Modified soyabean oil aqueous flexographic printing ink

A flexographic, soybean oil technology, applied in inks, printing devices, printing and other directions, to achieve the effect of improving storage and use stability, significant safety and environmental protection, storage stability and effective storage period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

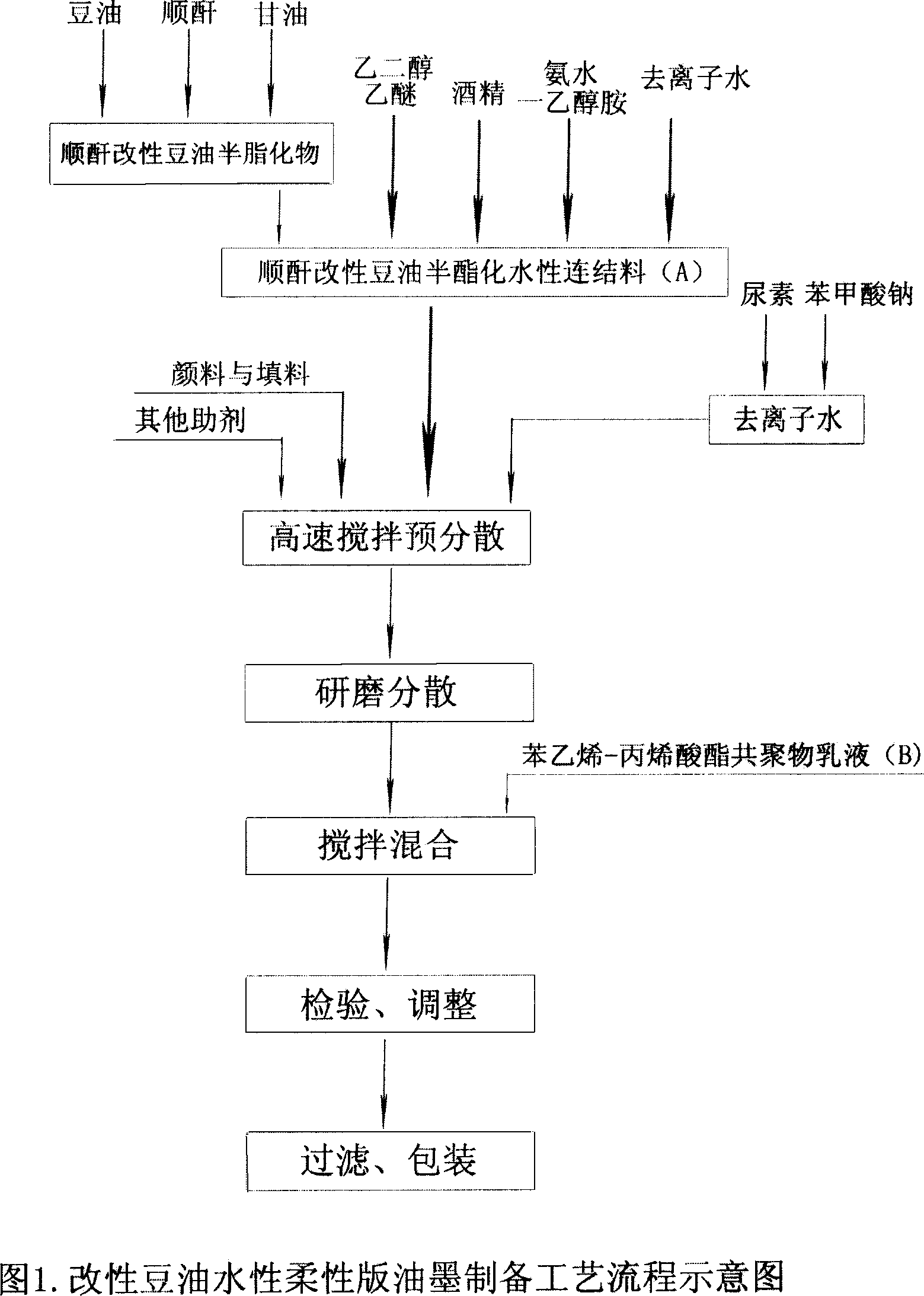

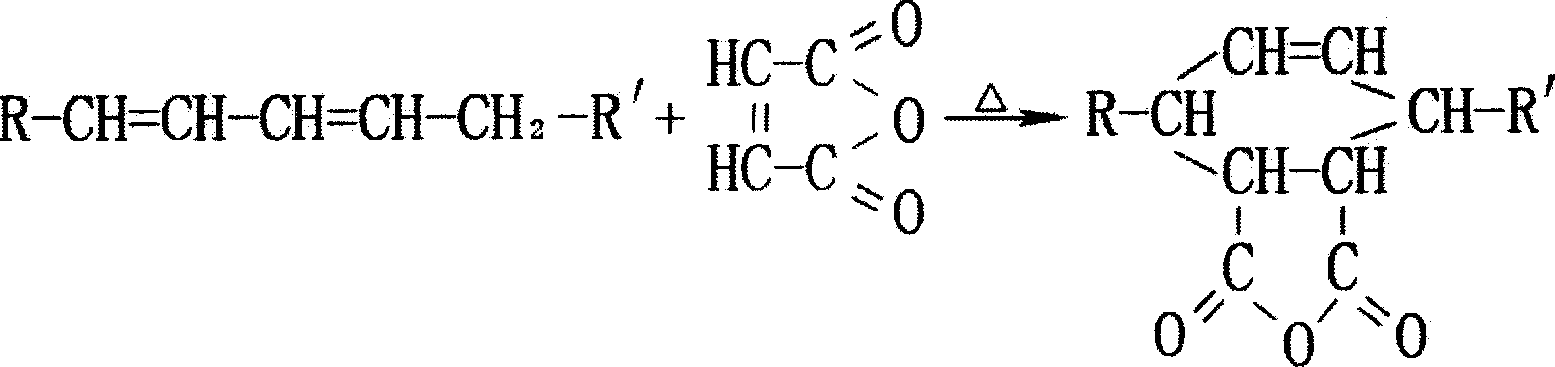

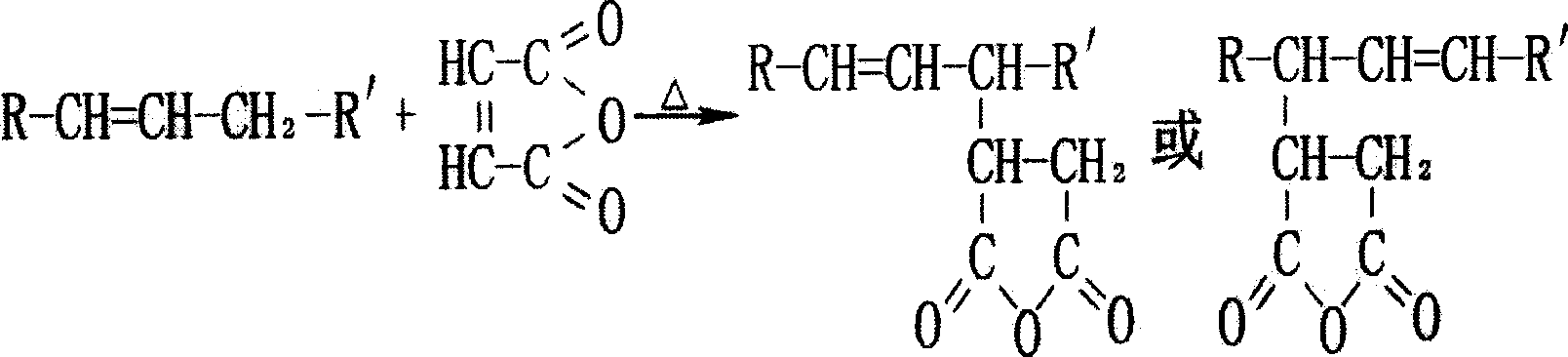

Method used

Image

Examples

manufacture example

[0046] The modified soybean oil water-based flexographic ink proposed by the present invention is mainly suitable for paper substrates. The manufacturing examples are as follows (based on mass %, see Table 4)

[0047] raw material name

Big red ink

Medium yellow ink

Sky Blue Ink

Black ink

Maleic anhydride soybean oil semi-esterified waterborne binder (A)

50.0

50.0

50.0

40.0

0.5

0.5

1.0

5.0

Sodium benzoate (preservative)

0.2

0.2

0.2

0.2

Deionized water

15.5

14.5

14.0

15.0

Antifoaming agent PI-40

0.4

0.4

0.4

0.4

Aqueous dispersant P-19

0.1

0.1

0.2

0.3

Light Fast Red BBN (P.R48:1)

11.0

Benzidine Yellow GTNS (P.Y12)

12.0

Phthalocyanine Blue BGS (PB15:3)

12.0

Drum carbon black

7.0

Carbon bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com