Method for microporous treatment of metal surface

A metal surface and microporous technology, applied in the field of material processing, can solve the problems of low bonding strength, high cost, uneven and irregular rough surface, etc., and achieve the effect of good order and enlarged pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]A method for microporous treatment of a metal surface, comprising the following steps: 1) Anodizing: anodizing a pretreated metal substrate to obtain a metal substrate with an anodized film layer on the surface, the metal substrate being aluminum Alloy substrate or aluminum substrate; 2) Removal of anodized film: immerse the metal substrate containing the anodized film layer obtained in step 1) into an etching solution to obtain a metal substrate from which the anodized film layer has been removed. H in etching solution + / OH - The concentration is 0.55~5.5mol / L, the etching solution contains fluoride ions and / or phosphate ions, and the etching solution also contains an aluminum corrosion inhibitor; 3) modified anodic oxidation: the metal obtained in step 2) The substrate is put into an anodic oxidation tank containing sulfuric acid and ammonium chloride for modification treatment to obtain a metal substrate with a modified anodic oxidation film layer; 4) surface adjust...

Embodiment 2

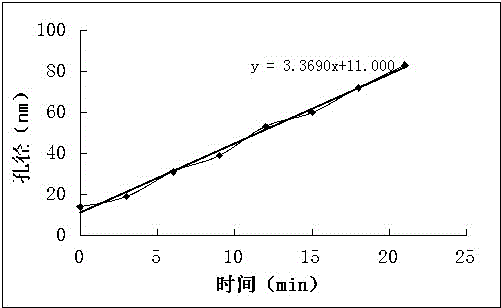

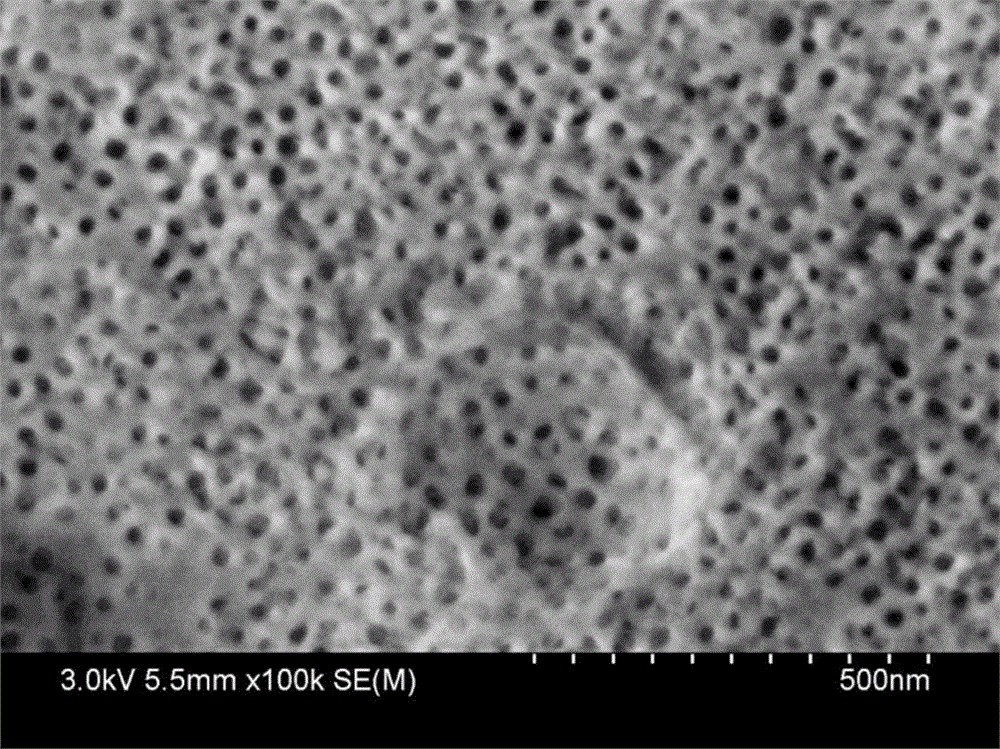

[0040] Adopt the same step in embodiment 1 to process ten aluminum alloy sheets, the difference is: c. anodic oxidation film is anodized, adopt 20g / l sodium hydroxide, 2g / l vinyl thiourea and 2g / l xylitol in Soak for 3 minutes at 40°C, e. During surface adjustment, the phosphoric acid soaking time is extended to 15 minutes. The SU-70 thermal field emission scanning electron microscope was used to observe the surface-treated aluminum sheet, and it was observed that alumina micropores with an average pore diameter of 70 nm were evenly distributed on the surface. Others are the same as Experimental Example 1, which will not be repeated here, and a linear relationship conforming to Y=a*X+b is also obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com