[0069] The embodiment of the present invention is based on optical frequency comb interference and acousto-optic effect, and the optical path design is as follows image 3 As shown, the measurement steps are as Figure 4 As shown, the entire method is as follows:

[0070] Step 201: Build a measurement optical path according to the optical path diagram;

[0071] Step 202: Make the precision displacement platform 14 continuously move so as to change the optical path of the interference optical path 24 and the first reflection optical path 27;

[0072] Step 203: Turn on the ultrasonic probe 6, adjust the ultrasonic probe 6 to ensure that the ultrasonic wave passes through the two parallel lights vertically, and collect the measurement data of the oscilloscope;

[0073] Step 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com