Anti-sulfur acid-resistant long conveying pipeline heat treatment process

A process method and technology of heat treatment equipment, applied in the field of pipeline systems, to achieve the effects of strong operability, improved heat treatment quality, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

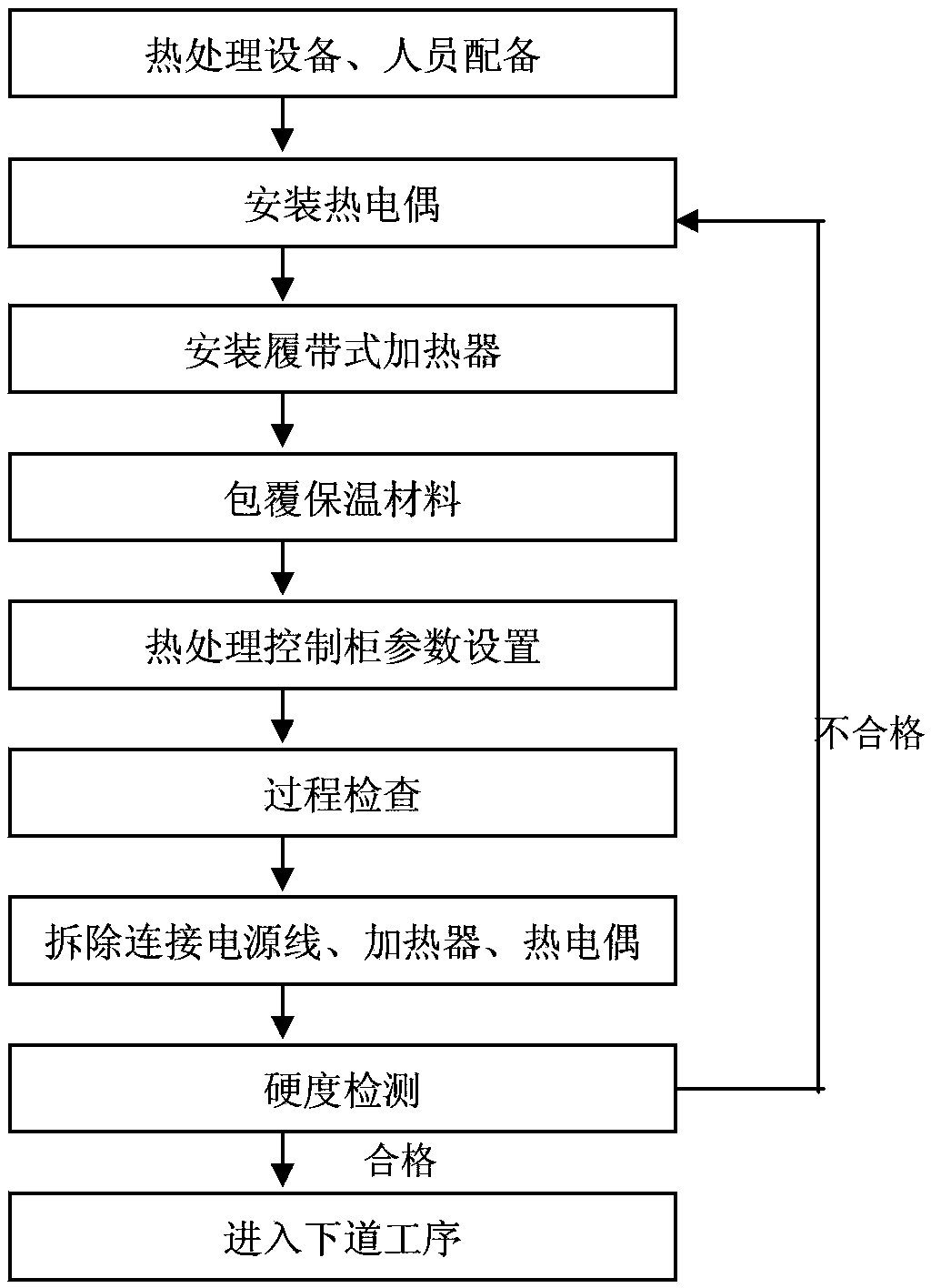

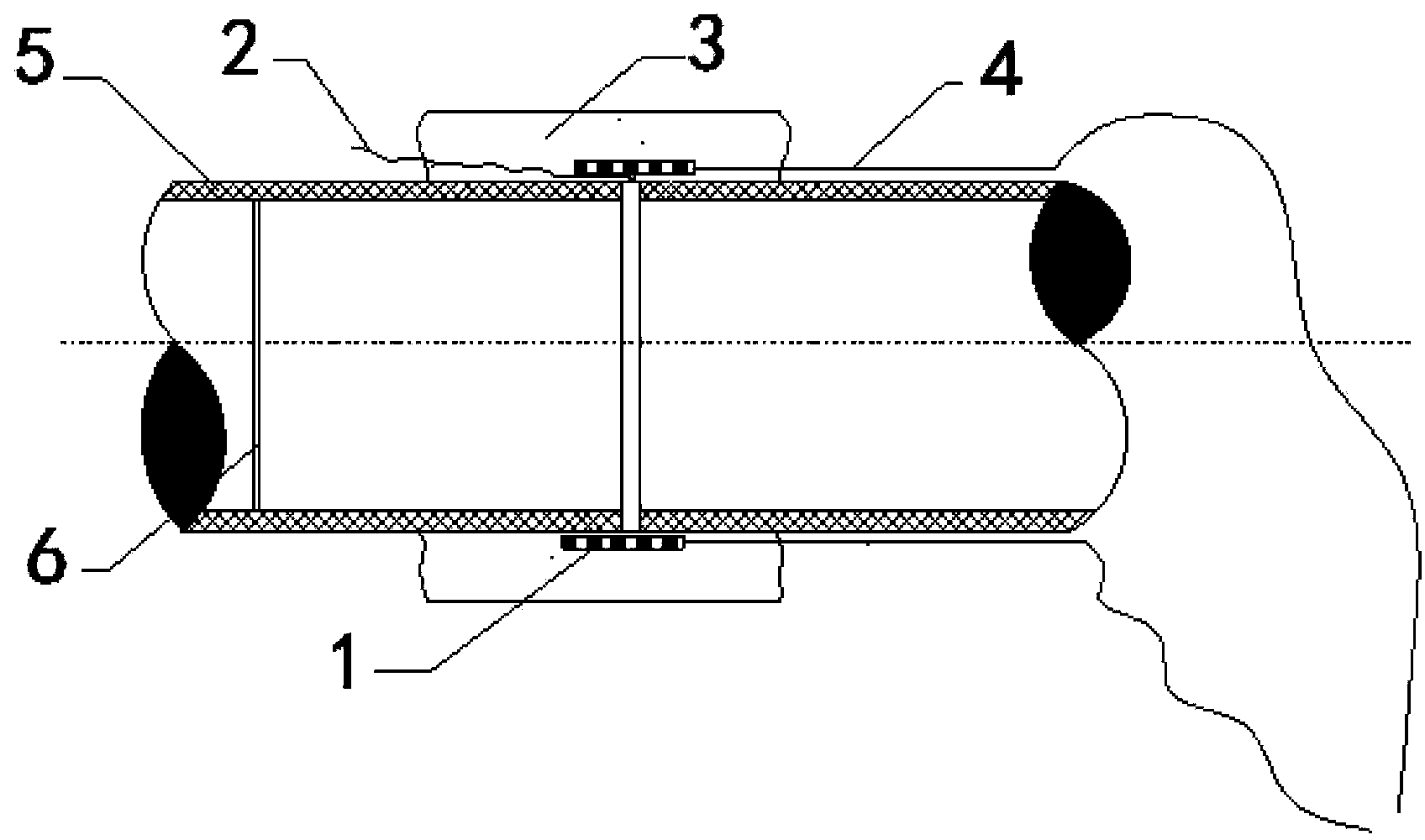

[0024] Embodiment 1: as figure 1 , figure 2 as shown,

[0025] The heat treatment process for sulfur-resistant and acid-resistant long-distance pipelines uses Jiangsu Yineng heat treatment equipment and uses infrared high-temperature ceramic crawler electric heaters. A complete set of heat treatment equipment is configured as follows: one truck (pulling), one 200KW generator, two temperature control cabinets (each temperature control cabinet can control 6 roads and 6 crossings at the same time, and the control process curve parameters of each road are set separately. set, each work independently) and the corresponding secondary power lines. At the same time, a forklift is specially equipped for heat treatment, which can build temporary access roads to ensure that heat treatment equipment can reach the designated site.

[0026] A thermocouple, a wire 2 and an electric heating sheet 1 are installed on the steel pipe 5 . The temperature measuring head of the thermocouple mus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com