Continuous flow synthesizing method and system for methyl 4-chloroacetoacetate without solvent

A technology of methyl acetate and chloroacetyl, which is applied to the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of acyl halides. It can solve the problems of cumbersome operations, poor quality, and low product yields, and achieve high yield and product content. Improve, save production cost, and process green environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

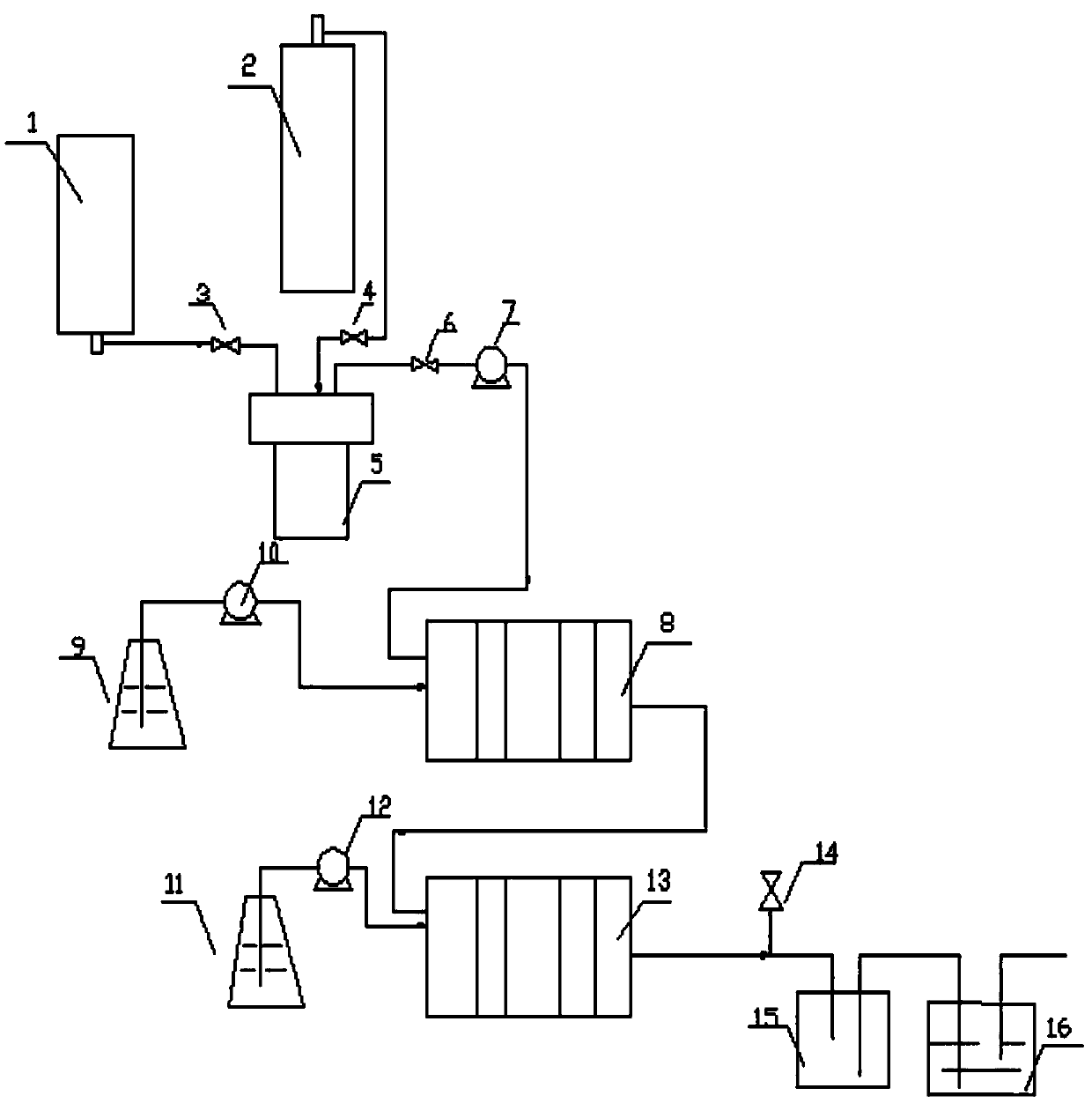

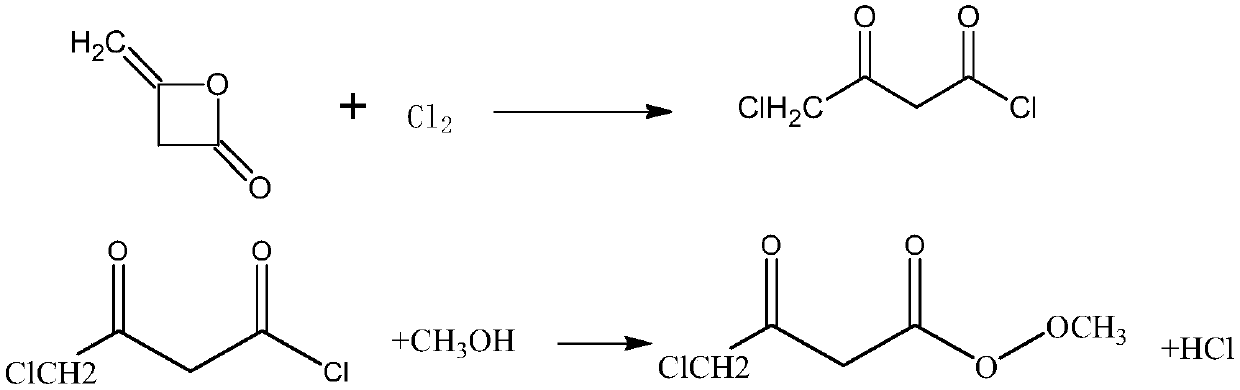

[0042] Embodiment 1: a kind of solvent-free 4-chloroacetoacetate methyl ester continuous flow synthetic method:

[0043] ① Open the valve of the inverted chlorine cylinder 1, and open the pipeline shut-off valve 3 to release the liquid chlorine and introduce it into the liquid chlorine pressurized tank 5. After the liquid level reaches 2 / 3, close the valve of the chlorine cylinder 1 and the shut-off valve 3, and open Nitrogen cylinder 2 valve and pipeline shut-off valve 4 pressurize the pressurized tank;

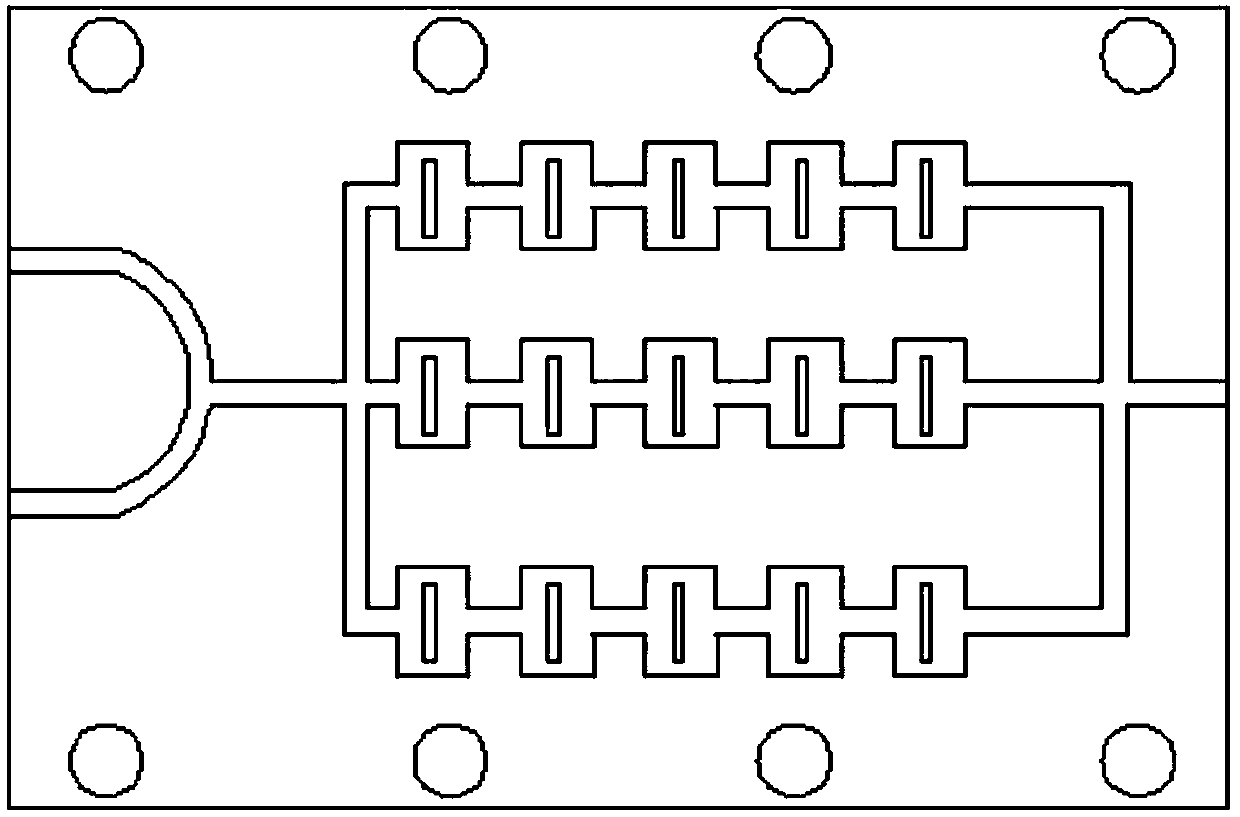

[0044] ② Open the pipeline shut-off valve 6, liquid chlorine and diketene 9 respectively pass through the metering pumps 7 and 10 and enter the reaction module 8 for chlorination reaction, the temperature of the chlorination reaction is -25°C, the reaction time is 5s, the liquid chlorine and diketene The reaction molar ratio is 1:1;

[0045] ③After the chlorination reaction, the methanol in the methanol storage tank 11 enters the reaction module 13 together with the chlorin...

Embodiment 2

[0048] Embodiment 2: a kind of solvent-free 4-chloroacetoacetate methyl ester continuous flow synthesis method:

[0049] 1. describe with embodiment 1;

[0050] ②Open the pipeline shut-off valve 6, and the liquid chlorine and diketene 9 respectively pass through the metering pumps 7 and 10 and enter the reaction module 8 for chlorination reaction. The temperature of the chlorination reaction is -5°C, and the reaction time is 20s. The reaction molar ratio is 1.05:1;

[0051] ③ After the chlorination reaction is finished, the methanol in the methanol storage tank 11 enters the reaction module 13 together with the chlorination solution through the metering pump 12, the temperature of the esterification reaction is 5°C, the reaction time is 15s, and the reaction molar ratio of methanol to diketene is 1.03:1;

[0052] ④The crude product enters the gas-liquid separation buffer tank 15 after the pressure is relieved through the pressure gauge back pressure valve 14, and the tail ga...

Embodiment 3

[0054] Embodiment 3: a kind of solvent-free 4-chloroacetoacetate methyl ester continuous flow synthesis method:

[0055] 1. describe with embodiment 1;

[0056] ②Open the pipeline shut-off valve 6, liquid chlorine and diketene 9 respectively pass through the metering pumps 7 and 10 and enter the reaction module 8 for chlorination reaction, the temperature of the chlorination reaction is 15°C, and the reaction time is 35s. The molar ratio is 1.1:1;

[0057] ③After the chlorination reaction is finished, the methanol in the methanol storage tank 11 enters the reaction module 13 together with the chlorination solution through the metering pump 12, the temperature of the esterification reaction is 28°C, the reaction time is 30s, and the reaction molar ratio of methanol to diketene is 1.15:1;

[0058] ④The crude product enters the gas-liquid separation buffer tank 15 after the pressure is relieved through the pressure gauge back pressure valve 14, and the tail gas enters the absor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com