Post-treatment method for continuously synthesizing methyl 4-chloroacetoacetate

A technology of methyl acetate and chloroacetyl, which is applied in the post-treatment field of continuous synthesis of methyl 4-chloroacetoacetate, can solve problems such as poor product quality, environmental pollution, and difficult product separation, and achieve product yield and quality improvement, Inhibit the deep chlorination of products and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

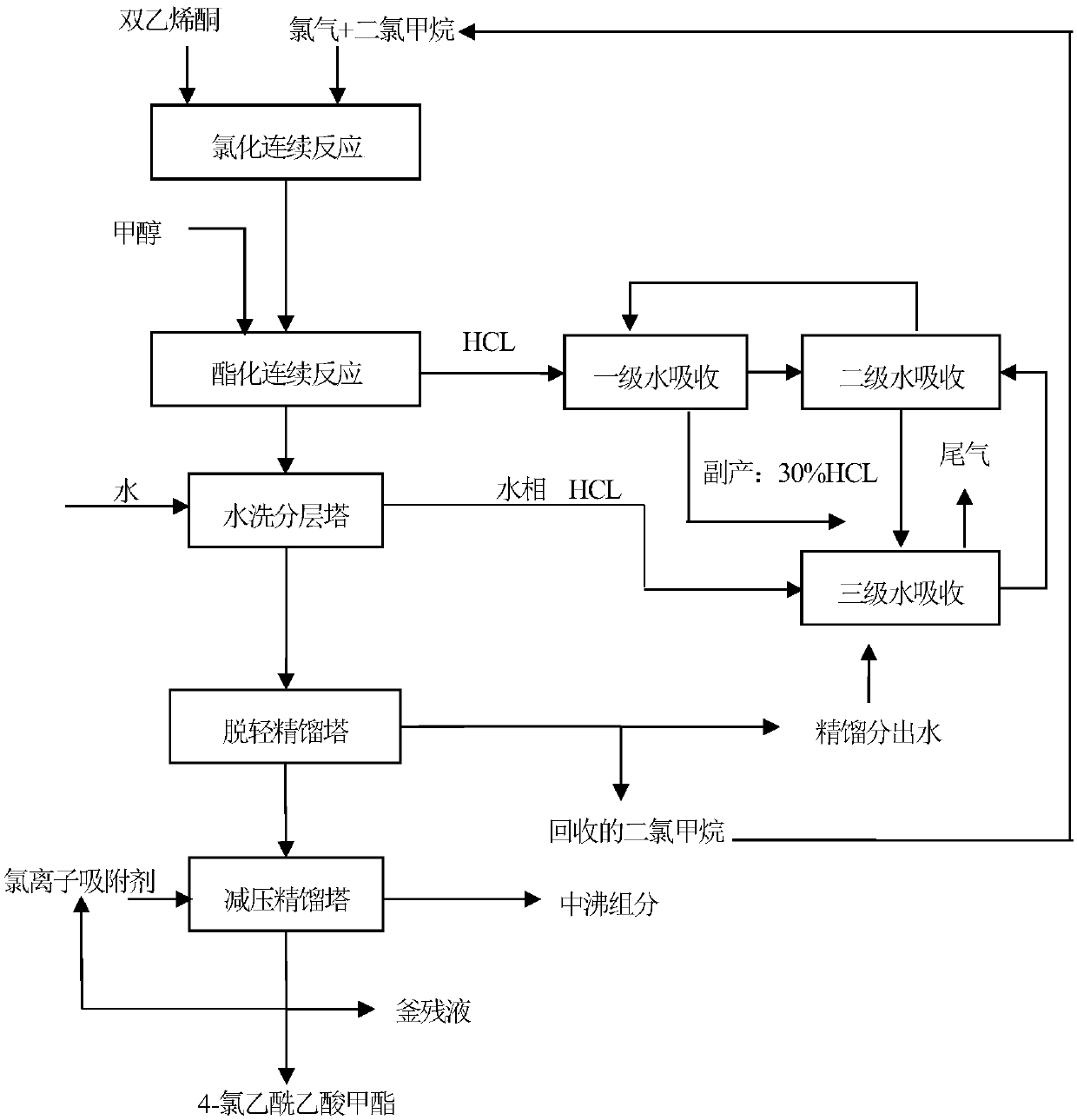

[0040] Embodiment 1: a kind of post-processing method of continuous synthesis of methyl 4-chloroacetoacetate:

[0041] 1) Using diketene, chlorine gas, dichloromethane and methanol as raw materials, first dissolve chlorine gas in dichloromethane, and enter the chlorination reaction module of the microchannel continuous flow reactor through a metering pump together with diketene, and then enter into the esterification reaction with methanol The module synthesizes methyl 4-chloroacetoacetate, and the HCl tail gas generated in the process is connected to the three-stage HCL absorption system, and the water absorption range of each stage is m (water absorption of each stage): m (diketene) = 1.5: 1;

[0042] 2) After the esterification reaction, the dichloromethane solution of methyl 4-chloroacetoacetate is obtained, which is added to the washing layered tower, and the amount of washing in the washing layered tower is the same as that of the three-stage HCL. 7. After washing with w...

Embodiment 2

[0047] Embodiment 2: a kind of aftertreatment method of continuous synthesis 4-methyl chloroacetoacetate:

[0048] 1) Step 1) is the same as in Example 1, the water absorption range of each stage is m (absorbed water amount of each stage): m (diketene)=1.7:1;

[0049] 2) After the esterification reaction, the dichloromethane solution of methyl 4-chloroacetoacetate is obtained, which is added to the washing layered tower, and the amount of washing in the washing layered tower is the same as that of the three-stage HCL. 7.5. After washing with water, the water phase goes to the three-stage HCL absorption system, and the organic phase enters the lightening distillation tower;

[0050] 3) The organic phase is preheated to 38°C by the preheater and fed continuously from the light-removing rectification tower. In the top receiving tank, the water is separated through the water separator (the separated water enters the HCL absorption system), and after the water content of the dichl...

Embodiment 3

[0054] Embodiment 3: a kind of aftertreatment method of continuous synthesis 4-methyl chloroacetoacetate:

[0055] 1) Step 1) is the same as in Example 1, the range of water absorption per stage is m (water absorption per stage): m (diketene) = 2:1;

[0056] 2) After the esterification reaction, the dichloromethane solution of methyl 4-chloroacetoacetate is obtained, which is added to the washing layered tower, and the amount of washing in the washing layered tower is the same as that of the three-stage HCL. 8. After washing with water, the water phase goes to the three-stage HCL absorption system, and the organic phase enters the light removal distillation tower;

[0057] 3) The organic phase is preheated to 40°C by the preheater and continuously fed from the light-removing rectification tower. In the receiving tank, the water is separated by a water separator (the separated water enters the HCL absorption system), and after the water content of the dichloromethane reaches 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com