Highly-ordered single-piece copper-based porous material and preparation method thereof

A highly ordered and porous material technology, applied in the field of monolithic copper-based porous materials, can solve the problems of the influence of material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

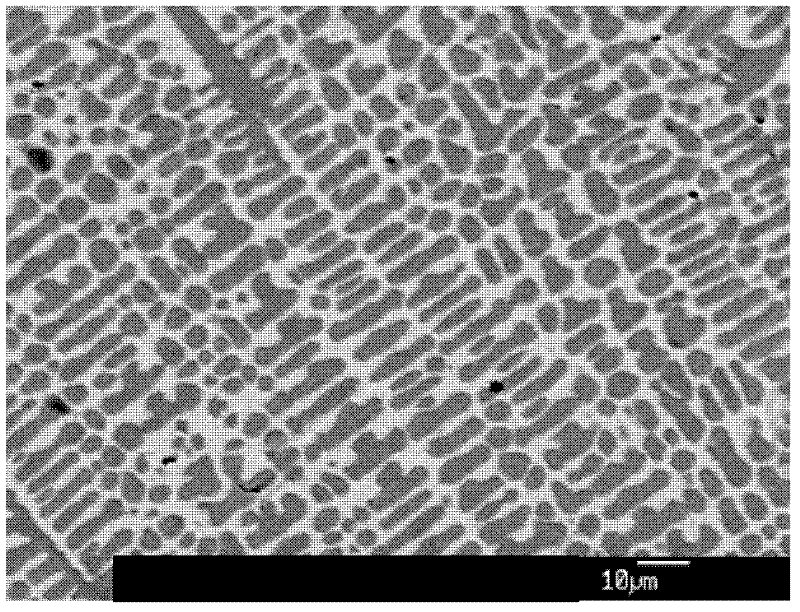

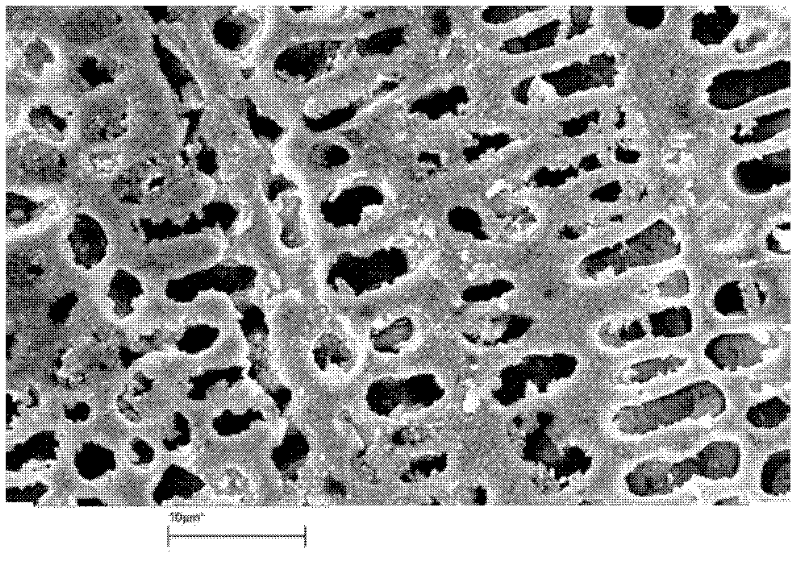

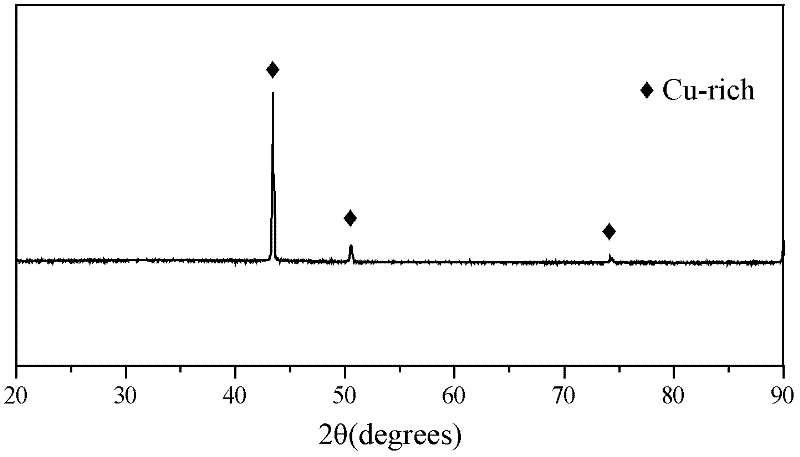

Embodiment 1

[0036] Using copper (purity 99.8%), iron (purity 99.8%), cobalt (electrolytic cobalt, purity 99.8%) as raw materials, after ultrasonic cleaning, press Cu 50 Fe 50-x Co x (x=1-20at.%) components are weighed, and the preset mass of the sample is 15-20g. The weighed metal is smelted in a vacuum melting electric arc furnace under an argon atmosphere. In the arc smelting process, in order to make the alloy smelt uniform, the magnetic stirring function of the electric arc furnace is turned on, and the smelted alloy ingot is turned upside down and smelted more than 3 times. The smelted alloy is polished with coarse sandpaper to remove the oxide layer on the surface of the alloy, and cut into slices of appropriate size and thickness of 0.5mm. The cut slices are polished. Put the polished sample in alcohol and clean it in an ultrasonic cleaner for 10 minutes to remove oil stains on the surface of the sample, and then vacuum seal the sample into a quartz tube on the packaging table. In...

Embodiment 2

[0039] As in Example 1, the heat treatment temperature was 900, and the heat treatment time was 2 weeks.

Embodiment 3

[0041] As in Example 1, the heat treatment temperature was 800, and the heat treatment time was 2 weeks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com