Cyclic utilization device and method for discarded aluminum plastic resources

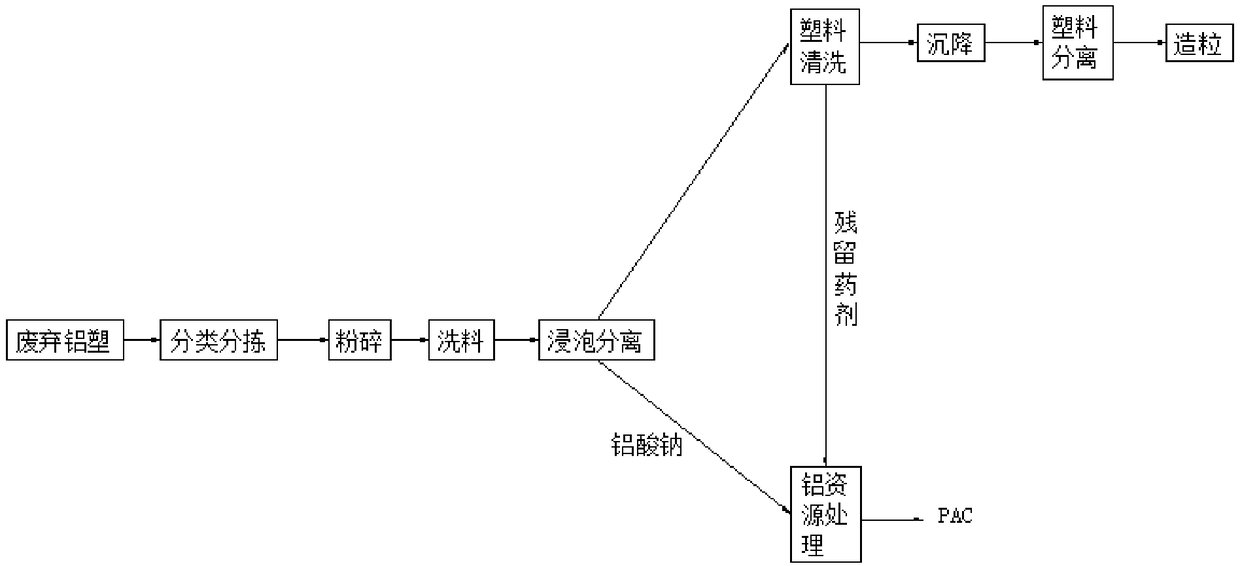

A resource, aluminum-plastic technology, applied in the field of waste aluminum-plastic resource recycling devices, can solve the problems that hinder the deep development of waste aluminum-plastic resources, incomplete equipment, backward technology, etc., and achieve the effect of promoting the development of circular economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

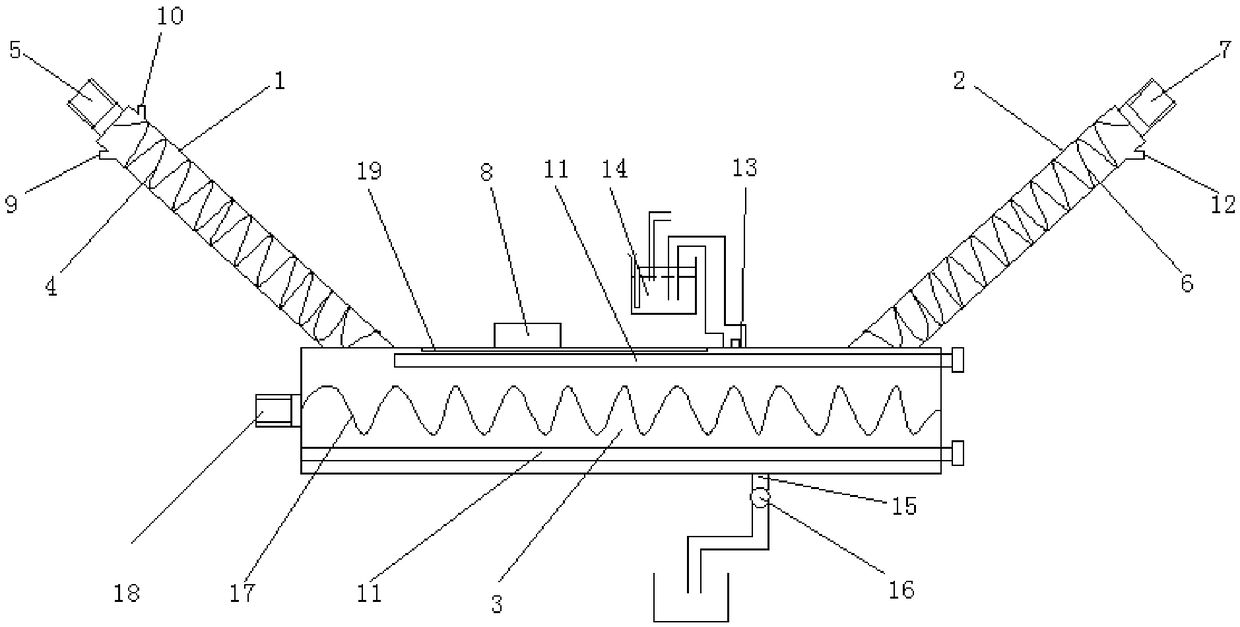

[0036] The device for recycling waste aluminum-plastic resources provided in this embodiment includes a pulverizer for pulverizing aluminum-plastic into particles, a washing tank for cleaning the particles, a soaking separation device for soaking and separating reaction, and a sedimentation tank for cleaning plastics, which are connected in sequence. The washing tank is connected with the first recycling tank, and the sedimentation tank is connected with the second recycling tank.

[0037] The immersion and separation device is U-shaped in front view and L-shaped in top view, including feed pipe 1, reaction pipe 3 and discharge pipe 2. The two sides of the upper part of reaction pipe 3 are respectively connected to feed pipe 1 and discharge pipe 2. The pipe 1 is provided with a feeding port 9 and a feeding port 10. The feeding port 9 and the feeding port 10 are respectively located on both sides of the side wall of the feeding pipe 1. The discharging pipe 2 is provided with a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com