Preparation method for well-organized high-capacity self-supporting film based on epitaxial growth of polyaniline on graphene surface

A graphene surface, self-supporting thin film technology, used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc. control, the method is simple and feasible, and the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

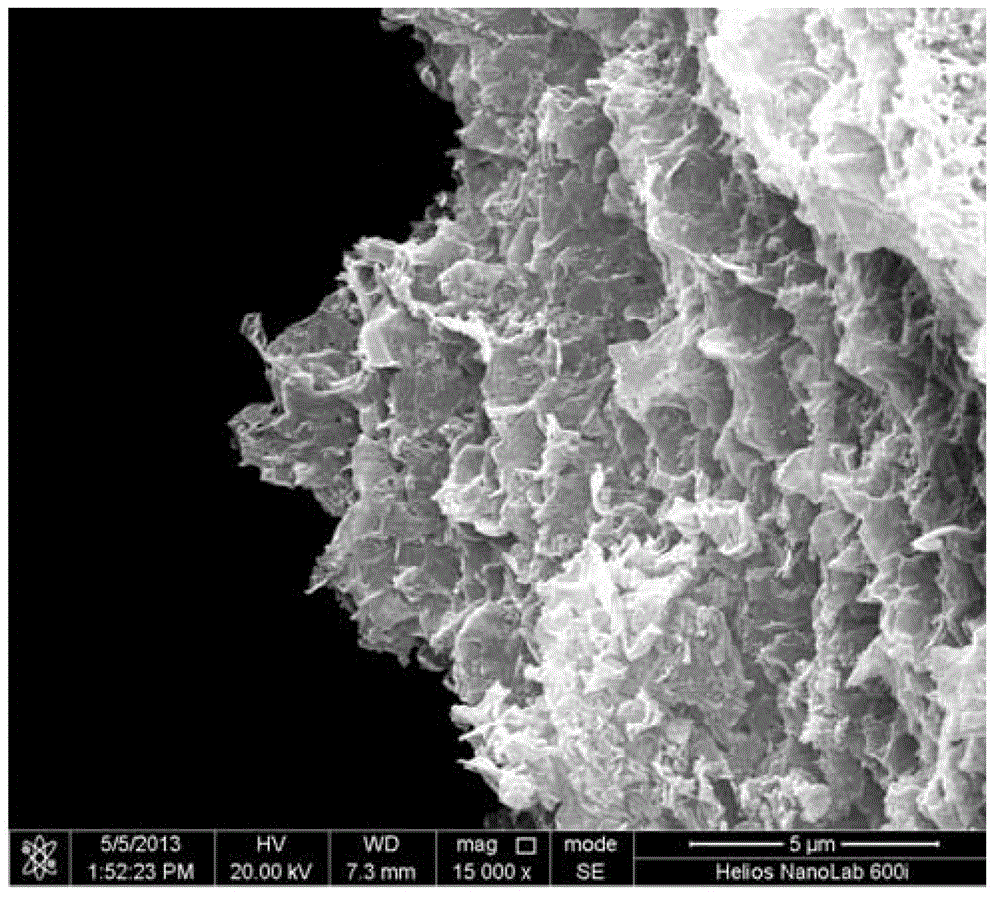

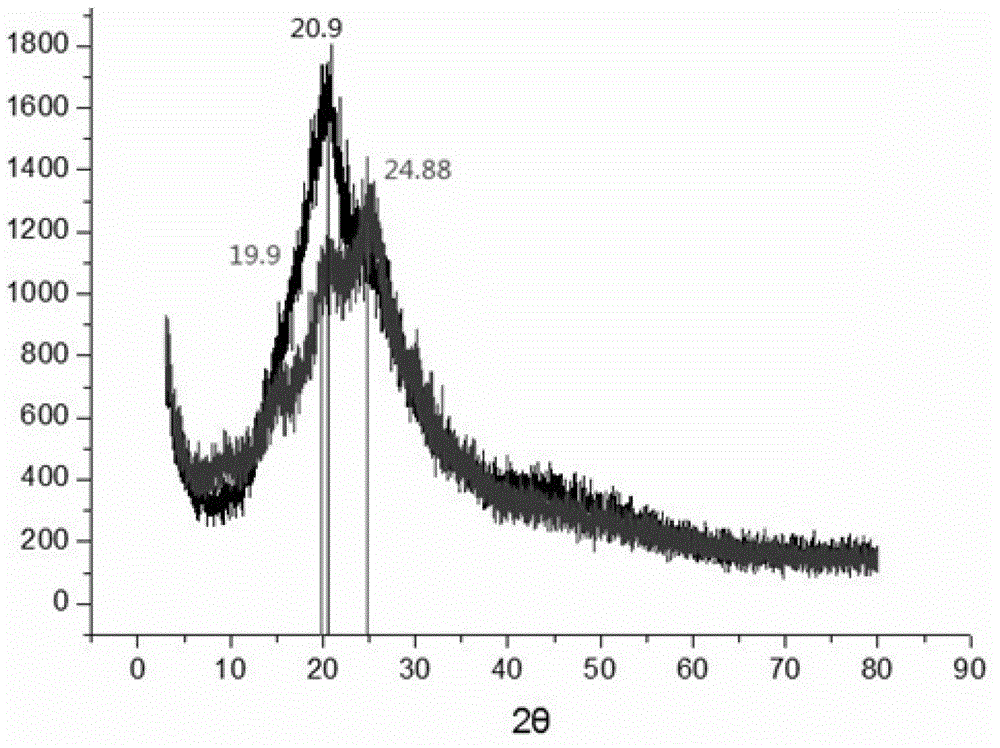

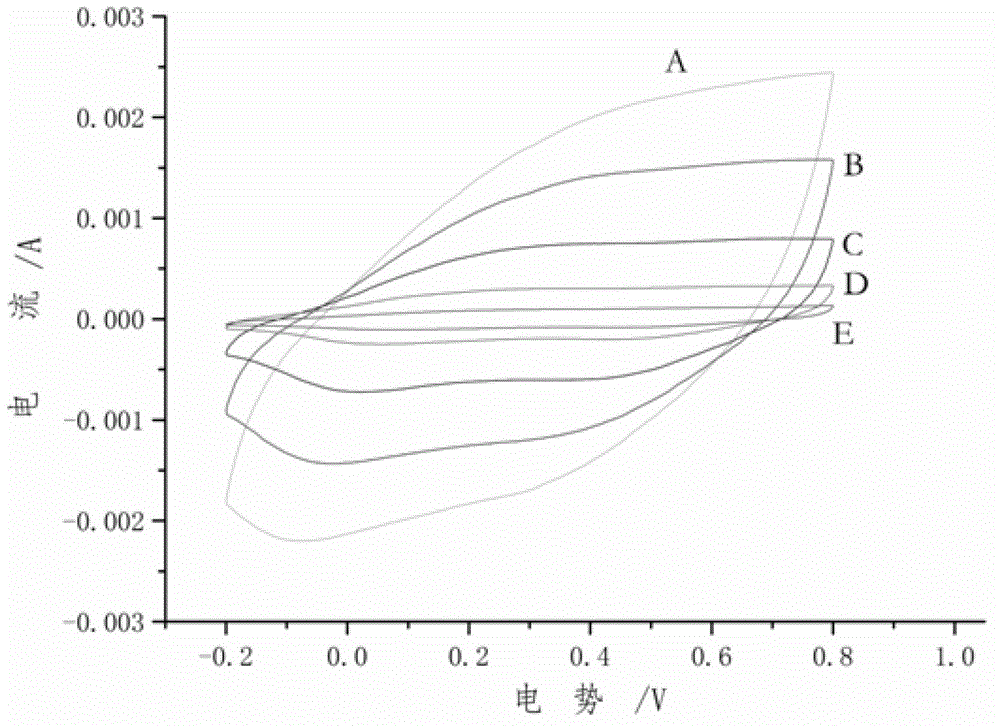

[0037] Embodiment 1: In this embodiment, a method for preparing an ordered high-capacity self-supporting film based on epitaxial growth of polyaniline on the surface of graphene is carried out according to the following steps:

[0038] 1. Preparation of graphene oxide:

[0039] Dry 2g of graphite at 80°C to obtain graphite powder, mix 3ml of concentrated sulfuric acid, 1gK 2 S 2 o 8 Mix with 1g of phosphorus pentoxide, heat to 80°C, add dried graphite powder, and the solution becomes black. When the color of the solution turns blue-black, keep it warm for 6 hours, cool down to room temperature naturally, dilute, filter with suction, and wash until the lotion is neutral , dry naturally at room temperature, add a solution consisting of 1g of sodium nitrate and 45ml of sulfuric acid while stirring at 0-4°C, stir for 30 minutes, add 6g of potassium permanganate, stir for 90 minutes to obtain a mixed solution, and then heat the mixed solution To 35°C, continue to stir for 30min,...

specific Embodiment approach 2

[0045] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of the graphene oxide solution in step 1 is 0.5 mg / mL. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0046] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the electrodeposition method described in step four is as follows:

[0047] Clean the 0.2mm thick Ni sheet or ITO glass with acetone, methanol and ultrapure water for 20 minutes, and then dry it, then insert the Ni sheet or ITO glass into the solution with a concentration of 1-100mg / mL, and adjust the electrophoresis instrument It is a constant voltage mode, deposited at a constant voltage of 1-100V for 5-200min, and obtains an ordered high-capacity self-supporting film based on the epitaxial growth of polyaniline on the surface of graphene. Others are different from the first or second specific embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com