Rejection processing technology for gas production wastewater in sulfur acid containing gas field

A technology for gas extraction wastewater and treatment process, which is applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of low construction and operation cost, extended use time and simple management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

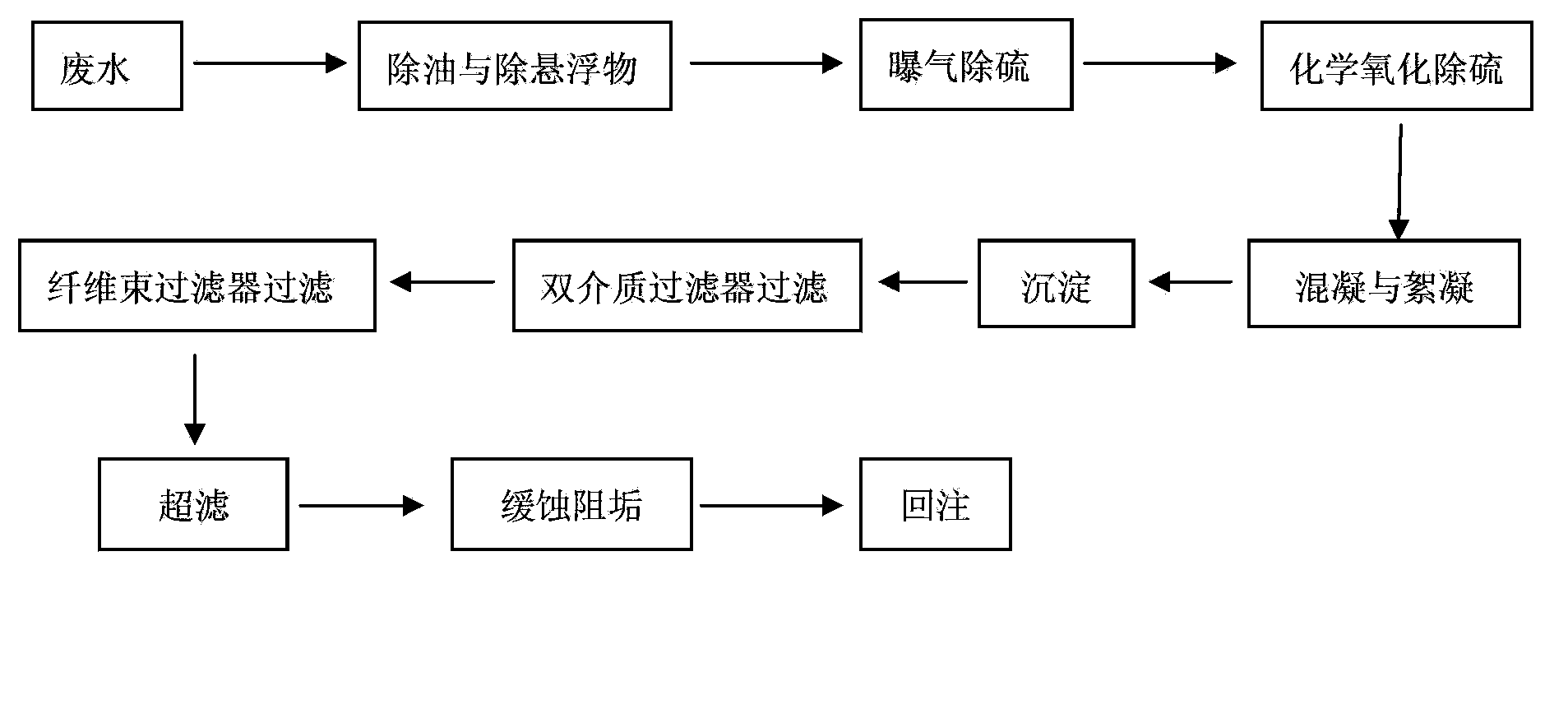

[0078] A trial production test was carried out on the gas production wastewater of a certain gas field (see attached figure 1 ), the system design water volume is 360m 3 / d, influent (most data) indicators are: general SS is 230~680mg / L, median particle size is 55μm~115μm, oil is 55mg / L~100mg / L, sulfur is 250mg / L~1200mg / L, SRB bacteria 10,000 / mL~30,000 / mL, TGB bacteria 300,000 / mL~800,000 / mL, iron bacteria 100,000 / mL~400,000 / mL, total iron 25mg / L~60mg / L, corrosion rate 2.350mm / a ~9.500mm / a.

[0079] All the above-mentioned treatment processes are carried out in a closed container, and the technological process used is as follows: the acid gas field gas extraction wastewater is degreasing and suspended matter, then desulfurized by aeration, desulfurized by chemical oxidation, and then coagulated. It enters the settler for mud-water separation, then sterilizes, and then enters the dual-media filter for filtration, then enters the fiber bundle filter for filtration, and then pas...

Embodiment 2

[0109] A trial production test was carried out on the gas production wastewater of a certain gas field (see attached figure 1 ), the system design water volume is 150m 3 / d. Influent water (most data) indicators are: general SS is 200-650mg / L, particle size median is 45μm-100μm, oil is 50mg / L-95mg / L, sulfur is 120mg / L-1200mg / L, SRB bacteria is 10000 / mL~30000 / mL, TGB bacteria 300000 / mL~700000 / mL, iron bacteria 300000 / mL~400000 / mL, total iron 25mg / L~50mg / L, corrosion rate 2.350mm / a~8.950mm / a.

[0110] All the above-mentioned treatment processes are carried out in a closed container, and the technological process used is as follows: the acid gas field gas extraction wastewater is degreasing and suspended matter, then desulfurized by aeration, desulfurized by chemical oxidation, and then coagulated. It enters the settler for mud-water separation, then sterilizes, and then enters the dual-media filter for filtration, then enters the fiber bundle filter for filtration, and then...

Embodiment 3

[0140] A trial production test was carried out on the gas production wastewater of a certain gas field (see attached figure 1 ), the system design water volume is 120m 3 / d. Influent water (most data) indicators are: general SS is 240-760mg / L, median particle size is 55μm-120μm, oil is 55mg / L-80mg / L, sulfur is 200mg / L-800mg / L, SRB bacteria are 10000 / mL~30000 / mL, TGB bacteria 300000 / mL~800000 / mL, iron bacteria 300000 / mL~400000 / mL, total iron 25mg / L~50mg / L, corrosion rate 1.350mm / a~8.550mm / a.

[0141] All the above-mentioned treatment processes are carried out in a closed container, and the technological process used is as follows: the acid gas field gas extraction wastewater is degreasing and suspended matter, then desulfurized by aeration, desulfurized by chemical oxidation, and then coagulated. It enters the settler for mud-water separation, then sterilizes, and then enters the dual-media filter for filtration, then enters the fiber bundle filter for filtration, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Surface load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com