Steel pipe concrete column variable section broken-line-shaped steel bracket and connecting construction method thereof

A technology of concrete-filled steel tubular columns and broken lines, which is applied in the direction of construction and building structure, can solve the problems of difficulty in controlling the concrete pouring density of steel anchoring quality, affecting the structural safety, and the collapse of the structural system, so as to ensure the pouring quality and guarantee The effect of improving construction quality and anchoring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

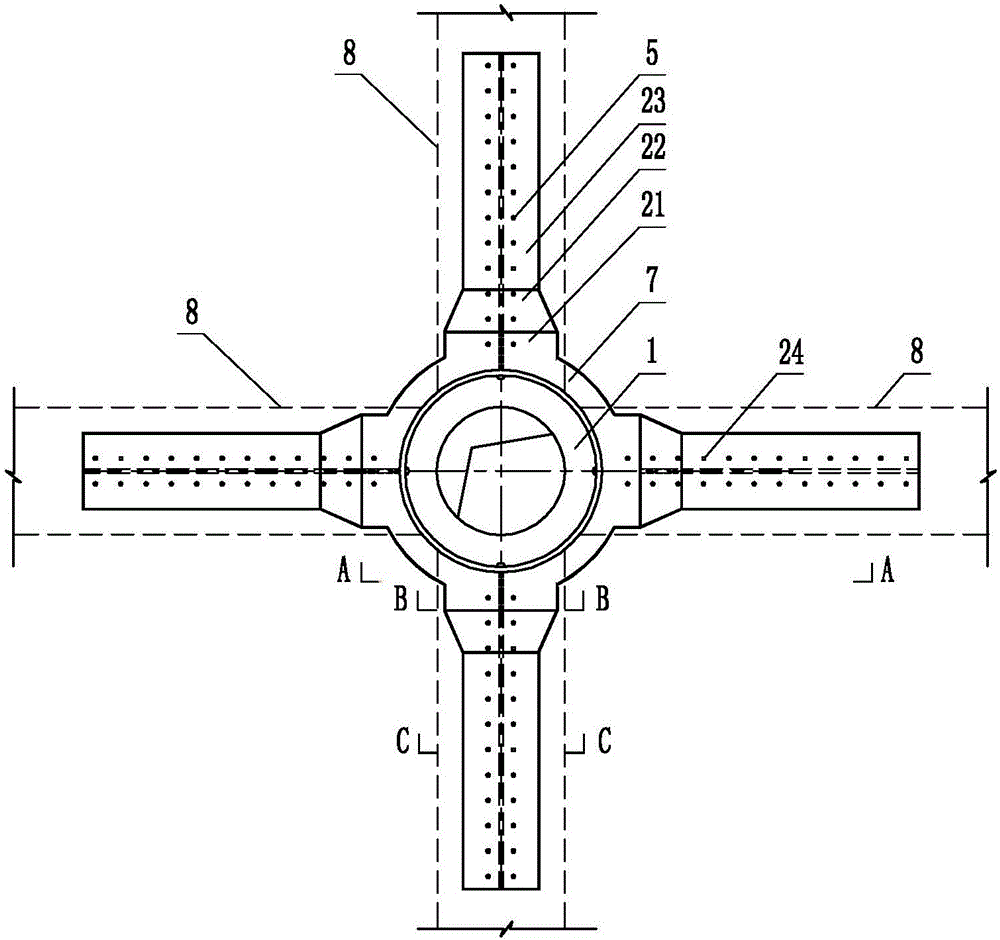

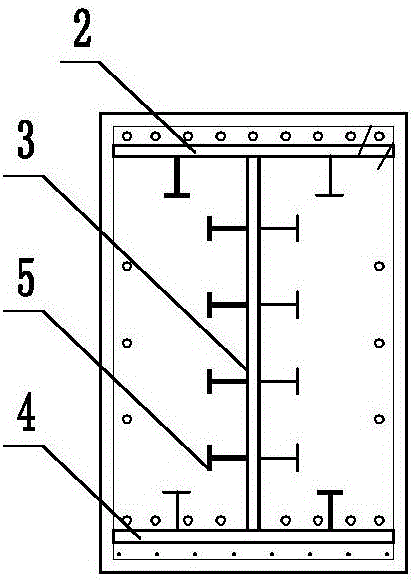

[0058] A steel corbel with a variable cross-section broken line steel pipe concrete column, comprising an upper flange plate 2 and a lower flange plate 4, and a web 3 vertically connected between the upper flange plate and the lower flange plate, the web is located on the upper On the center line of the flange plate and the length direction of the lower flange plate;

[0059] The upper flange plate and the lower flange plate have the same structure, including two sections of the flange plate and one transition section, and the two sections of the flange plate are connected by an inclined transition section, thereby forming a broken line two-layer structure: the first The first floor is connected to the second section (the second floor) through the transition section; the elevation of the flange plate of the second floor is lower than that of the first floor, and the width is smaller than that of the first floor. The height difference between the flange plates of the two floors ...

Embodiment 2

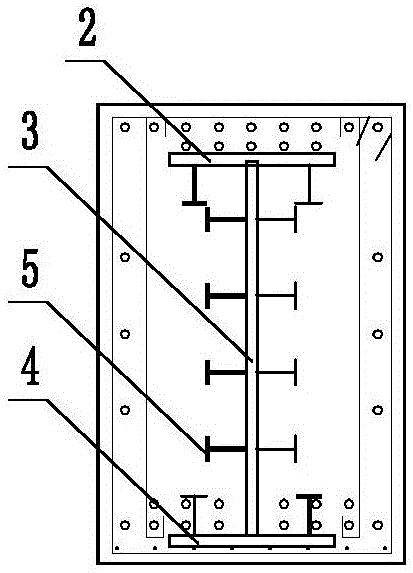

[0064] A steel corbel with a variable cross-section broken line steel pipe concrete column, comprising an upper flange plate 2 and a lower flange plate 4, and a web 3 vertically connected between the upper flange plate and the lower flange plate, the web is located on the upper On the center line of the flange plate and the length direction of the lower flange plate;

[0065] The upper flange plate and the lower flange plate have the same structure, including 3 sections of flange panels and 2 sections of transition sections, and the adjacent two sections of flange panels are connected by an inclined transition section, thus forming a three-layer structure in the shape of a broken line : The first section, that is, the first layer, is connected to the second section, that is, the second layer, through the transition section, and the second section, that is, the second layer, is connected to the third section, that is, the third layer, through the transition section;

[0066] Th...

Embodiment 3

[0069] A construction method for connecting a steel corbel with a variable cross-section broken line of a concrete-filled steel pipe column, the method is a construction method for connecting a steel-filled steel pipe concrete column with a broken-line steel corbel of a variable cross-section broken line described in Embodiment 1, Include the following steps:

[0070] S1: Deepening design of steel corbels with variable cross-section and broken line

[0071] According to the beam longitudinal reinforcement drawings, use AutoCAD, explorer TSSD, TeklaStructures and Revit software to combine 2D and 3D software to loft and model the design drawings according to 1:1; optimize the arrangement of steel bars, and set the corresponding variable cross-section broken line steel Corbel, Steel Corbel Dimensions:

[0072] S11: Determine the number of bendings of the upper and lower flange plates and the slope of the transition section according to the number of reinforcement rows N

[0073...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com