Treatment system and method for resource utilization of ferrous metallurgy high-salinity wastewater

A high-salt wastewater and treatment system technology, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high water consumption index requirements for users, difficult outlets for high-salt wastewater crystalline salt, and high treatment costs , to achieve the effect of resource utilization, low operating and maintenance costs, and strong anti-microbial pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

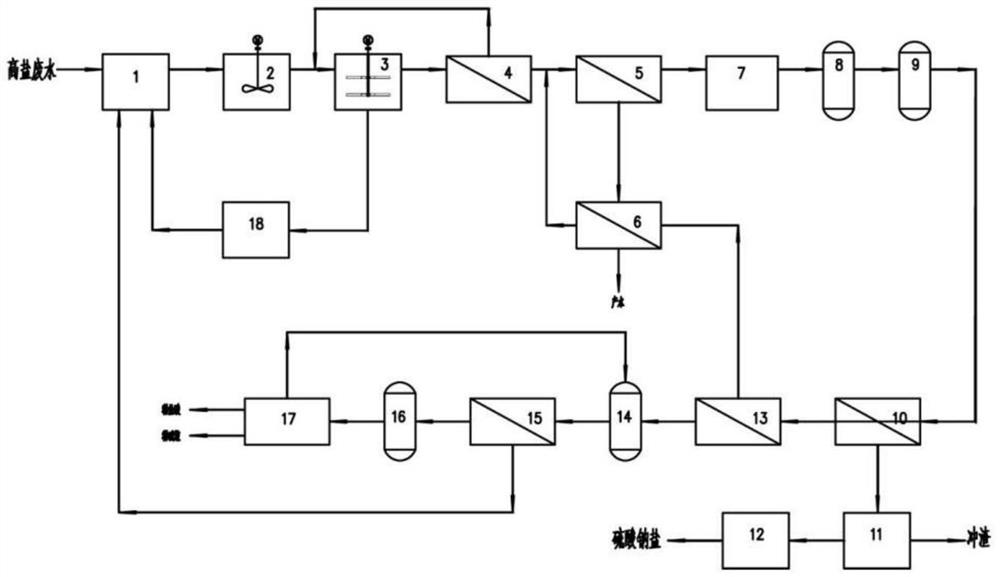

[0058] like figure 1 As shown, in this embodiment, a treatment system for resource utilization of iron and steel metallurgy high-salt wastewater is given, which is used to treat and recycle high-salt wastewater in the iron and steel industry.

[0059] The treatment system includes:

[0060] The high-salt wastewater regulating pool 1 is connected with the inlet pipeline of the high-salt wastewater regulating pool, and is used for adjusting and buffering the volume and quality of the high-salt wastewater;

[0061] The softening reaction tank 2 is connected with the outlet of the high-salt wastewater regulating tank 1, and is used to reduce the hardness and alkalinity of the high-salt wastewater, and remove silicon scale and heavy metals;

[0062] The concentrated sedimentation tank 3 is connected with the outlet of the softening reaction tank 2, and is used to reduce the suspended solids of the high-salt wastewater;

[0063] The sludge dewatering device 18 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com