Process for preparing strong acid and strong alkali by separating cobalt smelting wastewater

A waste water and strong acid technology, which is applied in metallurgical waste water treatment, alkali metal compounds, sulfur trioxide/sulfuric acid, etc., can solve the problems of large evaporation concentration and high concentration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

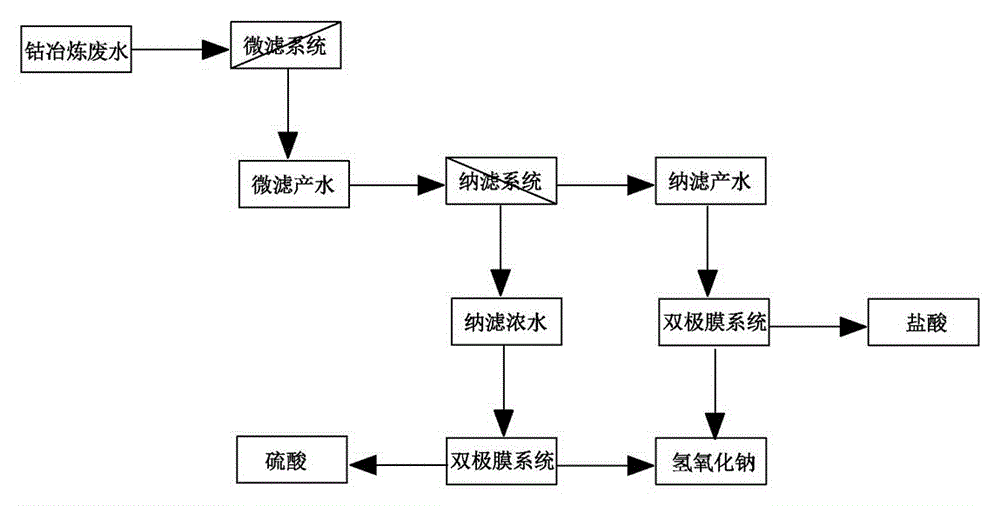

[0020] A kind of cobalt smelting waste water separation system strong acid, strong alkali process of the present invention is as follows figure 1 As shown, the wastewater is the production wastewater generated in the cobalt chloride smelting industry.

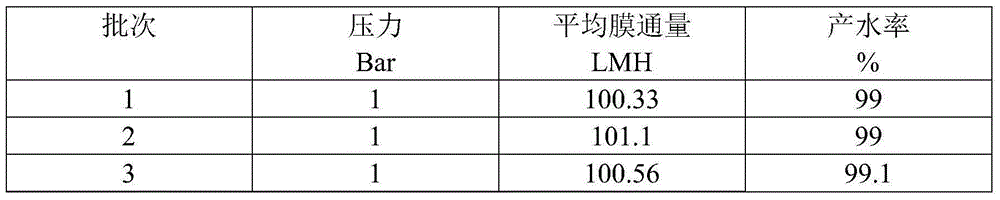

[0021] Step 1: Use a microfiltration system to treat ammonium chloride wastewater to remove suspended solids, flocs and particles in the feed liquid to ensure the stable operation of subsequent reverse osmosis. Three batches of experiments were carried out, of which the microfiltration system used in batch 1 The molecular weight cut-off of the filter membrane is 60KD, the molecular weight cut-off of the microfiltration membrane used in batch 2 is 70KD, and the molecular weight cut-off of the microfiltration membrane used in batch 3 is 80KD:

[0022]

[0023] From the experimental data, the microfiltration system has the characteristics of high pressure, high water production rate, etc. At the same time, because the flux has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com