Method of refining and processing rosin

A technology of refining treatment and rosin, applied in the direction of natural resin refining, etc., can solve the problems of large investment and energy consumption, and achieve the effects of less equipment investment, simple steps and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

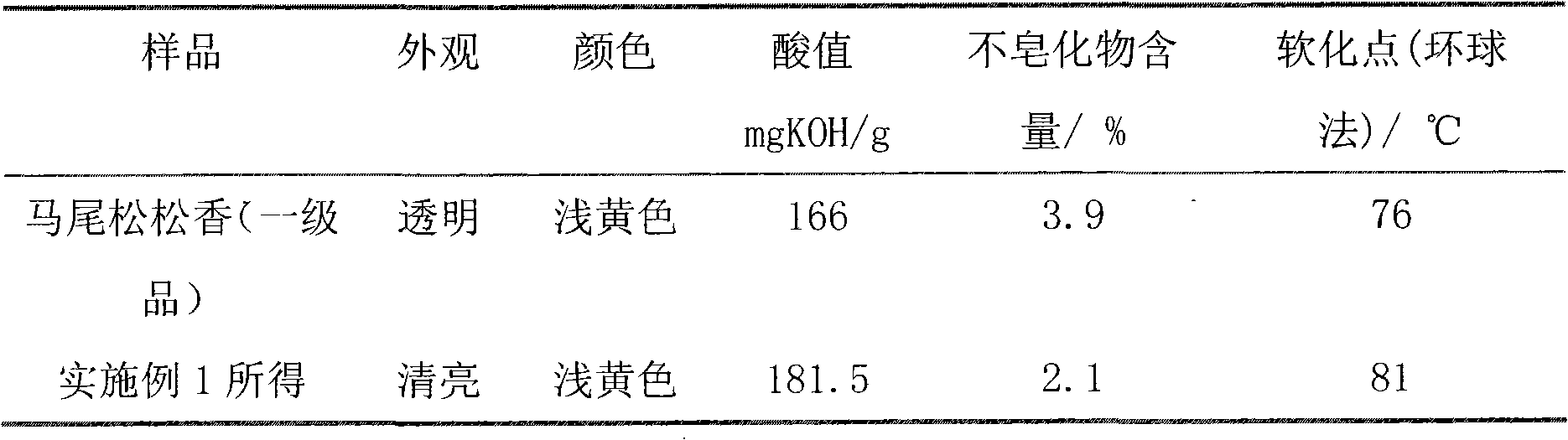

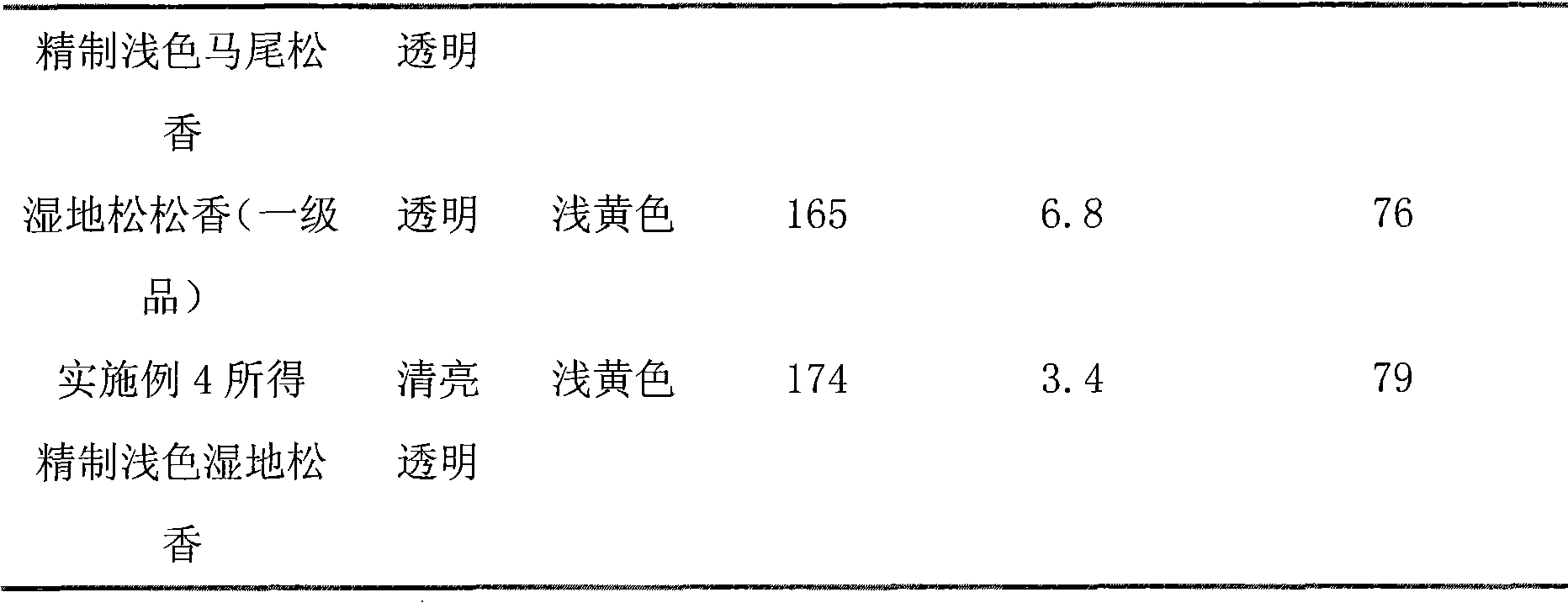

Embodiment 1

[0018] Weigh 50 grams of horsetail rosin, put it into a 100mL round-bottomed flask after fine grinding, fully dissolve with dichloromethane, the mass volume ratio of rosin and dichloromethane is 10:15, filter to remove insoluble solids; add acetonitrile under stirring , the mass volume ratio of rosin to acetonitrile is 10:20, let it stand for 10 minutes, so that the resin acid is fully precipitated; filter and collect the resin acid precipitate, heat and distill the filtrate, collect the fraction before 70 ° C, which is dichloromethane; cool the remaining solution To room temperature, the precipitated resin acid is collected by filtration again, the filtrate is combined, heated and evaporated to reclaim acetonitrile; finally the resin acid is precipitated in N 2 or CO 2 Under protection, heat fusion, cooling and solidification to obtain refined light-colored horsetail rosin.

Embodiment 2

[0020] Weigh 100 grams of horsetail rosin, put it into a 500mL round-bottomed flask after fine grinding, fully dissolve with dichloromethane, the mass volume ratio of rosin and dichloromethane is 10:20, filter to remove insoluble solids; add acetonitrile under stirring , the mass volume ratio of rosin to acetonitrile is 10:30, let it stand for 20 minutes, so that the resin acid is fully precipitated; filter and collect the resin acid precipitate, heat and distill the filtrate, collect the fraction before 70 ° C, which is dichloromethane; cool the remaining solution To room temperature, the precipitated resin acid is collected by filtration again, the filtrate is combined, heated and evaporated to reclaim acetonitrile; finally the resin acid is precipitated in N 2 or CO 2 Under protection, heat fusion, cooling and solidification to obtain refined light-colored horsetail rosin.

Embodiment 3

[0022] Weigh 500 grams of rosin, put it into a 1000mL round-bottomed flask after fine grinding, fully dissolve with dichloromethane, the mass volume ratio of rosin and dichloromethane is 10:20, filter to remove insoluble solids; add acetonitrile under stirring , the mass volume ratio of rosin to acetonitrile is 10:30, let it stand for 30 minutes, so that the resin acid is fully precipitated; the resin acid precipitate is collected by filtration, the filtrate is heated and distilled, and the fraction before 70 °C is collected, which is dichloromethane; the remaining solution is cooled To room temperature, the precipitated resin acid is collected by filtration again, the filtrate is combined, heated and evaporated to reclaim acetonitrile; finally the resin acid is precipitated in N 2 or CO 2 Under protection, heat fusion, cooling and solidification to obtain refined light-colored horsetail rosin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com