Whole-pneumatic air burst fire extinguishing bomb

An aerial explosion and all-pneumatic technology, which is applied in the field of fire extinguishing bombs, can solve the problems of blowing out the bottle cork, not being able to automatically realize the rotation and start of the control piece, and not being able to be used in simple combination, so as to achieve high throwing accuracy, convenient mobility, and easy use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

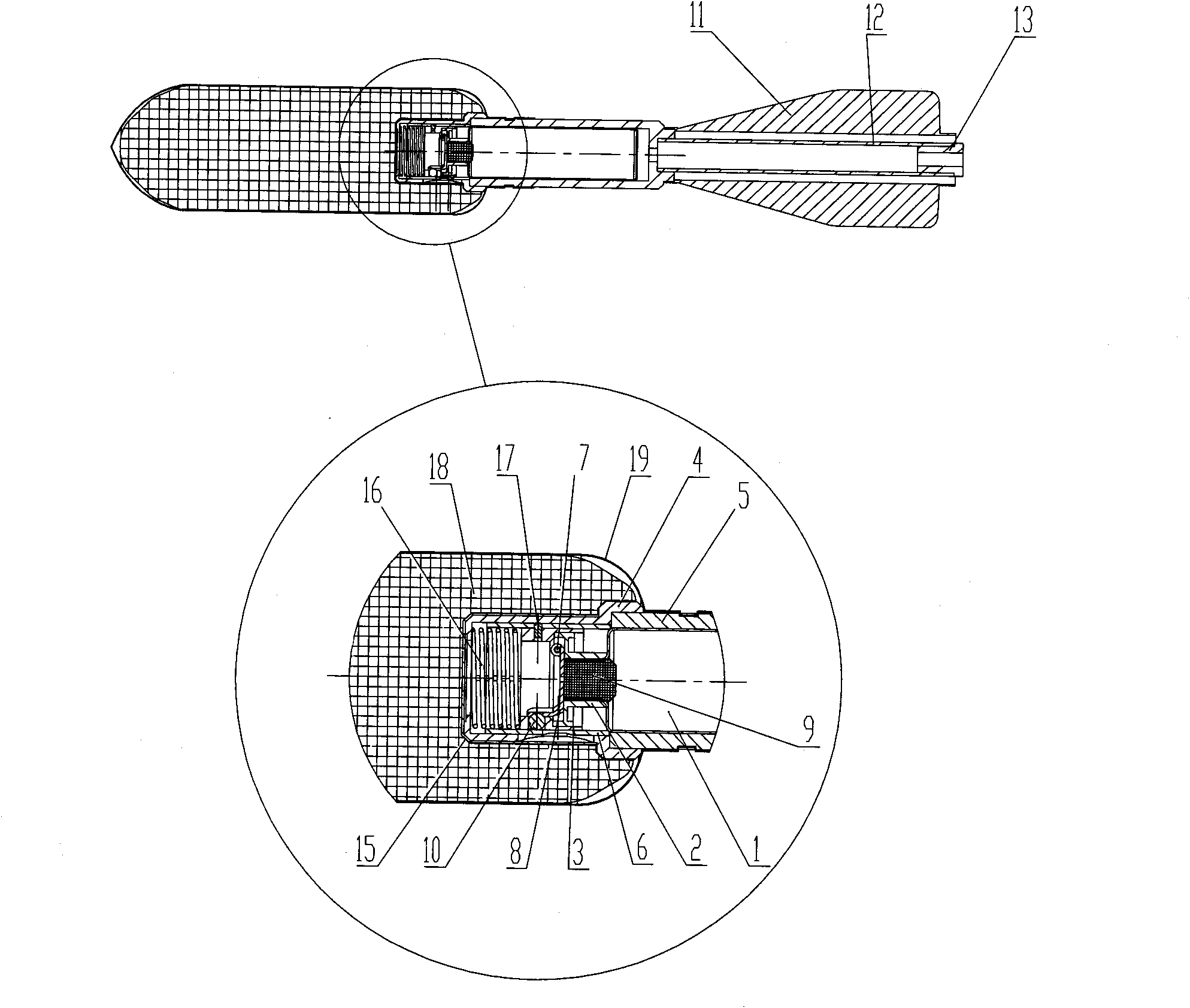

[0037] Such as figure 1 As shown, the all-pneumatic air explosion fire extinguishing bomb is equipped with high-pressure gas cylinder 1, stopper 9, gas cylinder fixing part 2, control piece 8, shaft 7, steel ball 10, starter 3, control sleeve 6, and shear pin 17. , Spring 16, delayed detonator shell 4, gas cylinder shell 5, push tube 12, tail cover 13, tail wing 11, fire extinguishing agent 18 and cartridge case 19, etc.

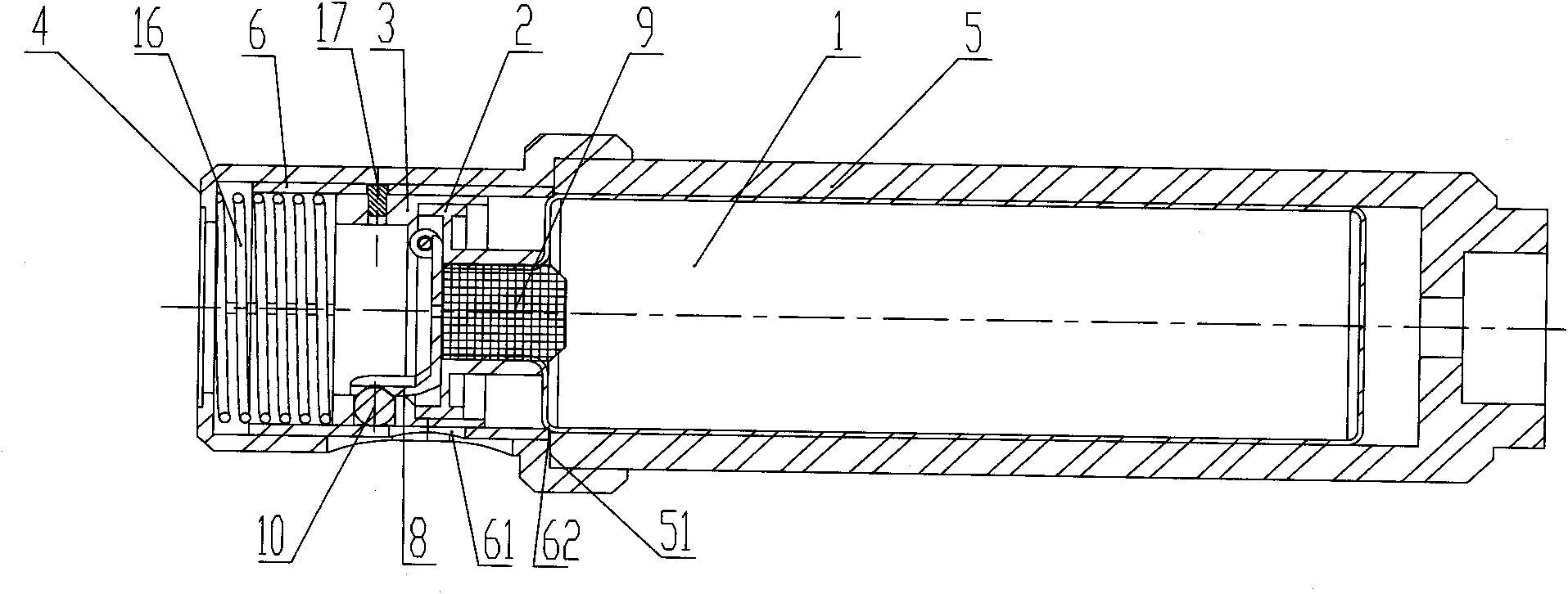

[0038] Such as figure 2 As shown, in standby, the starter 3 and the control sleeve 6 are connected as a whole through the shear pin 17. Under the action of the pre-compression force of the spring 16, the end surface 62 of the control sleeve 6 abuts against the end 51 of the gas cylinder sleeve 5. , In a safe state to be used. At this time, the starter 3 and the corresponding shear pin 17 holes of the control sleeve 6 are coaxial, and the steel ball sliding hole 61 opened on the control sleeve 6 deviates to the side of the high-pressure gas cylinder 1 relative ...

Embodiment 2

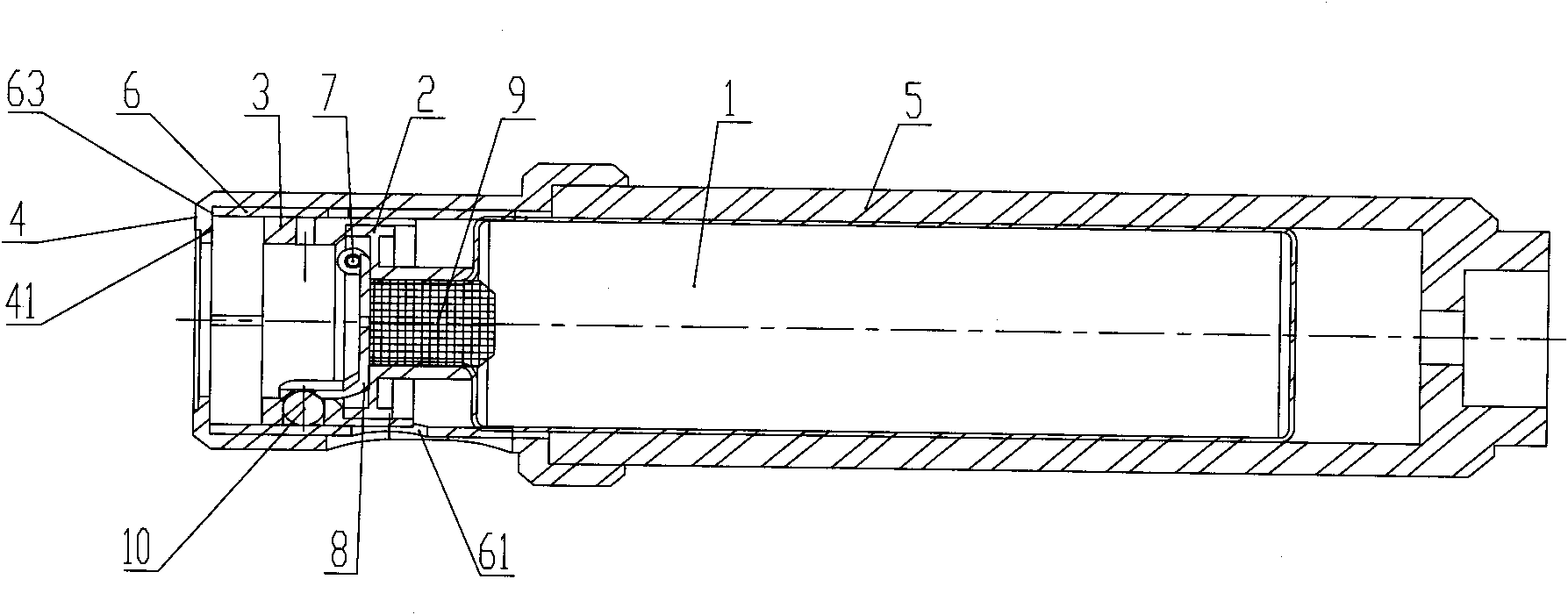

[0042] Example 2, such as Figure 5 As shown, it is similar to Embodiment 1, and the difference is that when the fire extinguishing bomb is launched by high-pressure gas, the launched high-pressure gas applies force to the bottom of the high-pressure gas cylinder 1 through the push rod 14, thereby controlling the high pressure in the projectile. When the air is delayed for detonation, the push rod 14 cooperates with the push tube 12. In the standby position, the force end of the push rod 14 is lower than the end surface of the tail cover 13 to prevent accidental triggering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com