Preparation method of intelligent temperature control glue and film

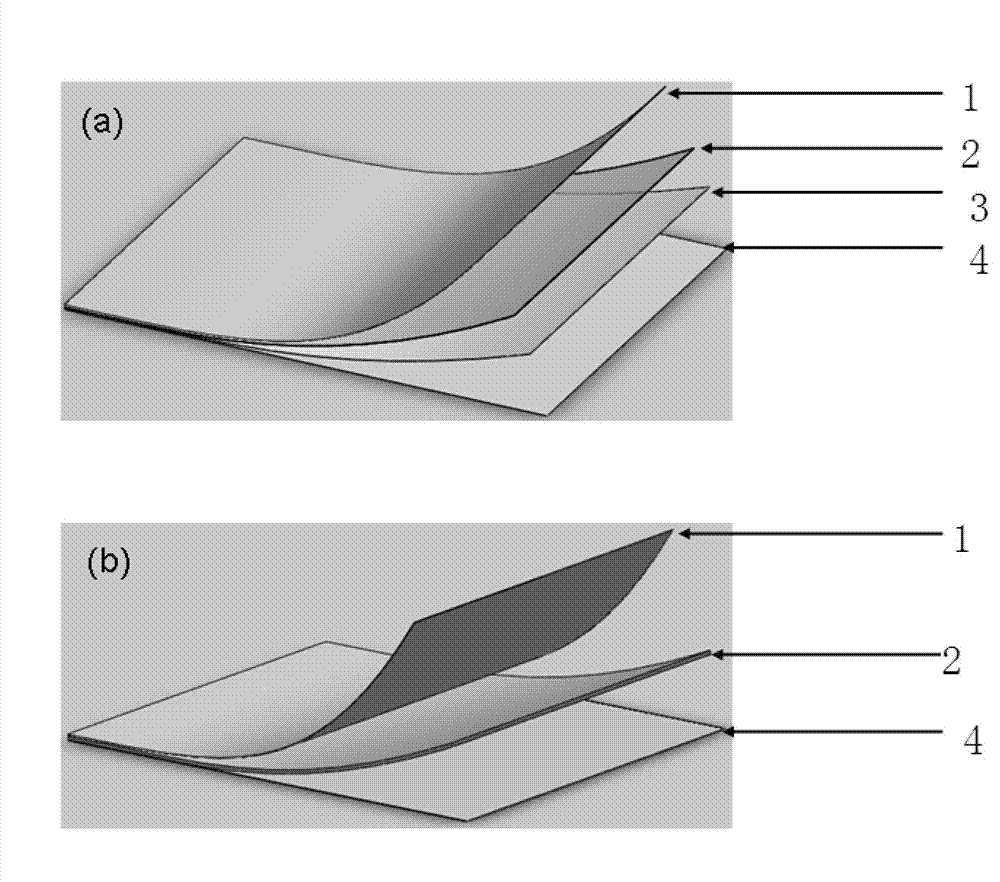

An intelligent temperature control and glue technology, which is applied in the direction of film/sheet adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of increasing film cost, complicated process, and limited application range, etc., and achieves easy The effects of transfer use, simple preparation process and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Get 0.5g of undoped vanadium dioxide powder; VO 2 The particle size of the particles is 100nm;

[0028] (2) preparing massfraction with ethanol is the vanadium dioxide dispersion liquid of 0.5%;

[0029] (3) Add the vanadium dioxide dispersion into a certain amount of PET glue, and stir to form a temperature-controlled glue with a vanadium dioxide content of 0.01g / L;

[0030] (4) Apply the glue on the PET film to get the intelligent temperature control film.

[0031] The thermal color performance of the test coating is as follows:

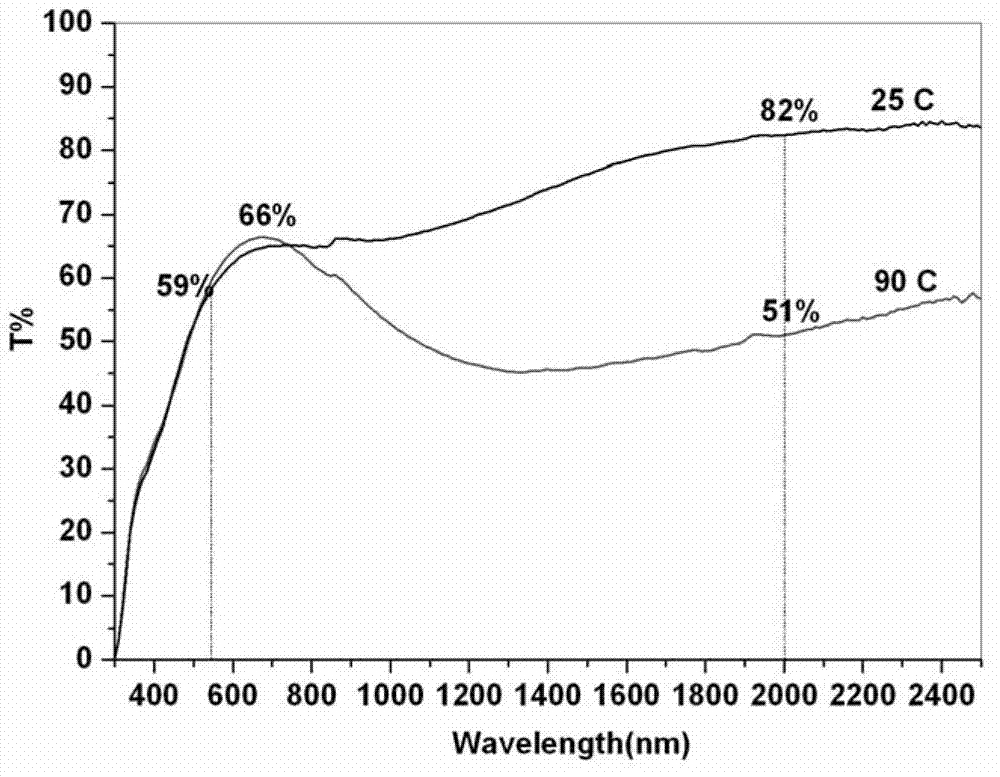

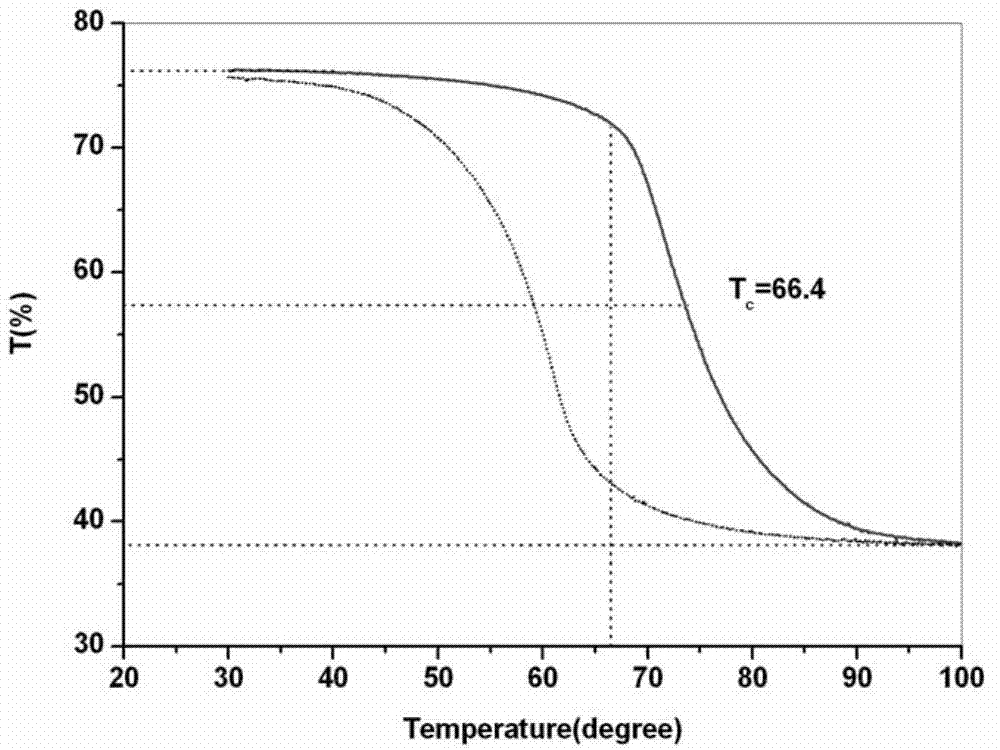

[0032] figure 1 It is the high and low temperature transmission spectrum of the glue coated on the PET film. It can be seen from the figure that the highest visible light transmittance of the glue coated on the PET film is 66%, and the transmittance at 550nm is 59%, indicating that the film has good visible light transmittance. The high and low temperature transmittance difference is 31%, indicating that the film has good thermochro...

Embodiment 2

[0034] (1) Get 0.5g vanadium dioxide powder with a tungsten molar content of 0.5%; VO 2 The particle size of the particles is 20nm;

[0035] (2) prepare the vanadium dioxide dispersion liquid that mass percent concentration is 1% with hexane;

[0036] (3) Add the dispersion of vanadium dioxide into the ABS glue, and form a temperature-controlled glue with a vanadium dioxide content of 10g / L after stirring;

[0037] (4) Apply the glue on the PET film to get the intelligent temperature control film.

Embodiment 3

[0039] (1) get 0.5g tungsten content to be the vanadium dioxide powder of 1%; VO 2 The particle size of the particles is 50nm;

[0040] (2) prepare the massfraction with dimethylbenzene as the vanadium dioxide dispersion liquid of 2%;

[0041] (3) Add the dispersion of vanadium dioxide into the PVC glue, and form a temperature-controlled glue with a vanadium dioxide content of 1g / L after stirring;

[0042] (4) Apply the glue on the PVC film to get the intelligent temperature control film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com