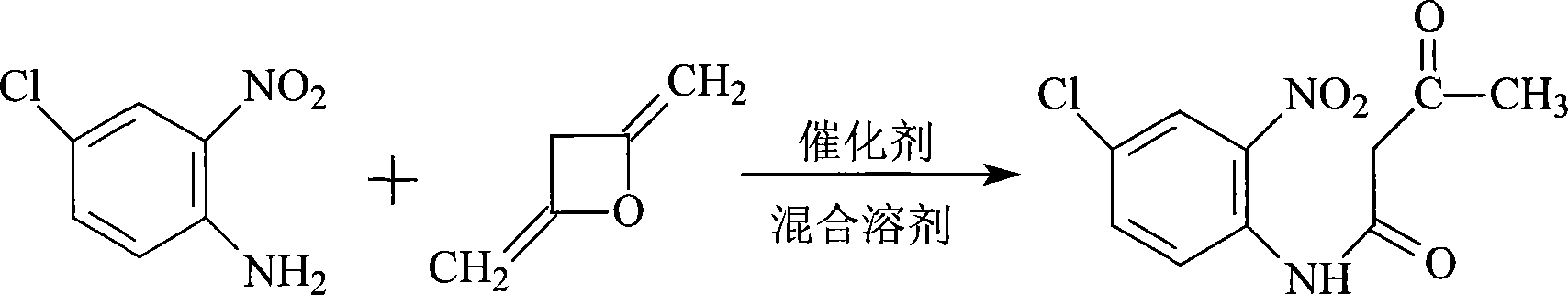

Method for preparing high-purity p-chloro-m-nitroacetoacetanilide

A technology of nitroacetoacetanilide and nitroaniline is applied in the field of preparation of pesticide intermediates, can solve problems such as poor product purity, recrystallization, low yield, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add mixed solvent [toluene: dichloromethane (weight ratio) = 1: 3] 2500kg, N, N, N', N'-tetramethylethylenediamine 20kg in the reaction kettle, start stirring, add p-chloro-o-nitrate Aniline 450kg; warm up to 60°C, start to add 229kg of DK (diketene) dropwise, and control the dropping time for 1h; continue to keep warm for 1h after dropping, and control the temperature at 60°C; Wash with mixed solvents and dry. Obtain product 605kg, yield 90.42%.

[0023] Mother liquor cycle times

[0024] The obtained mother liquor is reused in the following 10 reaction cycles without additional catalyst, and an average of 649.4 kg of product can be obtained with a yield of 97.06%.

Embodiment 2

[0026] Add 1500kg of mixed solvent [water:ethanol (weight ratio)=0.9:0.1], 0.45kg of 2-picoline to the reaction kettle, start stirring, then drop in 450kg of p-chloro-o-nitroaniline; heat up to 100°C, start dripping Add 260kg of DK, and control the dropping time to 0.5h; after the dropping, continue to keep warm for 0.5h; after the reaction, cool down to 5°C, filter, wash the filter cake with a mixed solvent, and dry. Obtain product 535kg, yield 80%.

Embodiment 3

[0028] Add mixed solvent [benzene: chloroform (weight ratio) = 0.1: 0.9] 4500kg, diethylamine 12kg in the reactor, start stirring, add p-chloro-o-nitroaniline 450kg; Warm up to 15°C, drop DK 245kg, control The dropwise addition time is 4h; after the dropwise addition, continue the heat preservation reaction for 6h; after the reaction is completed, the temperature is lowered to 0°C, filtered, and the filter cake is washed with a mixed solvent and dried. Obtain product 595kg, yield 88.93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com