Method for recovering acid making waste heat

A technology of waste heat recovery and heat, applied in steam generation methods using heat carriers, chemical instruments and methods, preheating, etc., can solve the problems of increased burden, increased cost, waste heat not being utilized, etc., to improve waste heat recovery rate and The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

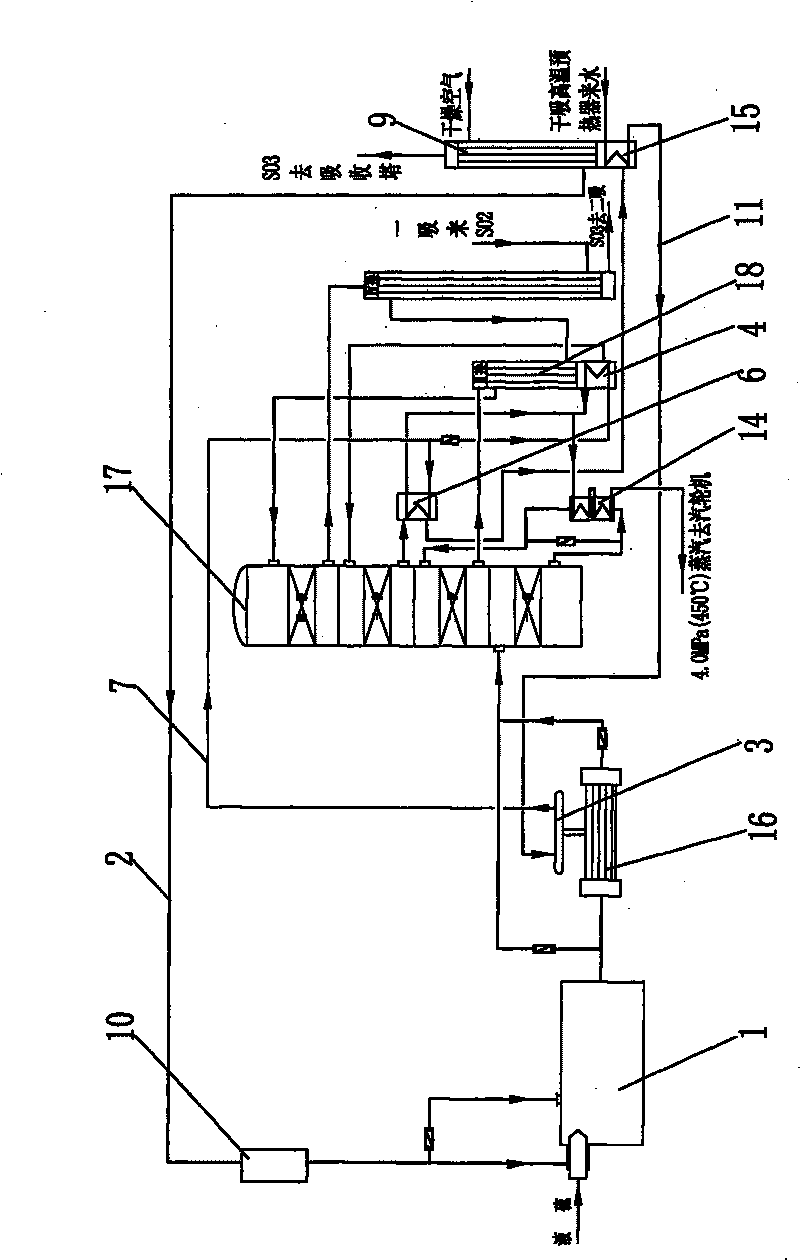

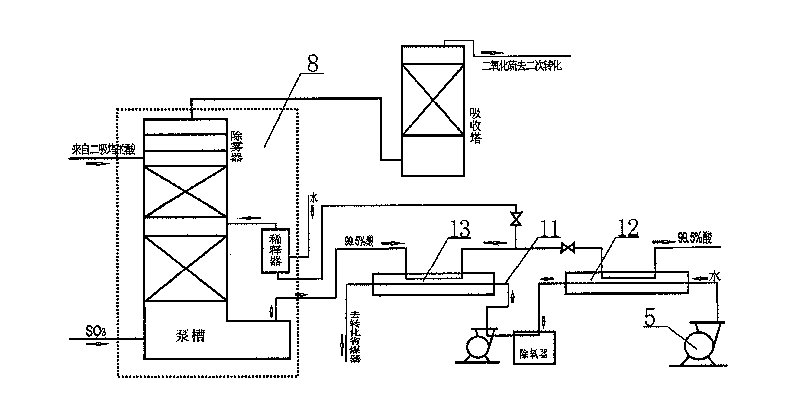

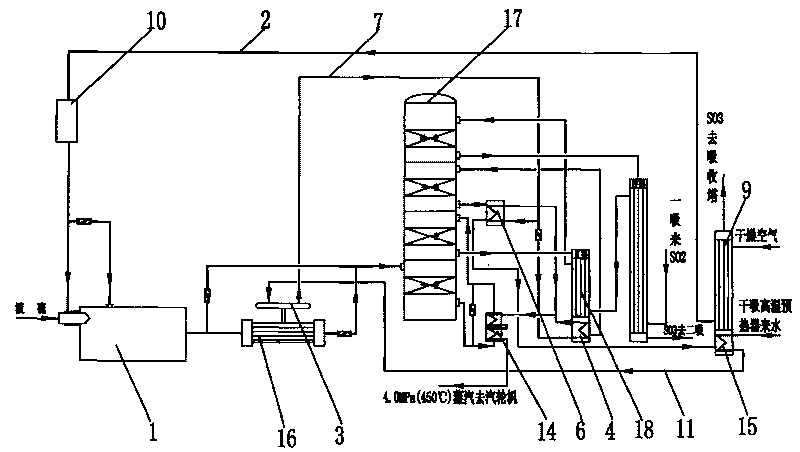

[0019] Such as figure 1 , 2 Shown, the method for waste heat recovery of sulfuric acid production, the method comprises the following steps:

[0020] a. Recover the SO discharged from the first, second and third outlets of the converter 17 in the sulfuric acid production process 3 A part of the heat carried by the gas, the specific scheme is: on the steam evacuation channel 7, SO2 with the three-stage outlet of the reformer is provided. 3 Low-temperature superheater 6 with gas as the heat source, and reformer II for SO at outlet 18 3 Low-temperature superheater 4 with gas as the heat source, SO discharged from the outlet of the first stage of the reformer 3 Gas is the high-temperature superheater 14 of the heat source, and finally utilizes the high-temperature superheater 14 to convert SO 3 Part of the heat carried by the gas is transferred to the steam, turning the steam into steam at 4.0MPa and 450°C.

[0021] b. reclaim the heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com