Technique for using dry discharging carbide slag to completely substitute natural calcareous raw material for producing cement chamotte

A technology of calcareous raw materials and cement clinker, which is applied in the field of building materials, can solve the problems of increasing heat consumption, and achieve the effects of reducing construction costs, simplifying special equipment, and reducing heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] (1) Raw materials and weight percentages are:

[0029] Carbide slag 71.8-77.8%, sandstone 8-12%, sulfuric acid slag 1.5-2.5%,

[0030] Fly ash 11.2-15.2%, wherein the calcium carbide slag water content ≤ 12%.

[0031] (2) Process method:

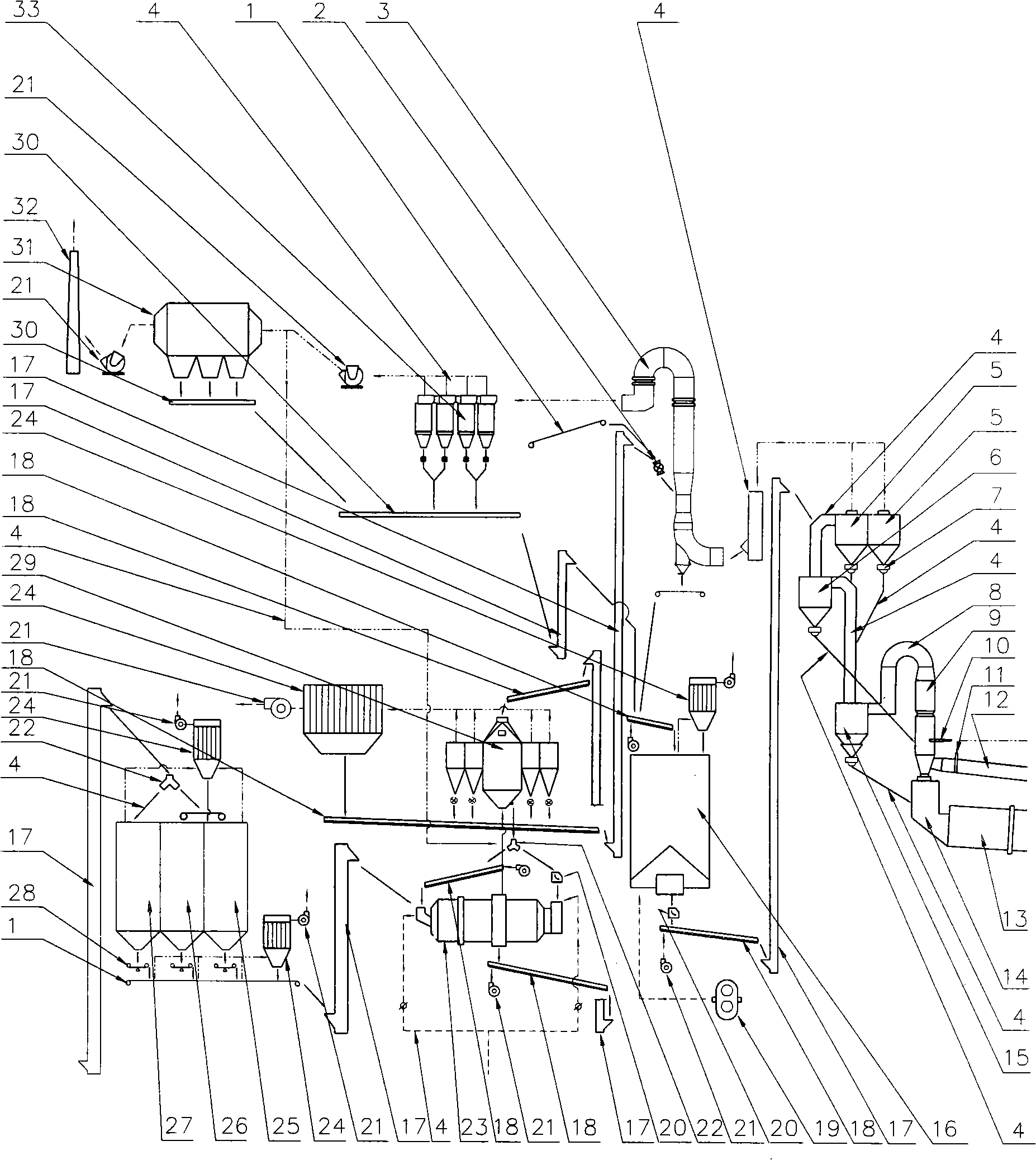

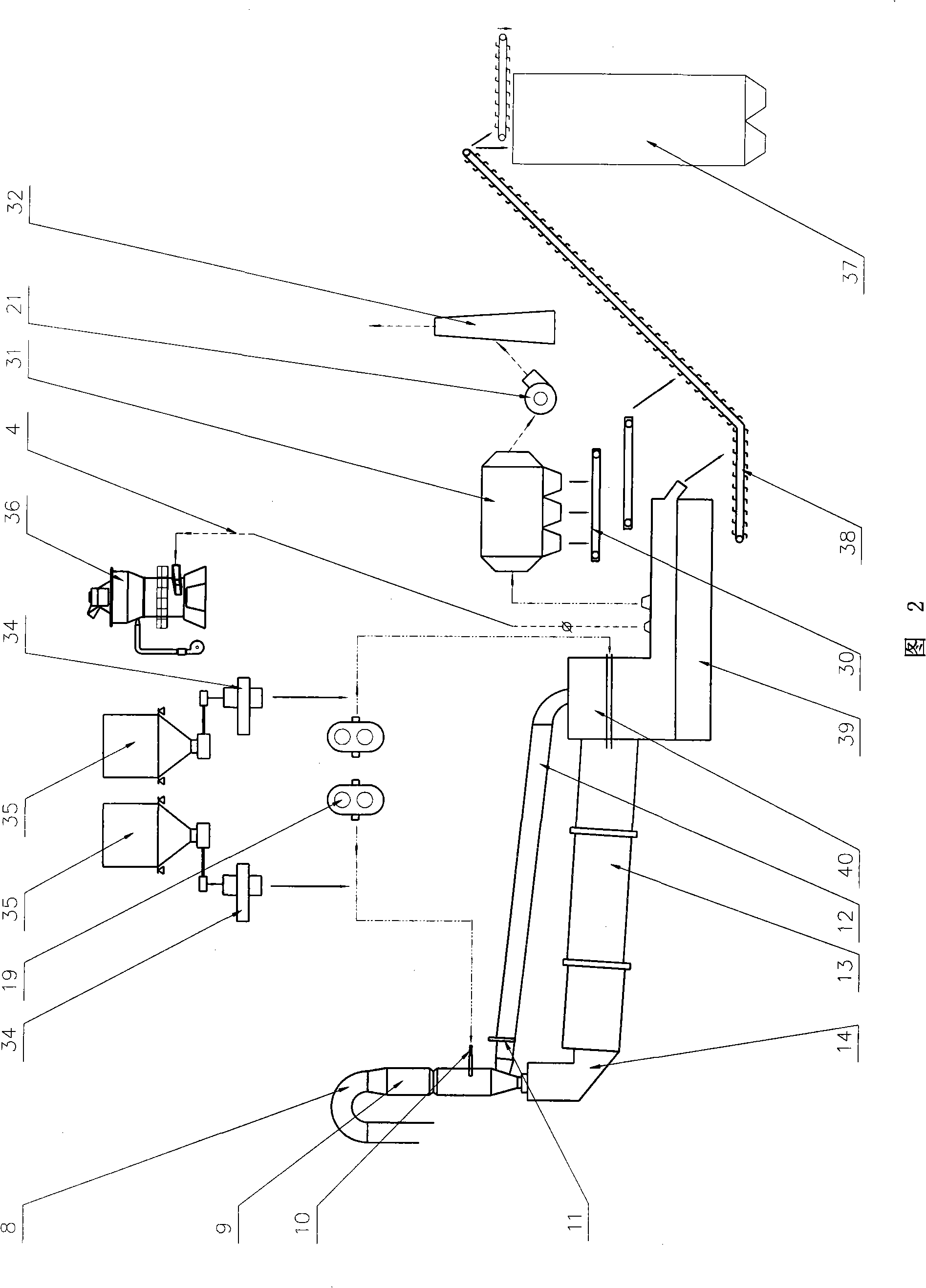

[0033] ① The auxiliary raw materials of the sandstone raw material warehouse 25, the fly ash warehouse 26 and the sulfuric acid slag warehouse 27 are automatically batched by the quantitative feeder 28 at the bottom of each warehouse, and sent to the middle discharge drying oven by the belt conveyor 1 and the hoist 17. Grinding in the dry and grinding machine 23, the raw meal powder after grinding is unloaded from the middle of the mill, and sent to the combined powder selection through the lowermost air conveying chute 18, the elevator 17 and the uppermost air conveying chute 18 Inside machine 29. The selected fine powder with a particle size of ≤0.08mm is sent to the air lock rotary feeder 2 throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com