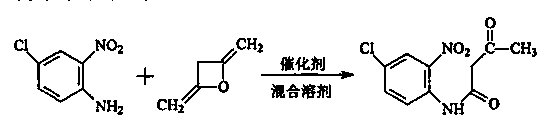

Green synthesis process for p-chloro-o-nitroacetoanilide

A technology of chloroacetoacetanilide and green process is applied in the field of green process for synthesizing o-nitro-p-chloroacetoacetanilide, and can solve the problems that mother liquor cannot be applied mechanically, product purity is not high, etc., and achieves shortened reaction time, no solid waste generation, The effect of solubility enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and beneficial effect of the present invention clearer, the present invention adopts the following specific examples to describe the technical solution of the present invention in detail.

[0019] Add a mixed solvent into the reaction kettle, add 1000kg of toluene, 0.4kg of pyridine, start stirring, add 400kg of p-chloro-o-nitroaniline, raise the temperature to 60°C, start to add 250kg of diketene dropwise, and complete the dropwise addition within 60°C. Continue to keep warm for 2 hours after completion. After the reaction is completed, cool down to 0°C, filter, and dry the filter cake. The yield reaches 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com