Hydraulic track changer

A rail changing machine and hydraulic technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems that do not meet the development needs of mechanization and intelligence of the public works system, require many personnel, and low operating efficiency, so as to save personnel Low cost, simple operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

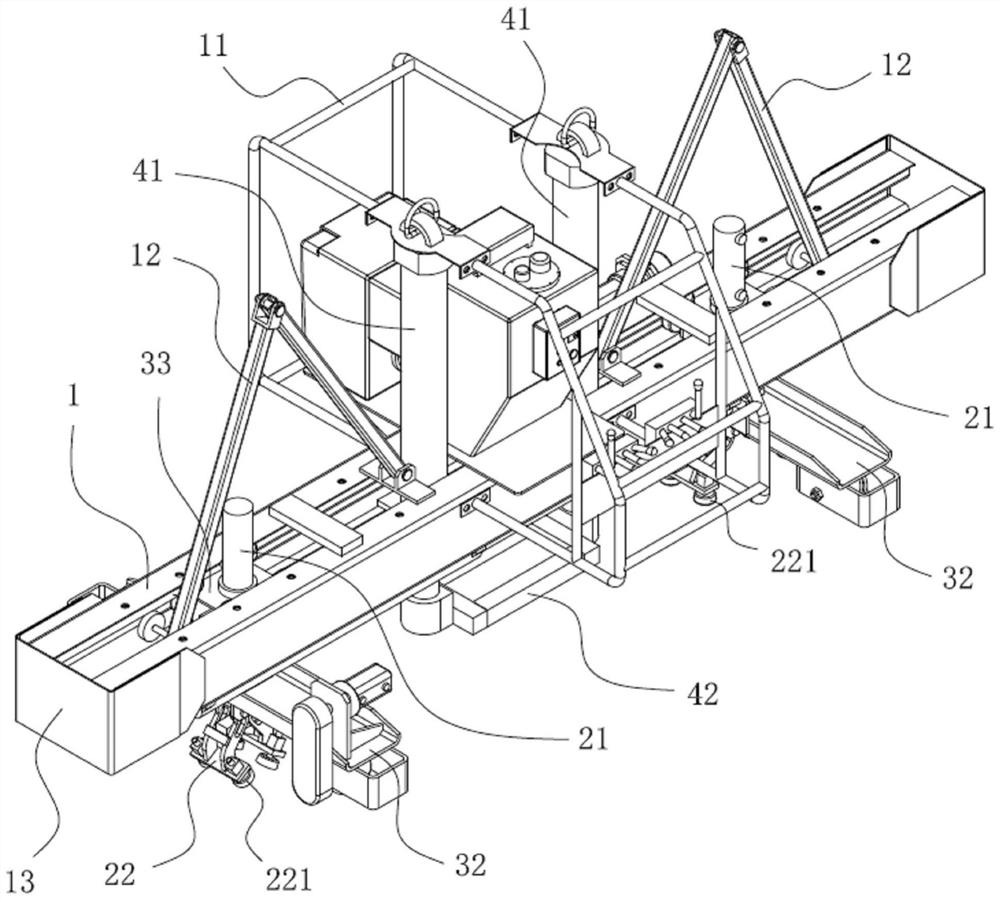

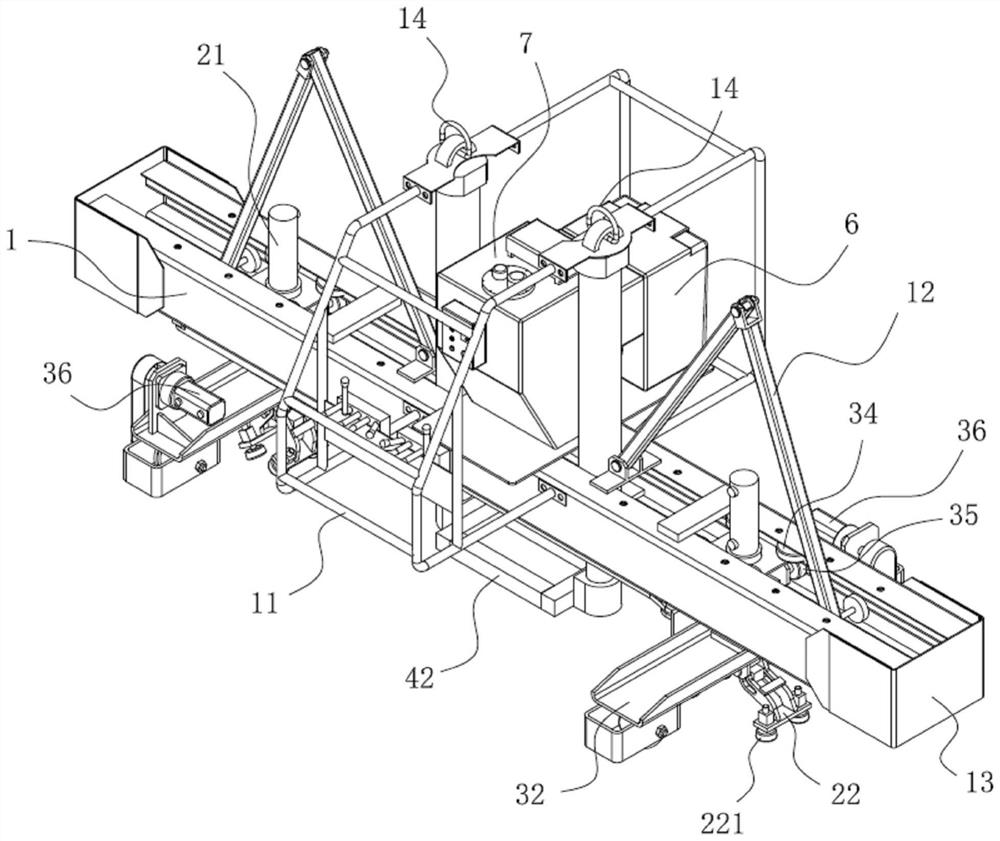

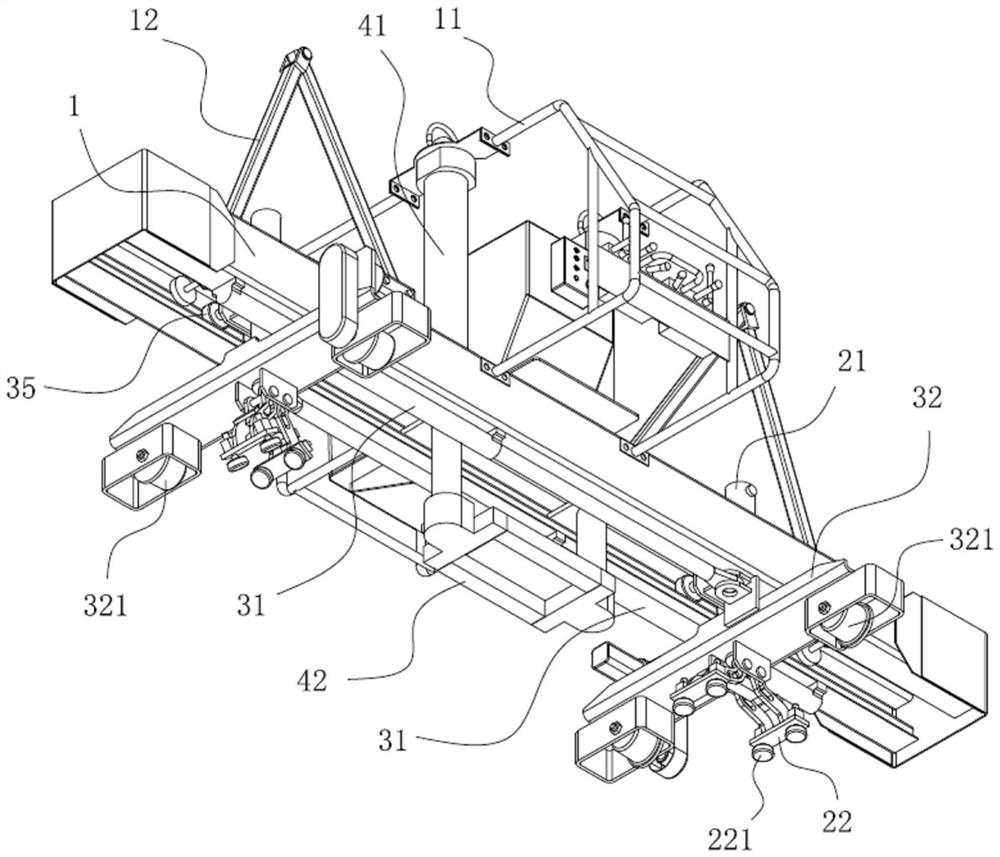

[0028] This embodiment discloses a hydraulic rail changing machine. like Figure 1 to Figure 6 As shown, the hydraulic rail changing machine includes a main frame 1 arranged horizontally. The main frame 1 is equipped with a clamping assembly for clamping the rail 5 to be replaced, a translation assembly for carrying the rail 5 to be replaced, and a lifting assembly for lifting the rail 5 to be replaced. The lifting assembly of the rail 5, the engine 6 and the hydraulic oil tank 7, the clamping assembly can move horizontally along the main frame 1; the clamping assembly, the translation assembly and the lifting assembly are all driven by the hydraulic cylinder, and the clamping assembly, the translation assembly and the lifting assembly The lifting components are controlled independently and non-int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com