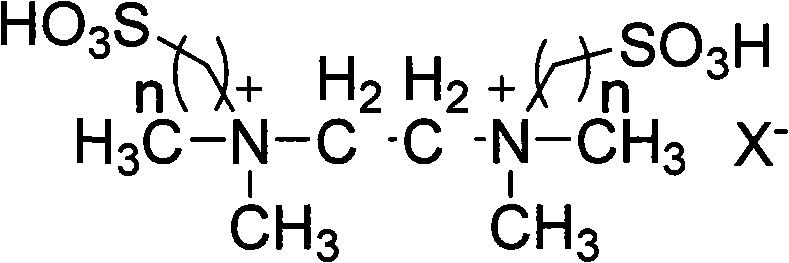

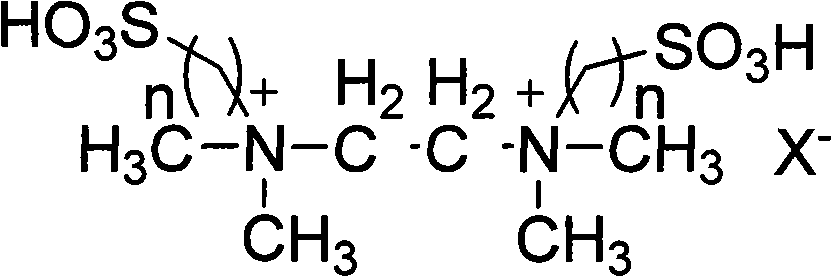

N,N,N,N-tetramethylethylenediamine sulphonate ionic liquid and preparation method thereof

A technology of tetramethylethylenediamine sulfonic acid and ionic liquid, applied in the field of N, can solve the problems of uneconomical, large loss and large usage, and achieve the effects of small loss, wide range and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

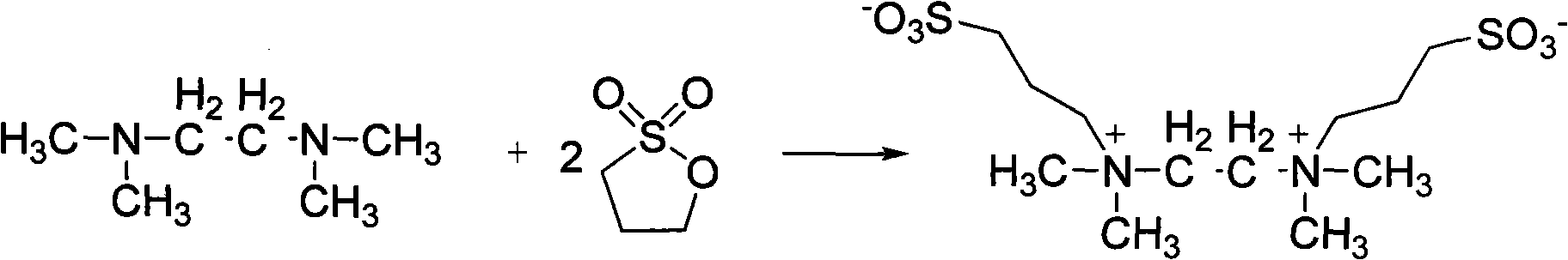

[0020] Embodiment 1: N, N, N, the preparation of N-tetramethyl-bis(3-sulfonic acid propyl) ethylenediamine ylide

[0021]

[0022] At room temperature under stirring conditions, slowly drop the mixed solution of 0.2mol 1,3-propane sultone and 30mL acetone into the mixed solution containing 0.1mol N,N,N,N-tetramethylethylenediamine and 50mL acetone, After 30 minutes, a white solid precipitated out. After 12 hours, it was filtered, and the obtained white solid was washed three times with acetone and anhydrous ether, and dried in vacuum at 50°C for 24 hours.

Embodiment 2

[0023] Embodiment 2: N, N, N, the preparation of N-tetramethyl-two (4-sulfonic acid butyl) ethylenediamine ylide

[0024]

[0025] At room temperature under stirring conditions, slowly drop the mixed solution of 0.2mol 1,4-butane sultone and 30mL acetone into the mixed solution containing 0.1mol N,N,N,N-tetramethylethylenediamine and 50mL acetone , which lasted 30min, and after 24h, filtered, and the resulting white solid was washed three times with acetone and anhydrous ether, filtered, and vacuum-dried at 50°C for 24h.

Embodiment 3

[0026] Embodiment 3: [hydrogen sulfate] [tetramethyl-two (3-sulfonic acid propyl) ethylenediamine] ionic liquid

[0027]

[0028] With 0.1mol of the N,N,N,N-tetramethyl-bis(3-sulfonic acid propyl)ethylenediamine ylide prepared in Example 1 and 0.2mol

[0029] Add concentrated sulfuric acid into a 250mL three-necked flask with a stirring bar and a condenser, react at 120°C for 24h, wash with dichloromethane three times, and then vacuum dry at 80°C for 24h to obtain viscous [hydrogen sulfate][ Tetramethyl-bis(3-sulfonic acid propyl)ethylenediamine] ionic liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com