Inter-plane sealing assembly for high-temperature zone gap of gas turbine

A technology for gas turbines and sealing components, which is applied to combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as difficulty in meeting use requirements, and achieve the effect of wide application range and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

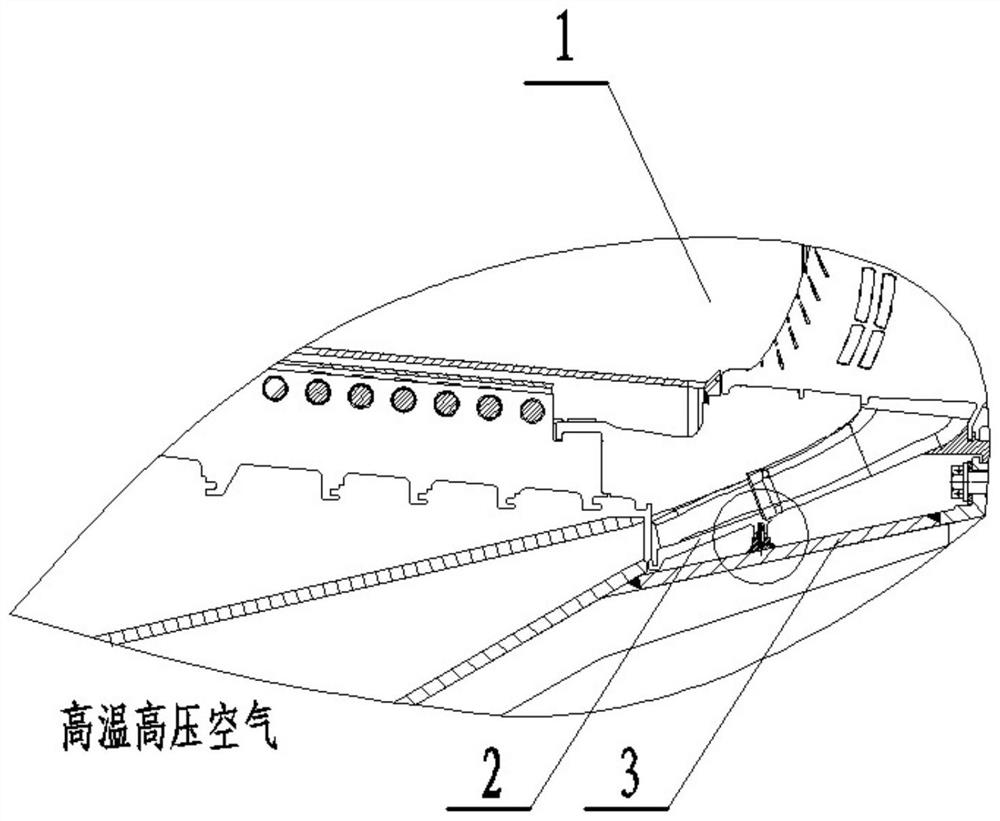

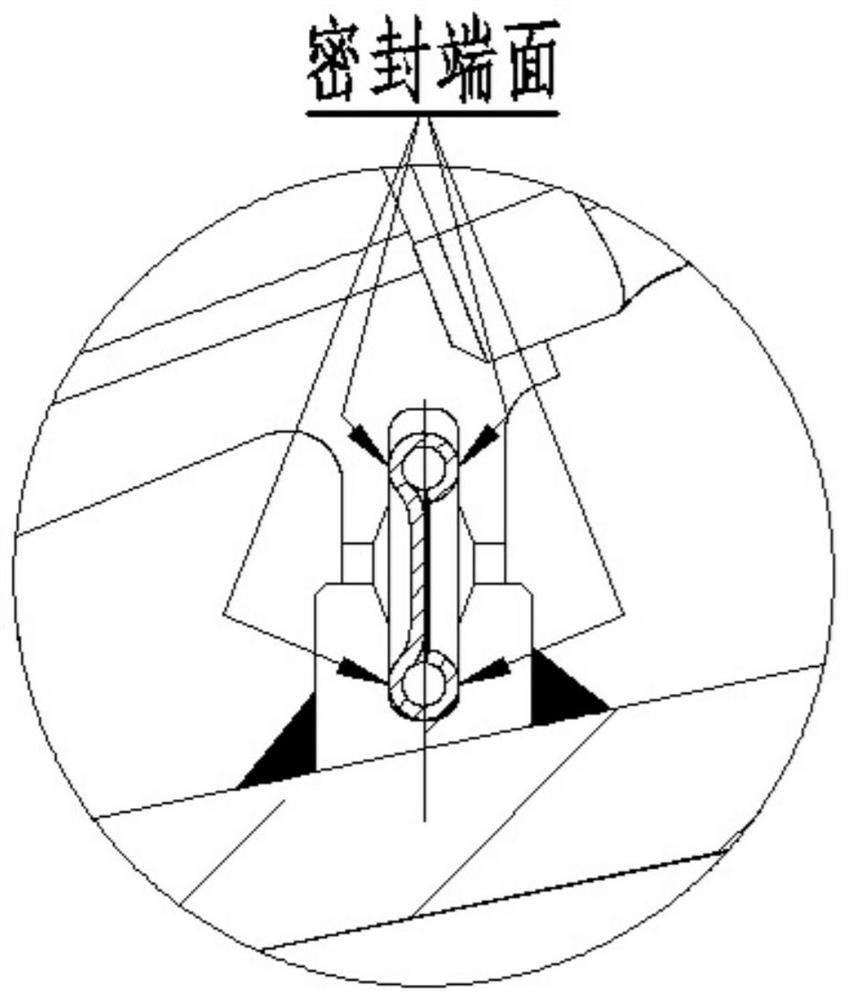

[0021] combine Figure 1a-Figure 4d , In Figure 1, there is a gap between the diffuser section and the support plate at the compressed air inlet of the combustion chamber. The traditional seal is generally sealed with a compressed gasket and fixed with fastening bolts. Because the current structure is limited by space, and the air flow through it is high-temperature and high-pressure air, the traditional structure is difficult to meet. In order to ensure that the compressed air from the compressor completely enters the combustion chamber, a clasp-type sealing assembly is invented between the support plate and the diffuser section, and a high-temperature alloy material is selected. Corrosion, easy installation, no fasteners, long life and other advantages.

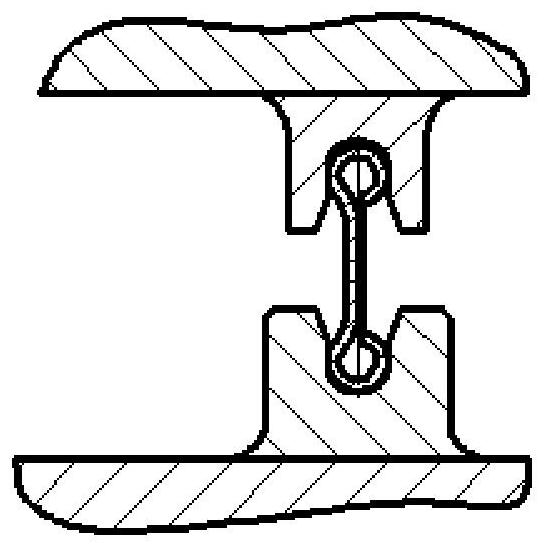

[0022] Referring to Fig. 2, the present invention mainly includes two groove holders and a sealing snap ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com