Continuous preparation method of acetoacetamido triethylamine sulfonate

A technology of triethylamine sulfonate and acetoacetamide, which is applied in the field of continuous preparation of triethylamine acetoacetamide sulfonate, can solve problems such as low reaction temperature, affecting product quality and yield, and punching materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

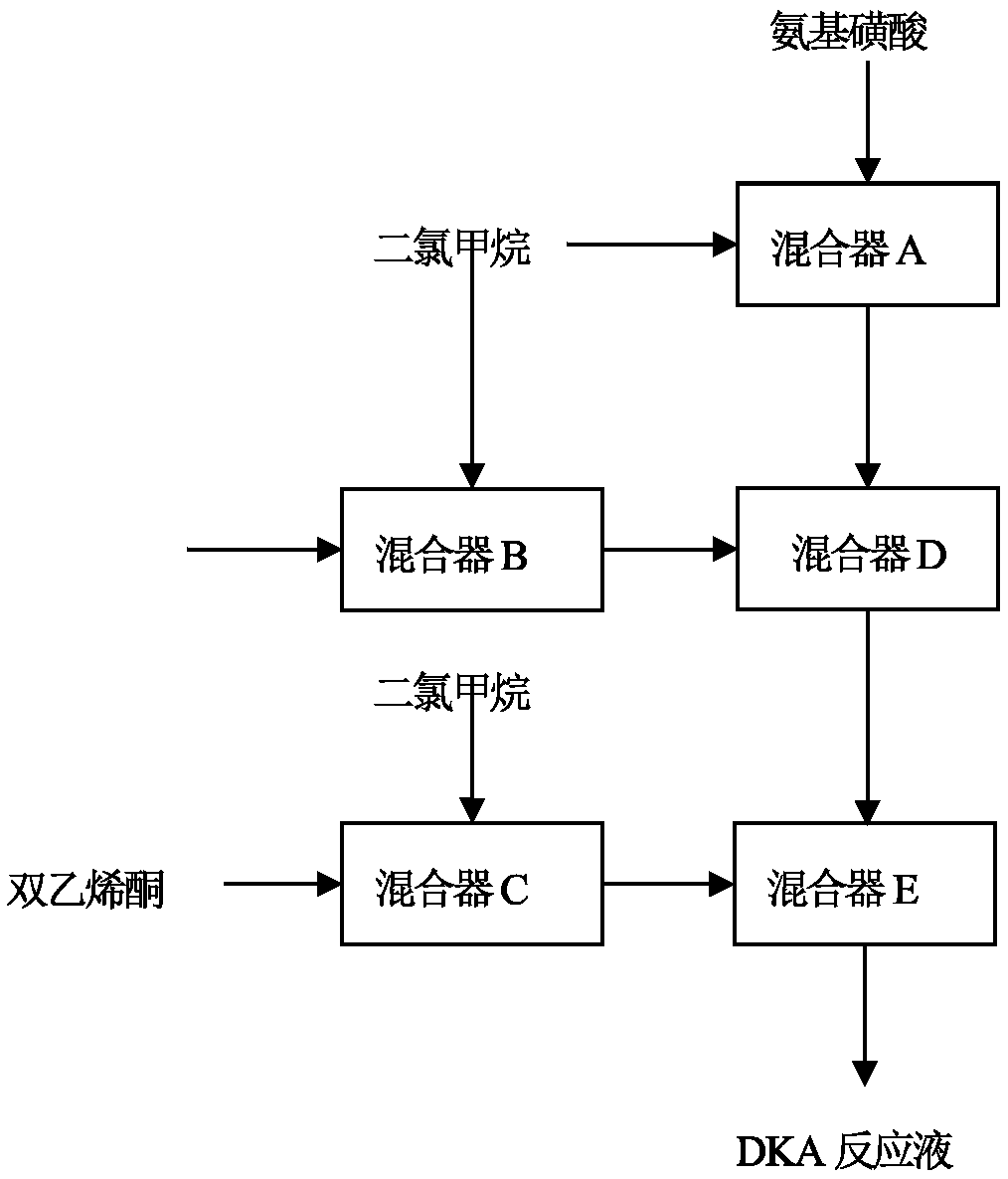

[0038] 97g / h (1mol / h) of sulfamic acid and 850g / h (10mol / h) of dichloromethane are continuously dropped into mixer A for dissolution, and the dissolution temperature is controlled at 20-25°C to obtain 947g / h of dichloromethane solution of sulfamic acid. h; continuously put 101g / h (1mol / h) of triethylamine and 85g / h (1mol / h) of dichloromethane into mixer B for mixing, and control the dissolution temperature at 20-24°C to obtain 186g / h of triethylamine solution; Mix 85.7g / h (1mol / h) of diketene and 85g / h (1mol / h) of dichloromethane in a continuous mixer C, and control the dissolution temperature at 20-24°C to obtain 170.7g / h of diketene solution.

[0039] Continuously put 947g / h of dichloromethane solution of sulfamic acid and 186g / h of triethylamine solution into mixer D for neutralization, control neutralization temperature at 25-30°C, neutralization solution pH 7-9, and obtain neutralization reaction solution 1133g 170.7g / h of diketene solution is continuously put into the ac...

Embodiment 2

[0041] 97g / h (1mol / h) of sulfamic acid and 1020g / h (12mol / h) of dichloromethane are continuously dropped into mixer A for dissolution, and the temperature of dissolution is controlled at 20-25°C to obtain 1117g / h of dichloromethane solution of sulfamic acid. h; continuously put 101g / h (1mol / h) of triethylamine and 170g / h (2mol / h) of dichloromethane into mixer B for mixing, and control the dissolution temperature at 20-25°C to obtain 271g / h of triethylamine solution; Mix 85.7g / h (1mol / h) of diketene and 85g / h (1mol / h) of dichloromethane in a continuous mixer C, and control the dissolution temperature at 20-25°C to obtain 170.7g / h of diketene solution.

[0042] Continuously put 1117g / h of dichloromethane solution of sulfamic acid and 271g / h of triethylamine solution into mixer D for neutralization, control neutralization temperature at 20-25°C, neutralization solution pH 7-9, and obtain neutralization reaction solution 1388g 170.7g / h of diketene solution is continuously put into...

Embodiment 3

[0044] 97g / h (1mol / h) of sulfamic acid and 680g / h (8mol / h) of dichloromethane are continuously put into mixer A for dissolution, and the dissolution temperature is controlled at 20-25°C to obtain 777g / h of dichloromethane solution of sulfamic acid. h; continuously put 101g / h (1mol / h) of triethylamine and 170g / h (2mol / h) of dichloromethane into mixer B for mixing, and control the dissolution temperature at 20-25°C to obtain 271g / h of triethylamine solution; Mix 85.7g / h (1mol / h) of diketene and 85g / h (1mol / h) of dichloromethane in a continuous mixer C, and control the dissolution temperature at 20-25°C to obtain 170.7g / h of diketene solution.

[0045]Continuously put 777g / h of dichloromethane solution of sulfamic acid and 271g / h of triethylamine solution into mixer D for neutralization, control the neutralization temperature at 20-25°C, and neutralize the pH of the solution at 7-9 to obtain 1048g of neutralization reaction solution 170.7g / h of diketene solution is continuously p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com