Mechanical pressure machine electronic control method and electronic cam control device

A mechanical press and electronic control technology, applied in the field of mechanical press, electronic control method of mechanical press and electronic cam controller, can solve the problem of lack of human-machine interface, inability to monitor the performance of pneumatic clutch friction plates, and inability to meet the high efficiency of stamping production , safety and other issues, to achieve the effect of reducing manual adjustment work, reducing the number of components, and improving the level of automation and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

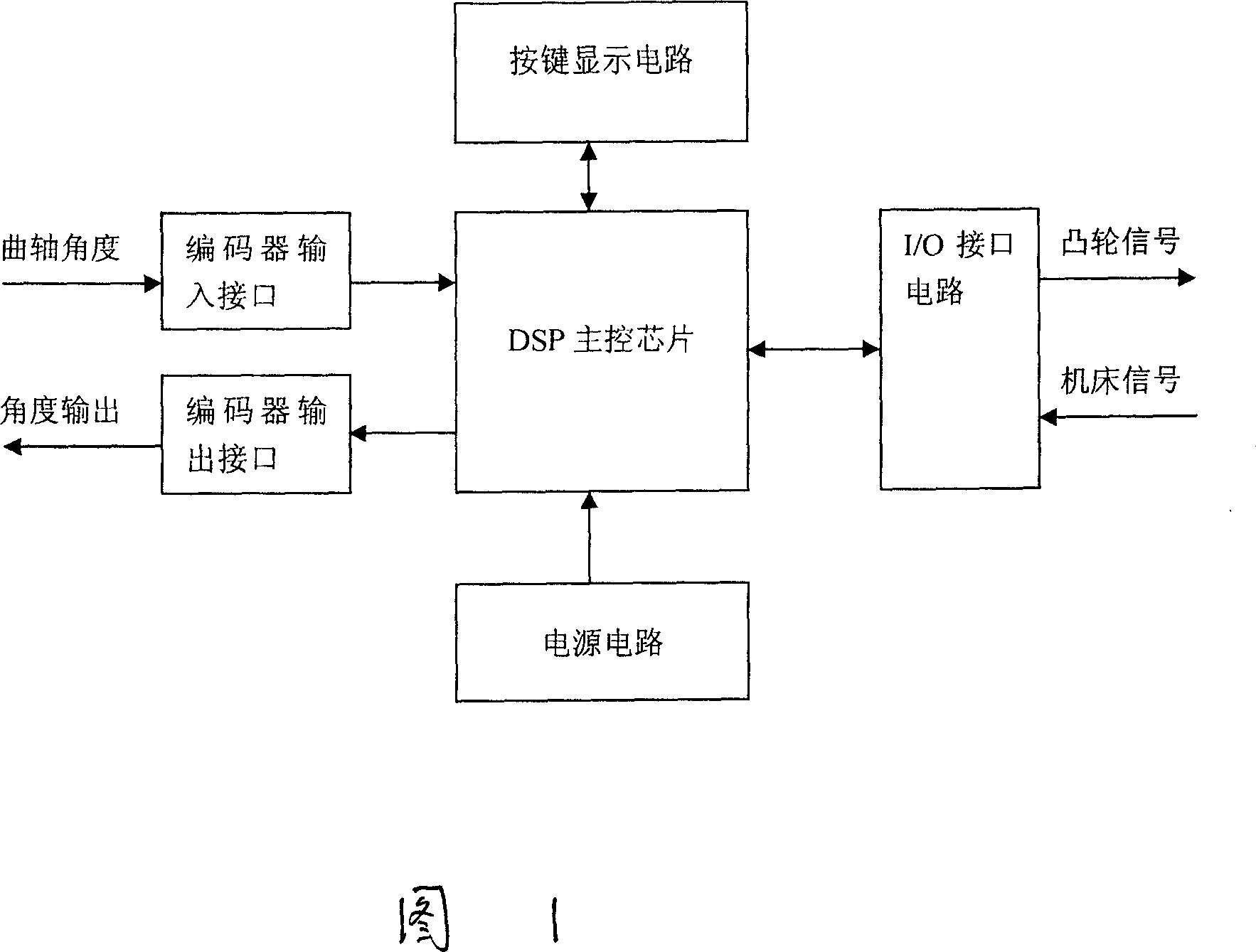

[0026] As shown in Figure 1, the electronic cam controller is composed of a button display circuit, a DSP main control chip, an I / O interface circuit, an encoder input interface circuit, an encoder output interface circuit, and a power supply circuit. The button display circuit is used to display crankshaft angle and speed, production count, braking distance, alarm prompt and other information as well as user input parameters. The encoder signal is sent to the DSP main control chip through the encoder input circuit, which is convenient for the program processing of the DSP chip, and outputs the cam signal, clutch brake signal, etc. The I / O signal of the machine tool is sent to the DSP main control chip through the I / O interface circuit, and it is also the channel for the output of the cam signal. The power supply circuit supplies the required voltage to the controller. Among them, the DSP main control chip stores the control program to realize the control of the press.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com