Supersonic spiral bladeless dust collection device suitable for coal mine transfer point

A technology of dust collecting device and transfer point, which is applied in the direction of safety device, dust prevention, mining equipment, etc., can solve the problems of inability to effectively capture respirable dust, large fog volume of atomization device, and fragile atomization device, etc. Daily inspection and maintenance, easy to use, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below with reference to the accompanying drawings and through specific embodiments.

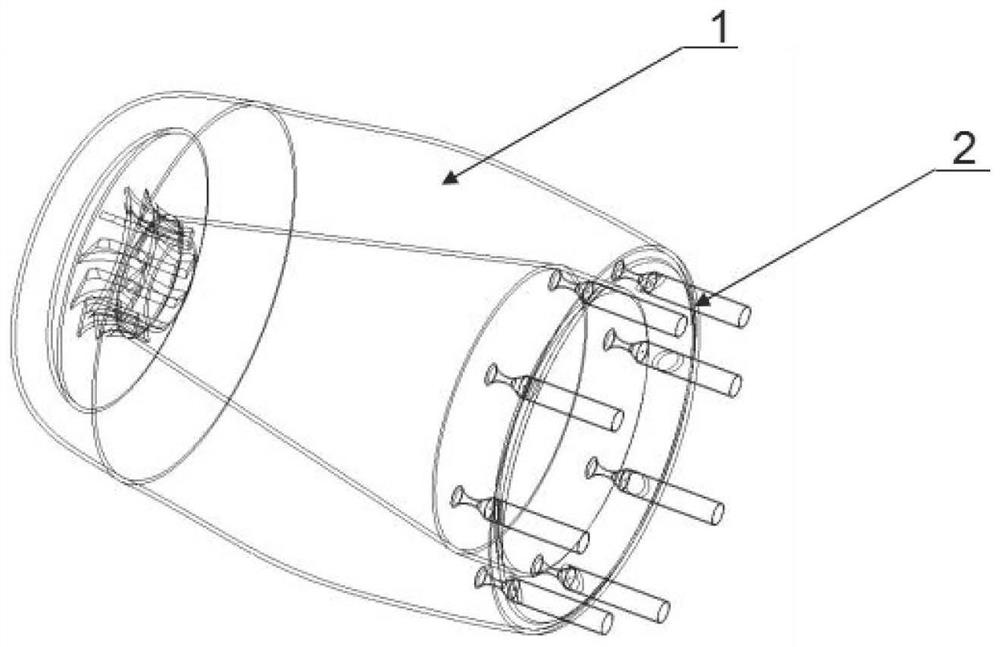

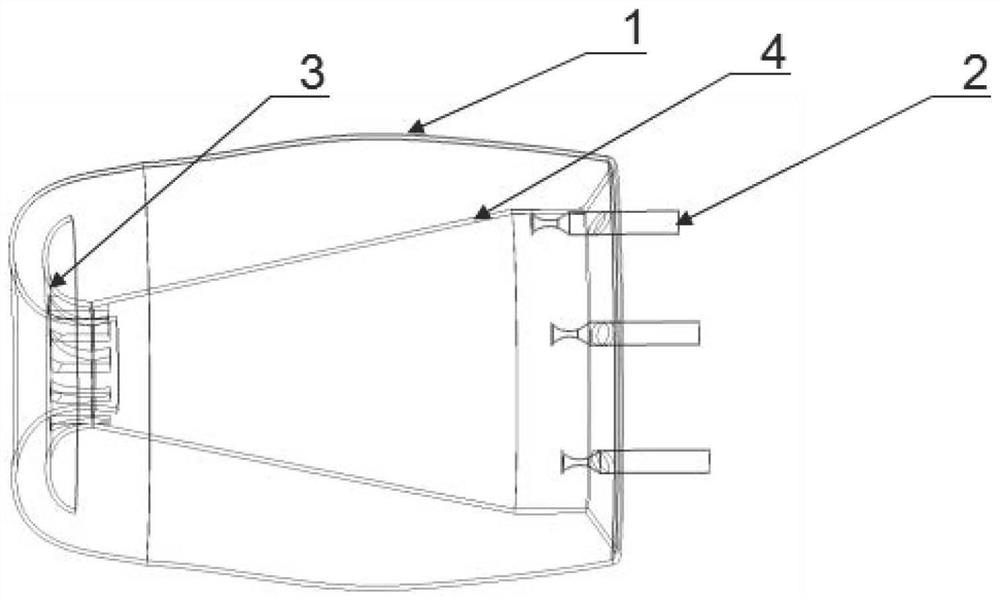

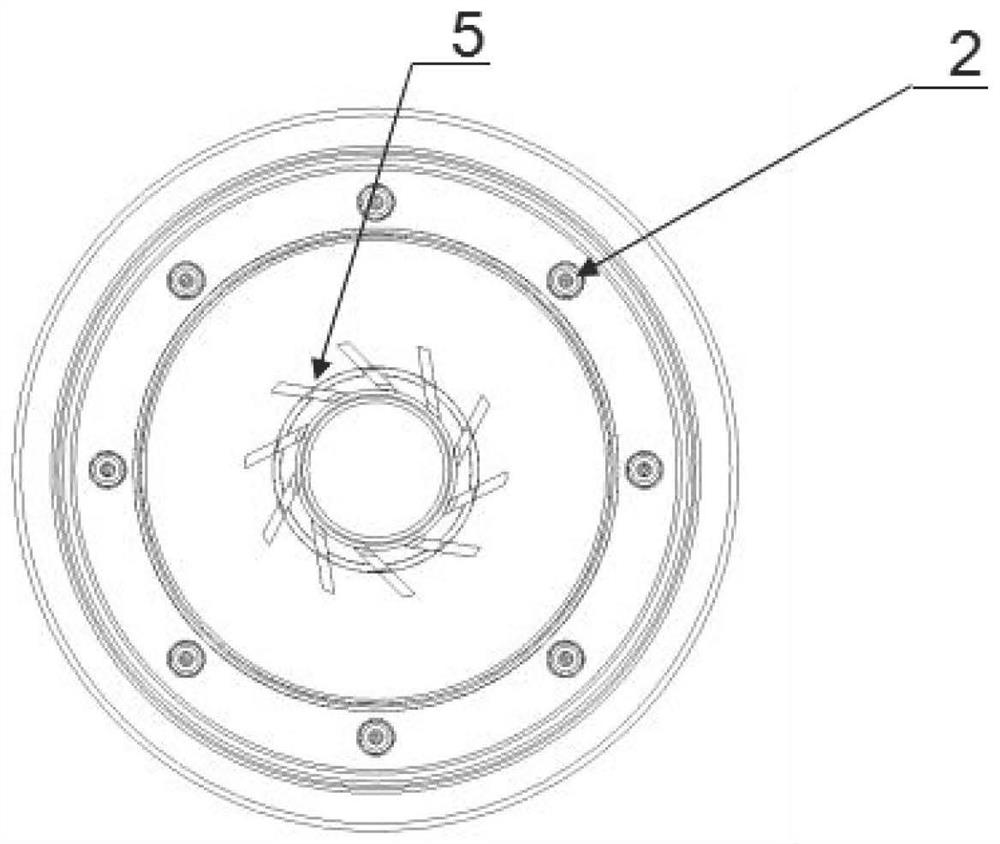

[0023] like Figures 1 to 4 As shown in the figure, a supersonic spiral bladeless dust collector suitable for a coal mine transfer point includes an outer casing 1, an inner casing 4, a Laval supersonic airflow generation device 2, a wind flow reversal acceleration device 3, and a spiral airflow generation device 5. ; The inner shell 1 and the outer shell 4 form a hollow cylindrical cylindrical structure, and the outer shell 1 and the front end of the inner shell 4 are connected with 8 devices for installing the Lava tube supersonic airflow generating device 2. Internal thread hole, this hole is regarded as the first air inlet. At the connection between the outer casing 1 and the rear end of the inner casing 4, the cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nozzle diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com