Method for controllably preparing composite nano pattern array

A composite and array technology, which is used in the coupling of optical waveguides, the fabrication of microstructure devices, and the process for producing decorative surface effects. and other problems, to achieve the effect of simple and controllable spacing, less interference of organic components, and diversified substrate morphology and configuration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

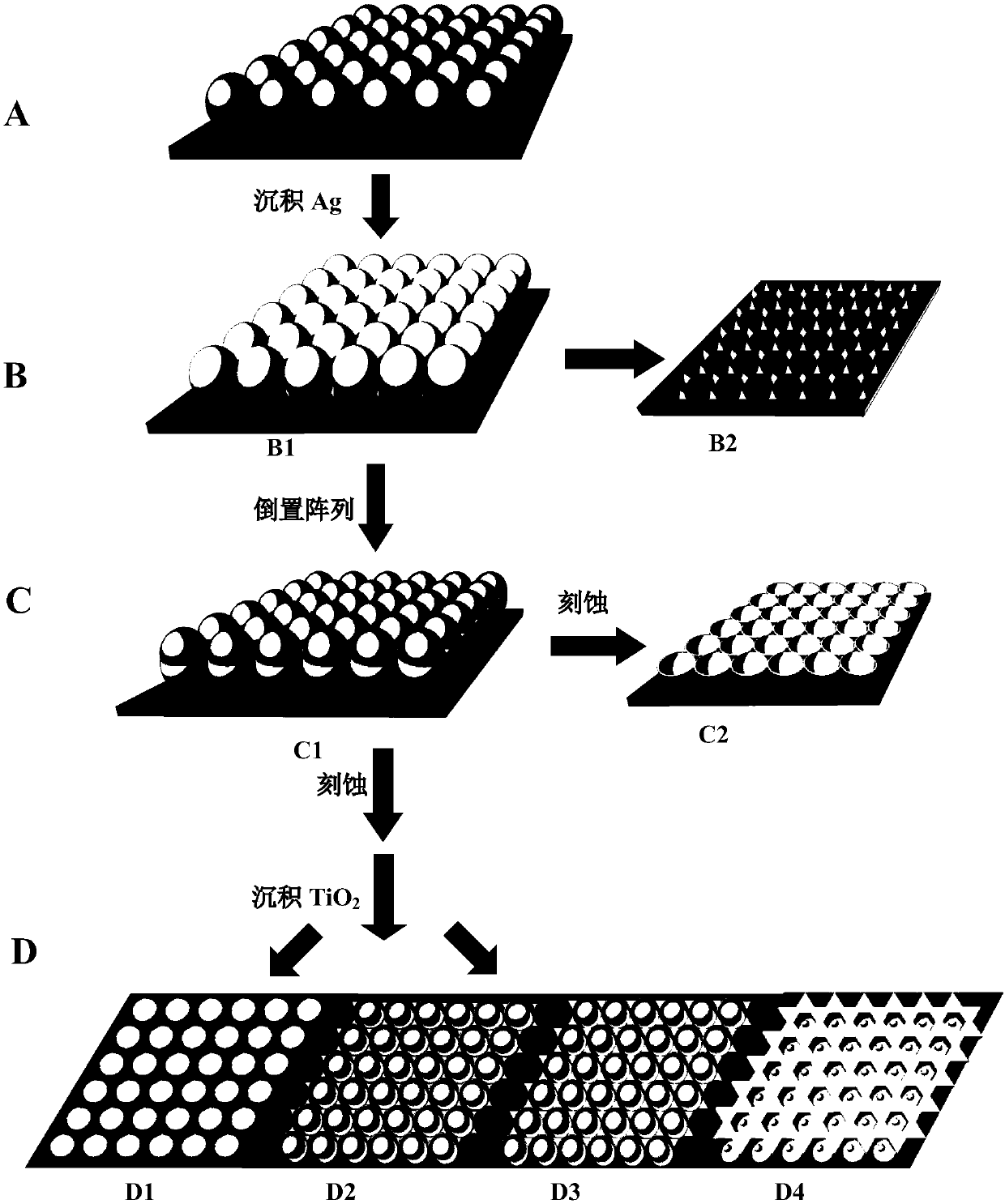

[0032] Such as figure 1 As shown, a controllable method for preparing composite nanopattern arrays, the preparation method includes the following steps:

[0033] (A) Using the self-assembly method, a densely packed array of PS colloidal balls with a diameter of 200 nm was self-assembled on a Si substrate with a hydrophilic surface to obtain an ordered nano-patterned structural template;

[0034] (B) After magnetron sputtering a layer of Ag film with a thickness of 20nm on the surface of the ordered nanopatterned structure template obtained in step (A), an Ag nanocap array (as shown in B1) is formed; the surface is coated with Ag The PS colloidal ball array of the film is glued down with double-sided adhesive, and the Ag nanotriangular array is obtained on the original Si substrate (as shown in B2);

[0035] (C) Transfer the double-sided adhesive with the PS colloidal ball array with Ag film on the surface in step (B) upside down to another Si substrate, and re-expose the PS t...

Embodiment 2

[0038] The difference from Example 1 is that in this example, the etching time in step (D) is changed to 60s, and a layer of TiO with a thickness of 50nm is deposited on the surface by sputtering 2 Ag-TiO 2 Nanocap-star array (shown in D2).

Embodiment 3

[0040] The difference from Example 1 is that in this example, the etching time in step (D) is changed to 120s, and a layer of TiO with a thickness of 50nm is deposited on the surface by sputtering 2 Ag-TiO 2 Nanocap-star array (shown in D3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com