Process for preparing sodium dehydroacetate

A technology of sodium dehydroacetate and preparation process, applied in the directions of organic compound/hydride/coordination complex catalyst, organic chemistry, physical/chemical process catalyst, etc., can solve the problem of high production cost, complicated production steps and product yield Low problems, to achieve the effect of saving energy and material consumption, inhibiting the formation of polymers, and shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

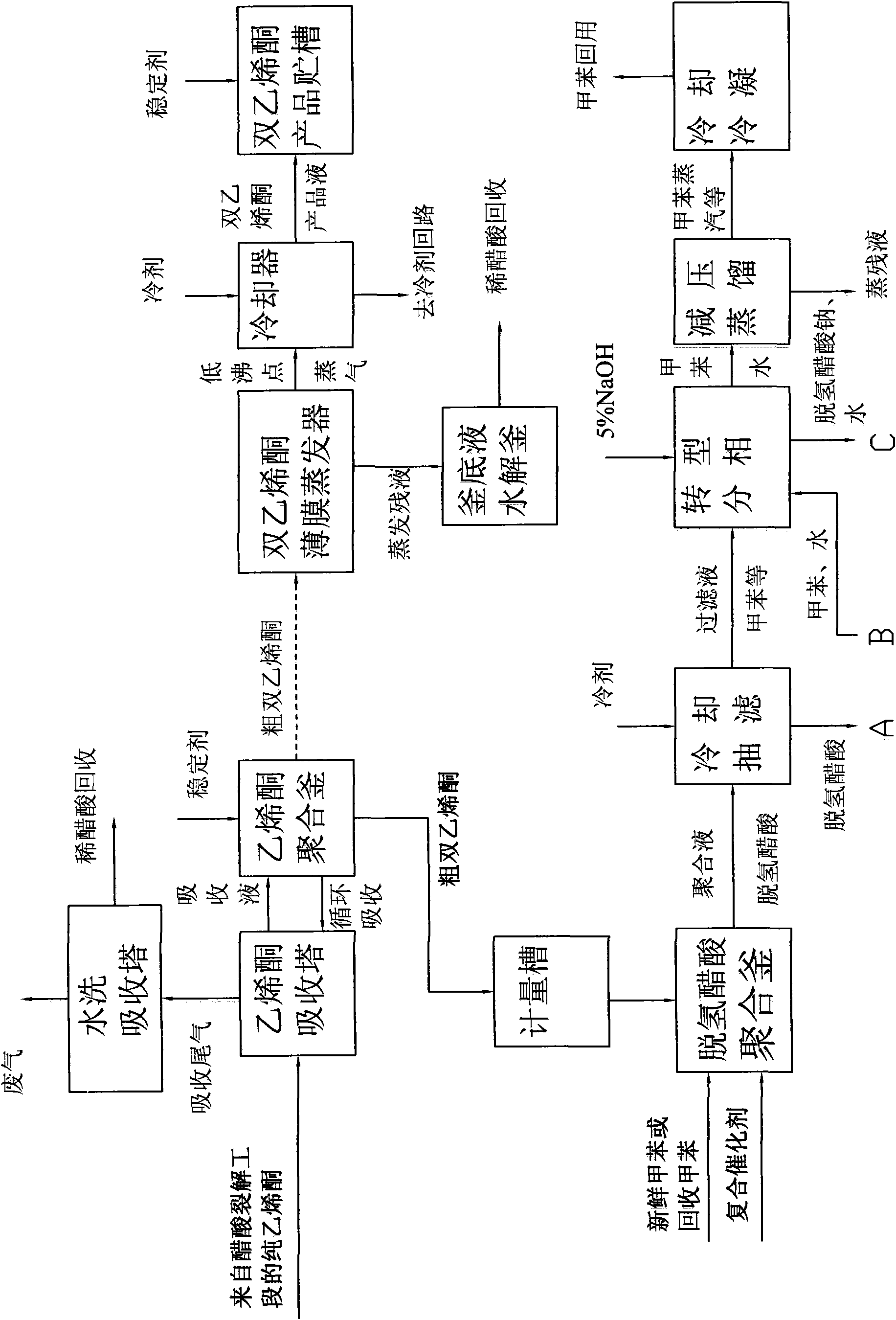

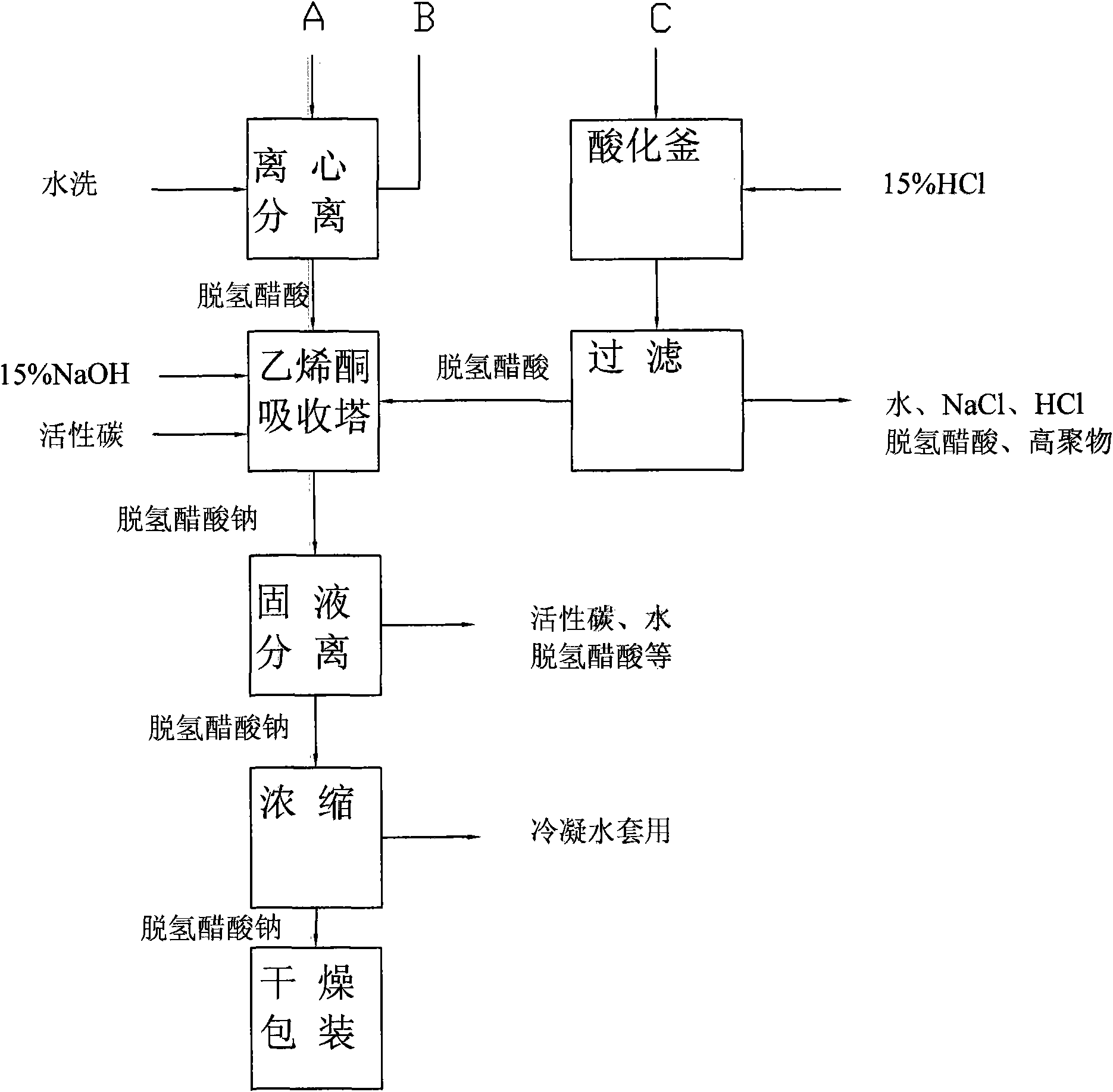

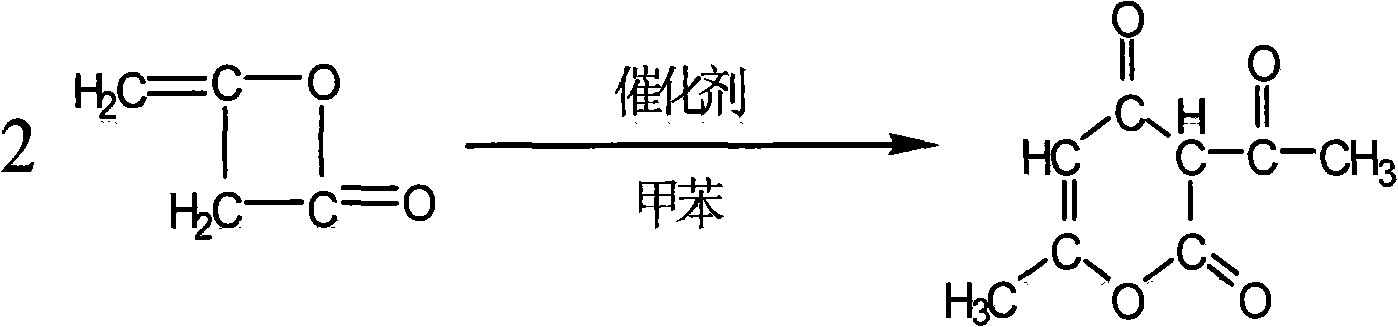

[0026] like figure 1 , figure 2 Shown, the preparation process of sodium dehydroacetate is characterized in that: comprise the preparation process of diketene; The polymerization process of dehydroacetic acid; The separation process of dehydroacetic acid; The preparation process of sodium dehydroacetate.

[0027] The preparation process of diketene includes:

[0028] Pure ketene gas from the acetic acid cracking section enters The crude diketene liquid introduced from the bottom of the corrugated full-plate packing absorption tower and the top of the tower is sprayed down and subjected to countercurrent contact at 8°C to be absorbed; the absorption liquid flows into 5m 3 Polymerization kettle, polymerized at 20°C to generate crude diketene, the crude diketene solution after polymerization is returned to the absorption tower, and the process of absorption and polymerization is carried out cyclically; the reaction tail gas escaping from the top of the tower is discharged int...

Embodiment 2

[0036] The preparation process of the diketene is to introduce the ketene gas into the bottom of the corrugated full-plate packed absorption tower, and spray and absorb the crude diketene entering from the top under the condition of 5° C. to form an absorption liquid, which enters the polymerization tank; Polymerize at ℃ to generate crude diketene, which is then pumped into the absorption tower for circular spraying; when the content of diketene in the polymerization kettle reaches 80%, it will be diverted into the crude diketene metering tank. All the other are with embodiment 1.

Embodiment 3

[0038] The preparation process of said diketene is to introduce ketene gas into the bottom of the corrugated full-plate packed absorption tower, and to spray and absorb the crude diketene entering from the top at 10°C to form an absorption liquid, which enters the polymerization tank; Polymerize at ℃ to generate crude diketene, which is then pumped into the absorption tower for circular spraying; when the content of diketene in the polymerization kettle reaches 90%, it will be split into the crude diketene metering tank; the rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com