Turbidity Flow Cell

A flow cell and turbidity technology, which is applied in the field of flow cells, can solve the problems of poor sealing performance of flow cells, bubbles generated in flow cells, and inaccurate measurement of instruments, etc., and achieves the effects of good structural sealing, increased accuracy, and enhanced drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

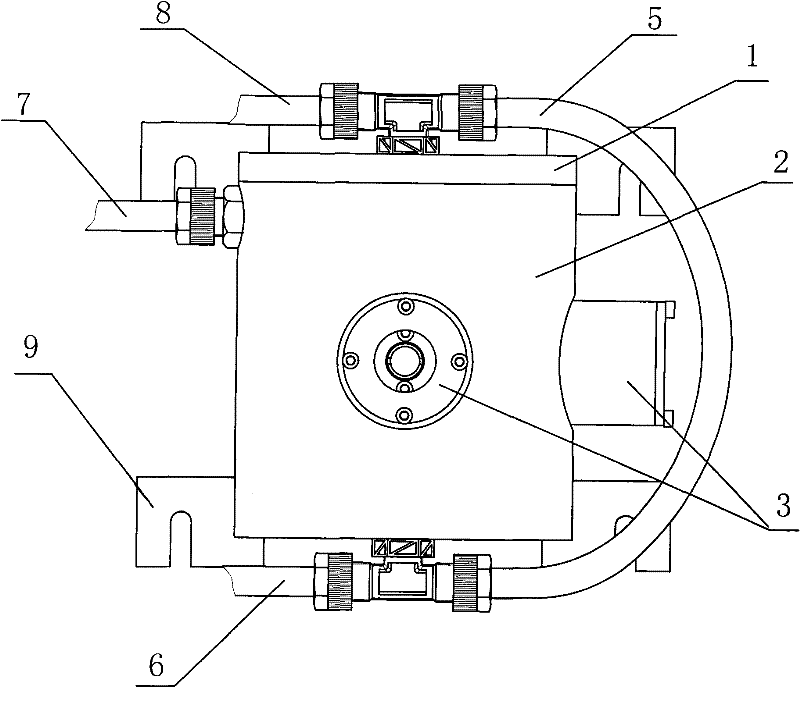

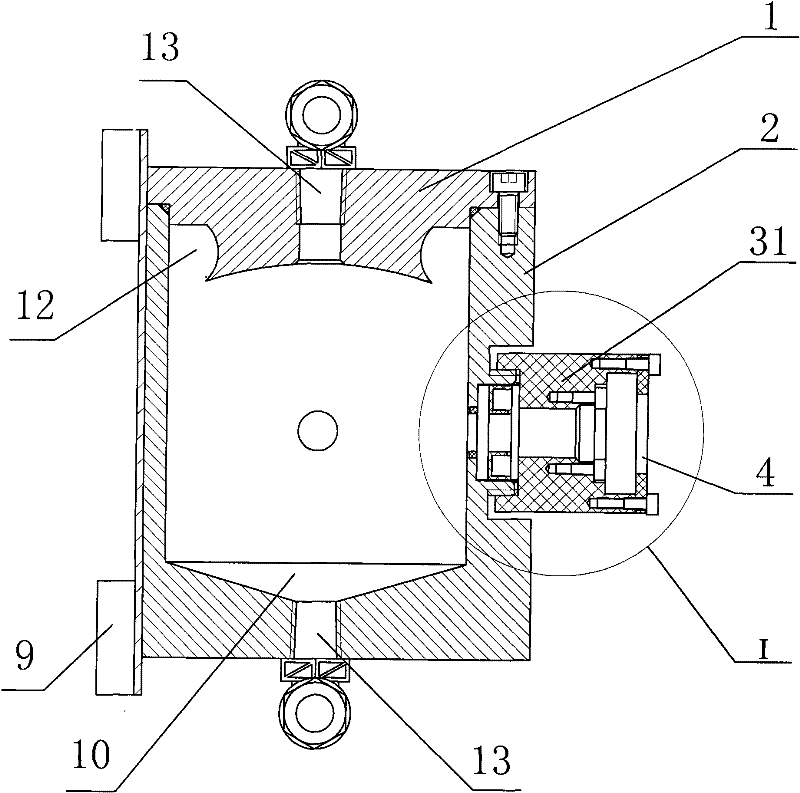

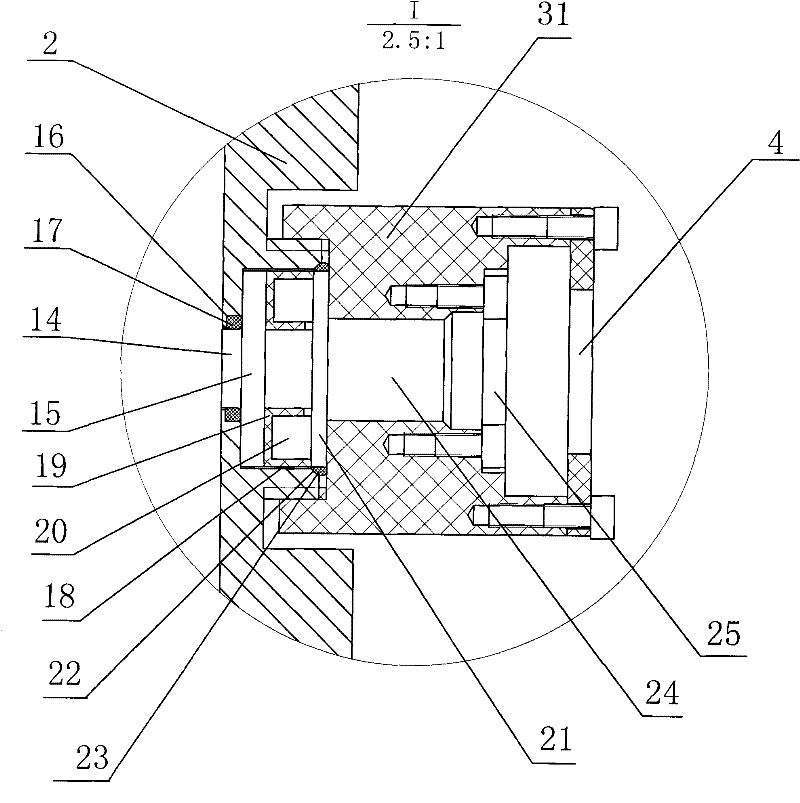

[0037] Preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings. figure 1 It is the front view of the turbidity flow cell of the present invention, figure 2 for figure 1 Longitudinal sectional view of the turbidity flow cell, image 3 for figure 2 Partial enlarged view of I, Figure 4 for figure 1 top view of Figure 5 It is a top view of the turbidity flow cell cover of the present invention, Figure 6 for Figure 5 side sectional view of Figure 7 It is a cross-sectional view of the base of the flow cell body when the transmitter / receiver housing is not installed, Figure 8 for Figure 7 Partial enlarged view of I, Figure 9 is the sectional view of the transmitter / receiver housing, Figure 10 is the side view of the stepped plane lens, Figure 11 for Figure 10 top view of Figure 12 is the side view of the drying box, Figure 13 for Figure 12 top view.

[0038] The invention provides a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com